Variable-angle knitting device of knitting machine

A weaving machine and angle-changing technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems that cannot meet the structural form and application requirements of fiber prefabricated bodies, and achieve the effect of promoting development and application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

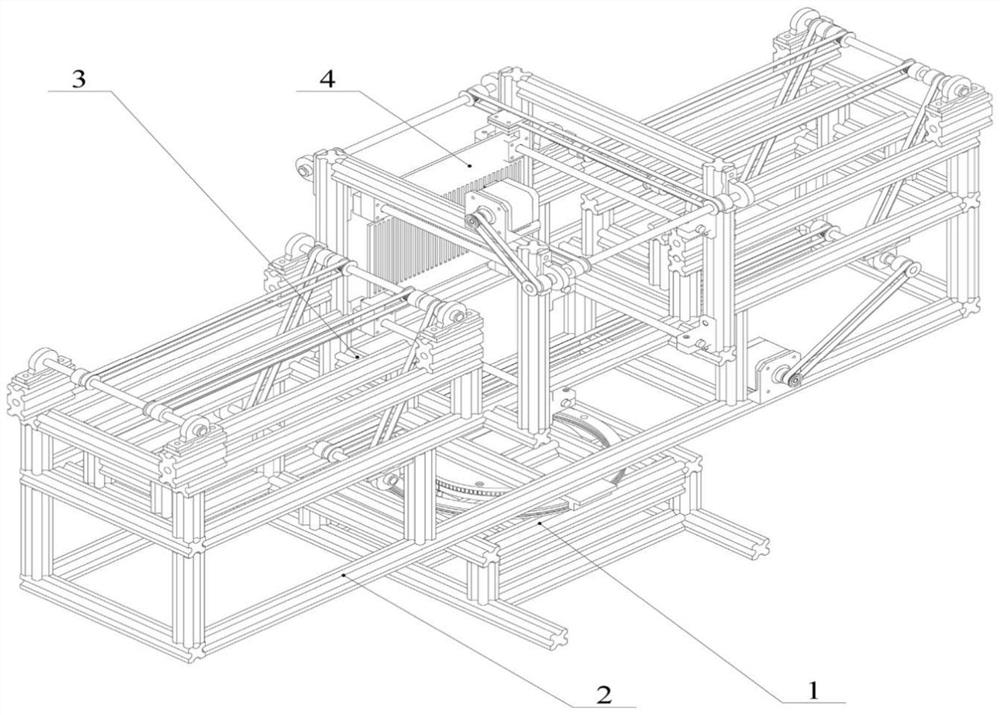

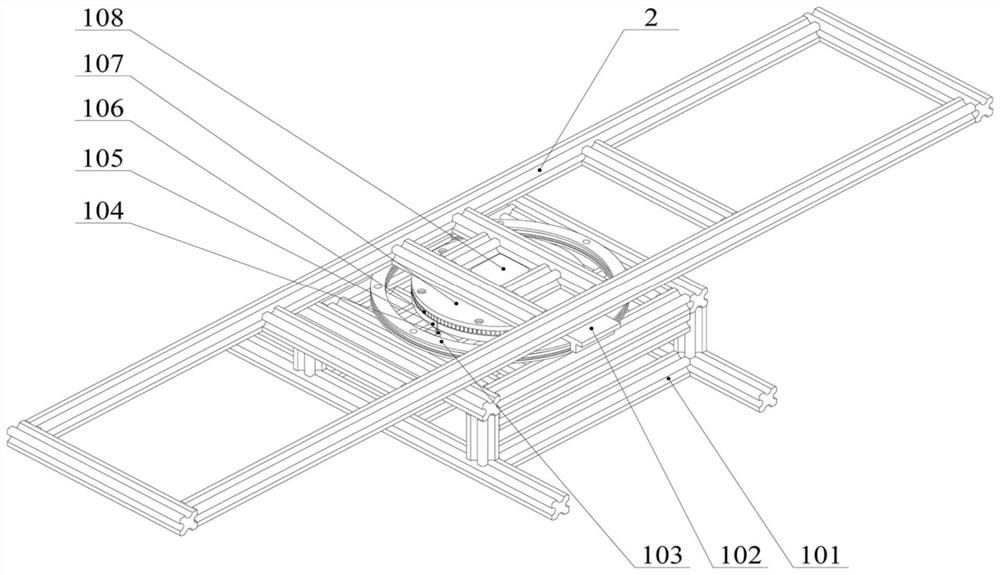

[0022] see figure 1 and Figure 7 As shown, a variable angle knitting device for a knitting machine includes a weft insertion device frame 2, a shuttle mechanism 3 and a beating-up mechanism 4, and the shuttle mechanism 3 and the beating-up mechanism 4 are integrated on the weft insertion device frame 2, and also