Wire breaking protection mechanism for radiation type fly shuttle on plastic flat wire circular knitting machine

A circular knitting machine, plastic flat yarn technology, applied in the direction of circular looms, looms, textiles, etc., can solve problems such as large manpower, re-threading damage, production stagnation, etc., to improve productivity and yield, solve manpower and materials the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

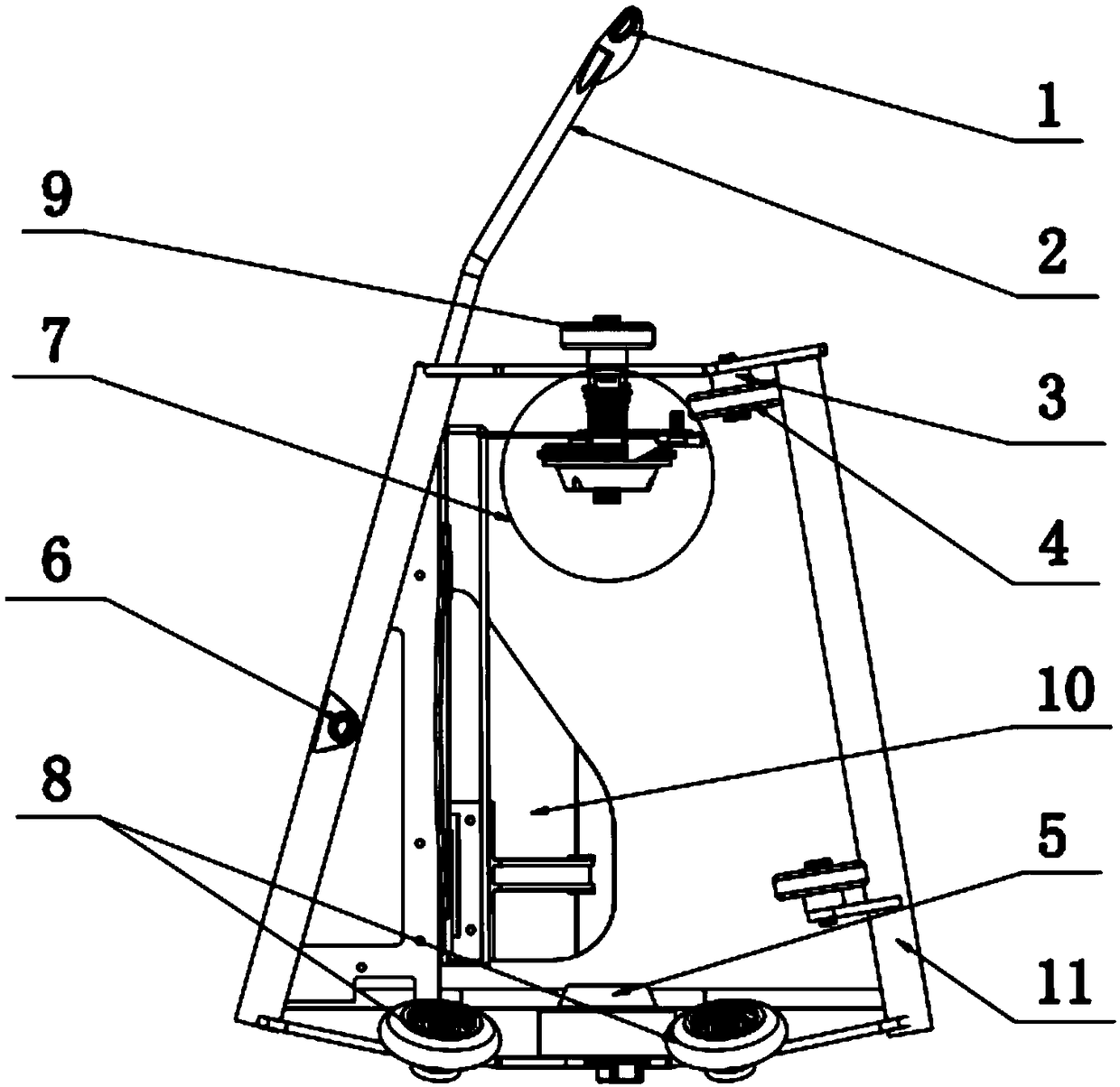

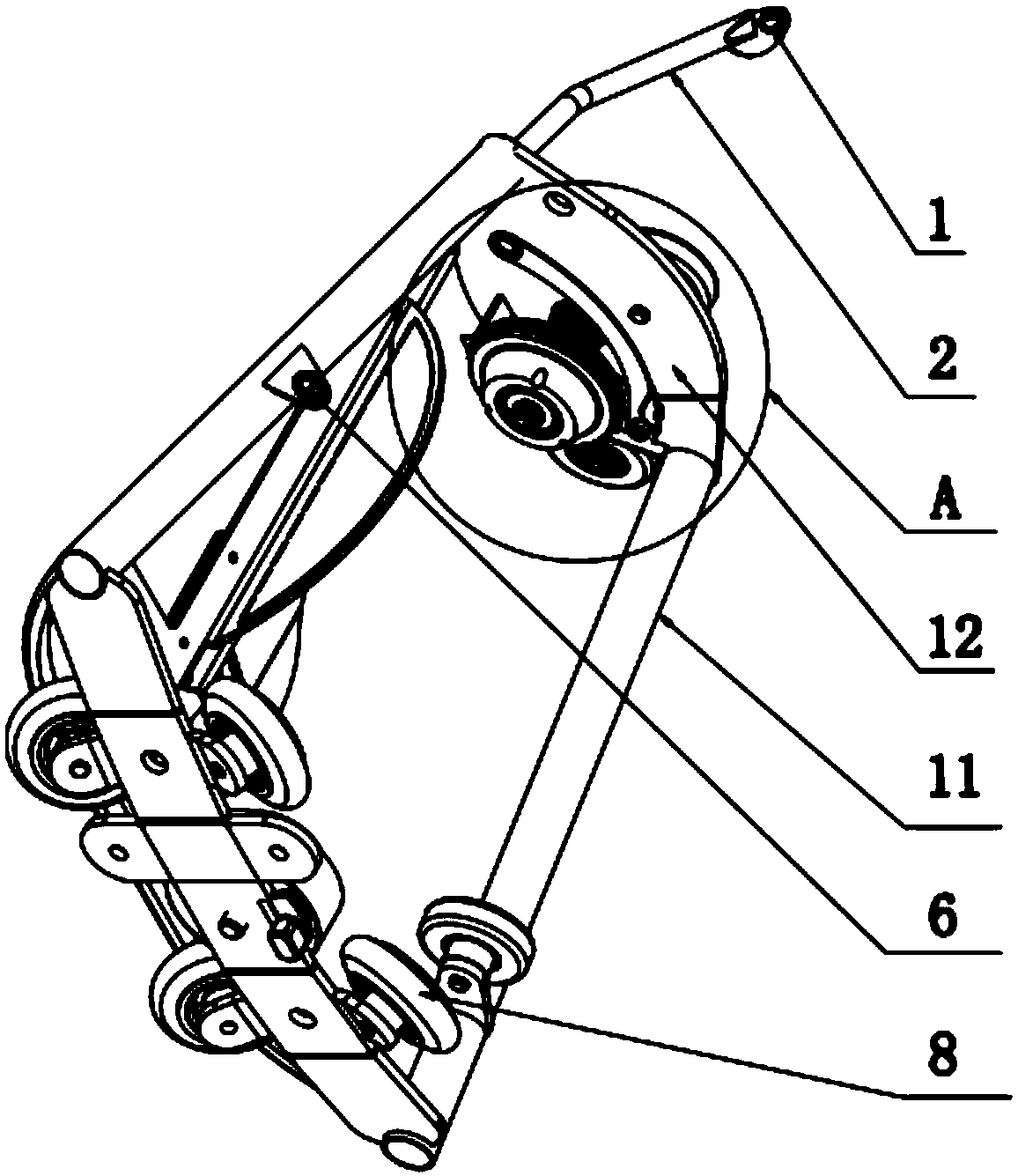

