Patents

Literature

100 results about "Tipped tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tipped tool is any cutting tool in which the cutting edge consists of a separate piece of material that is brazed, welded, or clamped onto a body made of another material. In the types in which the cutter portion is an indexable part clamped by a screw, the cutters are called inserts (because they are inserted into the tool body). Tipped tools allow each part of the tool, the shank and the cutter(s), to be made of the material with the best properties for its job. Common materials for the cutters (brazed tips or clamped inserts) include cemented carbide, polycrystalline diamond, and cubic boron nitride. Tools that are commonly tipped include milling cutters (such as end mills, face mills, and fly cutters), tool bits, router bits, and saw blades (especially the metal-cutting ones).

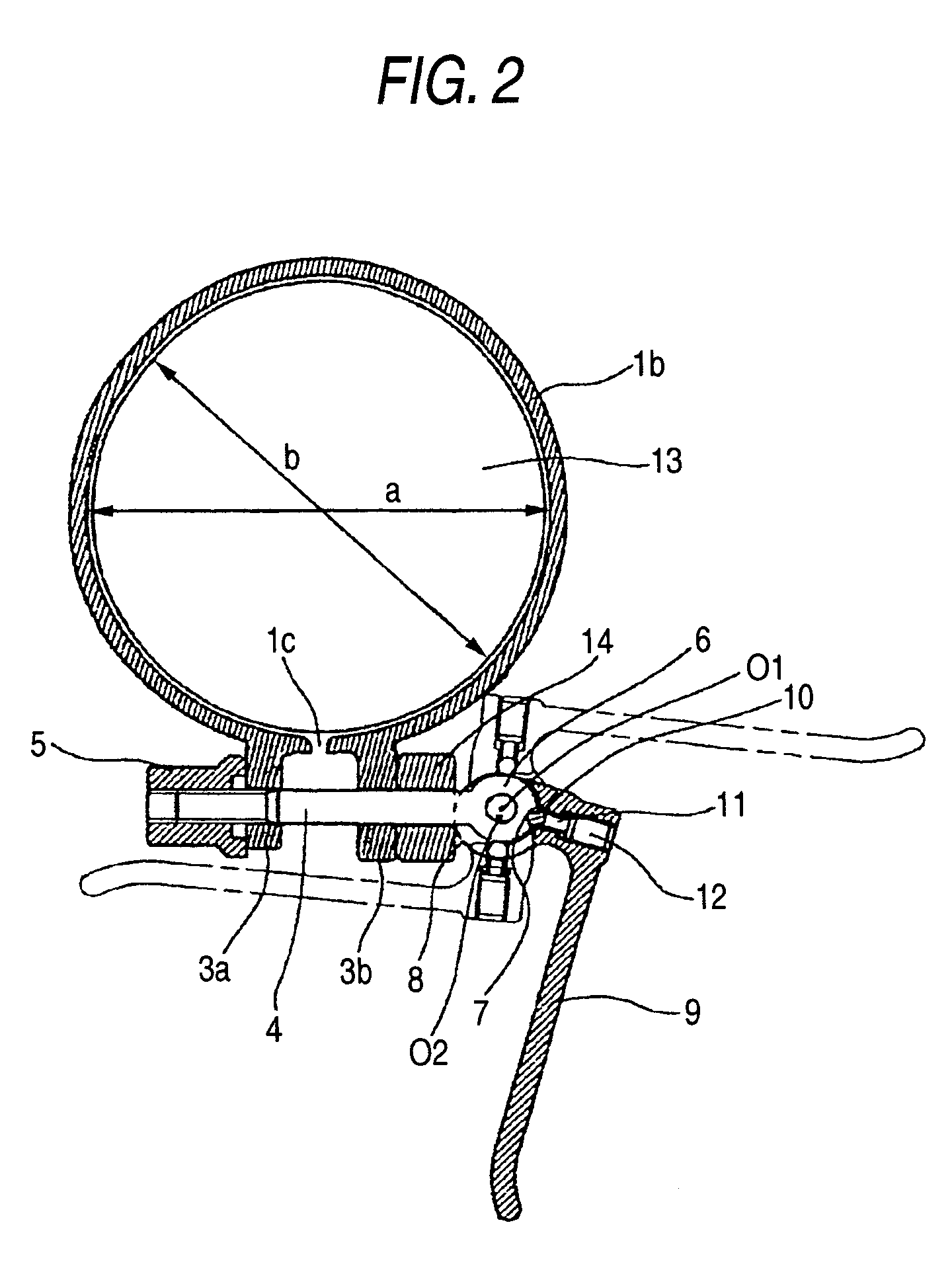

Impact tool

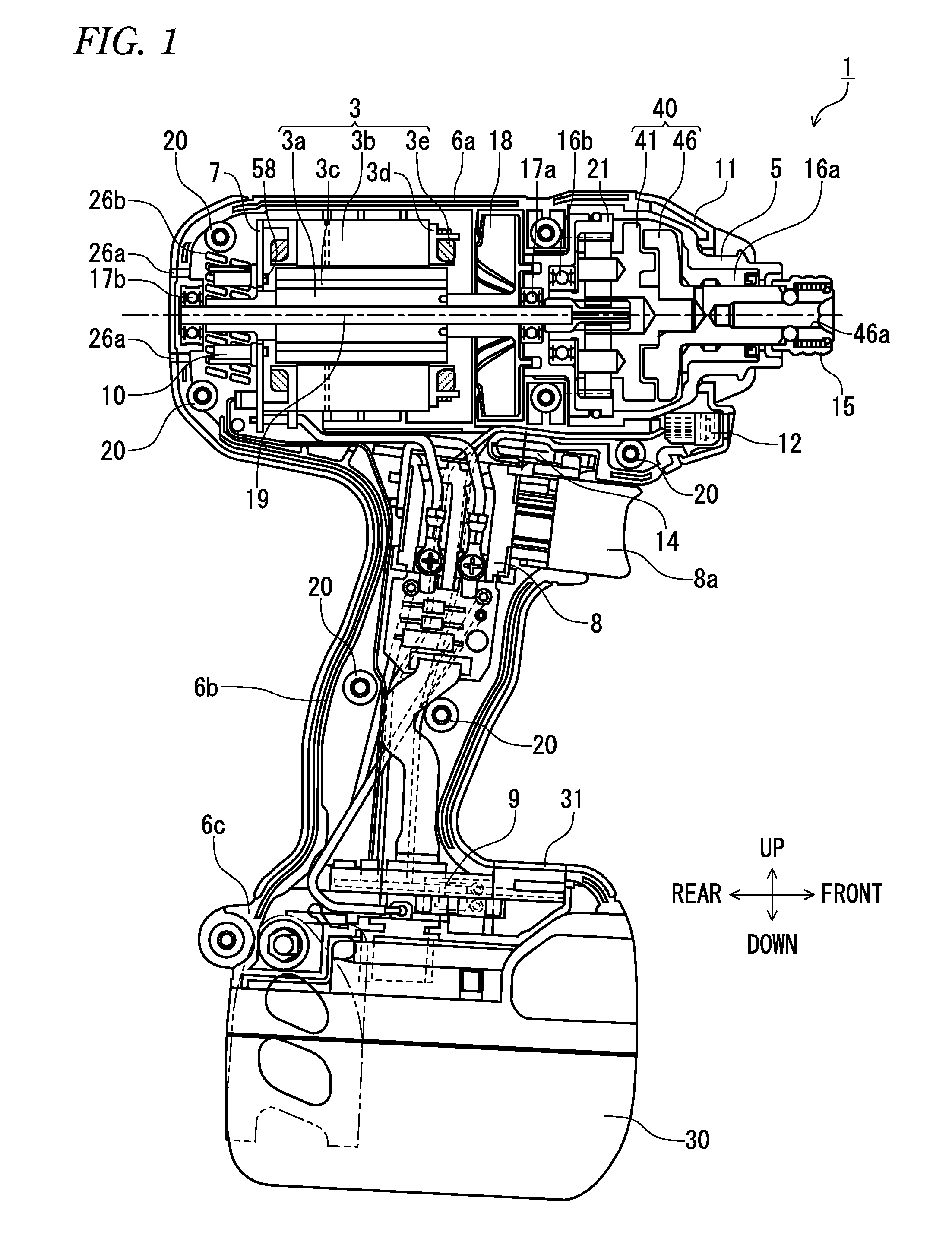

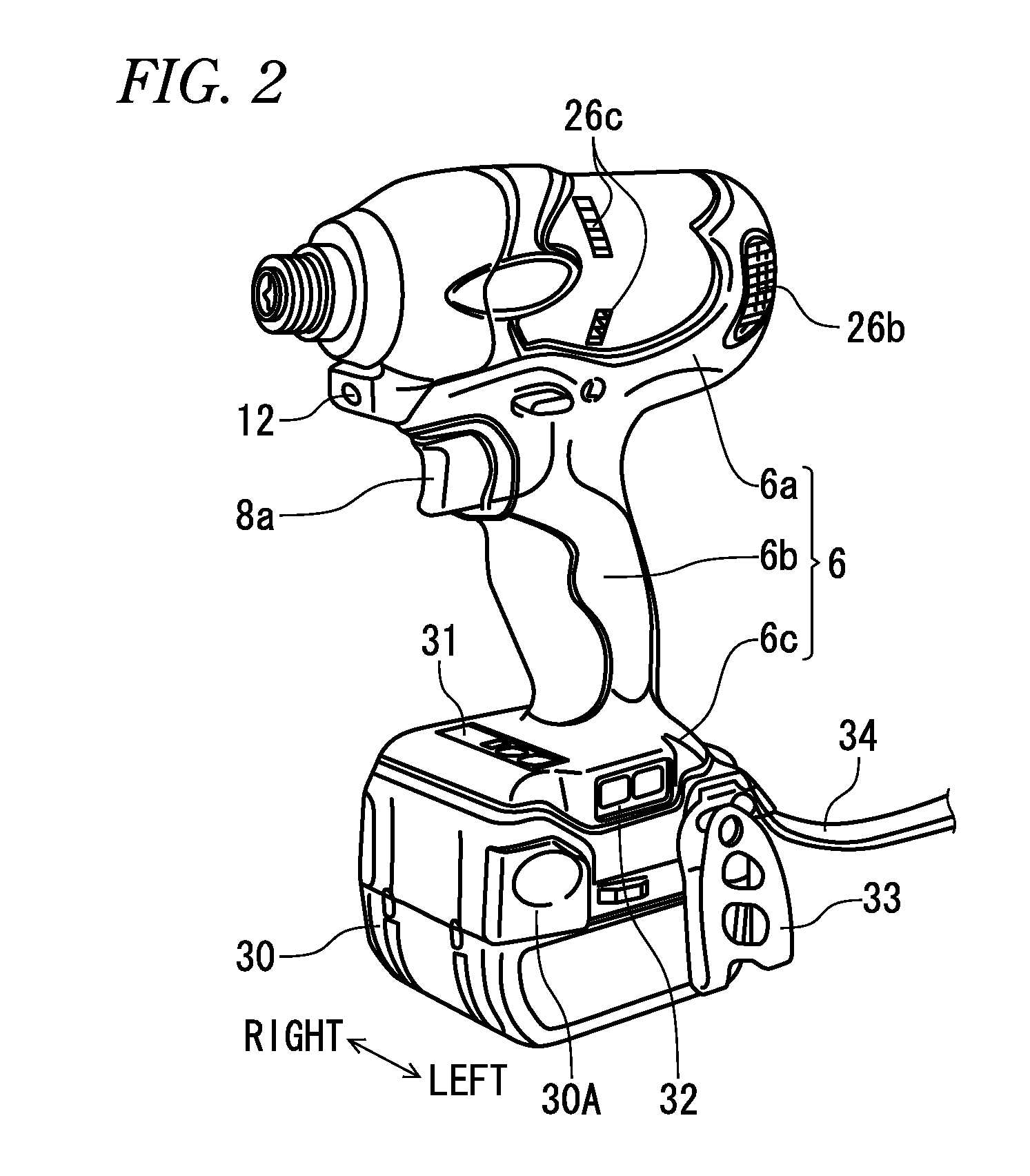

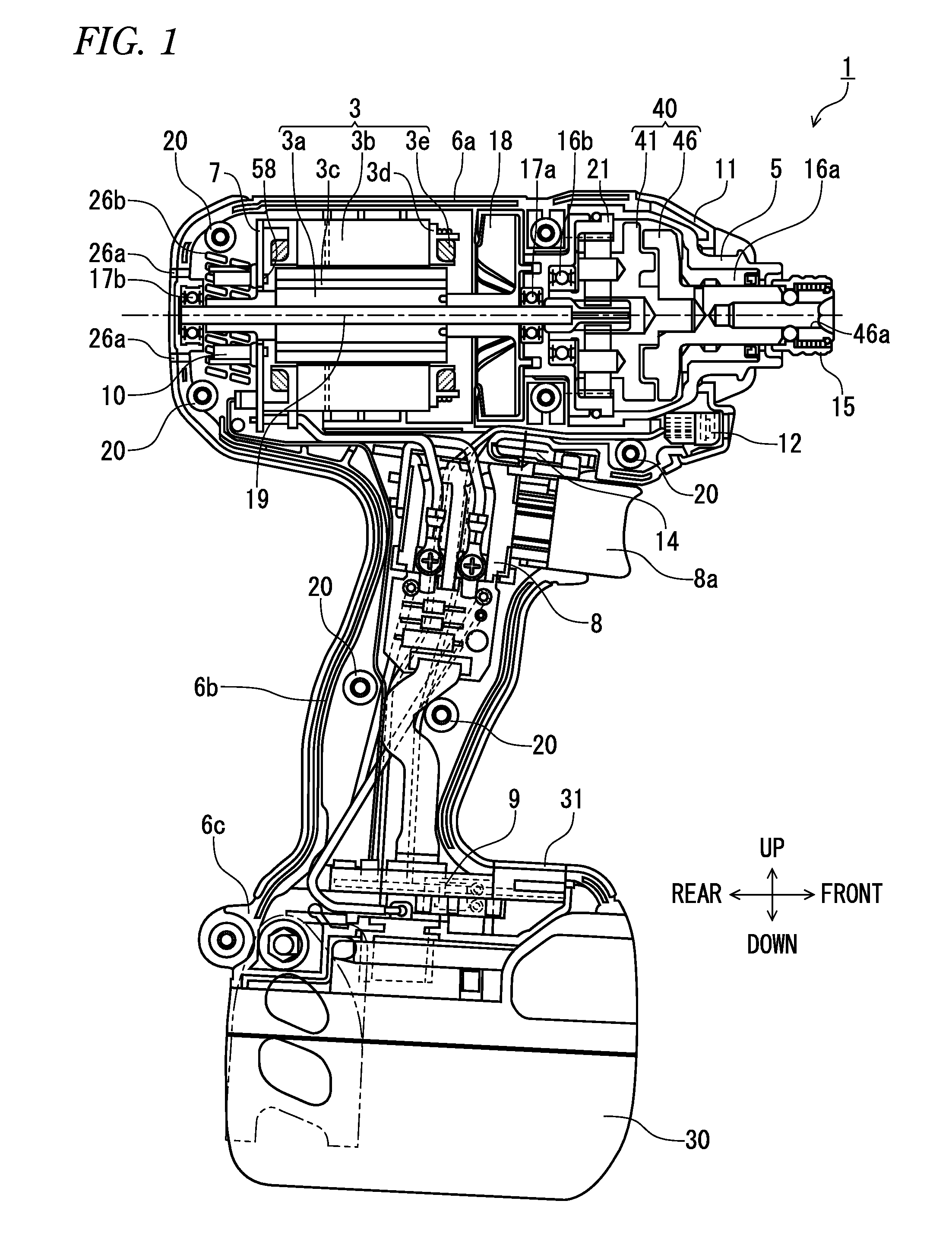

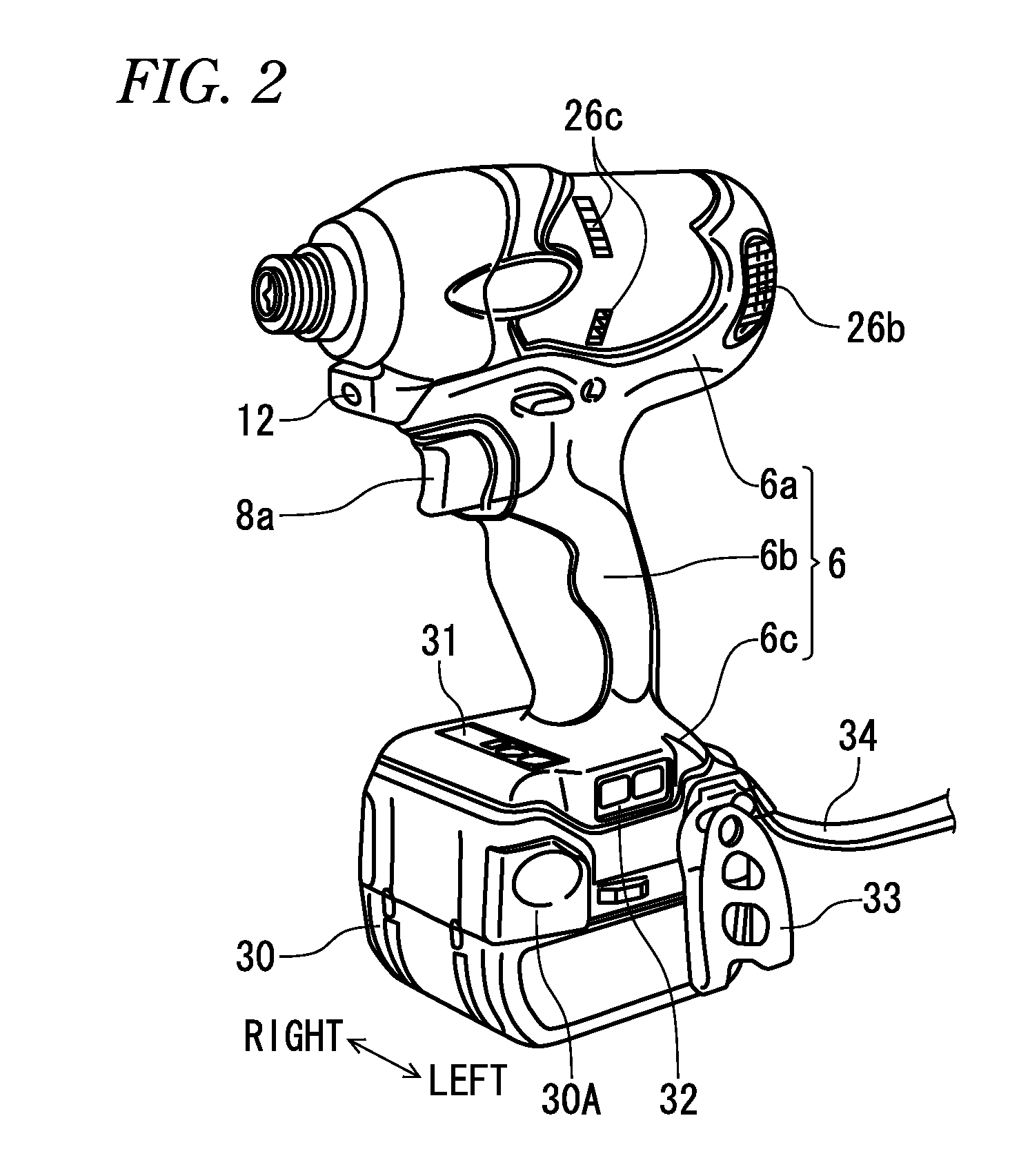