include The weft insertion device frame rotation mechanism 1, the weft insertion device frame 2 is arranged on the weft insertion device frame rotation mechanism 1;

[0023] Specifically, the rotating mechanism 1 of the weft insertion device frame drives the shuttle mechanism 3 and the beating-up mechanism 4 to change the angle through the weft insertion device frame 2, so as to realize the variable angle weaving of the fabric;

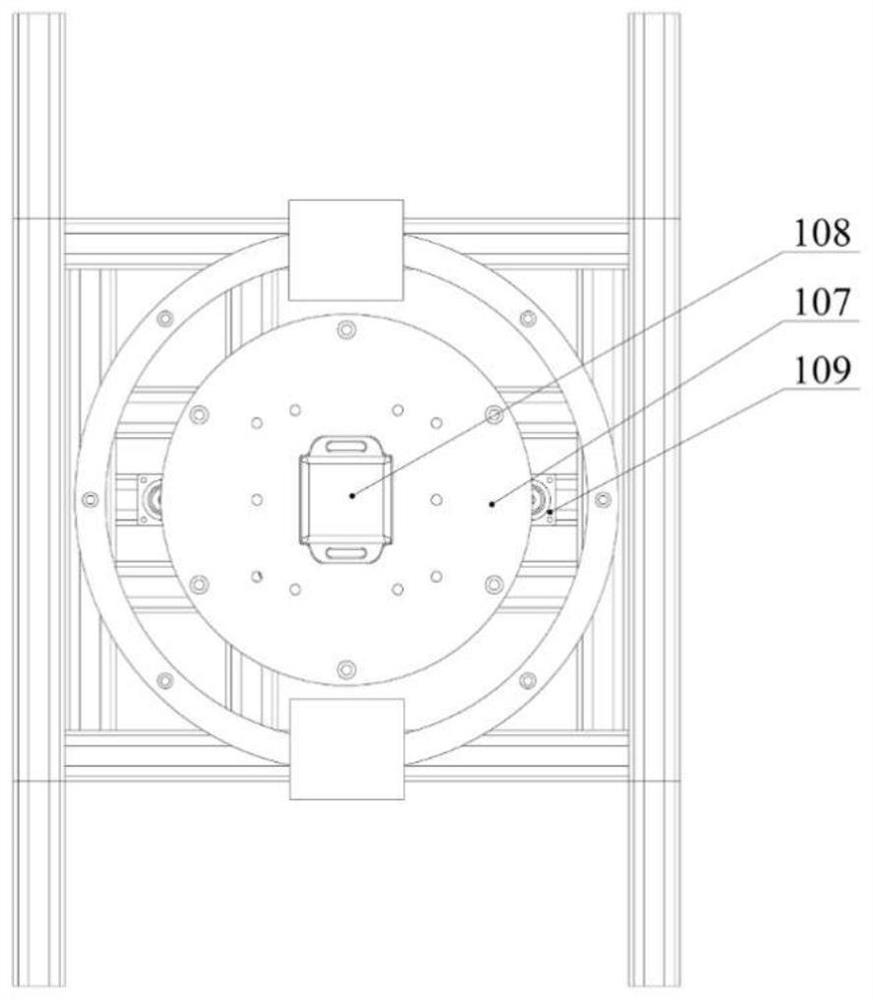

[0024] The frame rotating mechanism 1 of the weft insertion device includes a rotating mechanism frame 101 , several sliding seats 102 , an annular guide rail 103 , a planetary gear train 106 , a circular 3D printing connector 107 , an angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com