Enhanced conductive nylon material and preparation method thereof

A nylon and raw material technology is applied in the field of nylon composite materials with conductive metal powder and its preparation, which can solve the problems of difficult processing and high cost, and achieve the effects of simple processing, smooth surface and cost advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

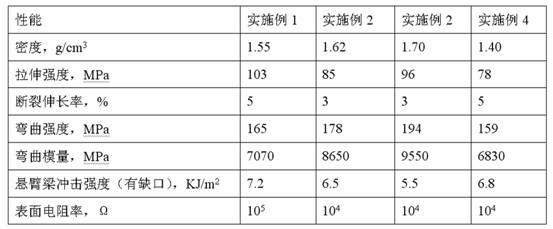

Embodiment 1

[0031]

[0032] Soak the glass fiber in the mixture of coupling agent, silicone oil and copper powder for 2 hours, take it out, and dry it at room temperature for 24 hours. In the mixed solution, aminopropyltriethoxysilane accounts for 5%, silicone oil accounts for 20%, copper powder Accounted for 75%. This step is the first time the metal powder is attached to the surface of the fiberglass.

[0033] At the main feeding port of the twin-screw extruder, mix 6.1kg of PA6, 20g of antioxidant 1010, and 20g of antioxidant 168 evenly and then add them to the extruder, and pass the glass fiber with copper powder attached at a uniform speed through the aluminum treated with silicone oil. Powder (this step is the second time to attach the metal powder to the surface of the glass fiber. When the aluminum powder is treated with silicone oil, the ratio is 10% for the silicone oil and 90% for the aluminum powder.), feed it into the extruder from the side feeding port, By adjusting the ...

Embodiment 2

[0036]

[0037] Prepare copper powder mixture, 3% of aminopropyl triethoxysilane, 2% of isopropyl tri(dioctyl ichthyloxy) titanate, 5% of silicone oil, and 90% of copper powder. Soak the glass fiber in the mixture of coupling agent, silicone oil and copper powder for 2 hours, take it out, and dry it at room temperature for 24 hours. This step is the first time the metal powder is attached to the surface of the fiberglass. Then use silicone oil to treat the aluminum powder, the ratio is 5% for silicone oil and 95% for aluminum powder.

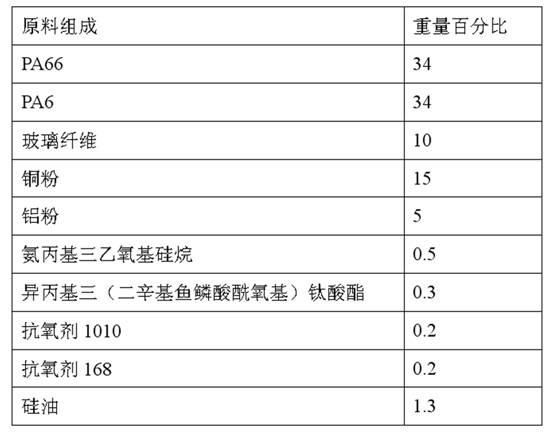

[0038] Mix 5.3kg of PA666, 20g of antioxidant 1010, and 20g of antioxidant 168 at the main feeding port of the twin-screw extruder, and then add them to the extruder, and pass the glass fiber with copper powder attached at a uniform speed through the silicone oil-treated aluminum powder (this step is the second time to attach the metal powder to the surface of the glass fiber), add it to the extruder from the side feeding port, adjust the sc...

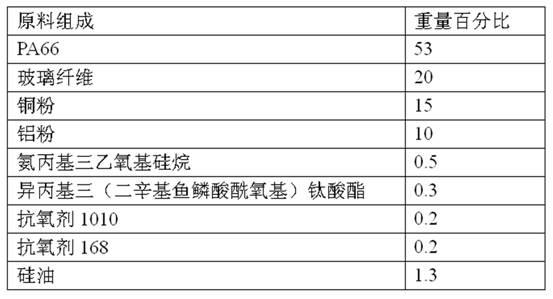

Embodiment 3

[0041]

[0042] Soak the glass fiber in the mixture of coupling agent, silicone oil and copper powder for 2 hours, take it out, and dry it at room temperature for 24 hours. In the mixed solution, aminopropyltriethoxysilane accounts for 5%, silicone oil accounts for 10%, copper powder Accounted for 85%. This step is the first time the metal powder is attached to the surface of the fiberglass.

[0043] Mix 3.6kg of PA6, 50g of antioxidant 1010, and 50g of antioxidant 168 at the main feeding port of the twin-screw extruder, and then add them to the extruder, and pass the glass fiber with copper powder attached at a uniform speed through the aluminum treated with silicone oil. Powder (this step is the second time to attach the metal powder to the surface of the glass fiber. When the aluminum powder is treated with silicone oil, the ratio is 5% for the silicone oil and 95% for the aluminum powder.), feed it into the extruder from the side feeding port, By adjusting the extruder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com