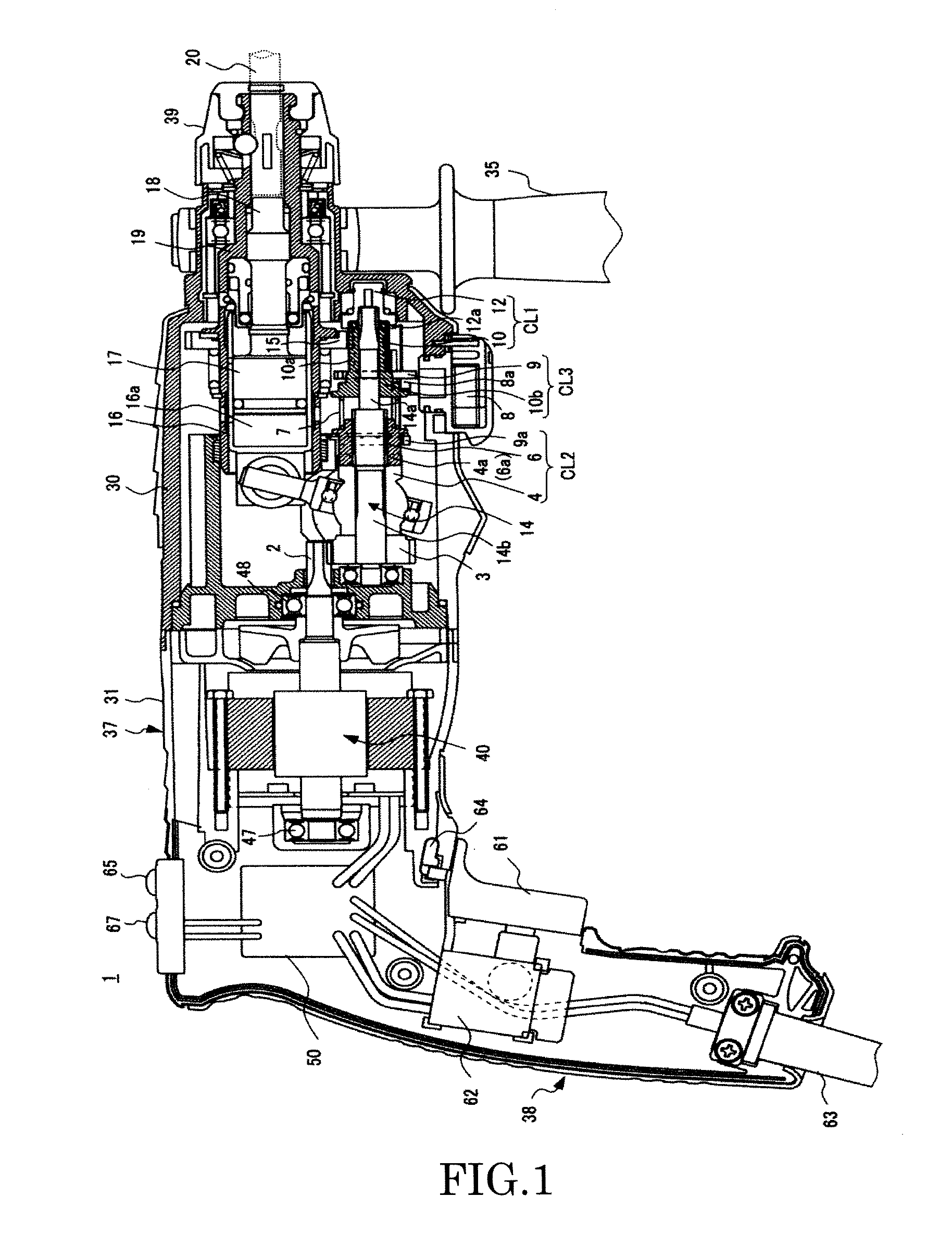

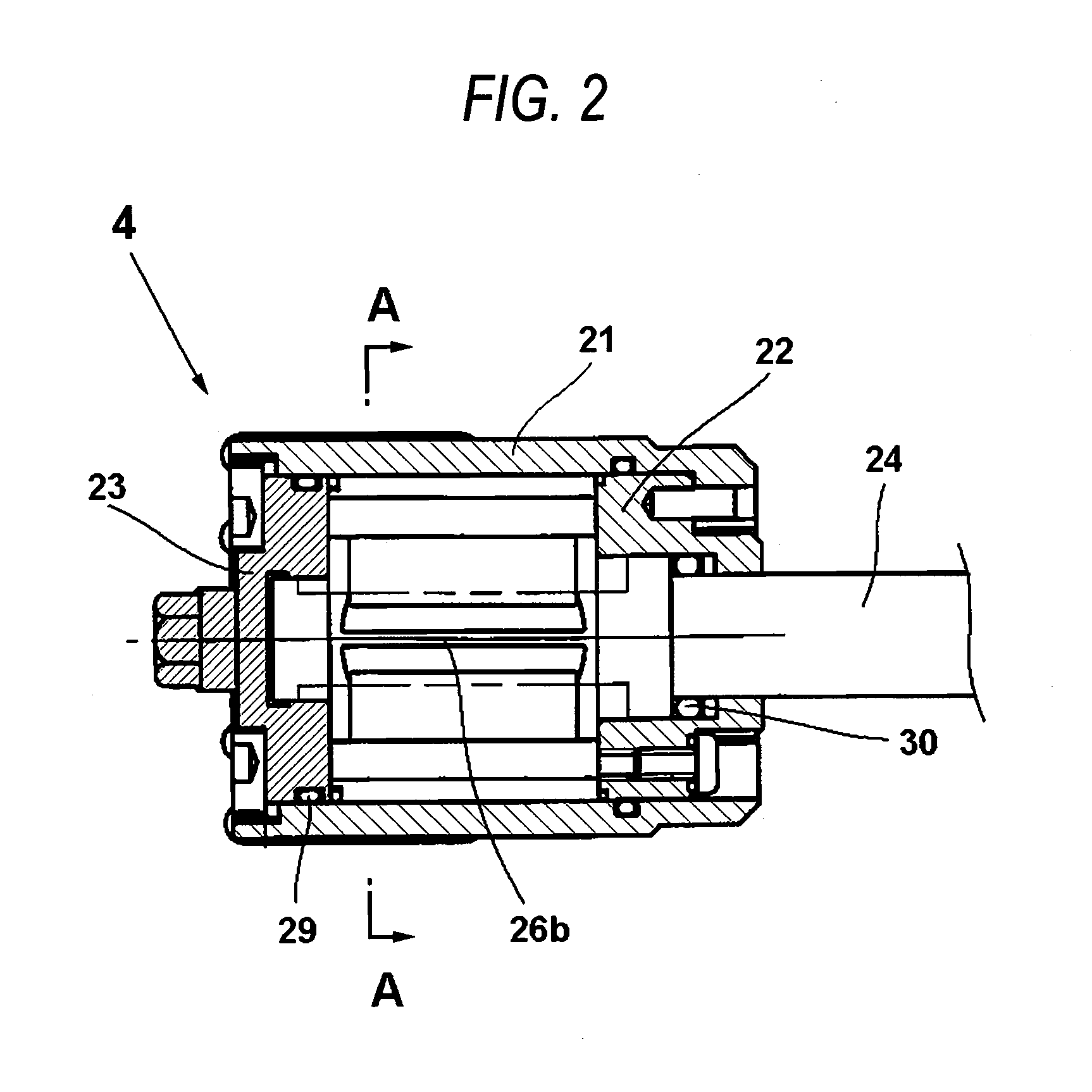

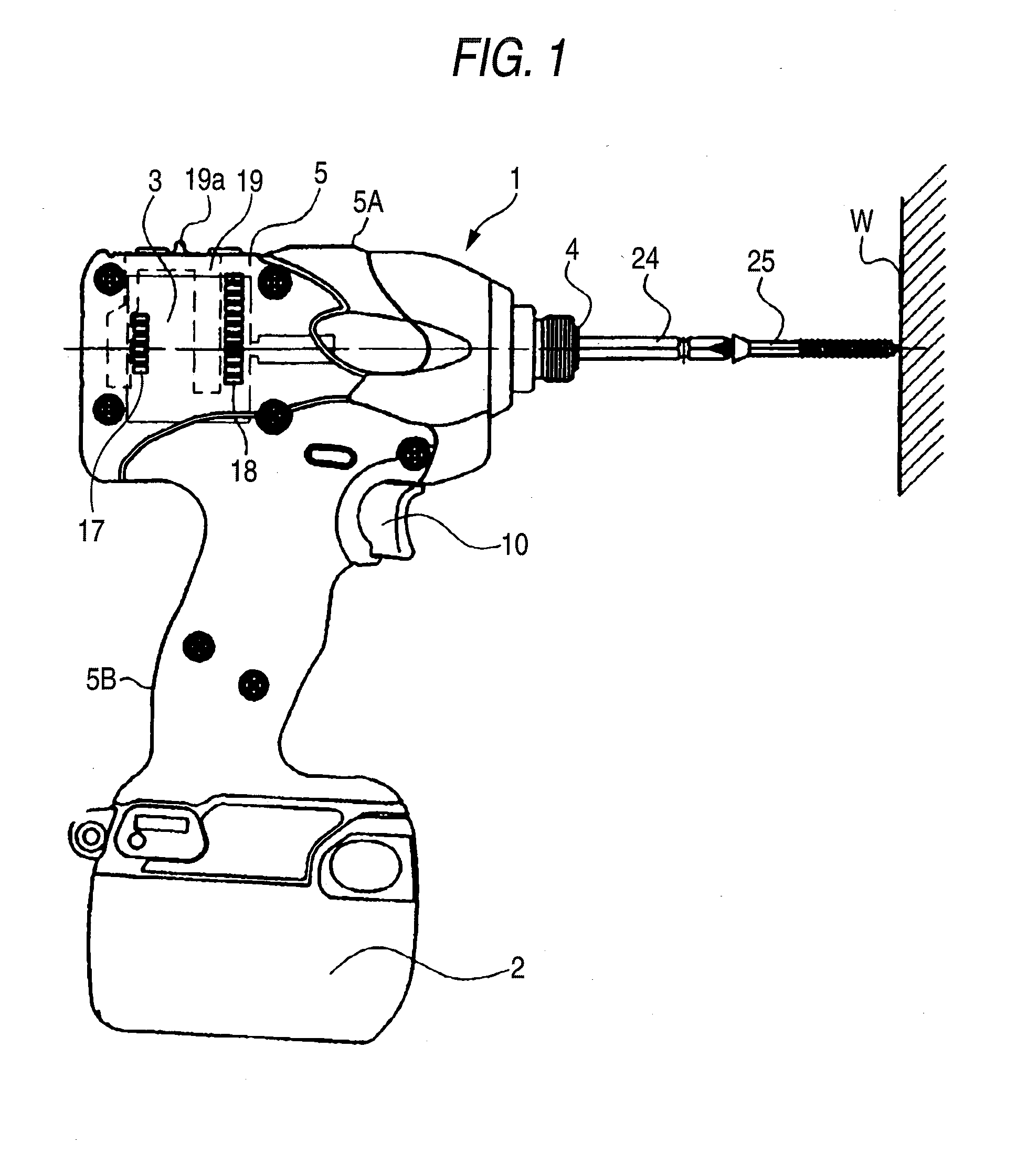

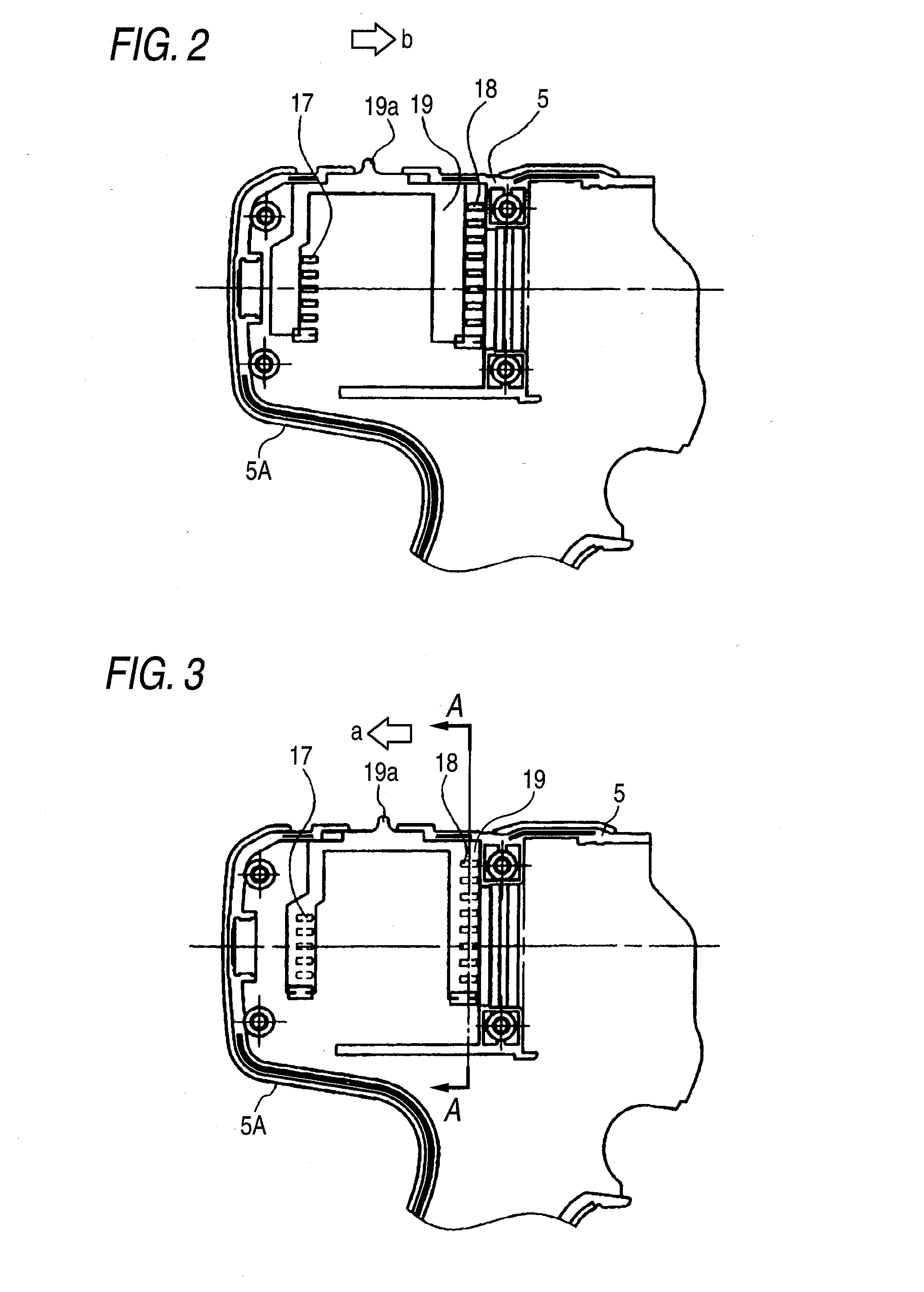

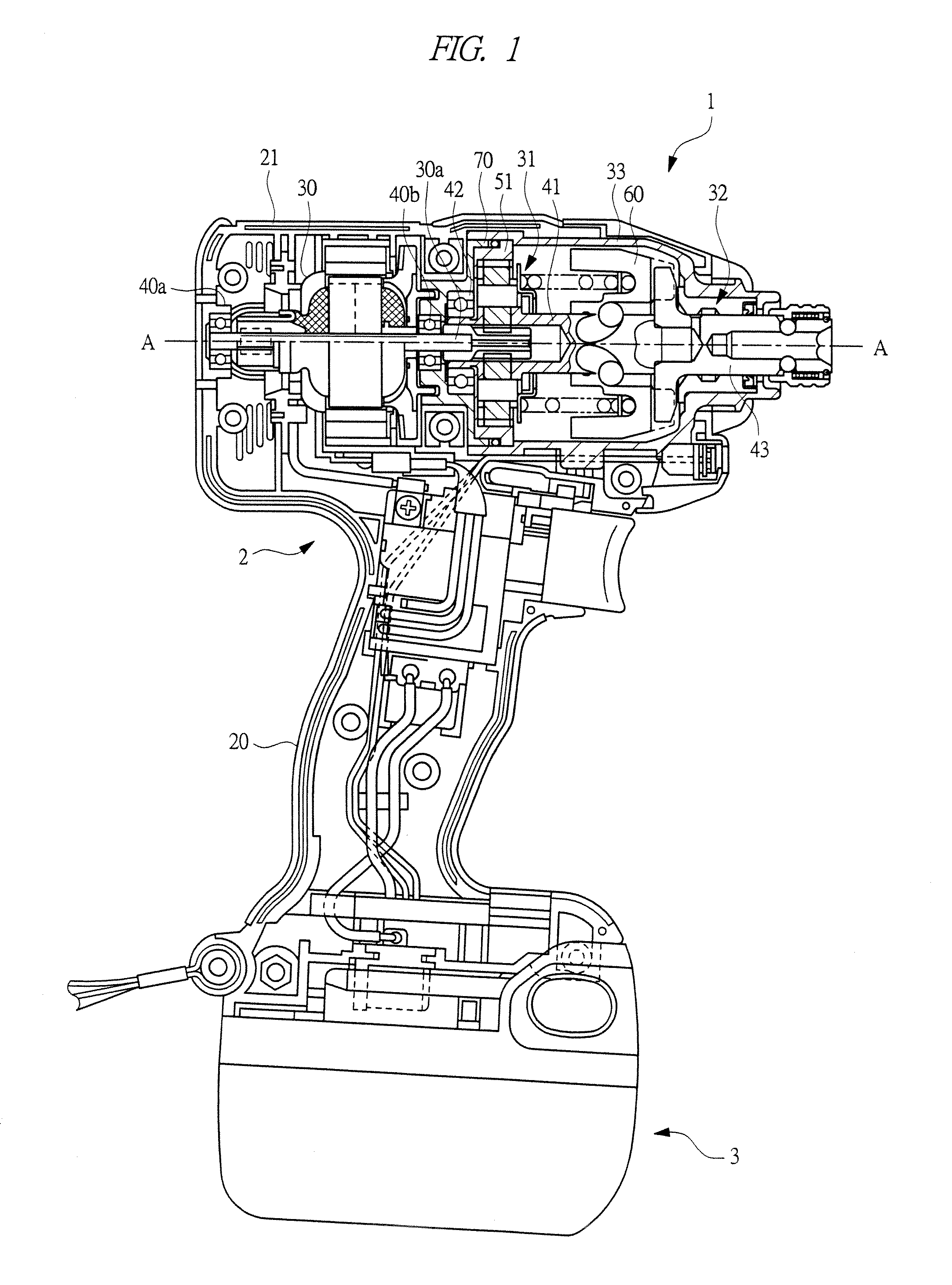

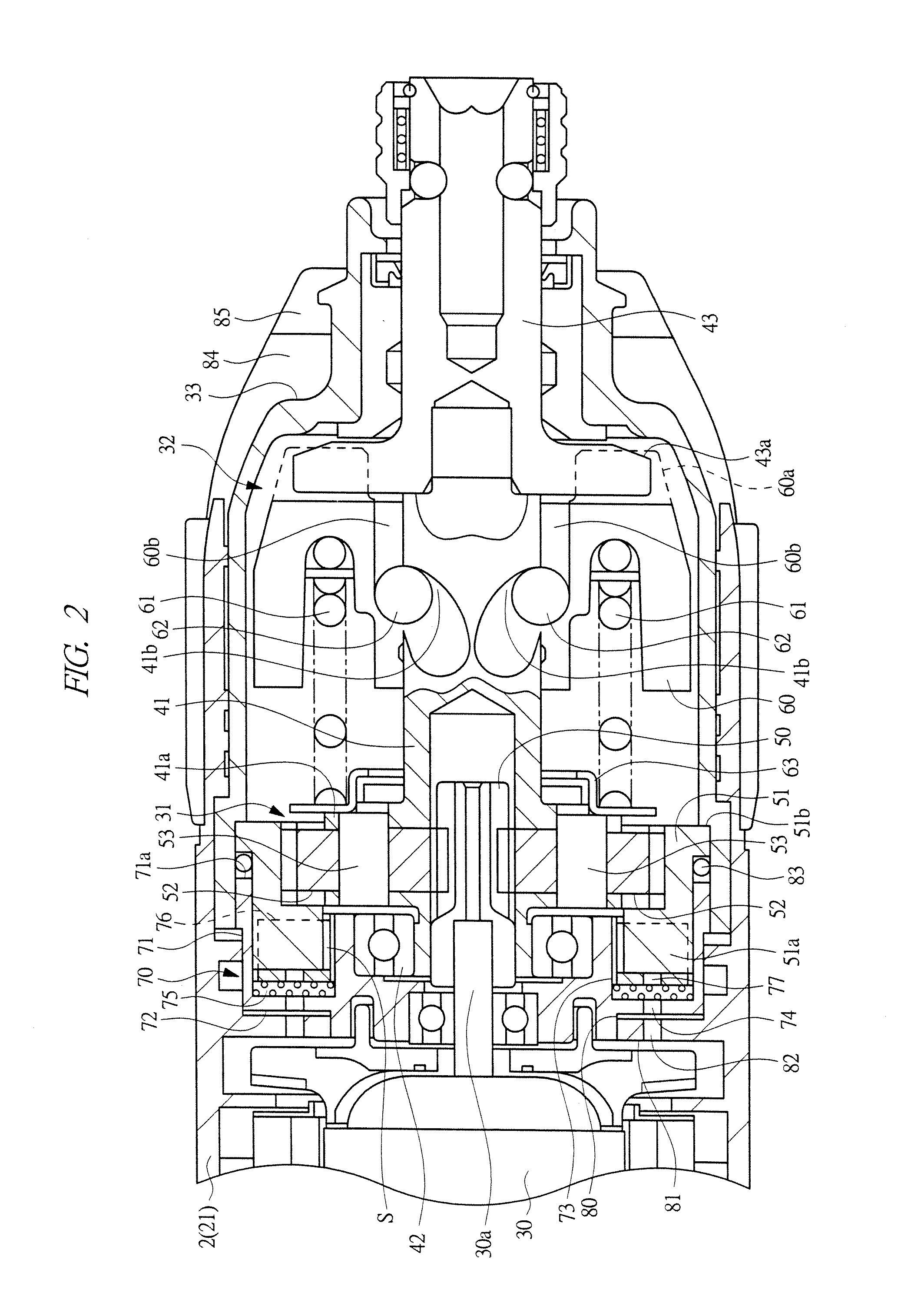

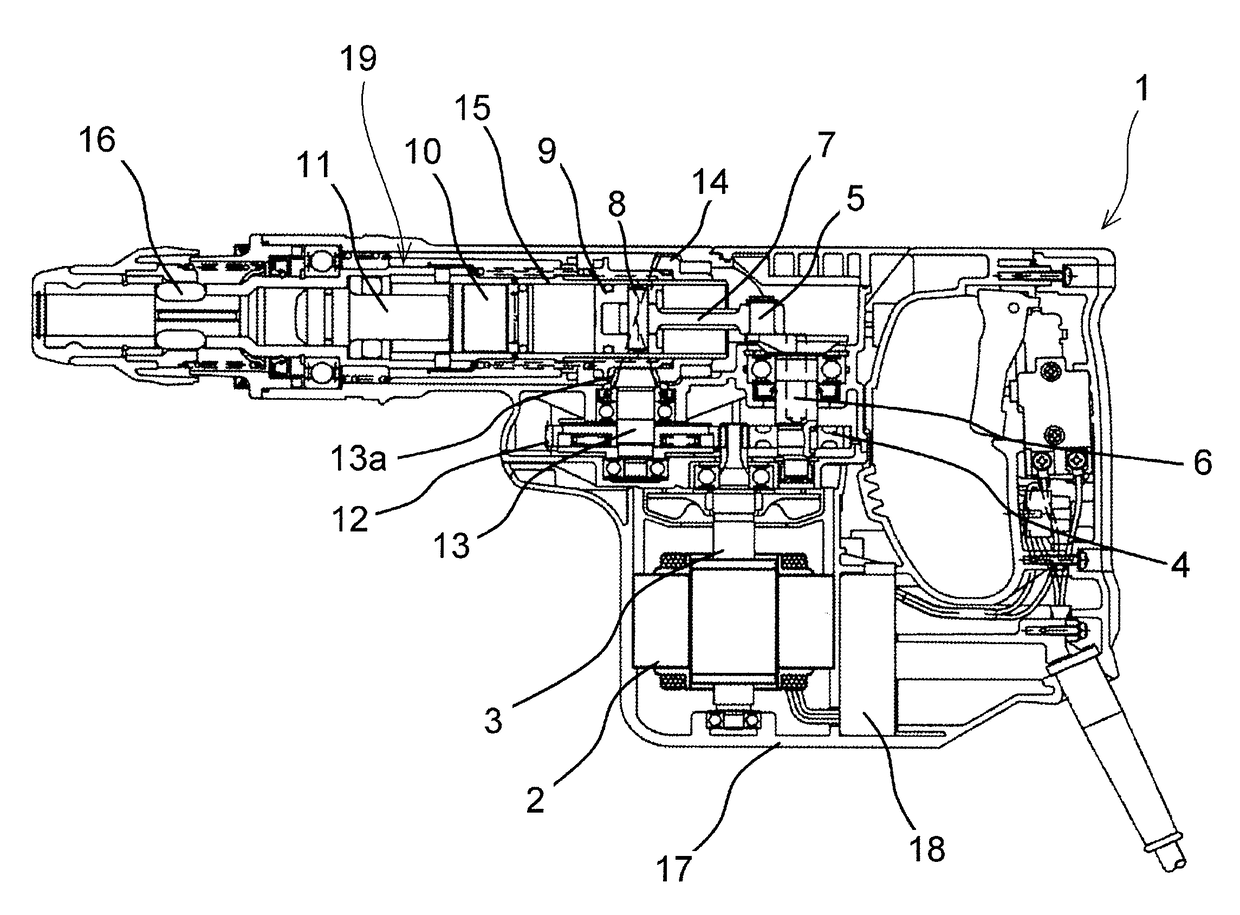

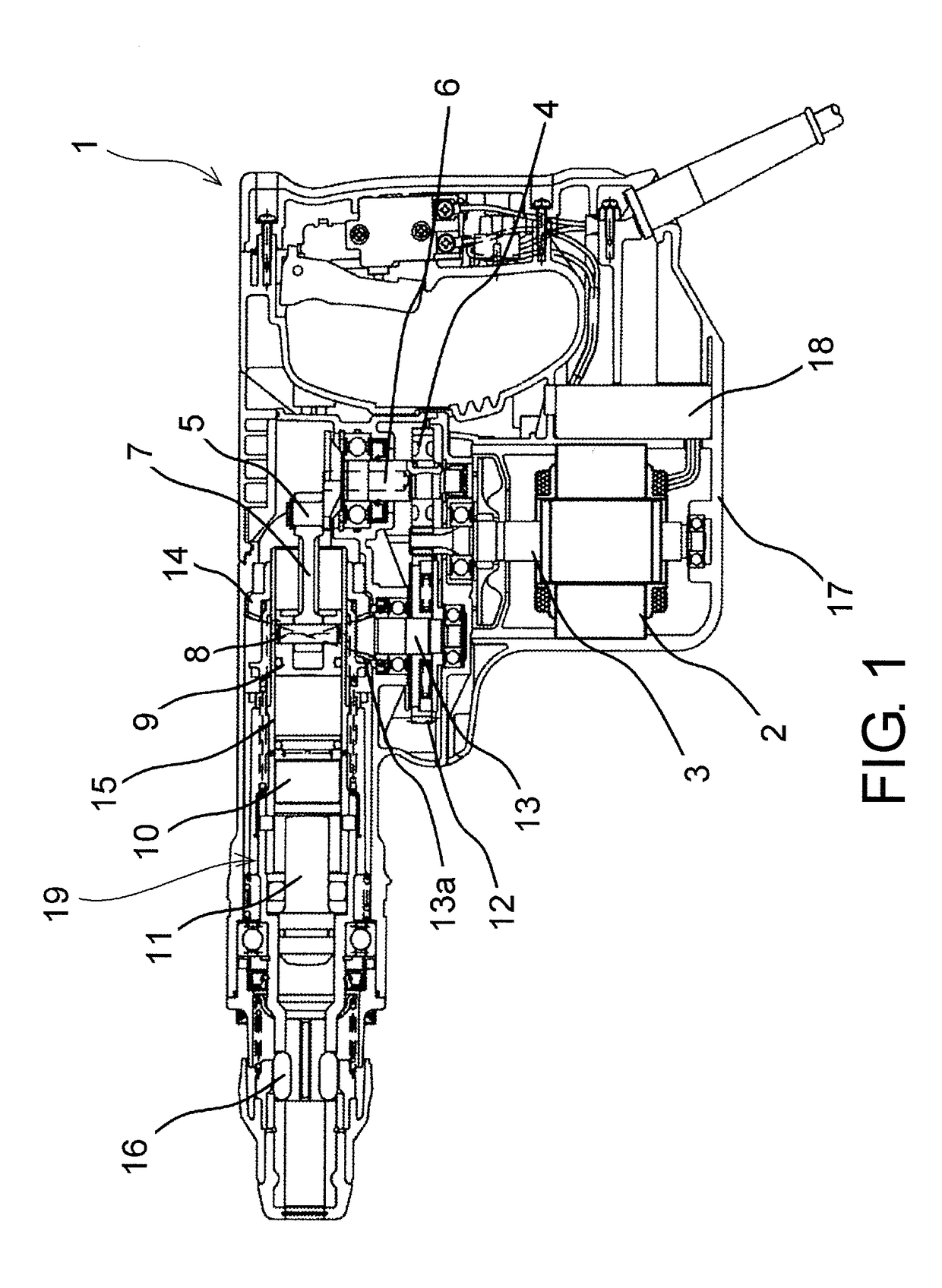

According to one embodiment, an impact tool includes: a motor; and a hammer that is connected to the motor and that has a striking-side surface; and an anvil that is journalled to be rotatable with respect to the hammer, that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor is drivable in: a first driving mode in which the motor is continuously driven in a normal rotation; a second driving mode in which the motor is intermittently driven only in the normal rotation; and a third driving mode in which the motor is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

Impact tool

ActiveUS9314908B2Optimization mechanismConstructionsReciprocating drilling machinesEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:KOKI HLDG CO LTD

