Polymer material with continuously-alternating layer structure and preparation method for same

A technology of polymer materials and alternating layers, which is applied in the field of polymer materials with continuous alternating layered structure and its preparation, can solve the problems of long time-consuming, complicated process and difficulty in industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

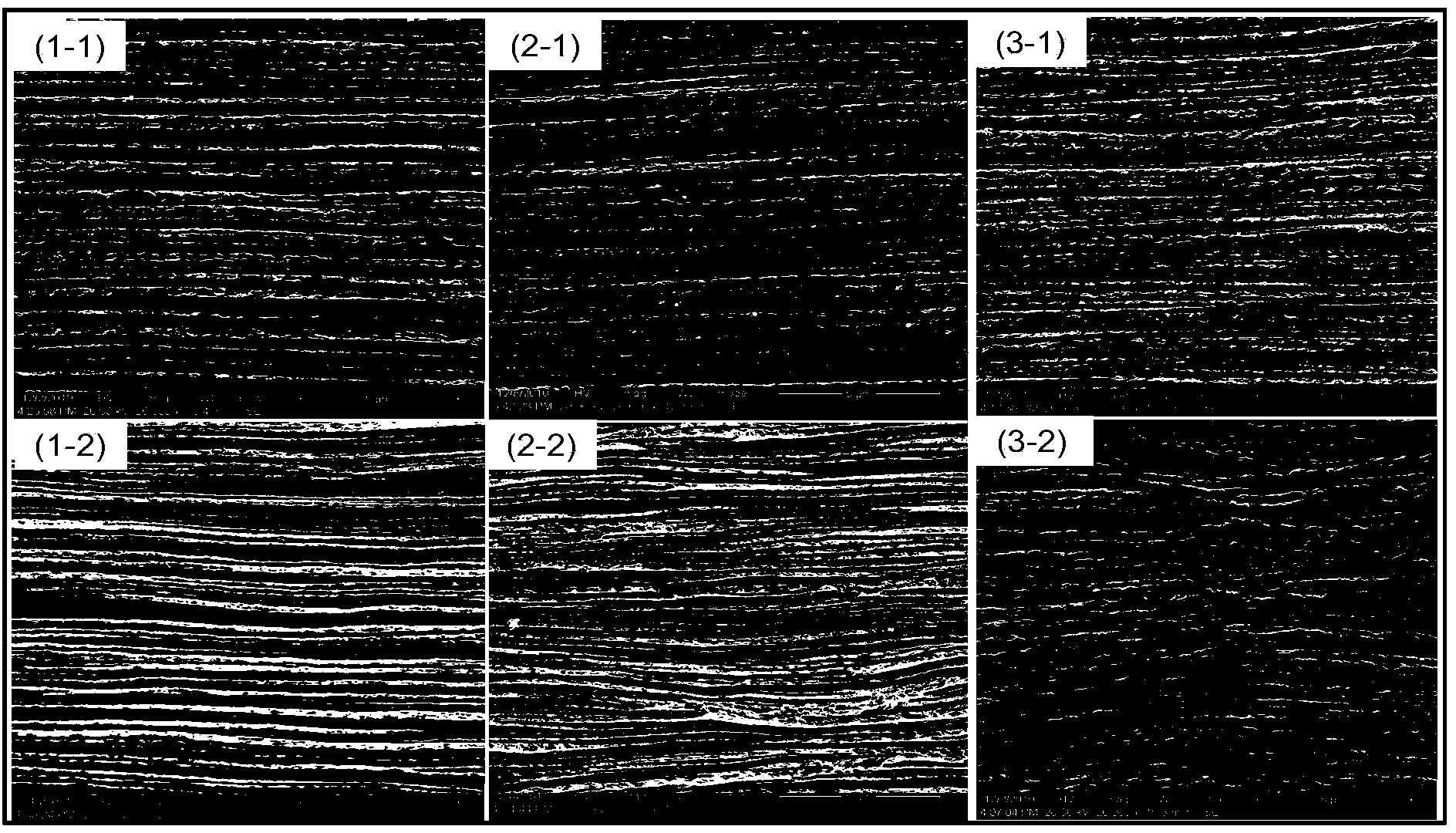

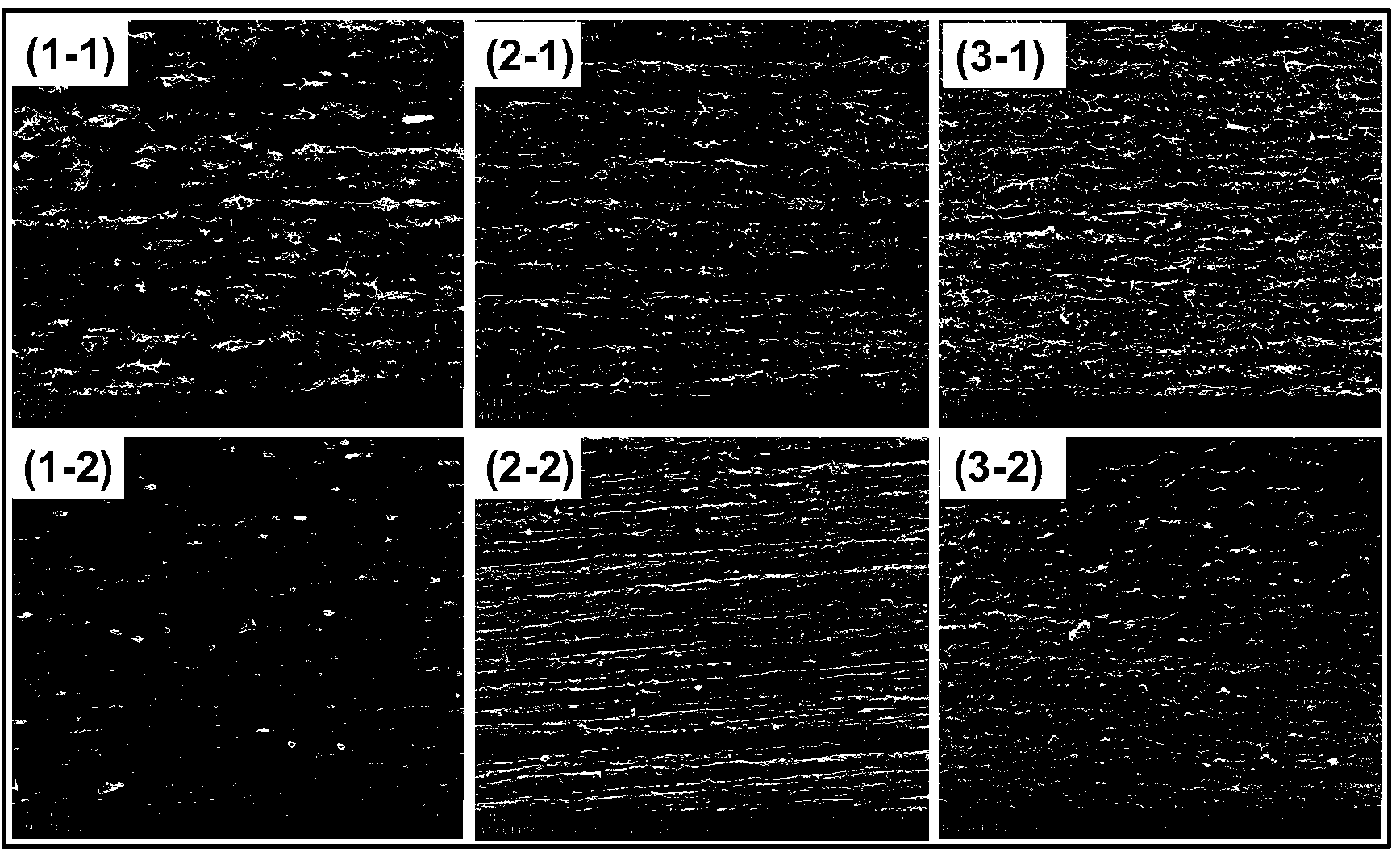

[0086] Firstly, 70 parts of polypropylene and 30 parts of polyethylene are premixed and then added to a twin-screw extruder, melted, blended, extruded, cooled, and pelletized at a temperature of 200°C to obtain blended pellets; and the obtained blended pellets High-speed thin-wall injection molding of the material, the injection temperature is 200 ℃, the injection speed is 300 mm / s, the material with continuous alternating layer structure can be prepared (see the internal phase morphology of the material) figure 1 Middle 1-1, 1-2).

Embodiment 2

[0088] Firstly, 50 parts of polypropylene and 50 parts of polyethylene are pre-mixed and then added to a twin-screw extruder, melt-blended, extruded, cooled, and pelletized at a temperature of 200°C to obtain blended pellets; and the obtained blended pellets High-speed thin-wall injection molding of the material, the injection temperature is 200 ℃, the injection speed is 300 mm / s, the material with continuous alternating layer structure can be prepared (see the internal phase morphology of the material) figure 1 Middle 2-1, 2-2).

Embodiment 3

[0090] Firstly, 30 parts of polypropylene and 70 parts of polyethylene are premixed and then added to the twin-screw extruder, melted, blended, extruded, cooled, and pelletized at a temperature of 200°C to obtain blended pellets; and the obtained blended pellets High-speed thin-wall injection molding of the material, the injection temperature is 200 ℃, the injection speed is 300 mm / s, the material with the continuous alternating layer structure can be prepared (see the internal phase morphology of the material) figure 1 Middle 3-1, 3-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com