Method for preparing nano-silver particle and nano-silver wire mixed conductive ink

A technology of nano-silver particles and nano-silver wires, applied in the field of nano-materials or printed electronics, can solve problems such as holes, and achieve the effects of ensuring electrical conductivity, reducing production costs, and reducing silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

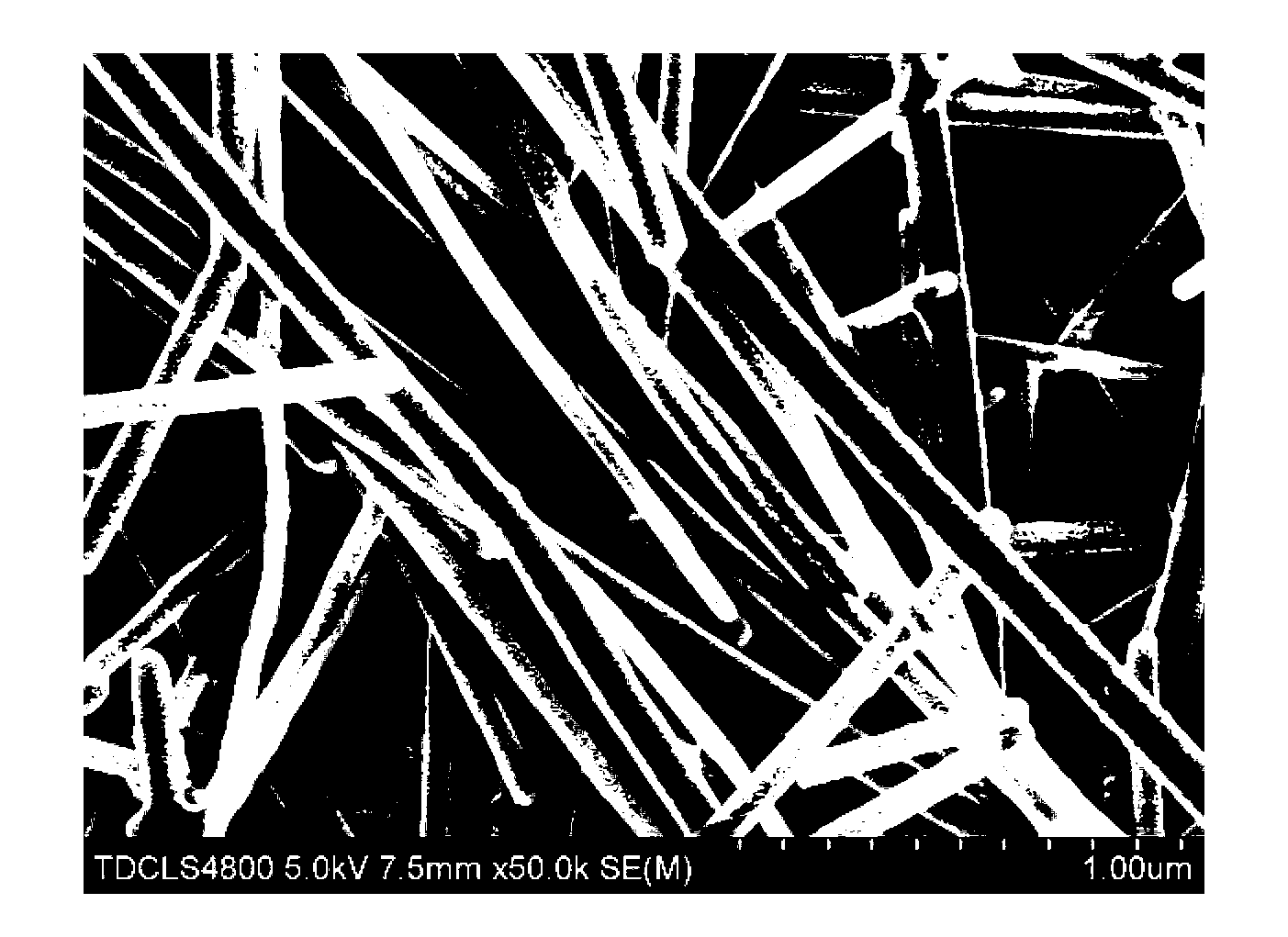

[0025] (1) Dissolve 1 g of silver nitrate and 1 g of surfactant polyvinylpyrrolidone k30 in 100 g of deionized water, and stir until a colorless and transparent solution; then add 16 mL of sodium borohydride aqueous solution with a concentration of 10 mg / mL into the above solution, and the whole The reaction process was vigorously stirred under a magnetic stirrer, and the reaction lasted for 25 minutes; after the reaction, the reaction product was centrifuged at a centrifugal rate of 1000 rpm for 20 minutes; the centrifuged product was dried in a nitrogen atmosphere at 50°C for 5 hours to obtain silver nanoparticles. pass figure 1 It can be seen that the prepared nano-silver particles are mainly spherical, the particle size distribution is uniform, and the average particle size is about 40nm.

[0026] (2) Dissolve 1.2g of silver nitrate and 1.05g of surfactant polyvinylpyrrolidone 360 in 130g of ethylene glycol, and stir until completely dissolved; heat the reaction system t...

Embodiment 2

[0029] (1) Dissolve 1g of silver acetate and 0.8g of surfactant polyacrylic acid (PAA) in 120g of deionized water, and stir until a colorless and transparent solution; then add 20mL of sodium borohydride aqueous solution with a concentration of 10mg / mL to the above solution , the entire reaction process was vigorously stirred under a magnetic stirrer, and the reaction lasted for 20 minutes; after the reaction, the reaction product was centrifuged at a centrifugal rate of 800 rpm for 30 minutes; the centrifuged product was dried in a nitrogen atmosphere at 50°C for 5 hours to obtain silver nanoparticles .

[0030] (2) Dissolve 1g of silver nitrate and 0.8g of surfactant polyvinylpyrrolidone 360 in 120g of ethylene glycol, stir until completely dissolved; then add 15g of -3 mol / L potassium chloride solution in ethylene glycol; heat the reaction system to 150°C and stir gently, the reaction time is 2h; after the reaction, filter the reaction product through slow quantitative fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com