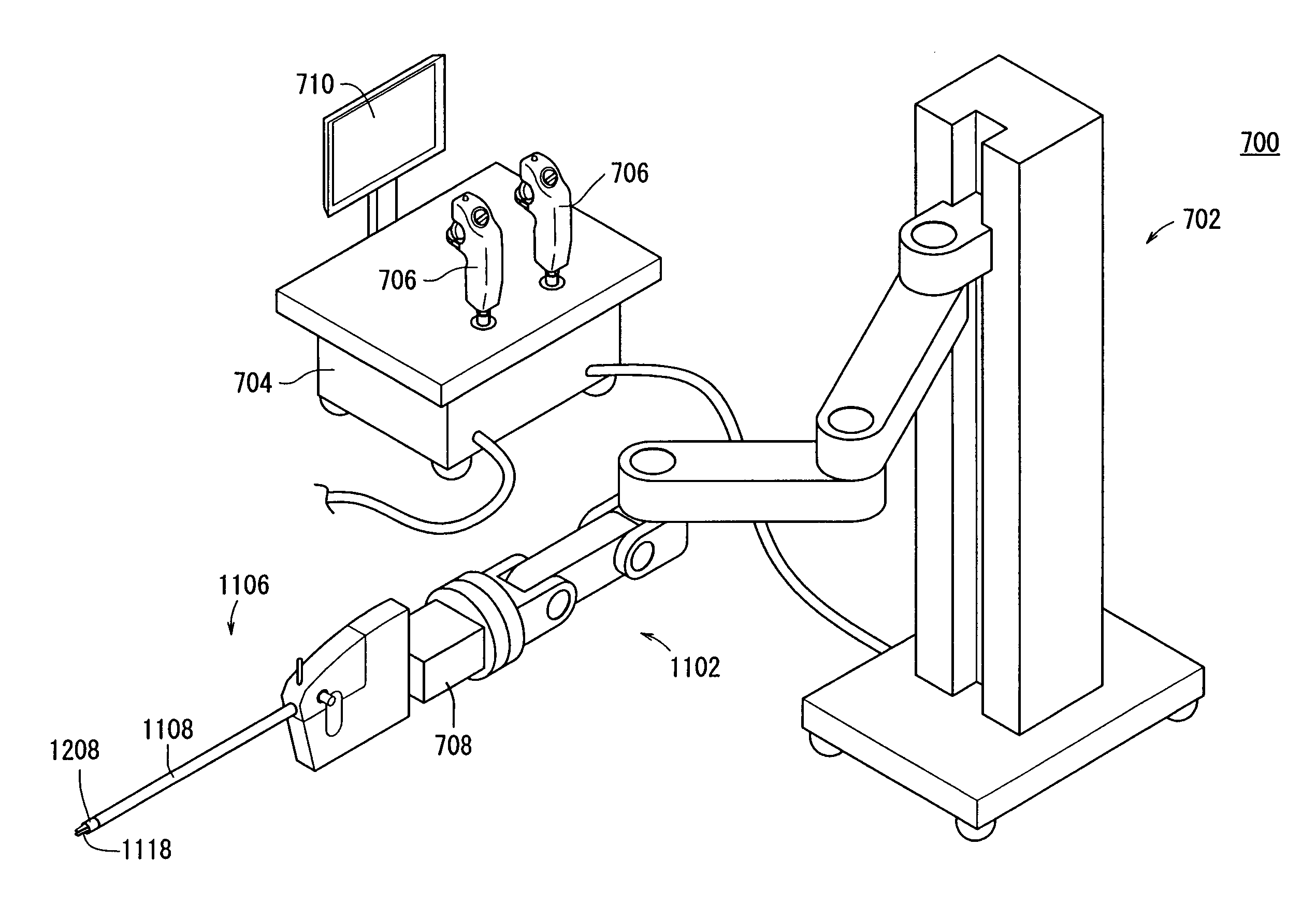

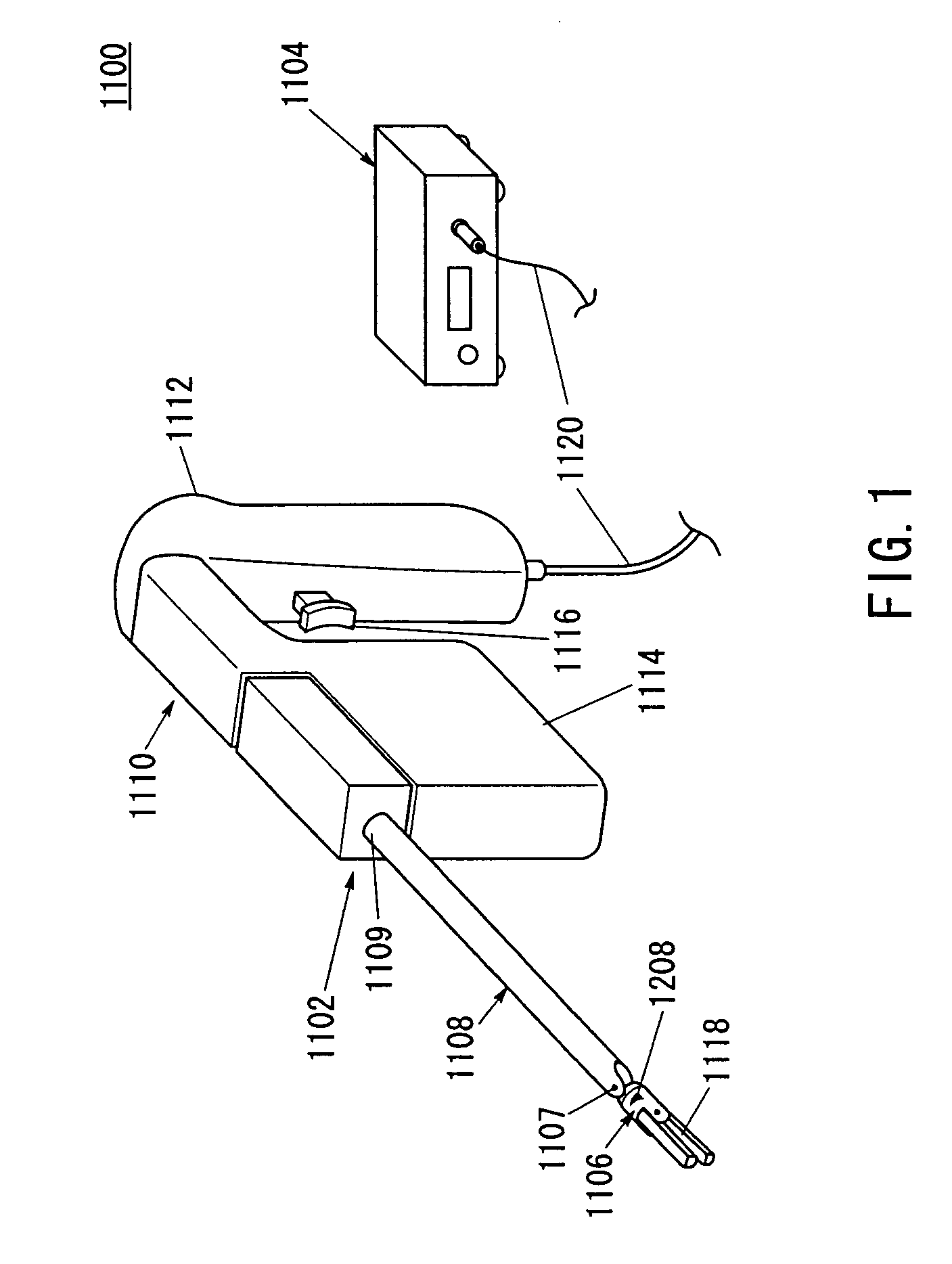

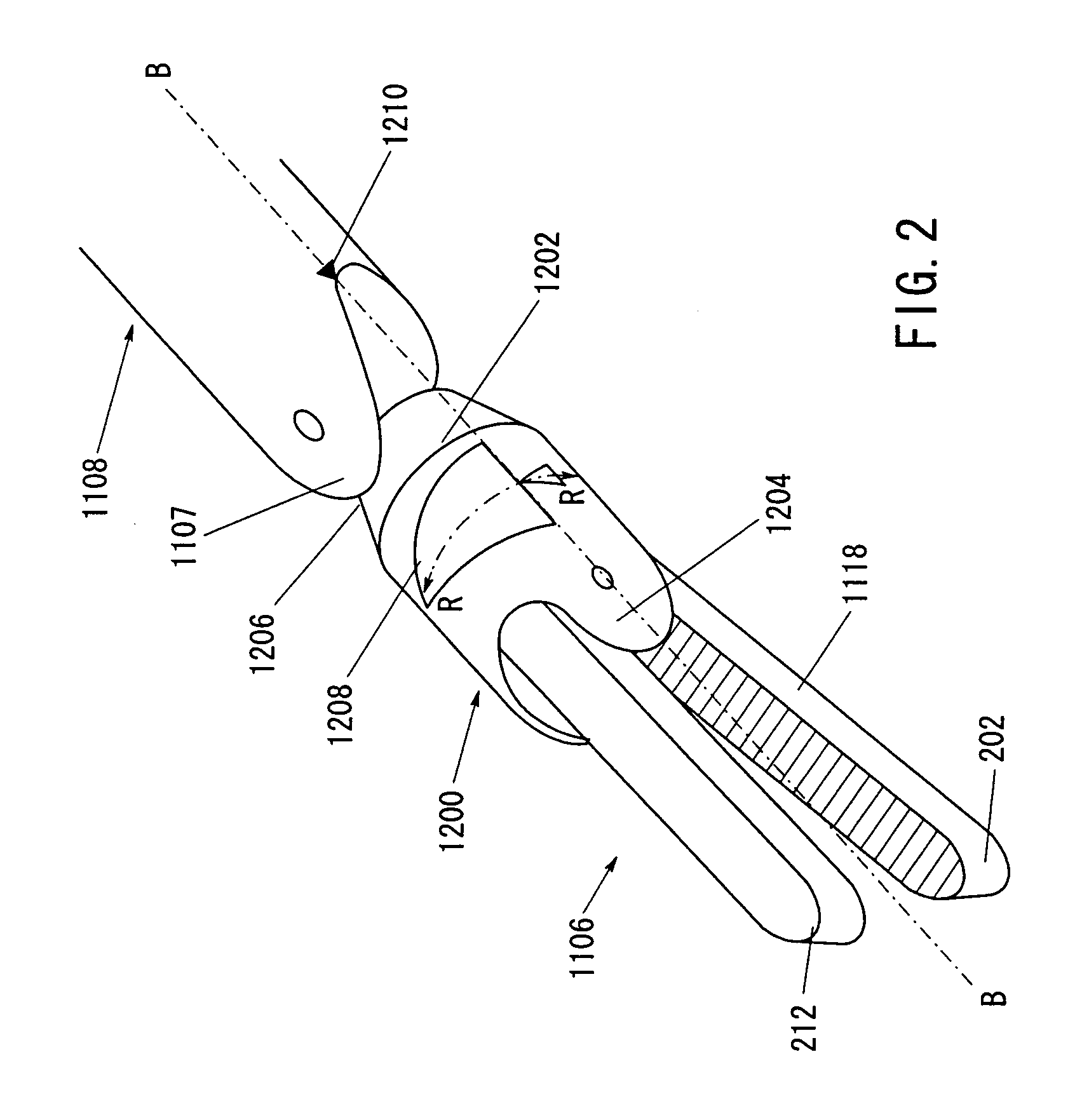

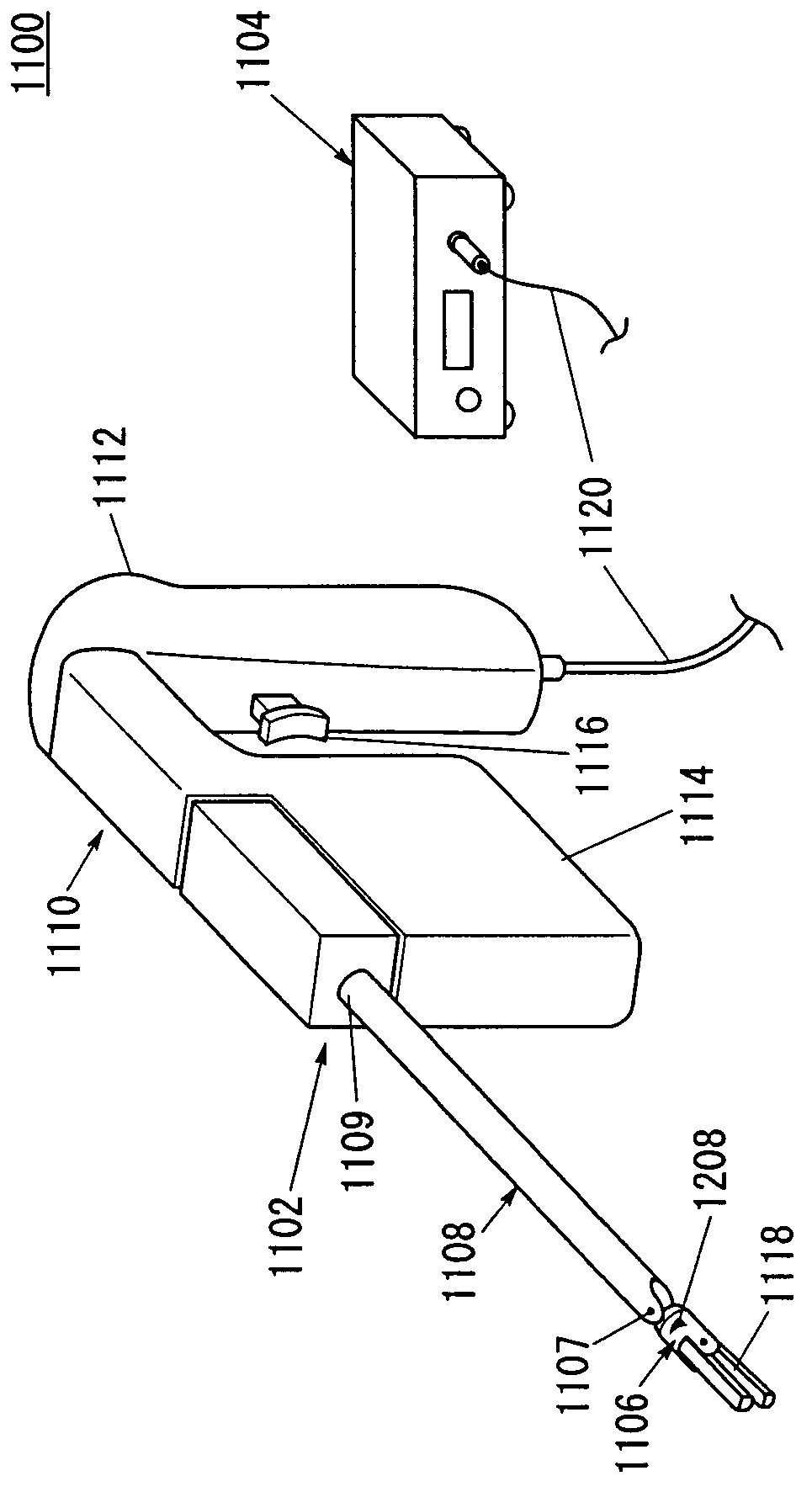

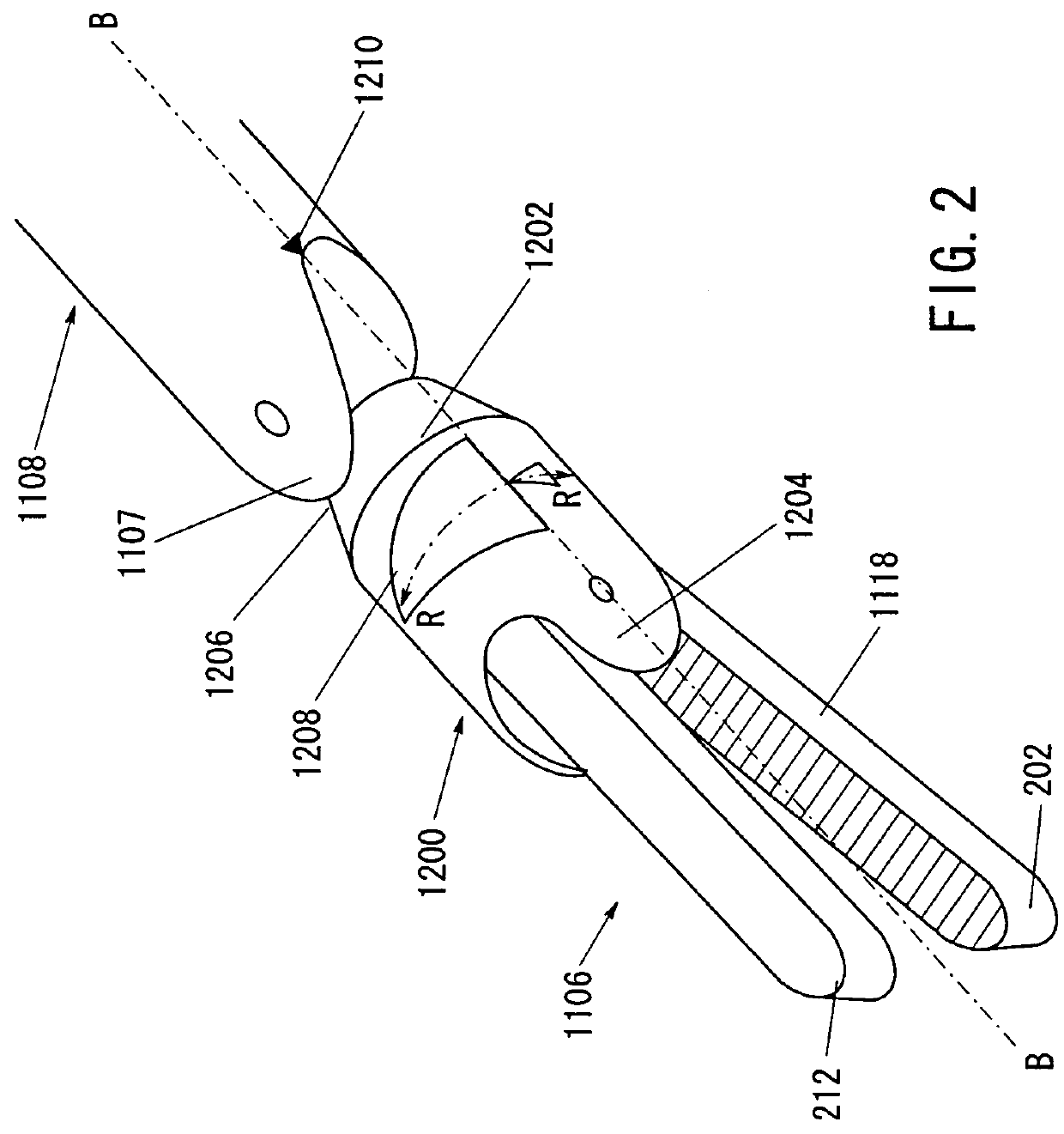

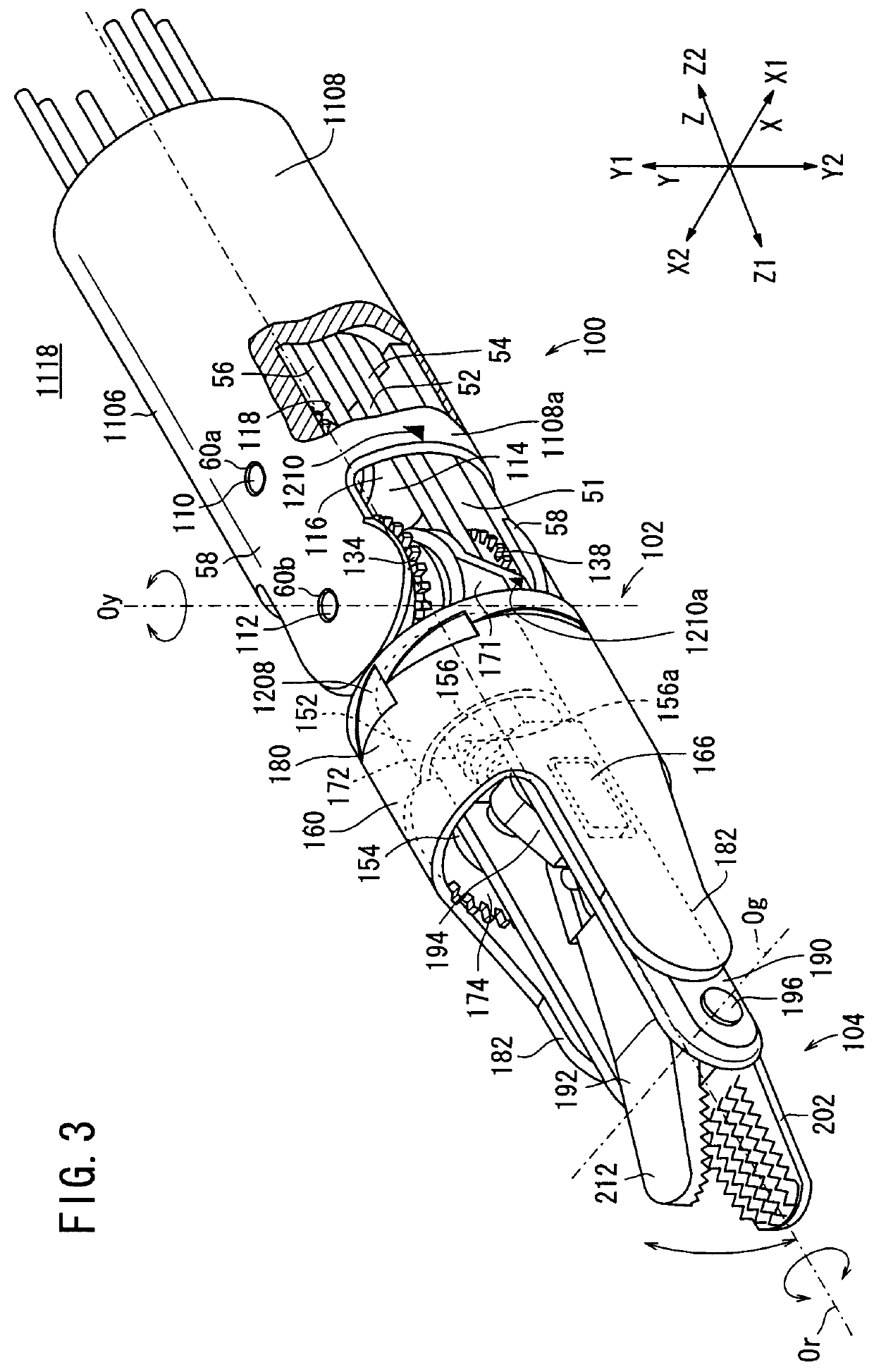

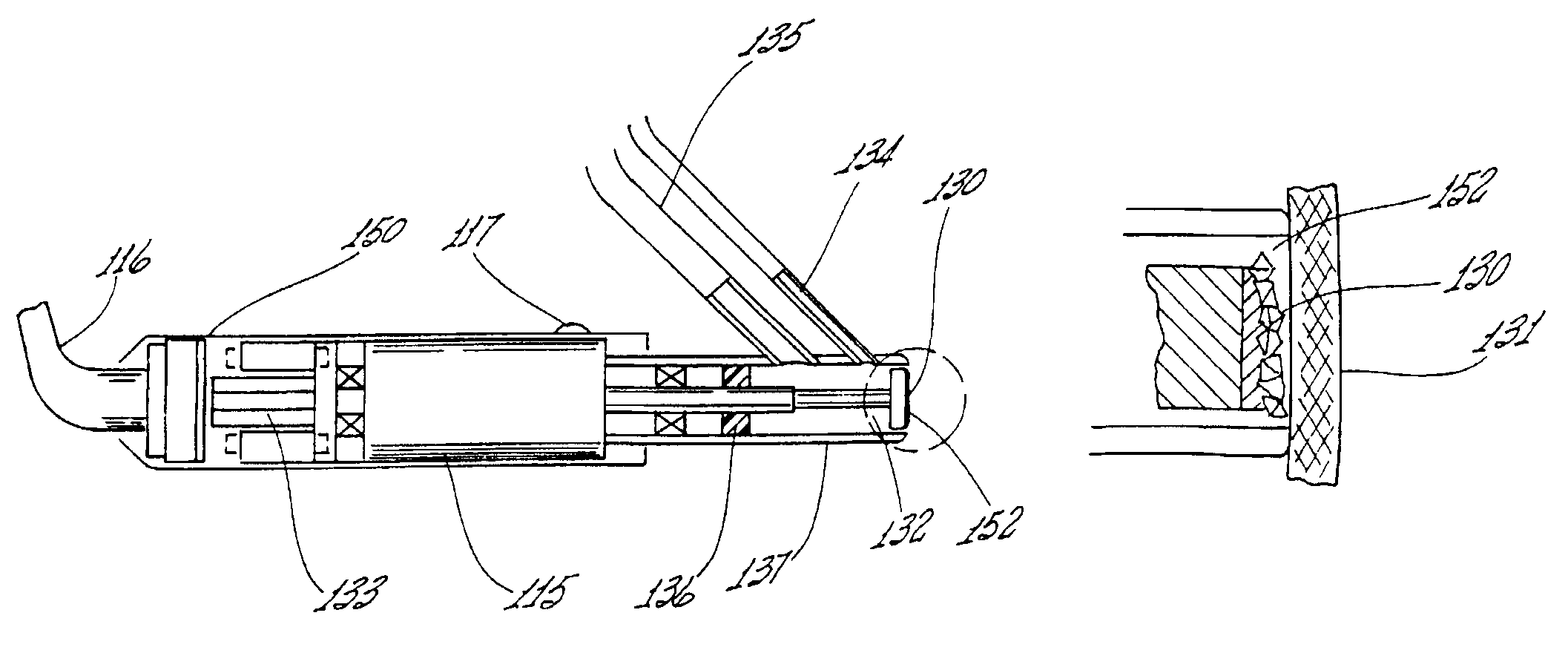

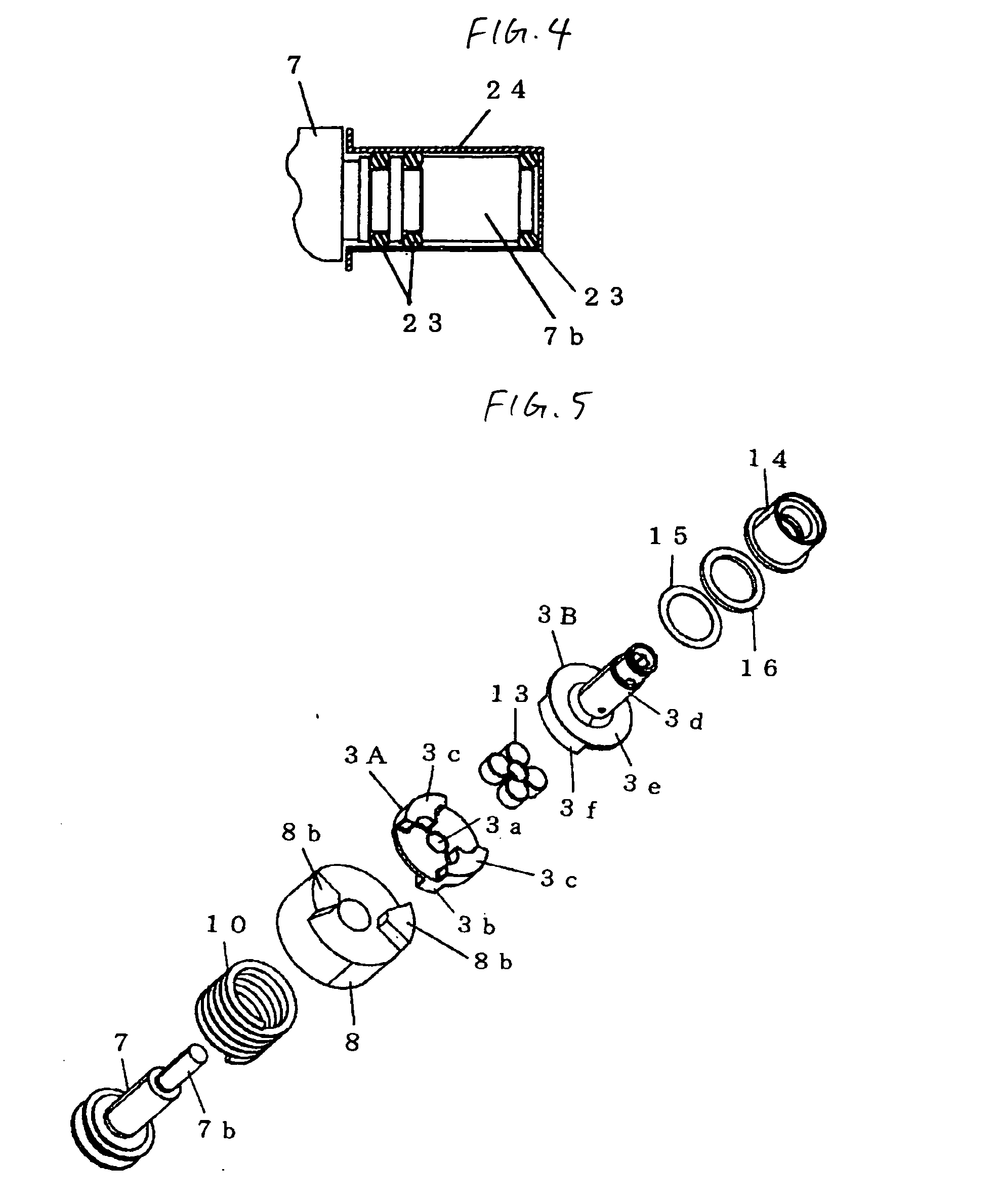

Manipulator for medical use

ActiveUS20080183193A1Easily confirm rotational angleEasy to confirmDiagnosticsSurgical manipulatorsWork unitManipulator

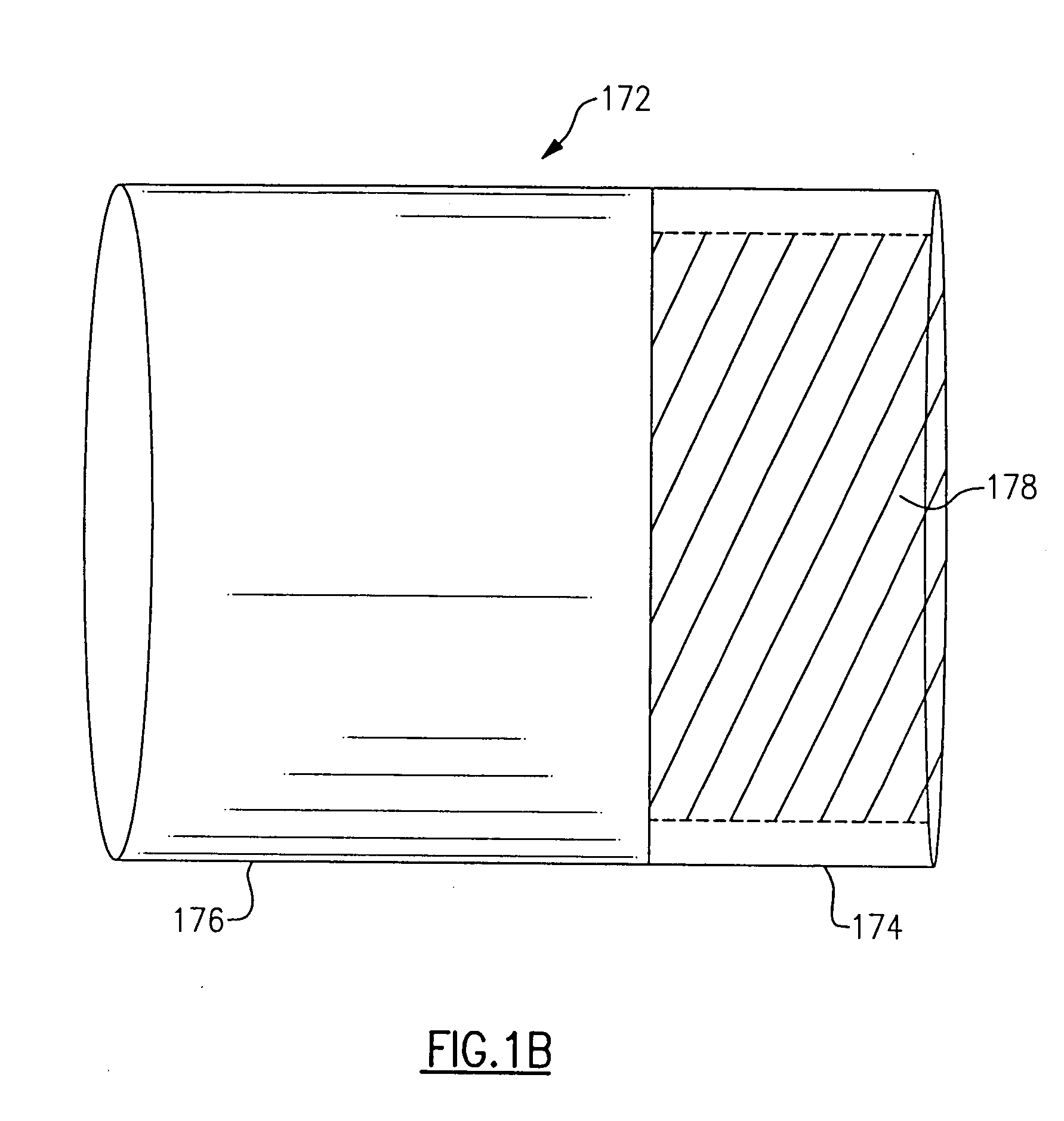

A manipulator comprises a hollow shaft, wires provided on the shaft and a working unit disposed on one end of the shaft and being driven by at least one wire of the wires, the working unit having a tip tool including a rolling mechanism which rotates about an axis Or directed to a distal end thereof. A tip side surface of a proximal end member and a cover of a distal end member are relatively rotated by the rolling mechanism. The cover has a rotation identifier for indicating a degree of relative rotation of the tip side surface. The tip side surface has an alignment indicator for indicating an initial position of the cover.