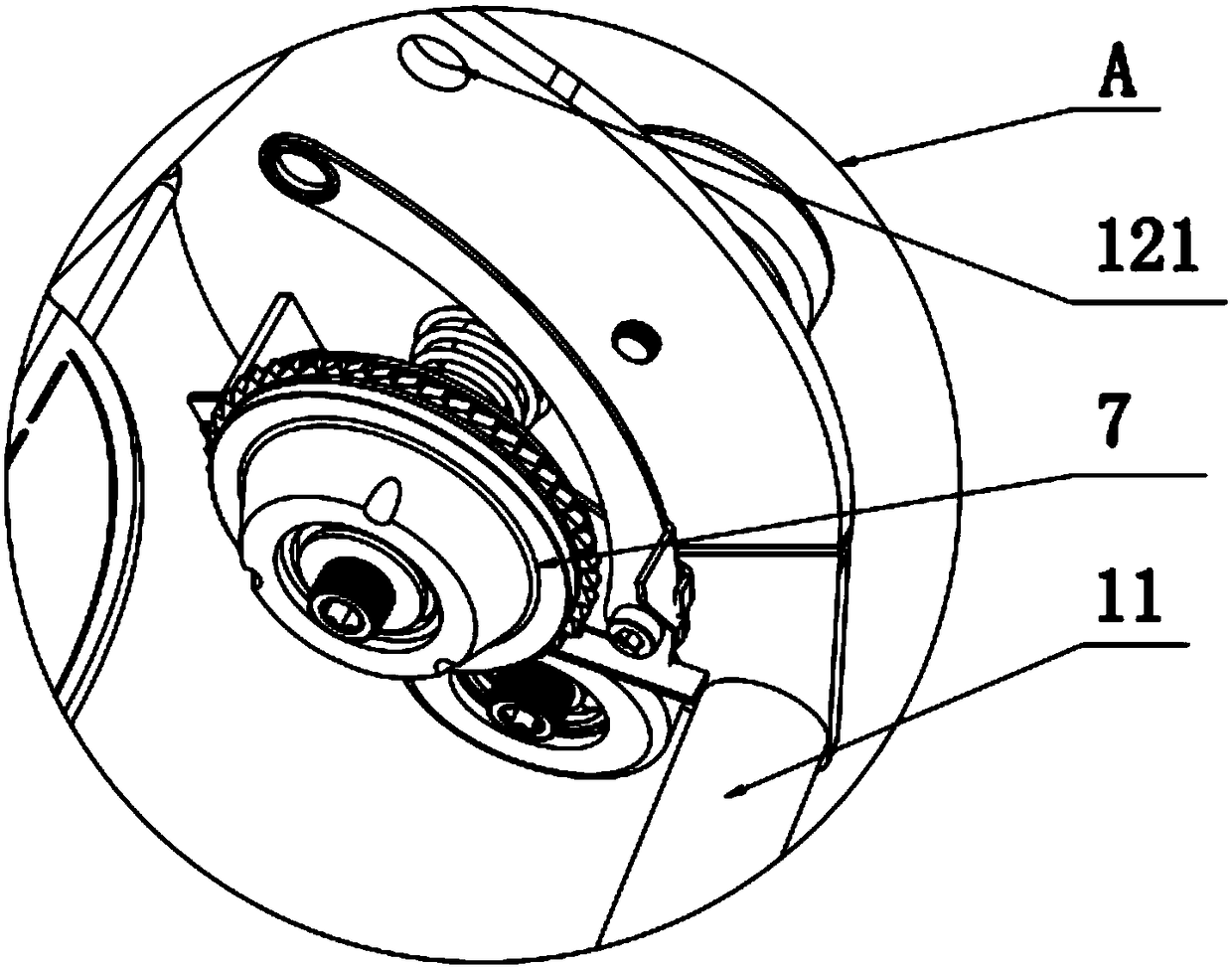

[0027] The present invention provides such Figure 1-5 The shown wire breakage protection mechanism of a radial shuttle on a plastic flat yarn circular knitting machine includes a shuttle main frame 11, and a fixed plate 12 is fixedly installed on the top of the shuttle main frame 11, and the fixed The inside of the plate 12 is equipped with a ratchet type broken thread locking assembly 7, and the ratchet type broken thread locking assembly 7 is composed of a set screw 701, an upper yarn cone 702, a ratchet 703, a ratchet pressing plate 704, a probe arm 705, a probe arm Thread hole 706, broken thread locking base 707, upper yarn cone shaft 708, upper yarn cone spring 709, probe arm clamp knife 710 and adjustment screw 711;

[0028] The top of the upper yarn cone 702 is screwed with the ratchet platen 704 and the ratchet 703 sequentially from top to bottom through the adjustment screw 711, and the inside of the fixed screw 701 away from the end of the ratchet 703 is connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com