Electrode current collector material of lithium ion battery and preparation method thereof

An electrode current collector, lithium-ion battery technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of battery safety performance hazards, shorten the electrode service life of lithium-ion batteries, and limit applications, and achieve enhanced Work safety performance, low cost, small effect of material deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the magnetron sputtering equipment, the high-purity copper foil with a thickness of 0.01mm is used as the sputtering substrate, the graphite target is used as the sputtering target, filled with argon gas, and the vacuum degree of the working room is 1.0*10 -2 Pa, sputtering power 2.5Kw, the distance between the sputtering target and the copper foil substrate is 45mm, the speed of the copper foil substrate is 15m / min, deposit a carbon layer on the surface of the copper foil, the thickness of the deposited layer is 0.003mm and then heat-treating the carbon-coated copper foil material in a heat-treating furnace containing a mixed atmosphere of hydrogen and nitrogen at a heat-treating temperature of 400° C. for 6 hours.

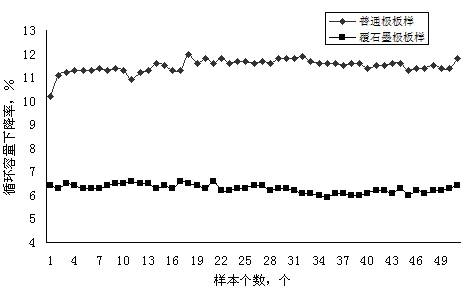

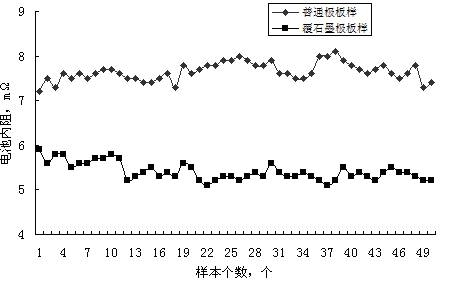

[0022] A copper foil covered with a carbon layer was prepared by the above method, and the thickness of the carbon layer was 0.003 mm. The carbon-coated copper foil of this embodiment and the common copper foil were respectively used as the negative ele...

Embodiment 2

[0025] In the magnetron sputtering equipment, the high-purity aluminum foil with a thickness of 0.015mm is used as the sputtering substrate, the graphite target is used as the sputtering target, filled with argon gas, and the vacuum degree of the working room is 3.0*10 -2 Pa, the sputtering power is 4.5Kw, the distance between the sputtering target and the aluminum foil substrate is 40mm, the walking speed of the aluminum foil substrate is 20m / min, a carbon layer is deposited on the surface of the aluminum foil, and the thickness of the deposited layer is 0.005mm; The carbonized aluminum foil material is heat treated in a vacuum heat treatment furnace at a heat treatment temperature of 500°C for 4 hours.

[0026] An aluminum foil covered with a carbon layer was prepared by the above method, and the thickness of the carbon layer was 0.005 mm. The carbon-coated aluminum foil of this embodiment and the ordinary aluminum foil were respectively used as the positive electrode curren...

Embodiment 3

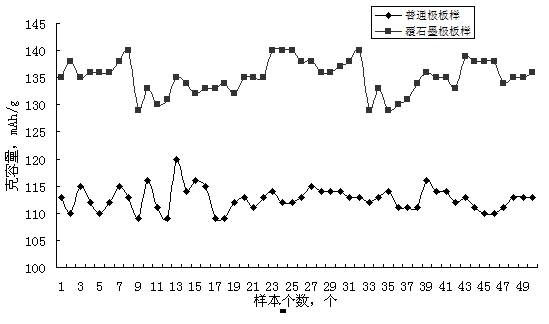

[0029] The carbon-coated copper foil of Example 1 is used as the negative electrode current collector, and the carbon-coated aluminum foil of Example 2 is used as the positive electrode current collector. The rest of the process is the same as the existing lithium-ion battery manufacturing process, and an improved lithium-ion battery is prepared. Under the same conditions Next, test the capacity of this improved lithium-ion battery and ordinary lithium-ion battery respectively, the test results are shown in the attached image 3 .

[0030] Depend on image 3 It can be seen that the gram capacity of the improved lithium-ion battery is significantly higher than that of the ordinary lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com