Owner:KARL STORZ GMBH & CO KG

Manipulator for medical use

ActiveUS10245058B2Easily confirm rotational angleEasy to confirmDiagnosticsSurgical manipulatorsWork unitEngineering

Owner:KARL STORZ GMBH & CO KG

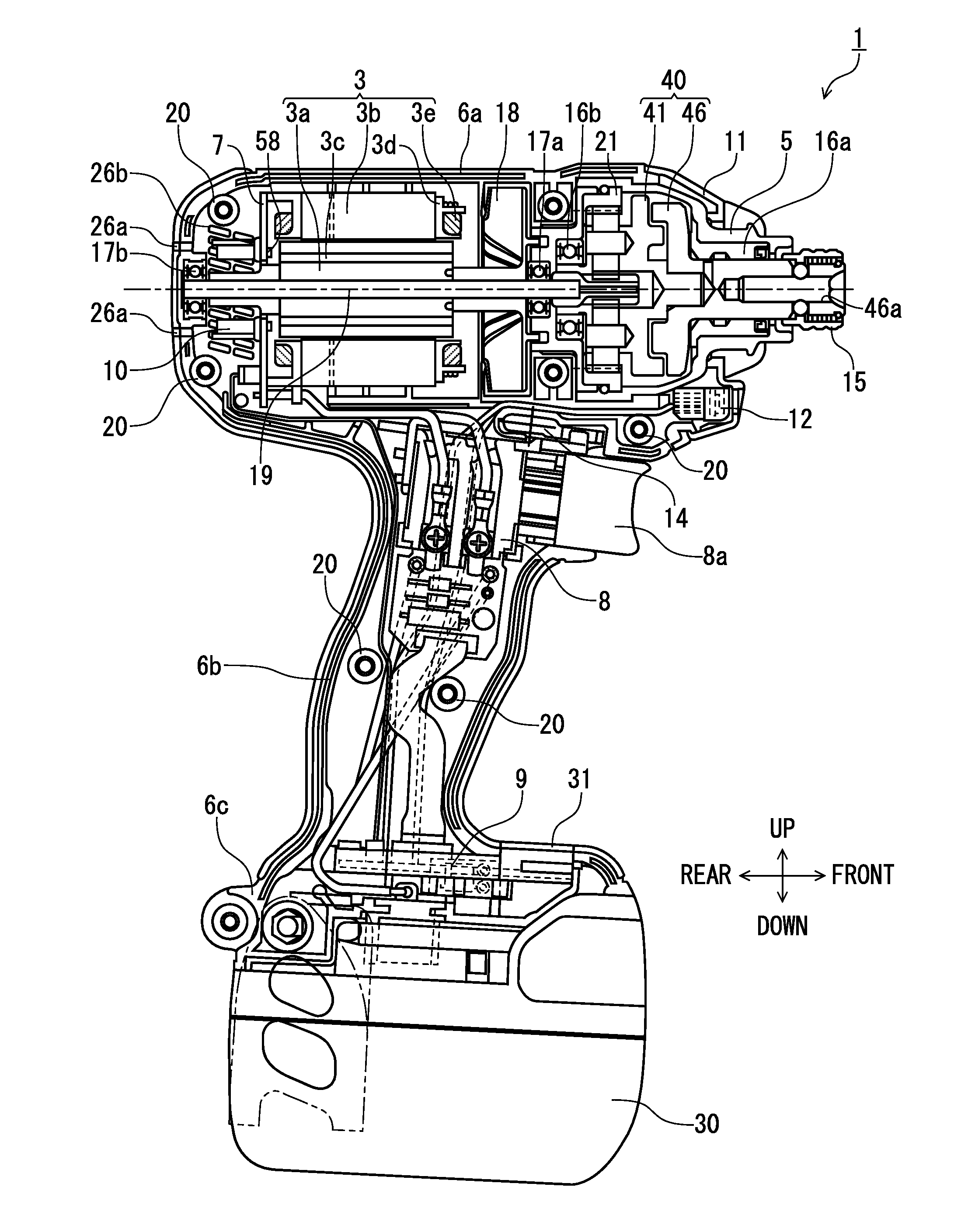

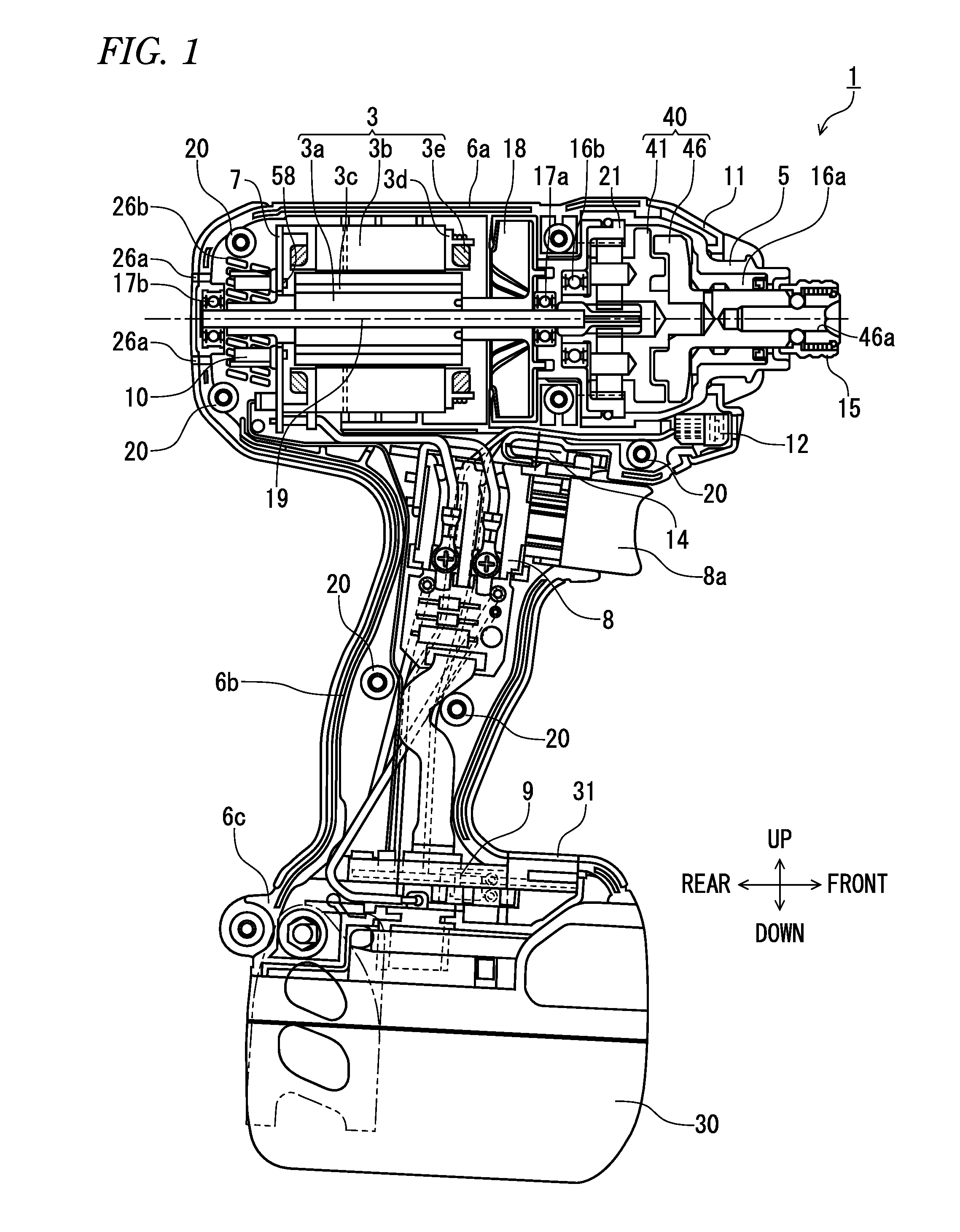

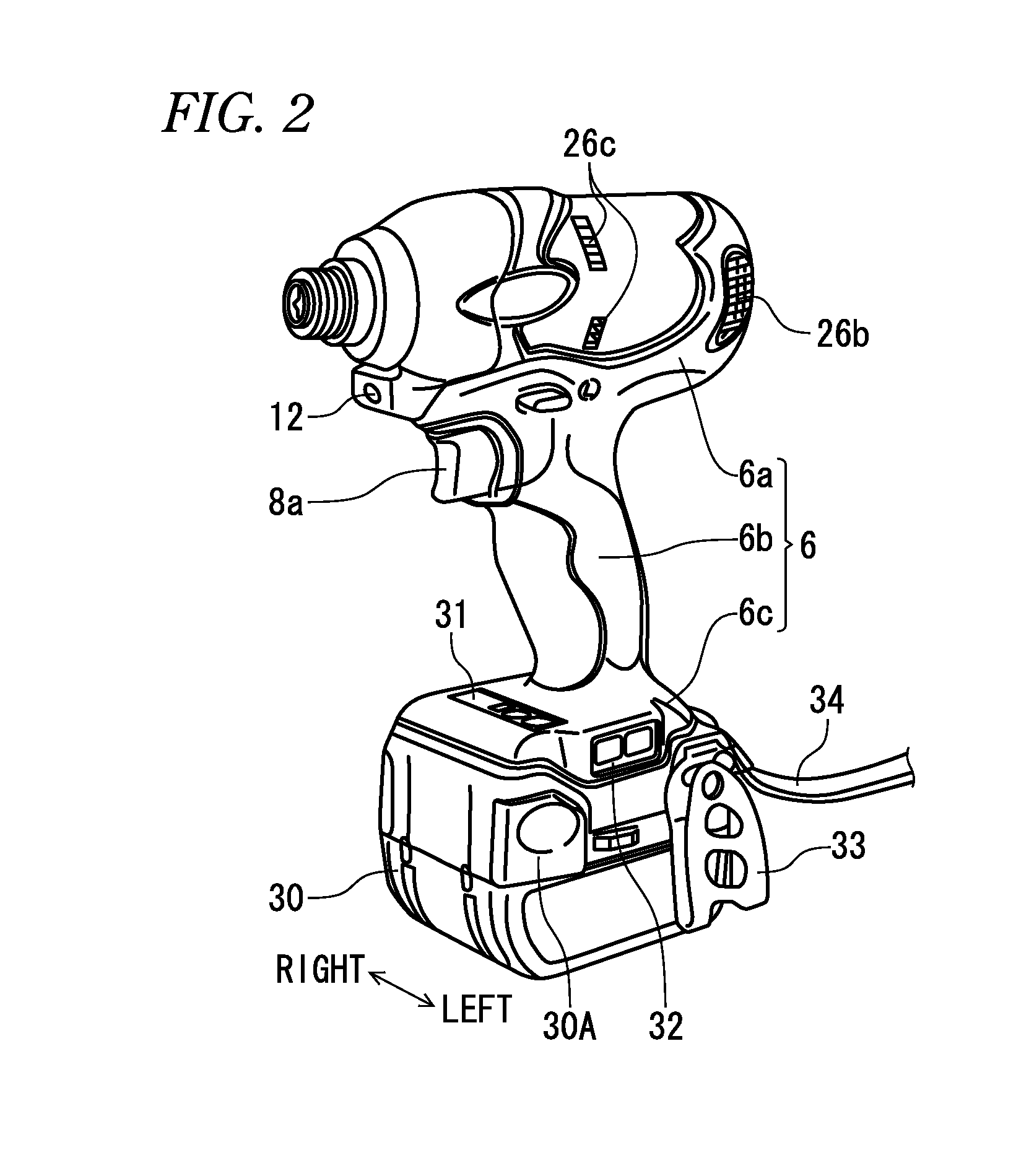

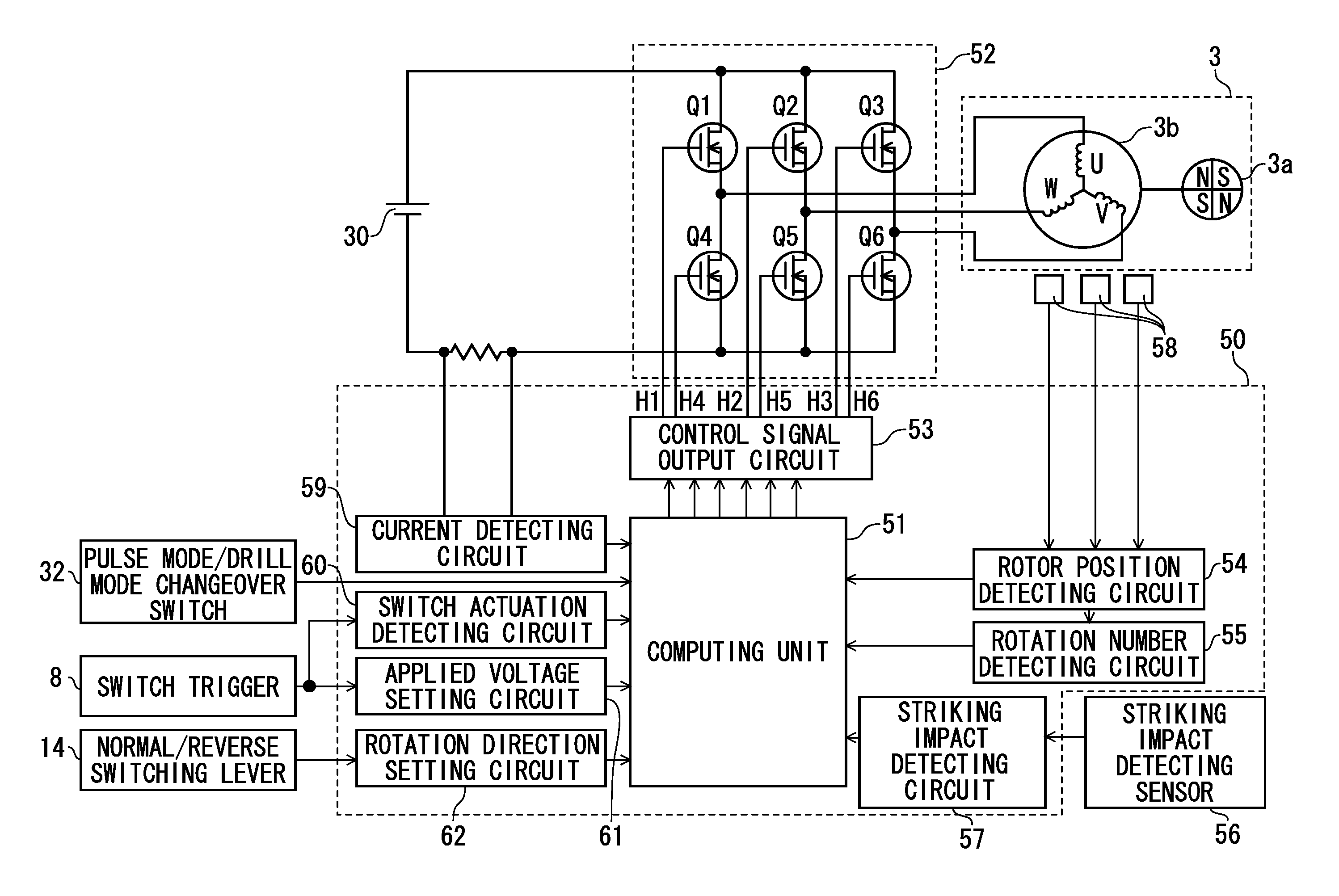

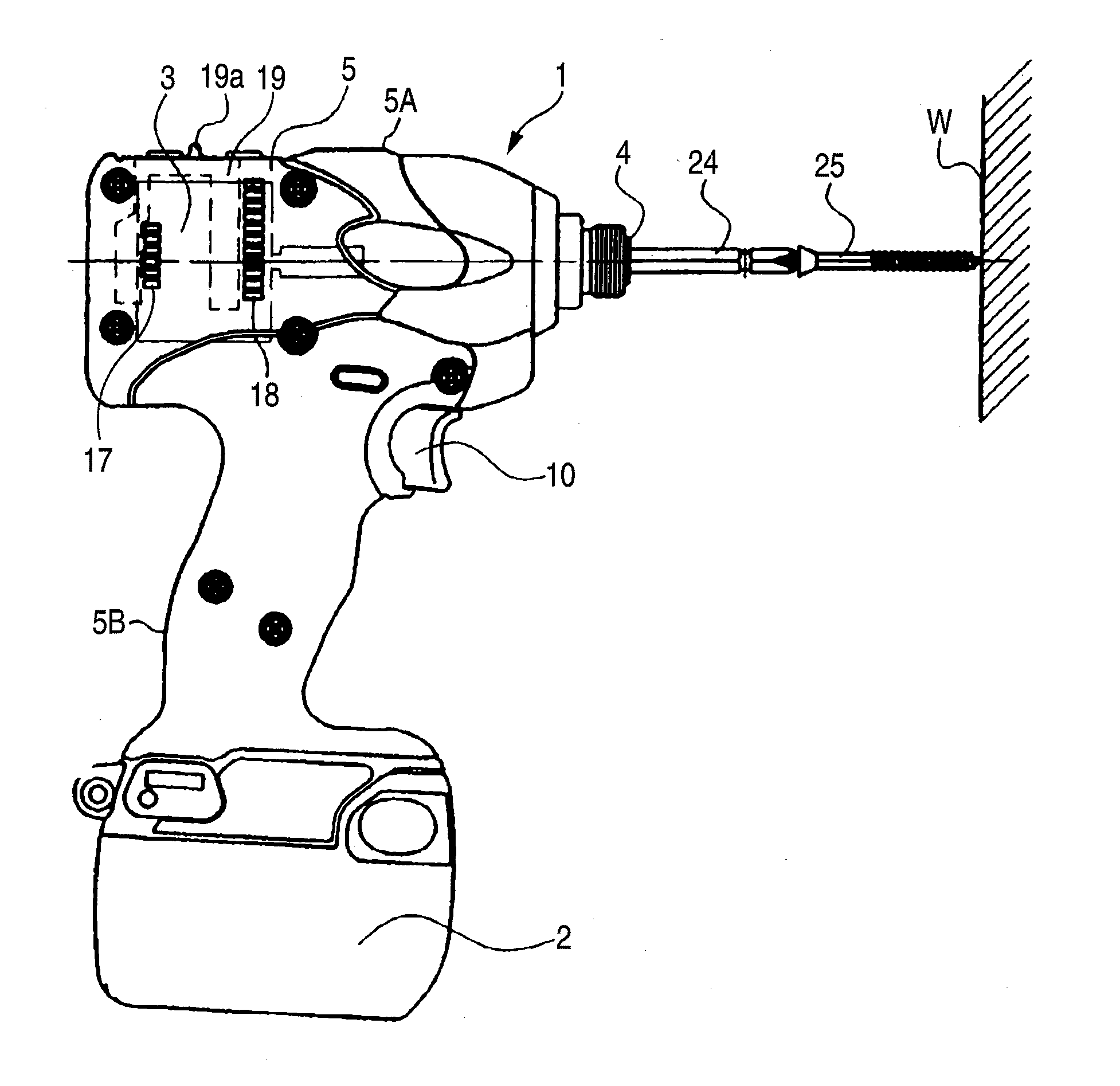

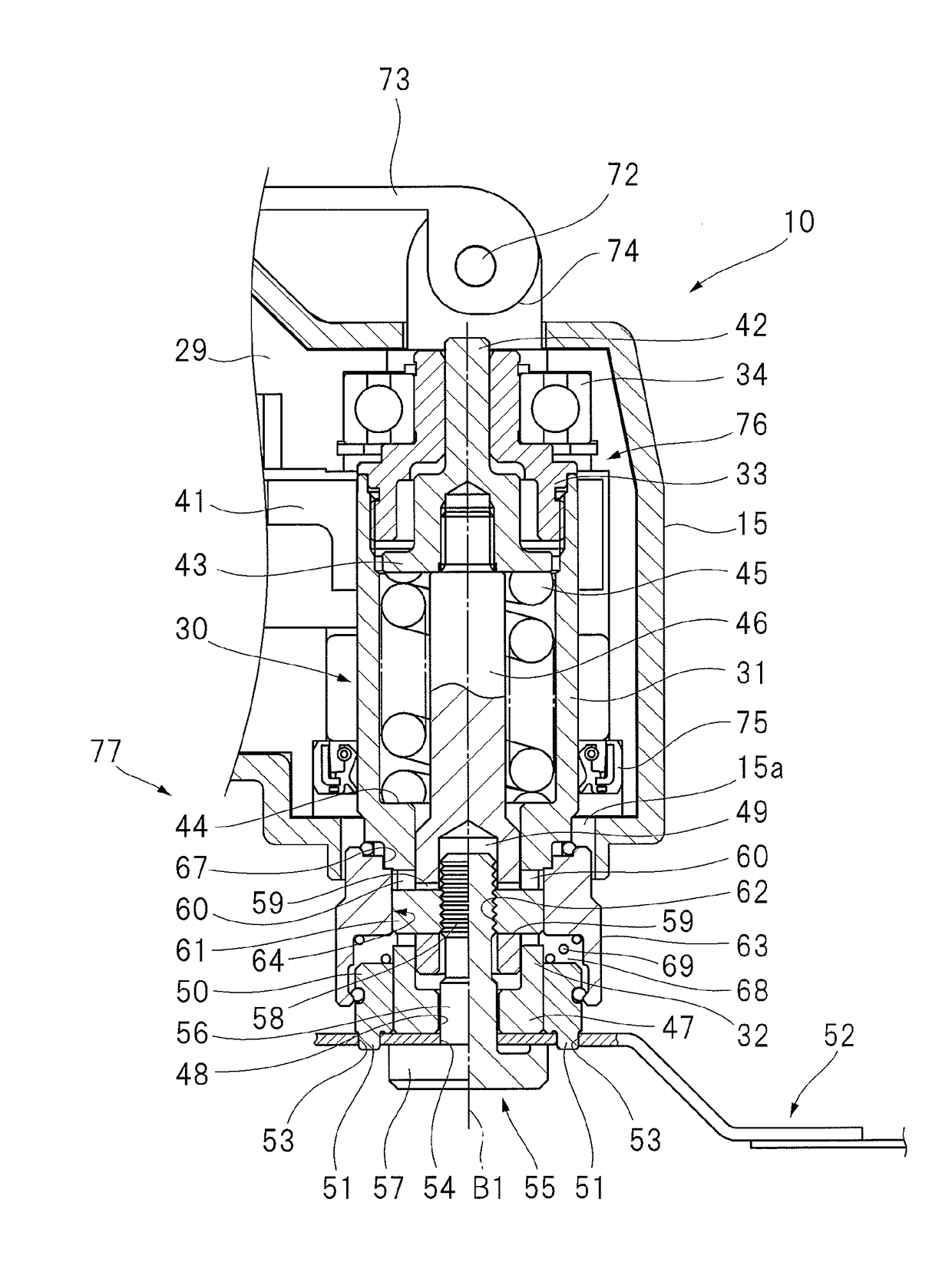

Impact tool and method of controlling impact tool

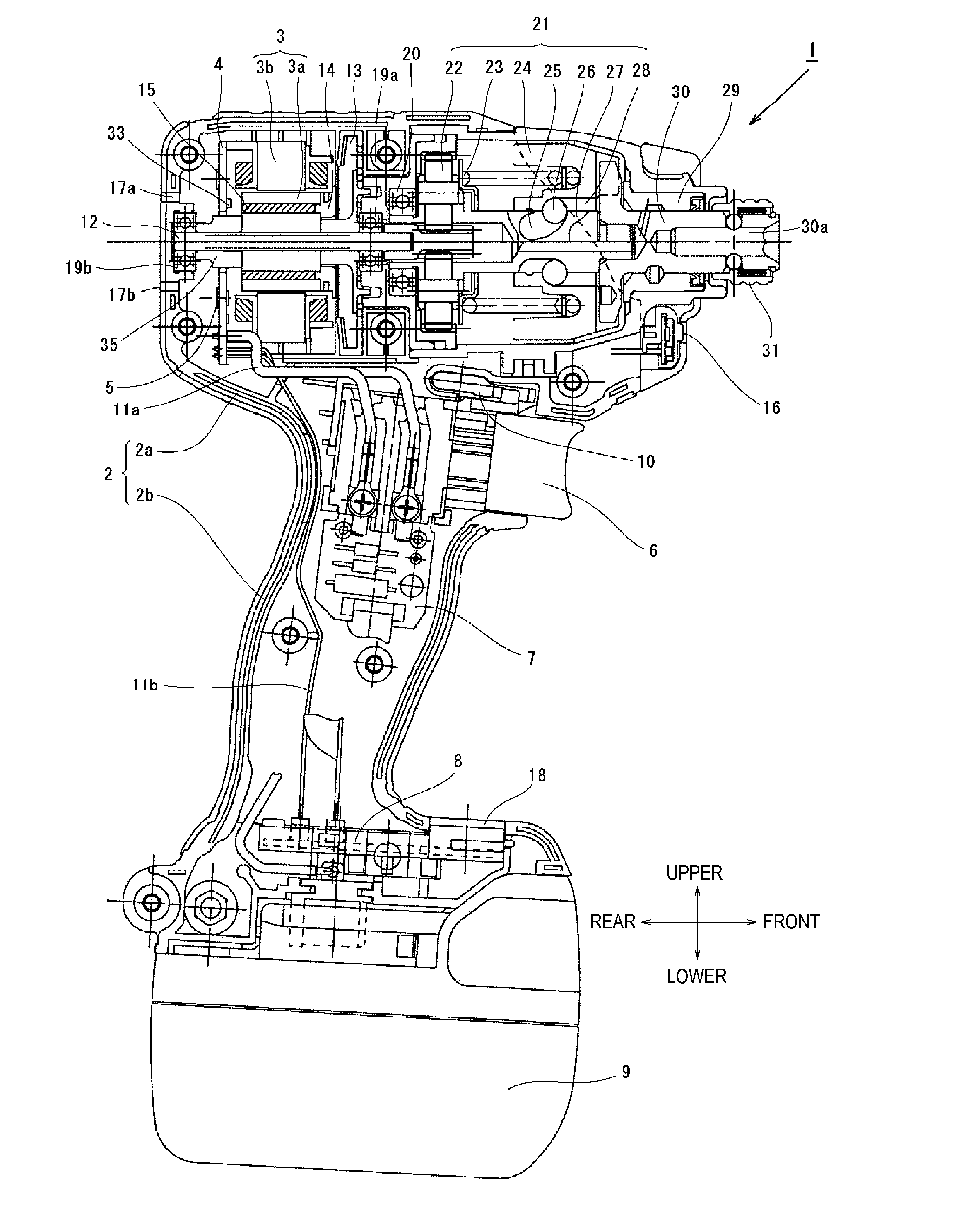

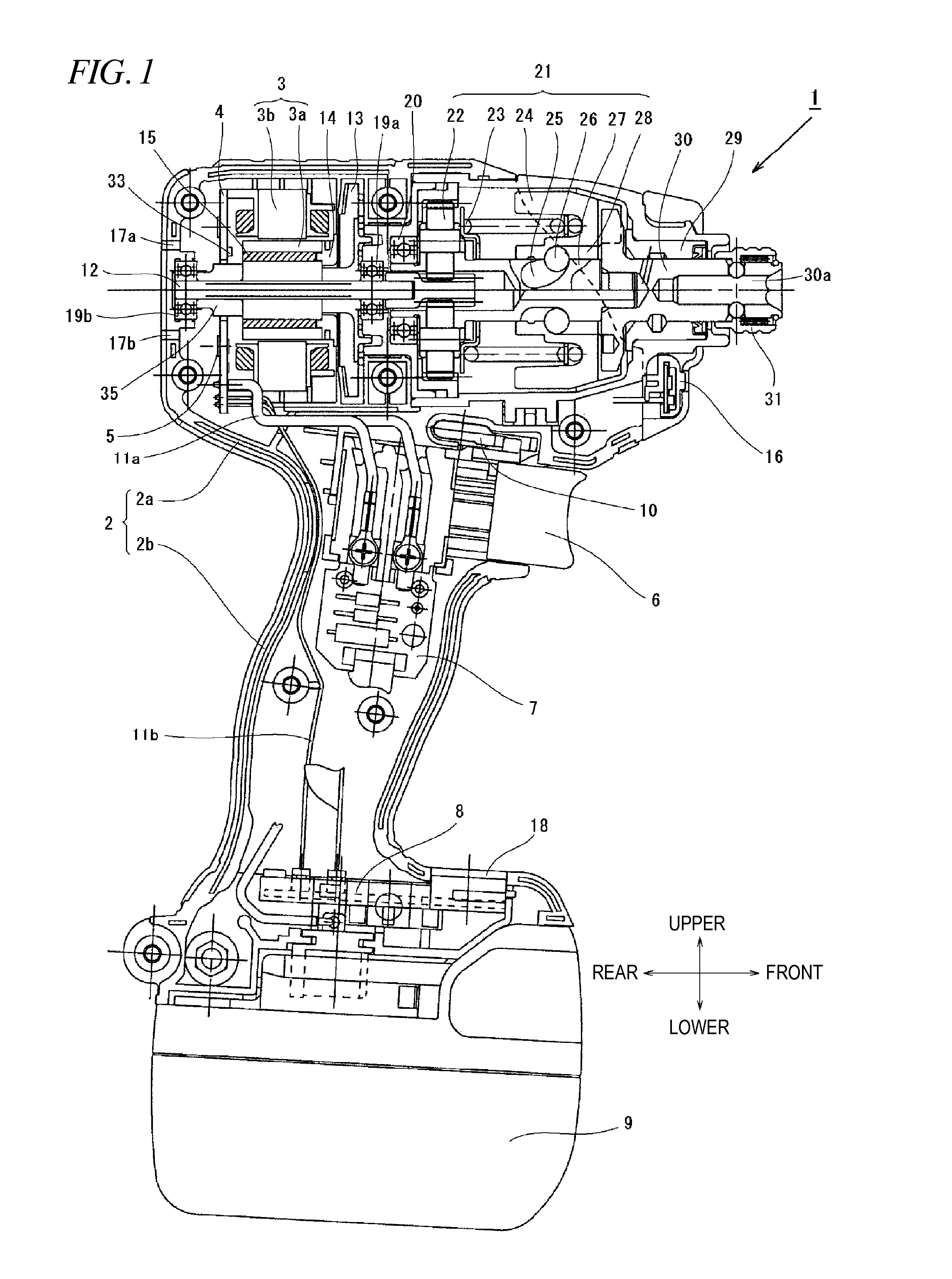

An impact tool includes: a motor; a trigger; a controller configured to control driving power supplied to the motor using a semiconductor switching element according to an operation of the trigger; a striking mechanism configured to drive a tip tool continuously or intermittently by rotation force of the motor, the striking mechanism including a hammer and an anvil. The controller drives the semiconductor switching element at a high duty ratio when the trigger is manipulated. The motor is driven so that the duty ratio is lowered before a first striking of the hammer on the anvil is performed and the first striking is performed at a low duty ratio lower than the high duty ratio.

Owner:KOKI HLDG CO LTD

Impact tool

ActiveUS20120279736A1Shorten the timeIncrease production capacityReciprocating drilling machinesConstructionsEngineeringDriving mode

According to an aspect of the present invention, there is provided an impact tool including: a motor drivable in an intermittent driving mode; a hammer connected to the motor; an anvil to be struck by the hammer to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor by switching a driving pulse supplied to the motor in accordance with a load applied onto the tip tool.

Owner:HITACHI KOKI CO LTD

Tip tool

InactiveUS20050050707A1Easy to operateManipulation is accurateSurgeryEndoscopesImaging equipmentBiomedical engineering

