A separate upside-down double-thread lock stitch sewing device

A separate and flip-chip technology, which is applied in the direction of the upper thread device, sewing machine thread take-up device, sewing equipment, etc., can solve the problems of small size of suture groove, large size and volume of sewing components, and cannot be placed in three-dimensional molds, etc., so as to ensure the suture intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

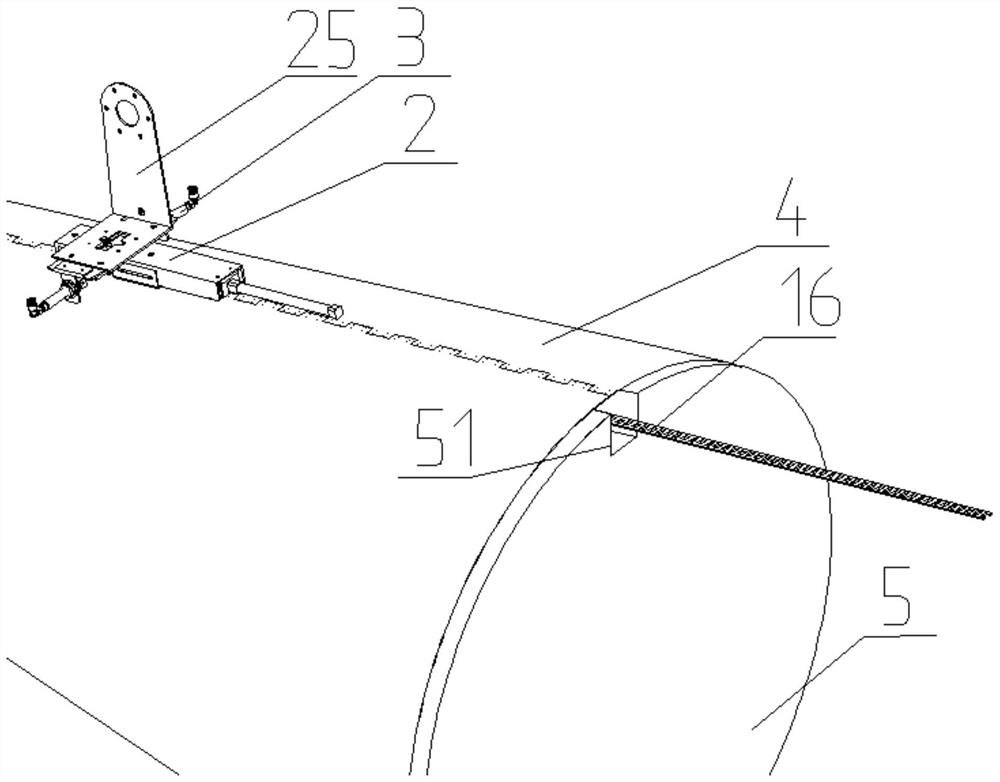

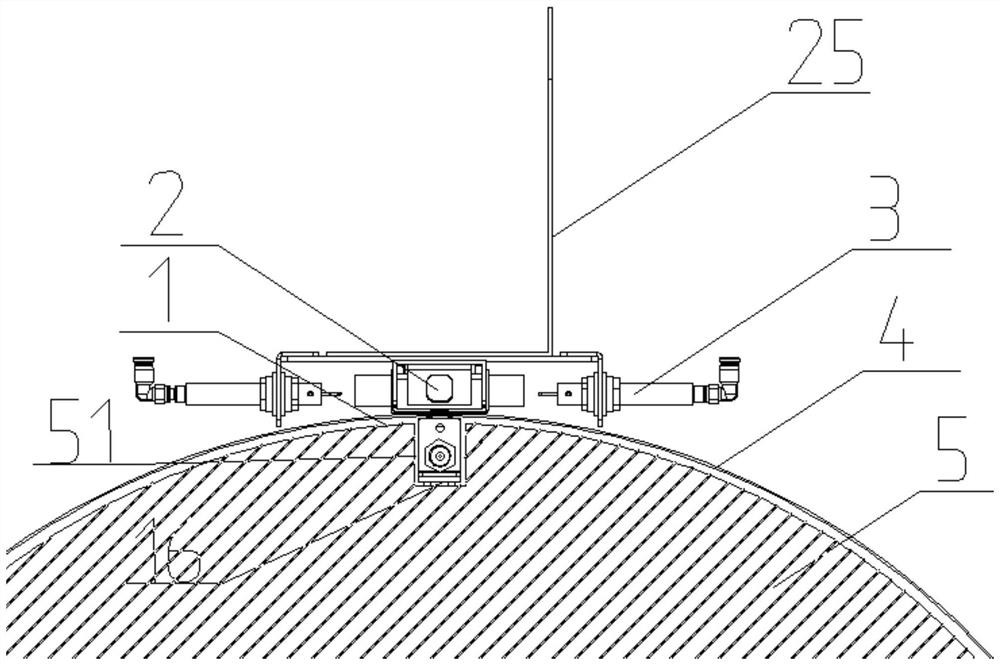

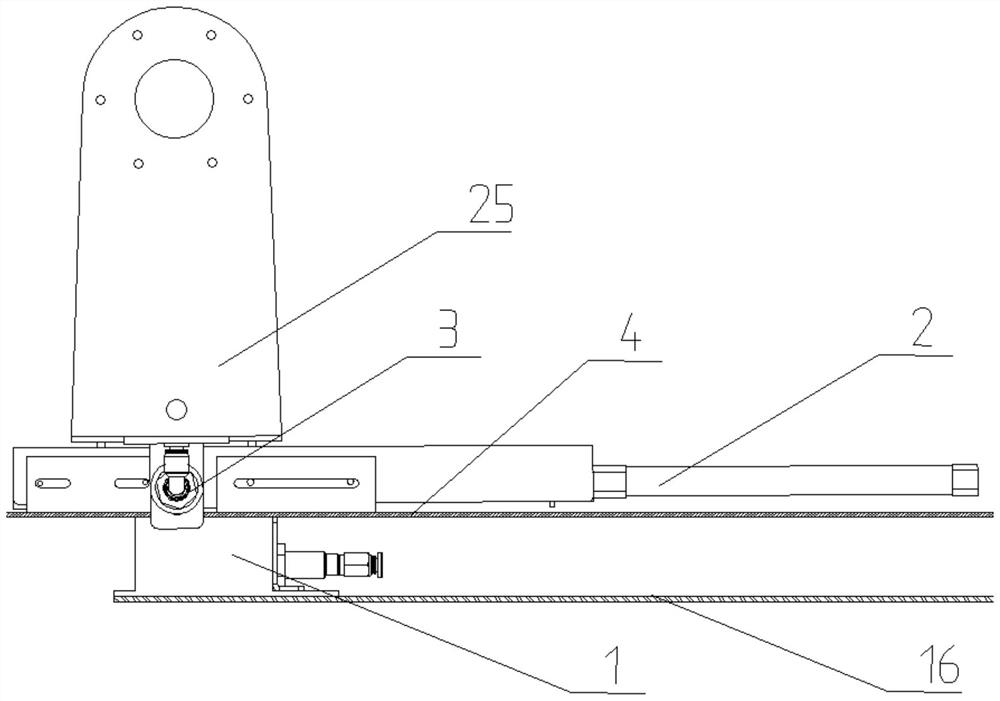

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] Such as Figure 1-Figure 4 As shown, a separate flip-chip double-thread lock stitch sewing device includes a needle-punching thread-leading module 1 and a threading and hooking module. An independent drive mechanism, the needle punching lead module 1 is set under the cloth to be sewn 4, and is used to pierce the sewing cloth with the double needle base 13 and drive the double needle base 13 back below, the threading hook module is set Above the cloth 4 to be sewn, it is used for hooking and shuttle threading.

[0025] Such as Figure 5 and Figure 6 As shown, the acupuncture lead module 1 includes a housing 11, a double lead needle group 12, a double needle seat 13, an acupuncture push block 14, and an acu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com