Photoelectrode using metal nitride as conductive substrate and preparation method thereof

A conductive substrate and metallic technology, applied in the field of photoelectrodes, can solve the problems of small photoresponse range, no proposal, high cost of conductive substrate, etc., and achieve the effects of low cost, photoactive layer protection and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of metallic titanium nitride: metal Ti sheet (33mm*20mm2 sheet) is placed in a tube furnace and sealed, evacuated, N 2 Replace 3 times, and then keep the 20sccm N 2 , the temperature of the tube furnace was raised to 600°C at 10°C / min, and then raised to 900°C at 5°C / min, kept for 6 hours and then lowered. Cool to room temperature and take it out to obtain titanium nitride, which is yellow in color, and the measured resistance is 2 ohms at a distance of about 1 cm from the test leads.

Embodiment 2

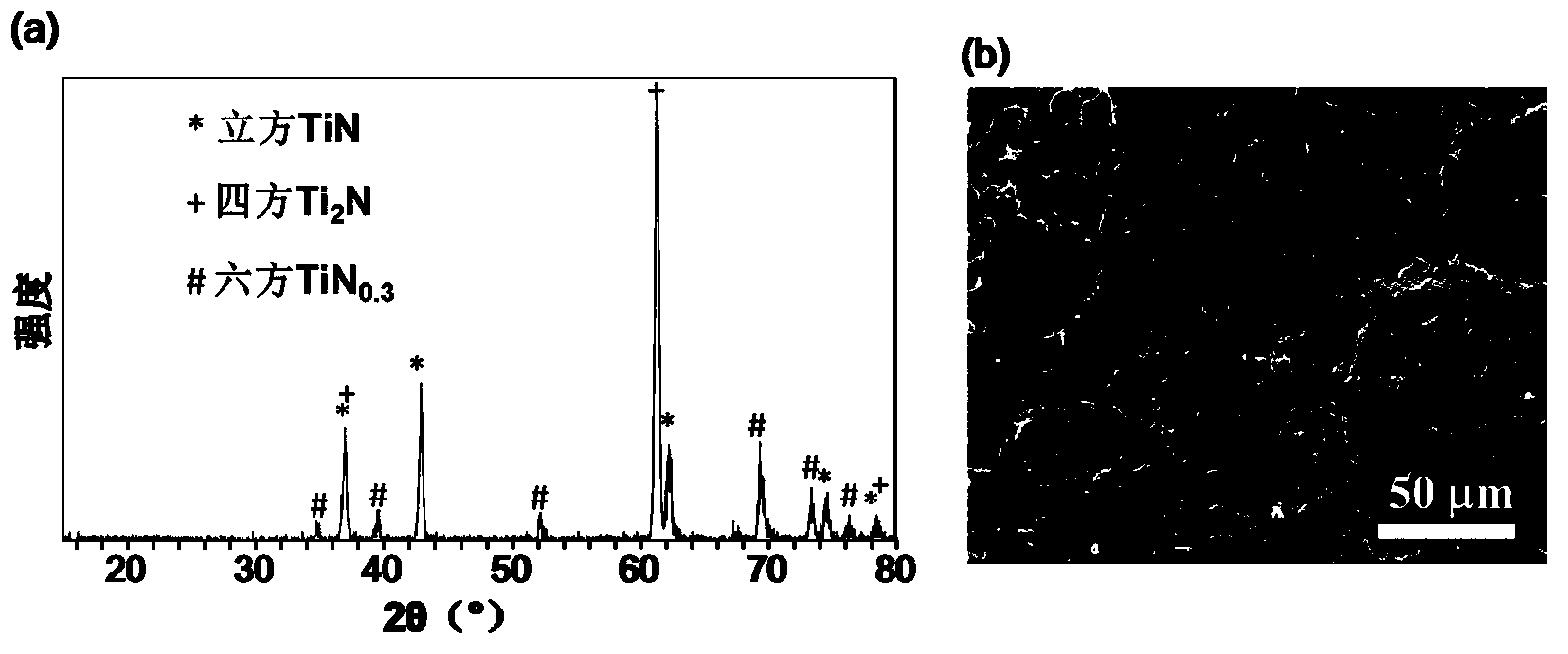

[0020] Preparation of metallic titanium nitride: metal Ti sheet (33mm*20mm2 sheet) is placed in a tube furnace and sealed, evacuated, N 2 Replace 3 times, and then keep the 20sccm N 2 , the temperature of the tube furnace was raised to 600°C at 10°C / min, and then raised to 1000°C at 5°C / min, kept for 6 hours and then cooled down. Cool to room temperature and take it out to obtain titanium nitride, which is yellow in color and darker and brighter than the sample treated at 900°C. figure 1 (a) is the XRD pattern of the prepared sample, showing cubic TiN phase, tetragonal Ti 2 N-phase and hexagonal TiN 0.3 Mutually, figure 1 (b) is the SEM image of the sample surface.

Embodiment 3

[0022] Preparation of metallic titanium nitride: metal Ti sheet (30mm*35mm2 sheet) is placed in a corundum tube furnace and sealed, evacuated, N 2 Replace 3 times, and then keep the 20sccm N 2, the temperature of the tube furnace was raised to 600°C at 20°C / min, then to 900°C at 10°C / min, and then to 1200°C at 5°C / min, kept for 18 hours and then lowered. Cool to room temperature and take out to obtain titanium nitride, which is brown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com