Owner:GE INSPECTION TECH LP

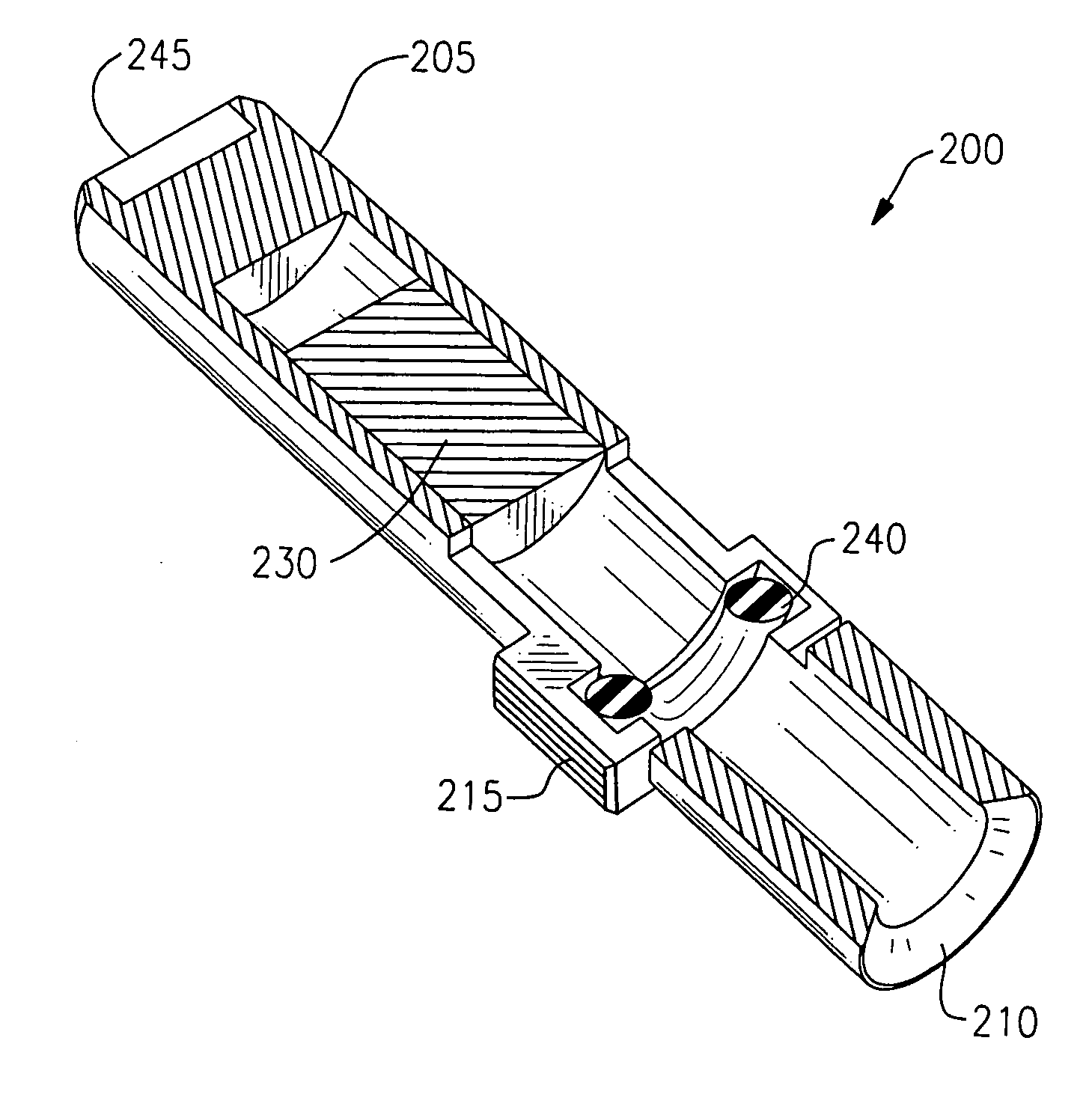

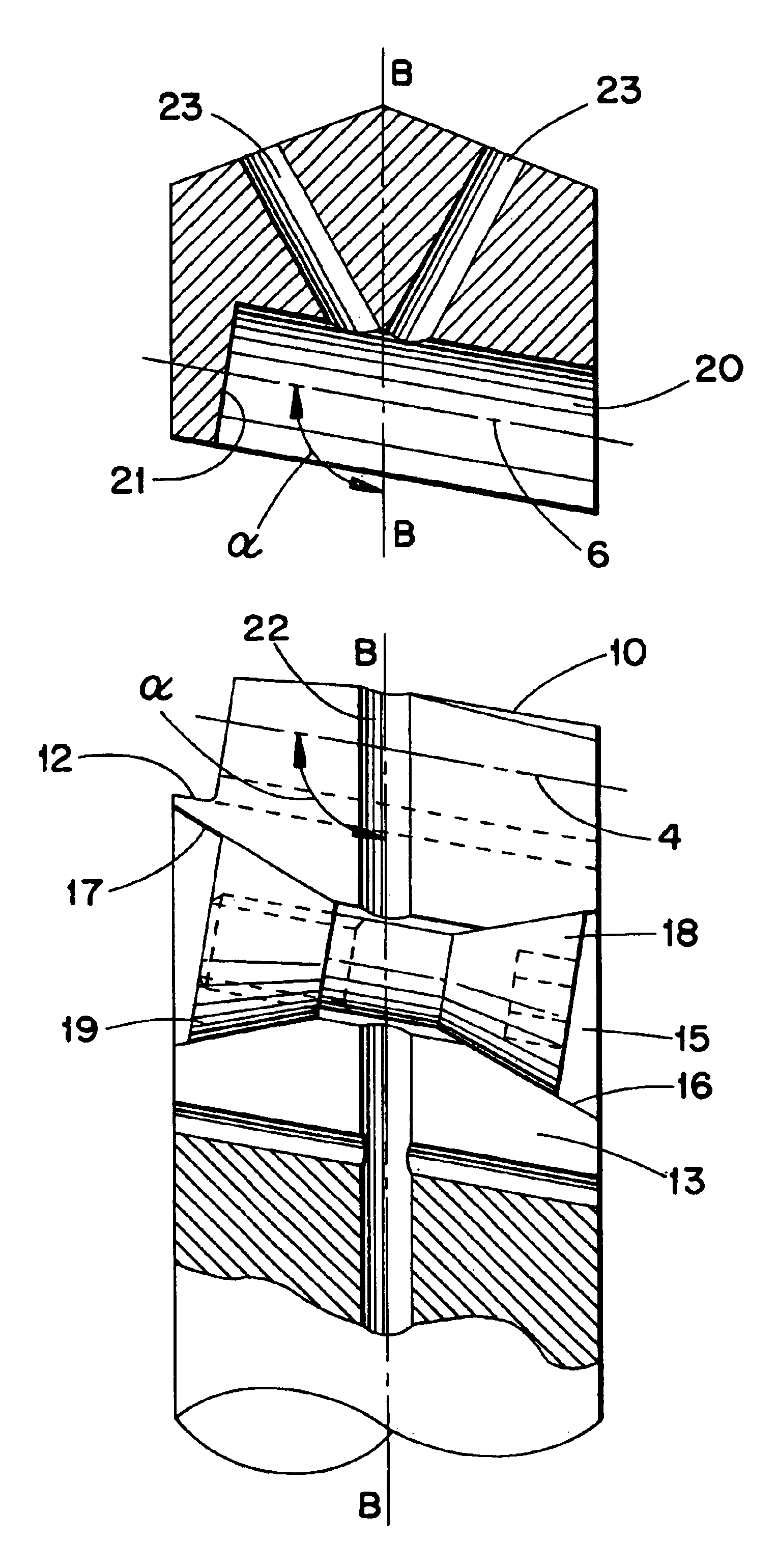

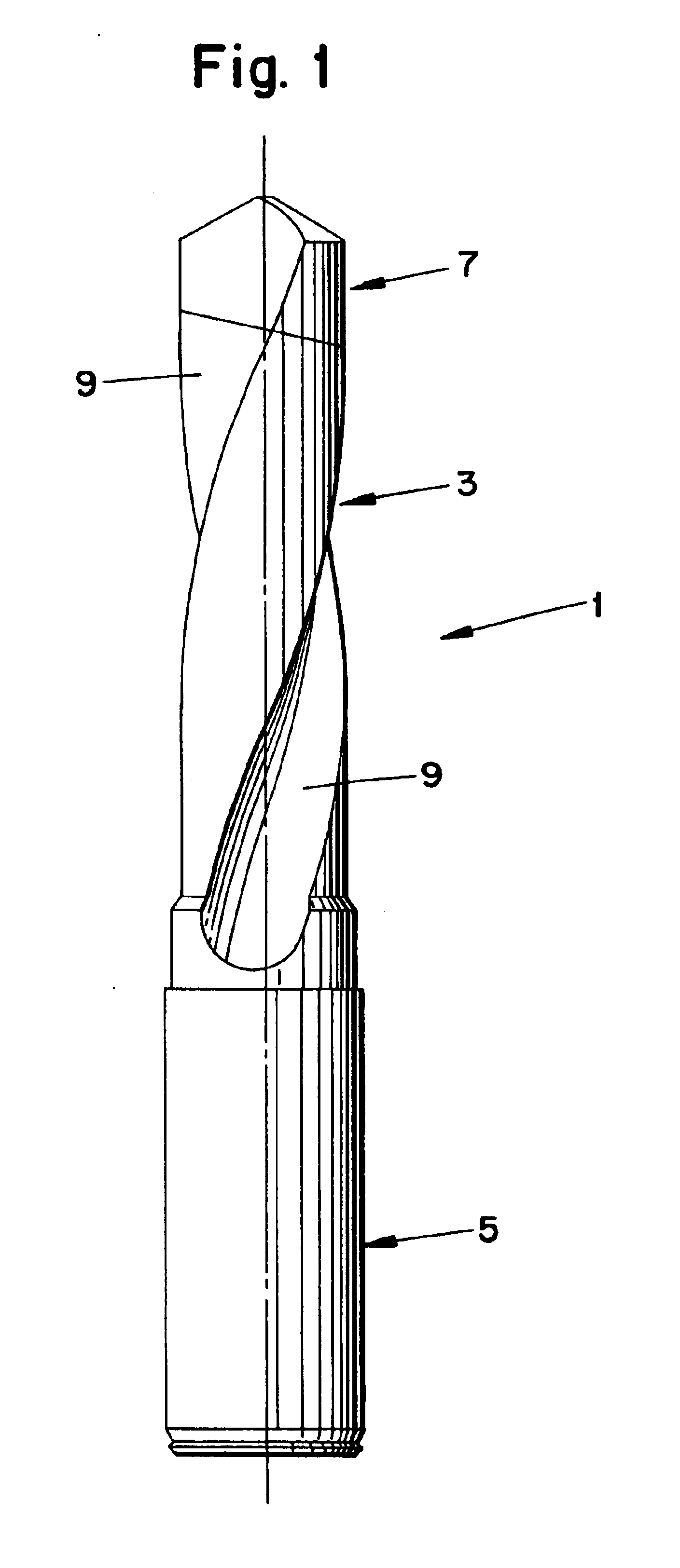

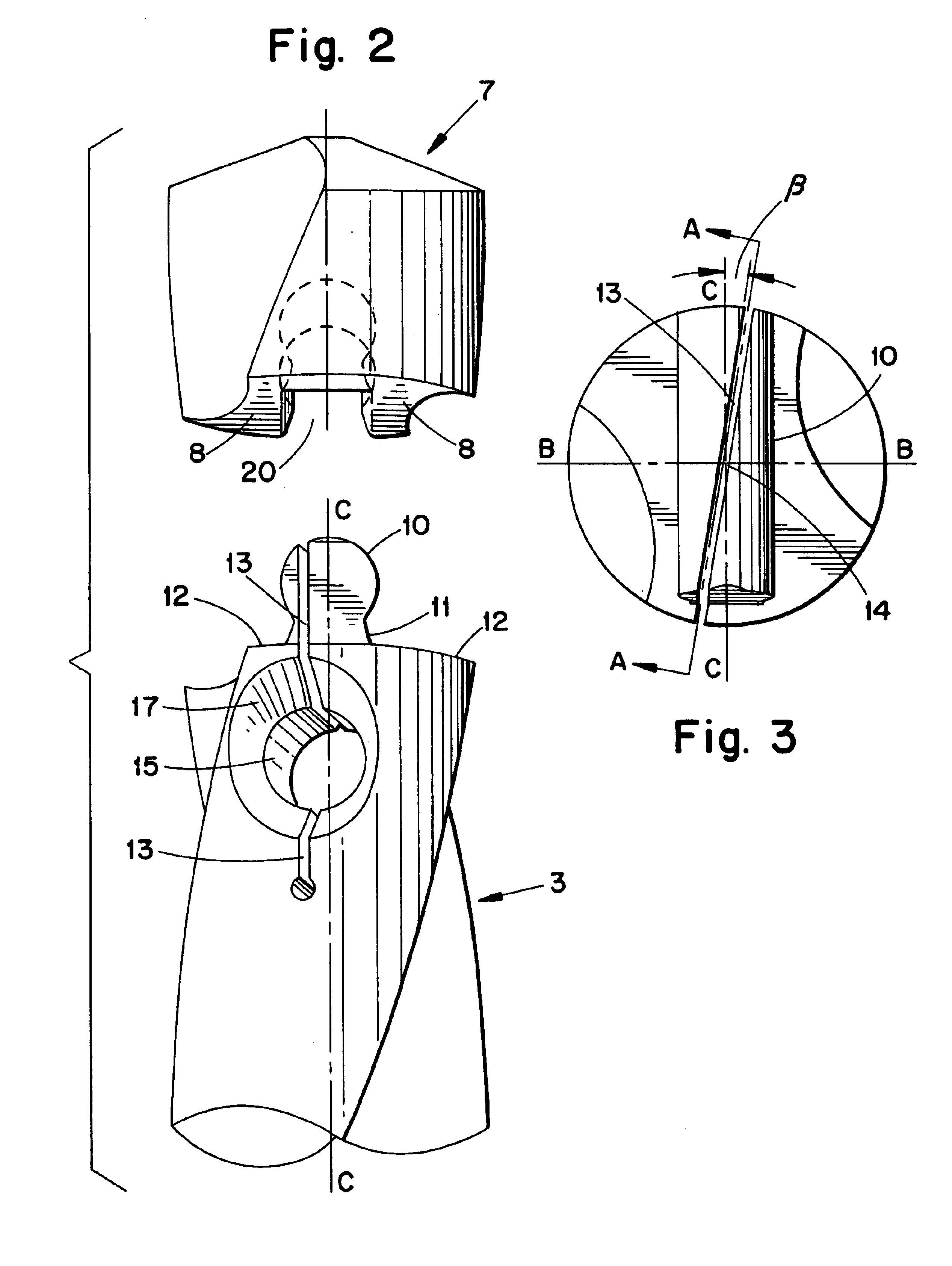

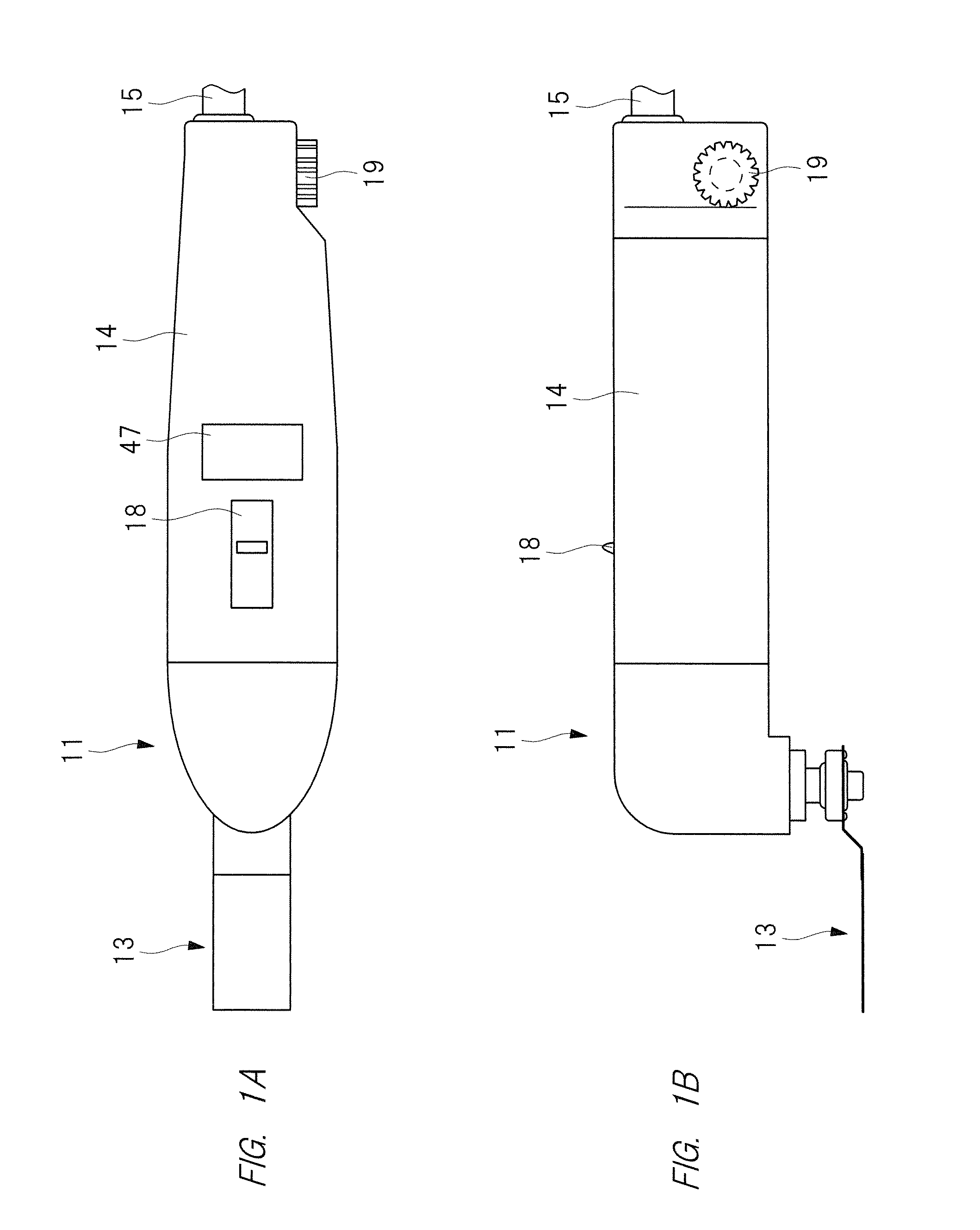

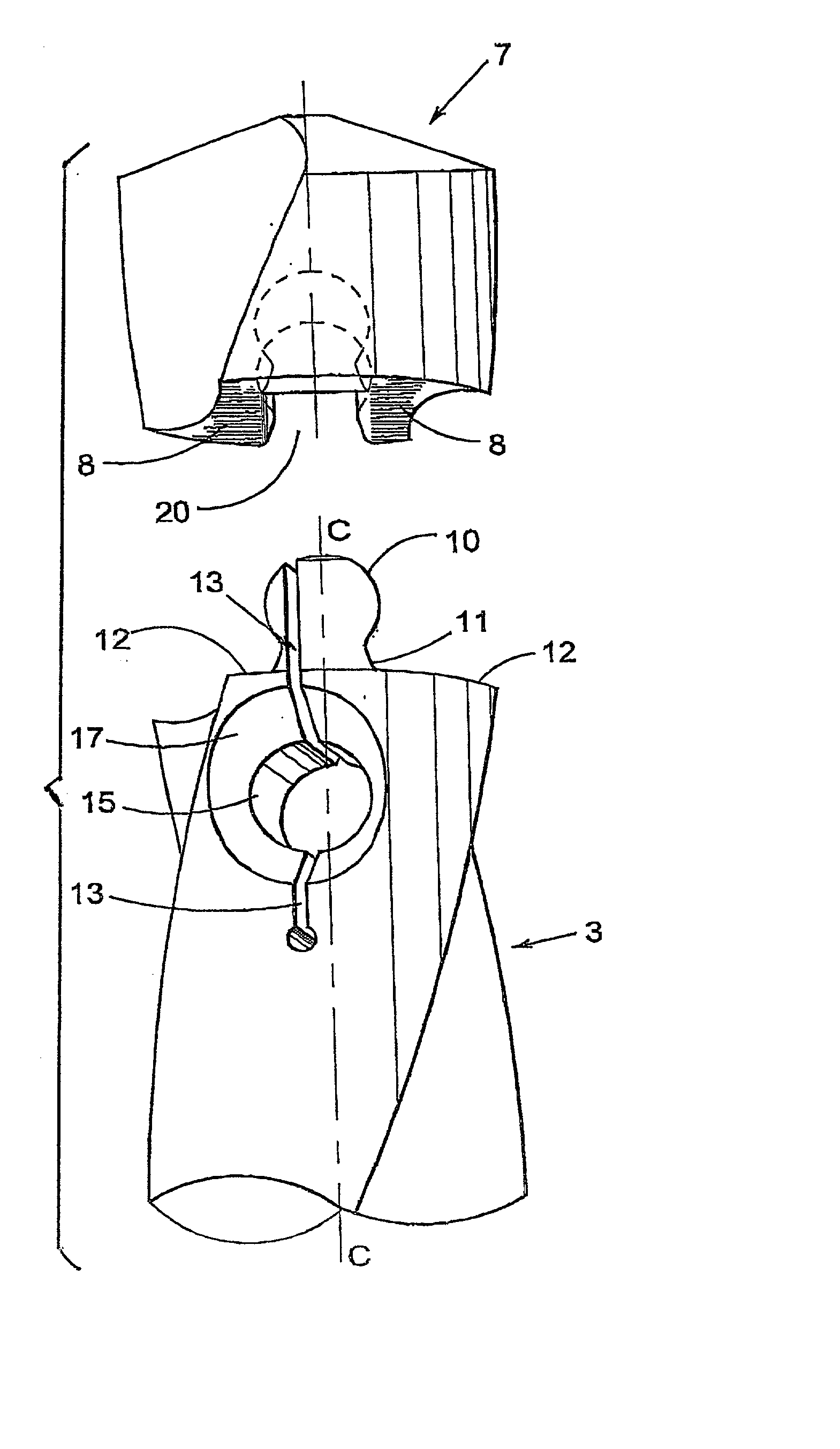

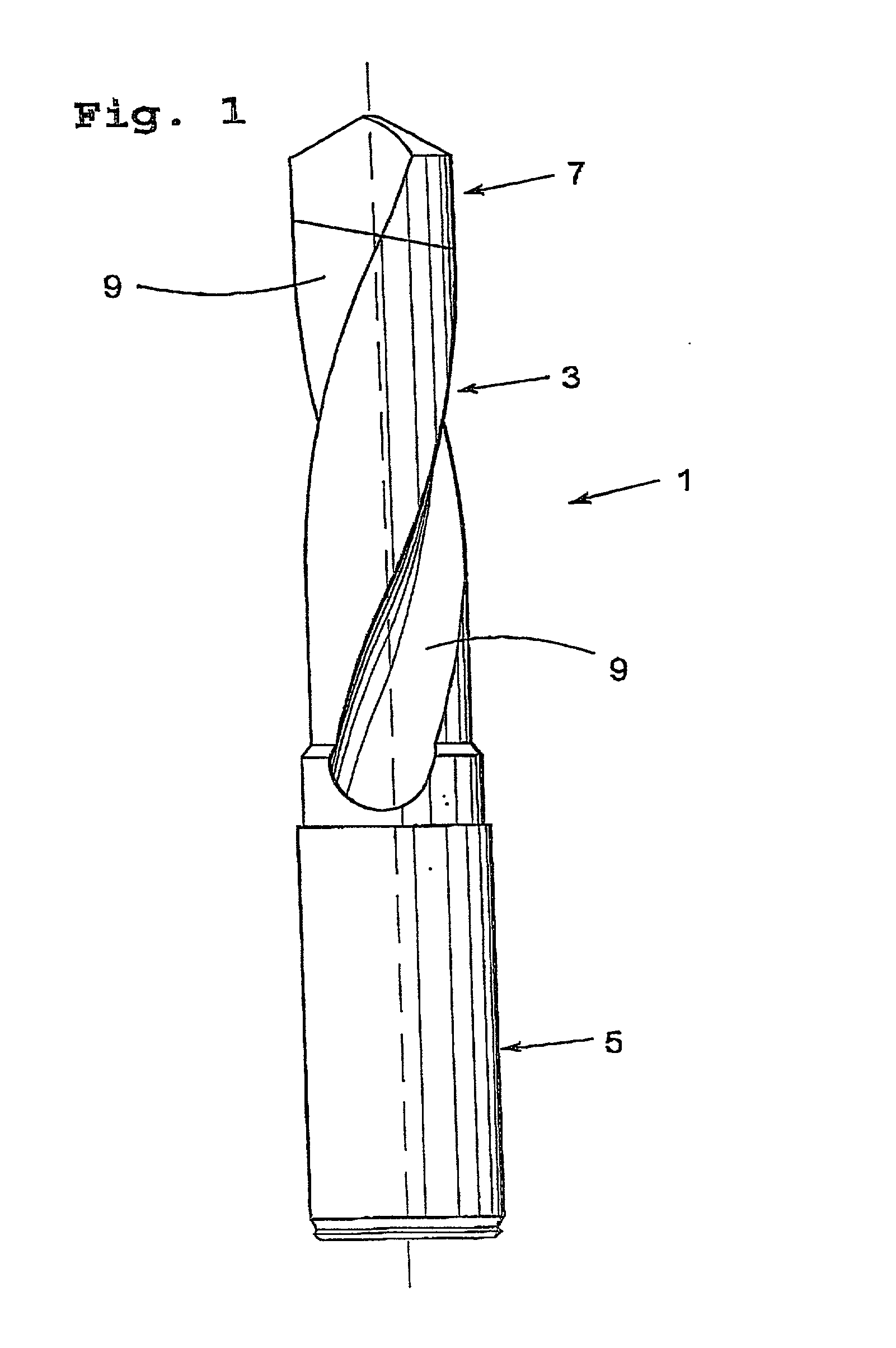

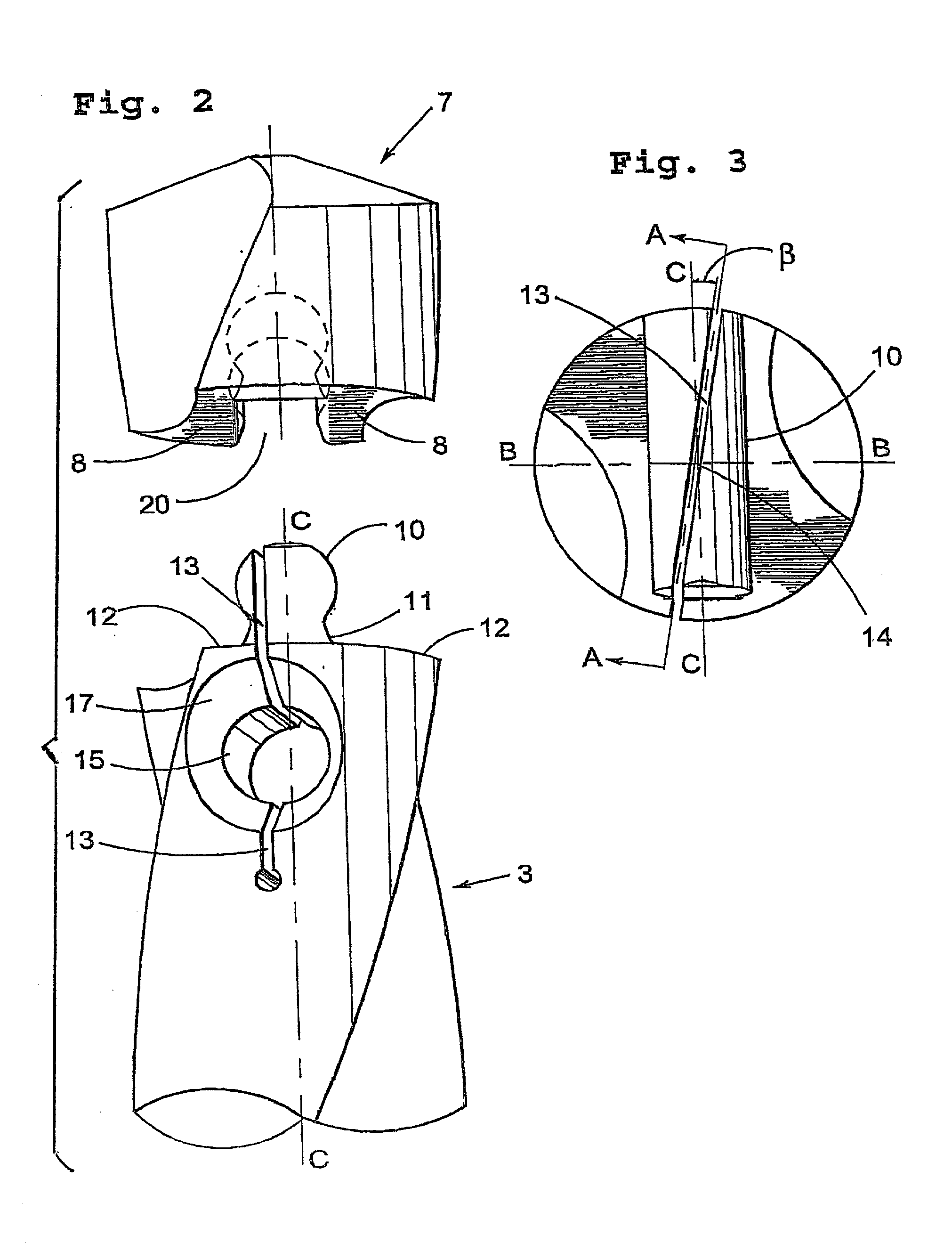

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

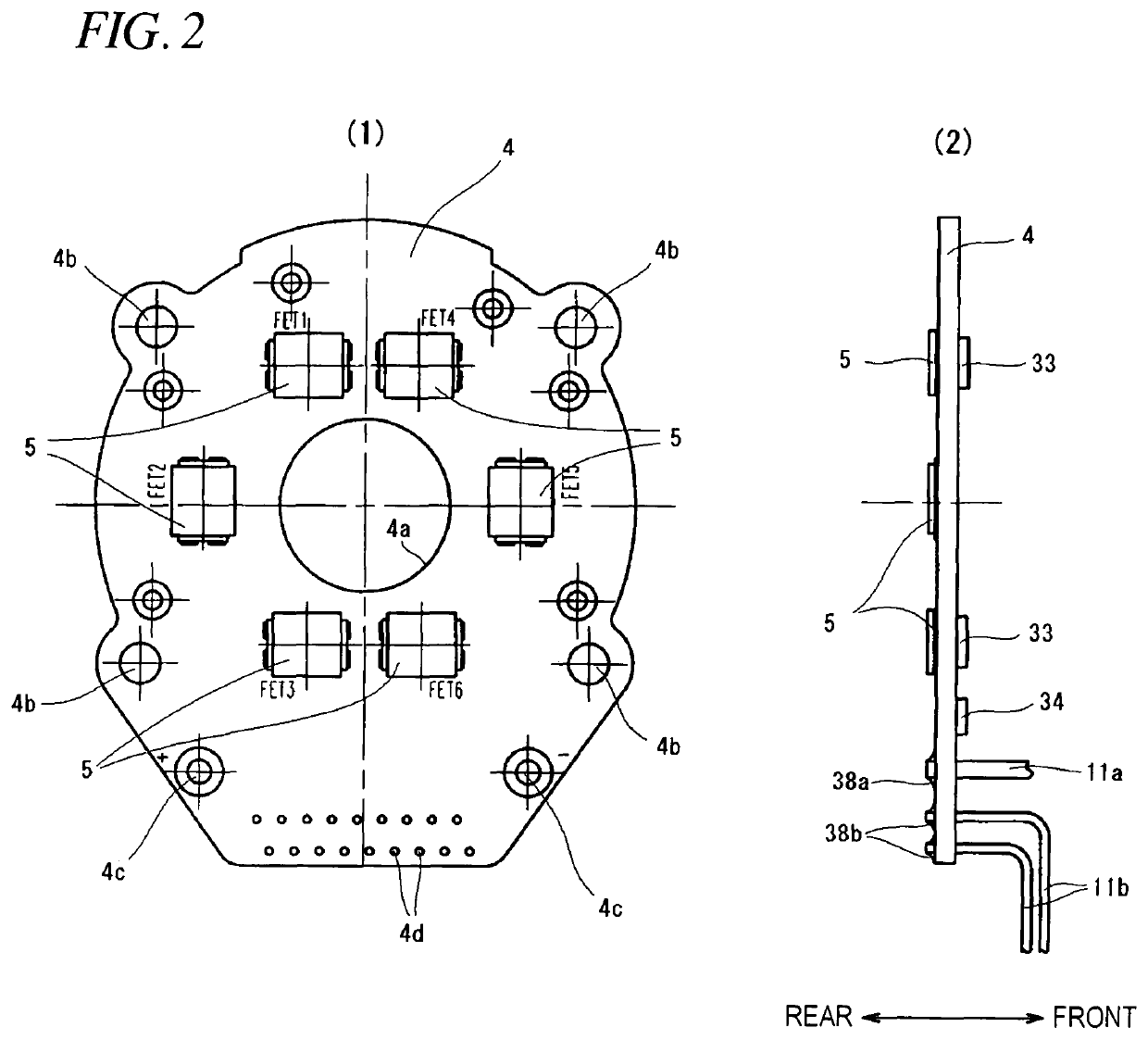

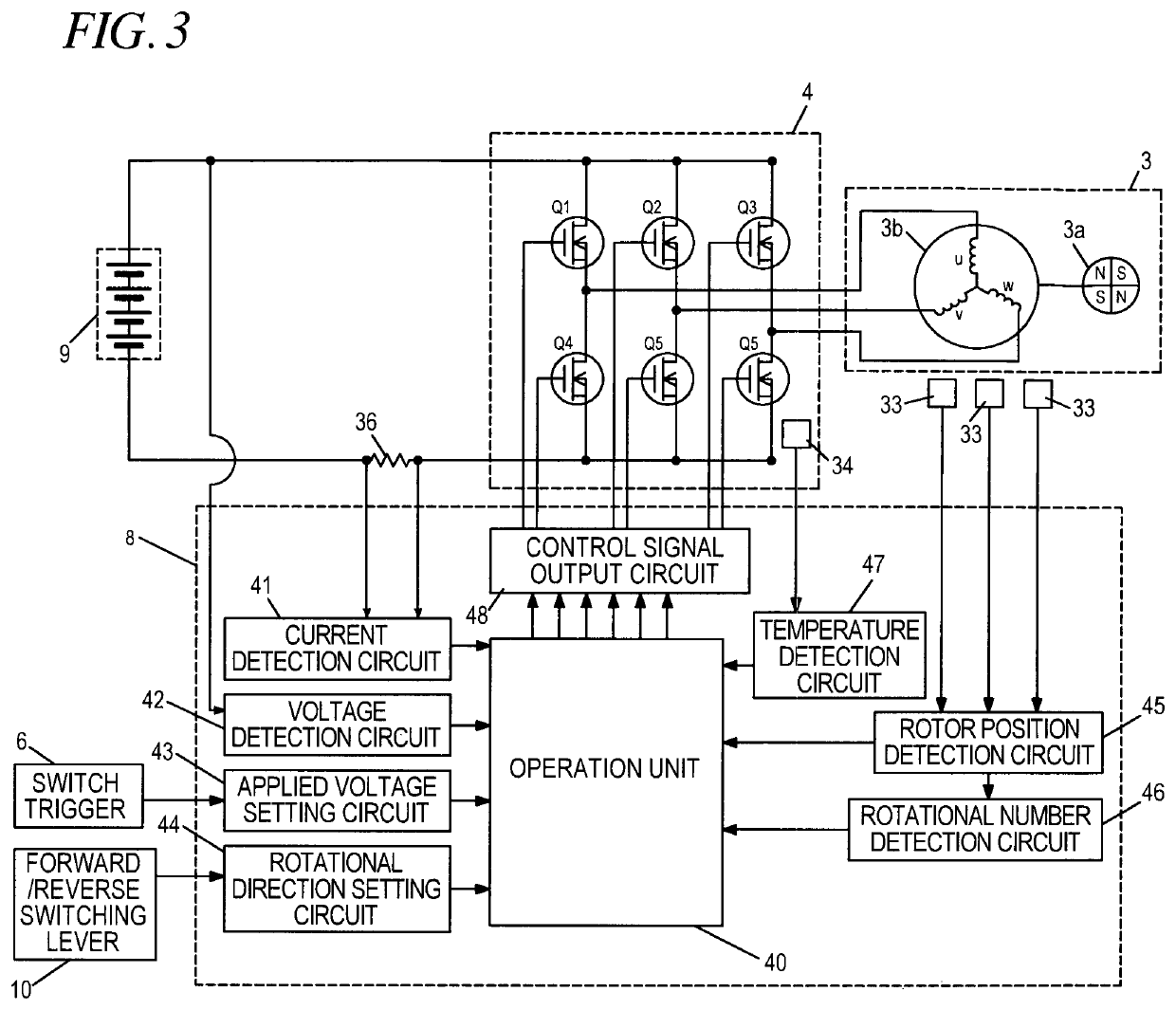

Electric tool

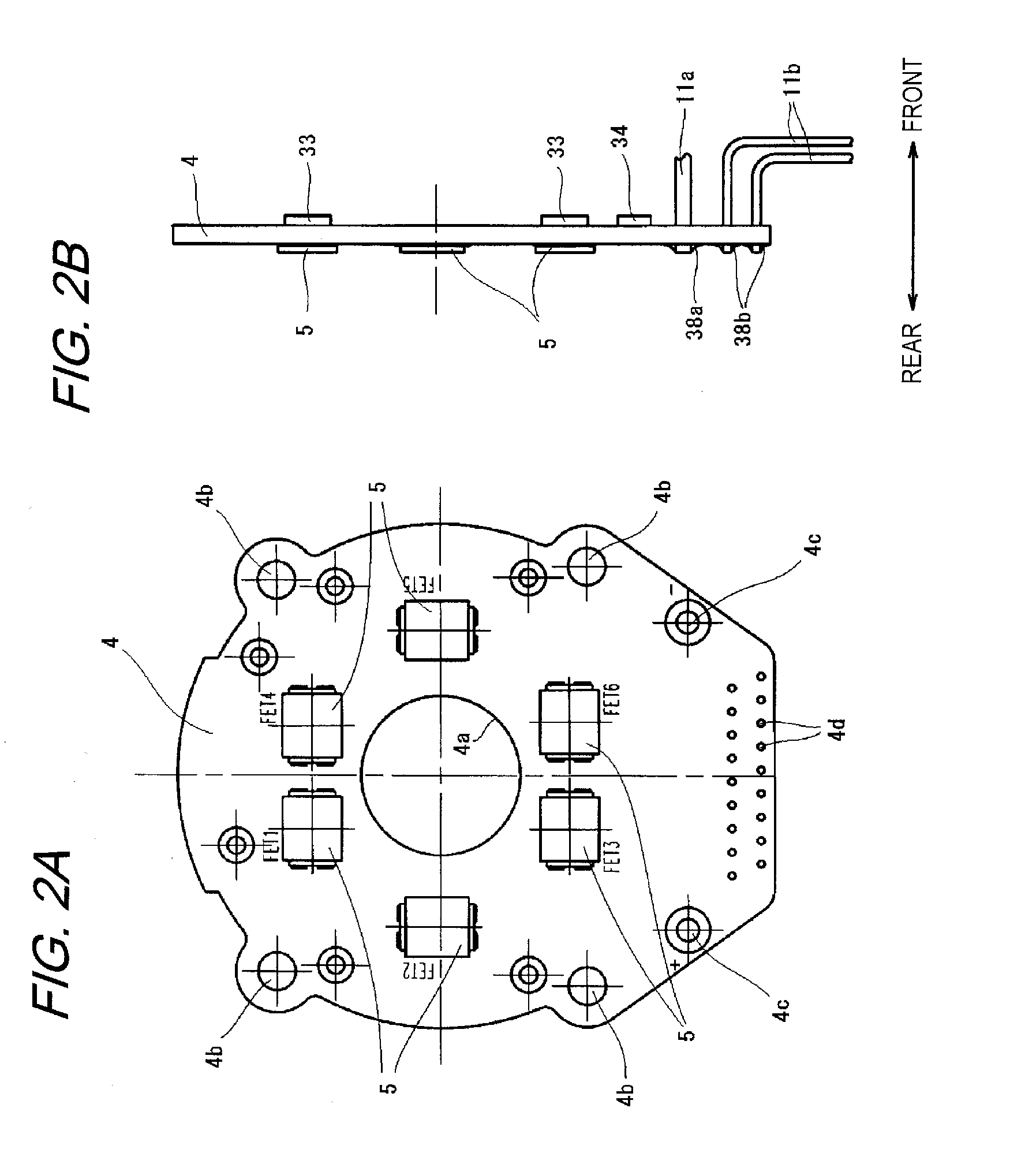

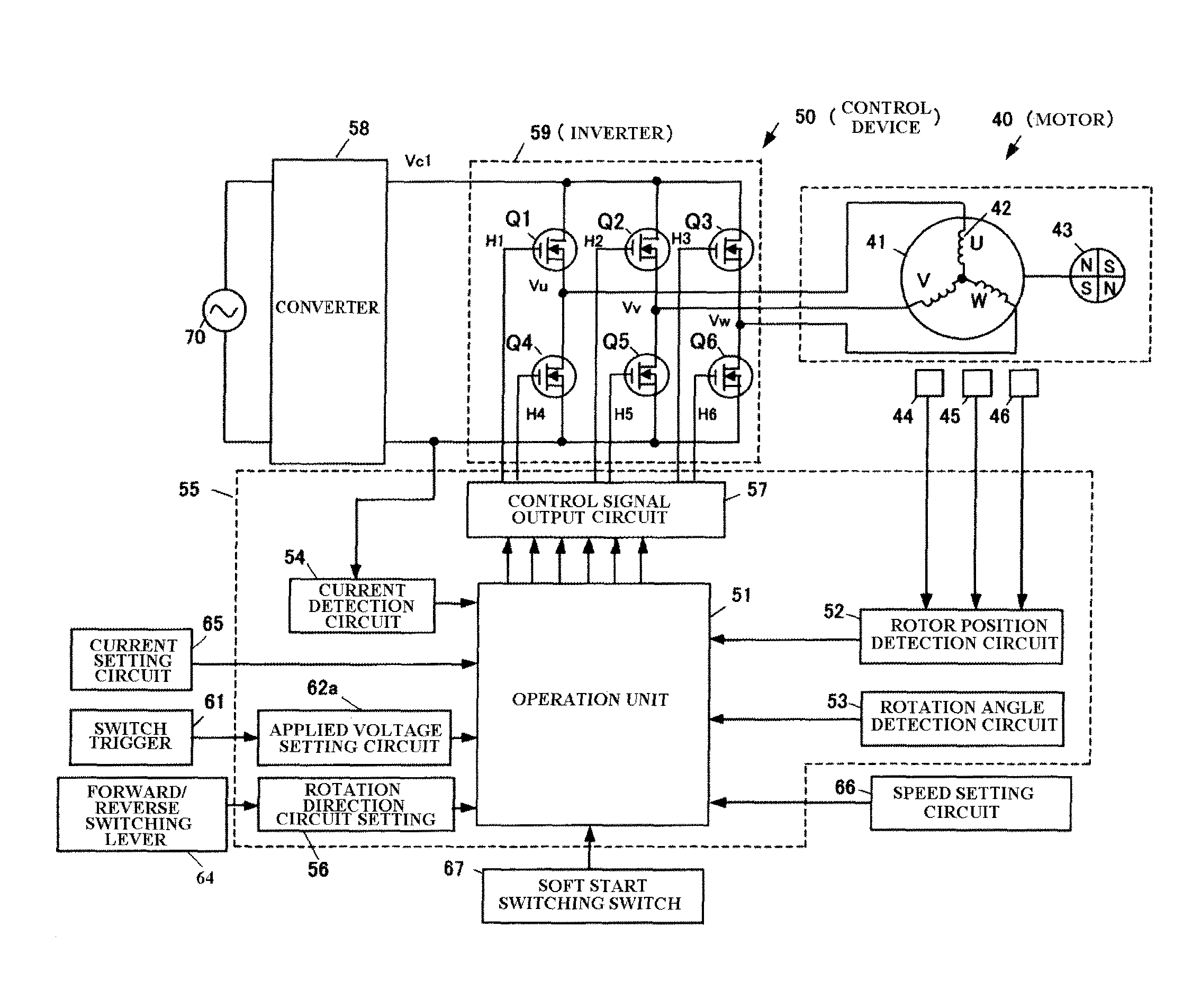

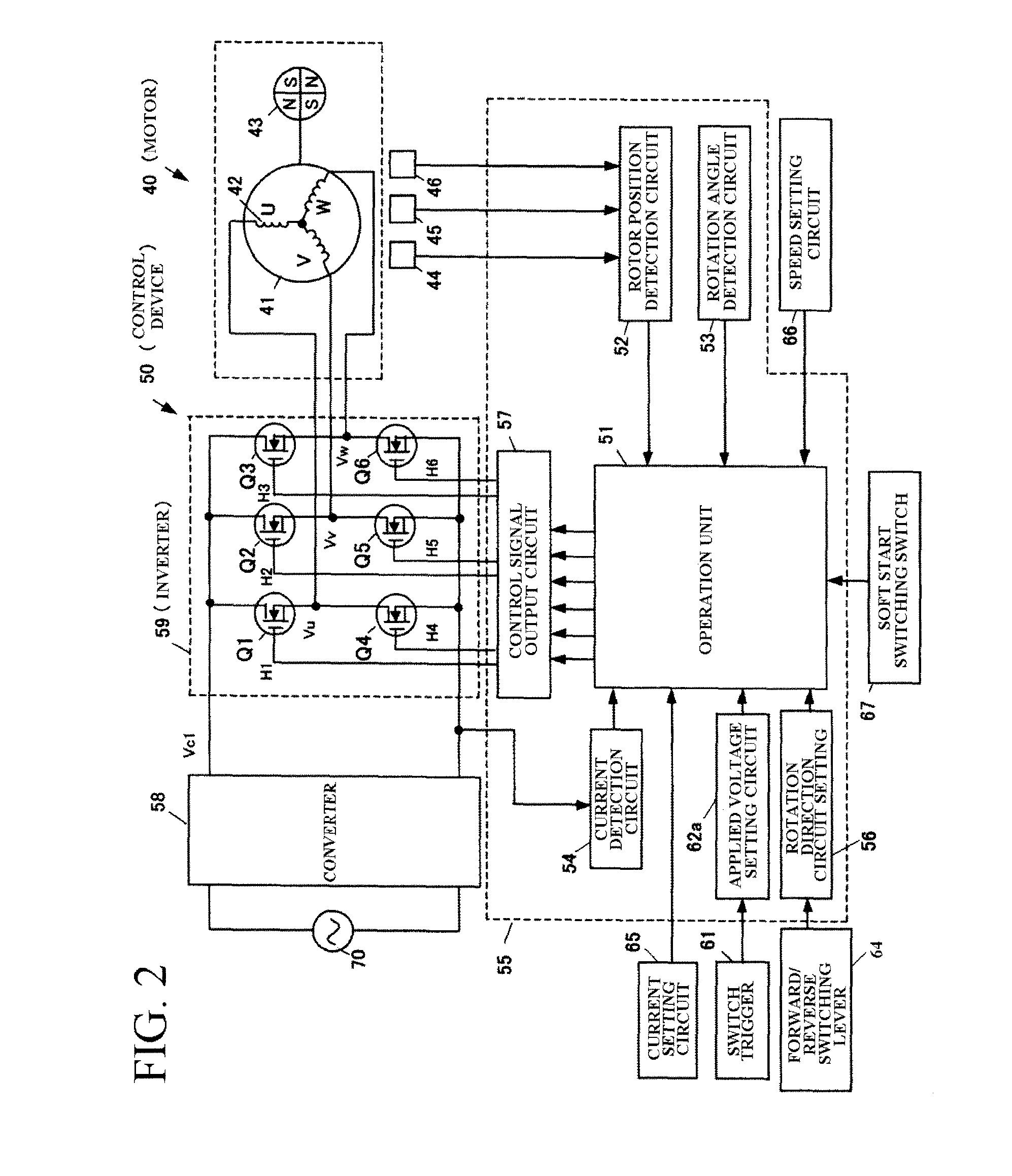

InactiveUS20150022125A1Change in duty ratioAvoid it happening againAC motor controlElectric motor controlPower inverterBrushless motors

An electric tool for driving a tip tool, the electric tool includes: a removable battery; the brushless motor configured to generate a driving force for driving the tip tool; an inverter circuit configured to supply drive power from the removable battery to the brushless motor using a plurality of semiconductor switching elements; a controller configured to control the inverter circuit to control rotation of the brushless motor; a temperature detector configured to detect a temperature of the brushless motor or the semiconductor switching elements; and a voltage detector configured to detect a voltage of the battery. The brushless motor is driven such that a duty ratio of PWM drive signal for driving the semiconductor switching elements is determined based on relationship between the temperature detected by the temperature detector and the voltage detected by the voltage detector.

Owner:HITACHI KOKI CO LTD

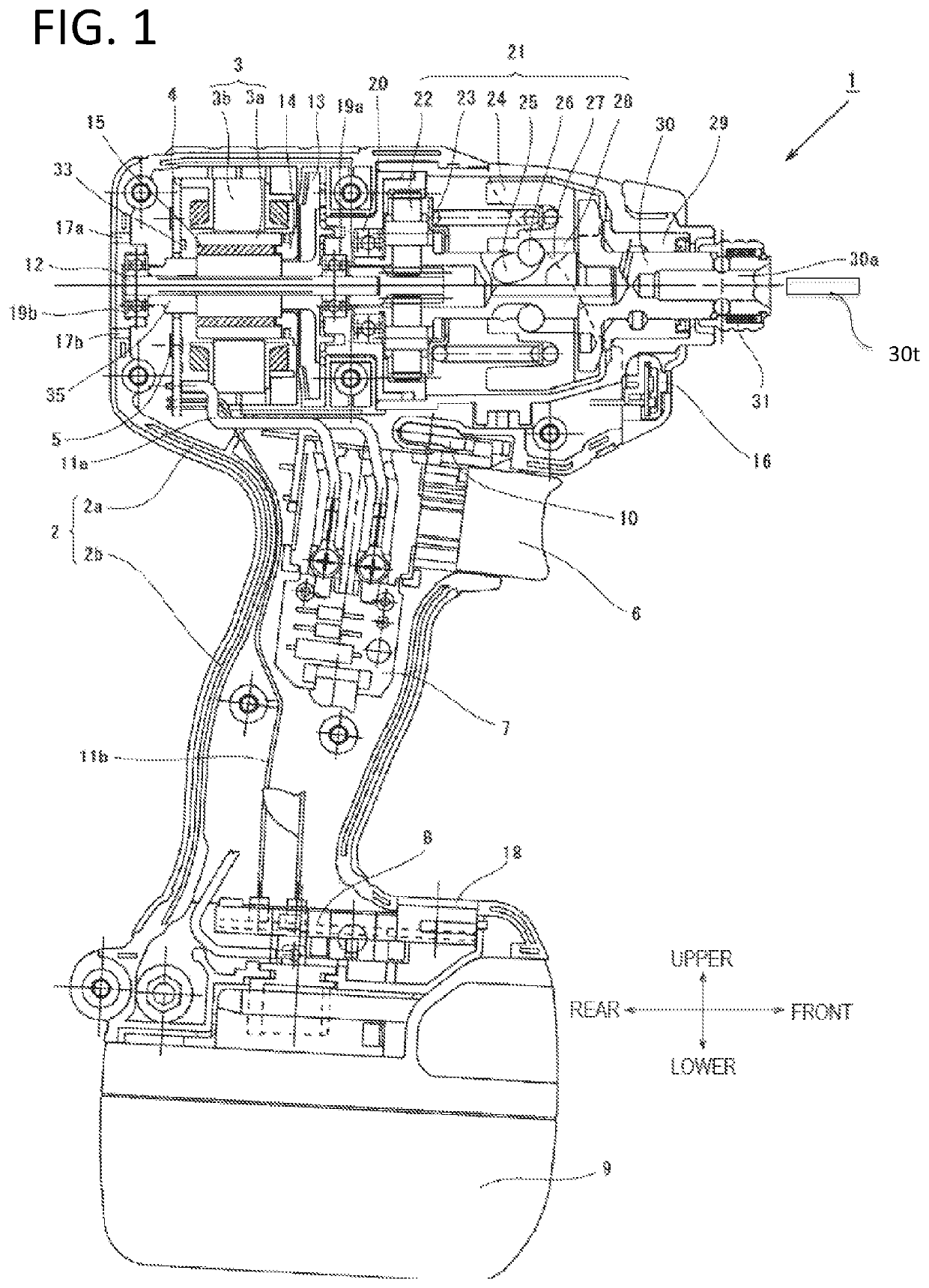

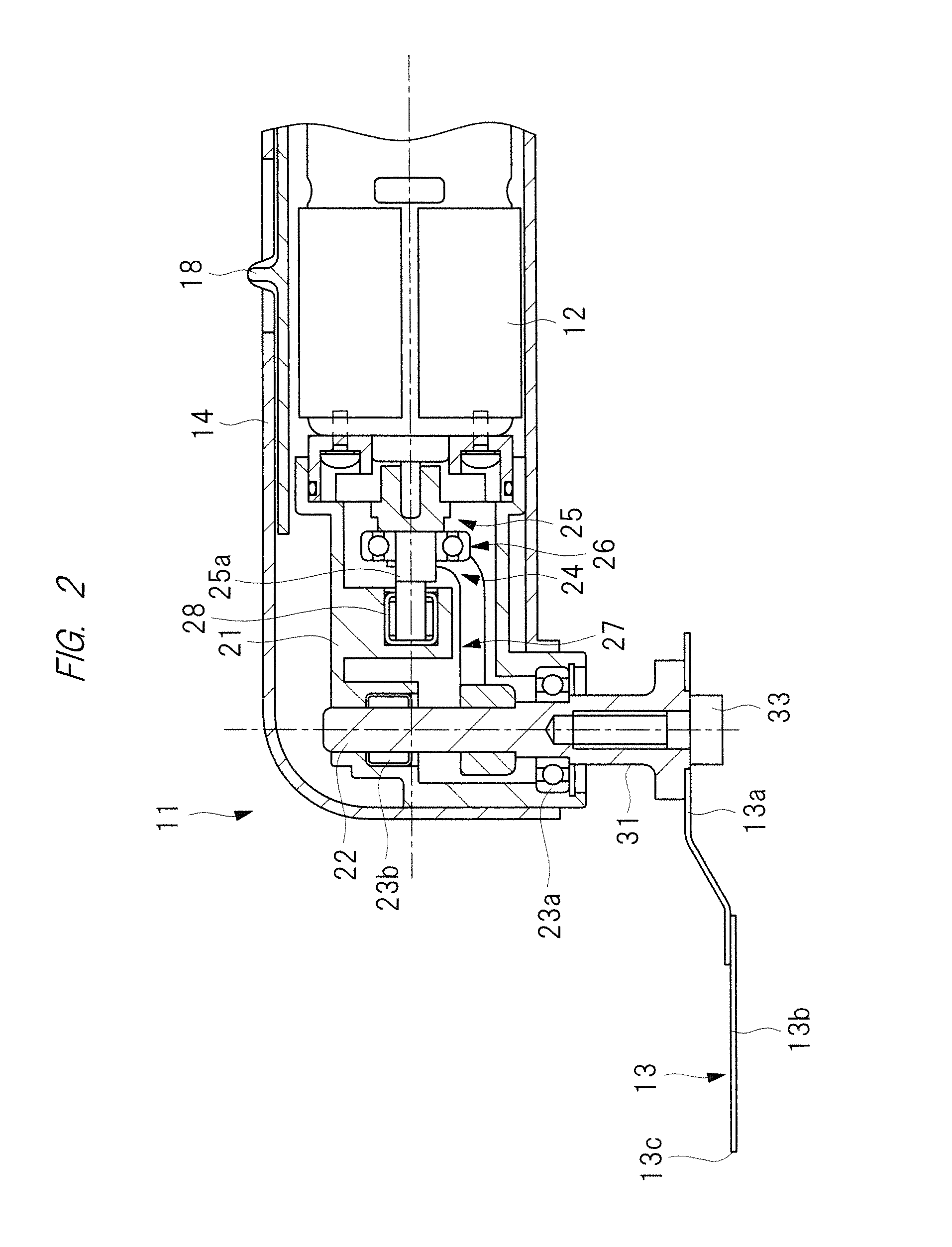

Electric boring tool

InactiveUS9314855B2Prevent and ease damageMotor control for very low speedsDC motor speed/torque controlPower flowMotor control

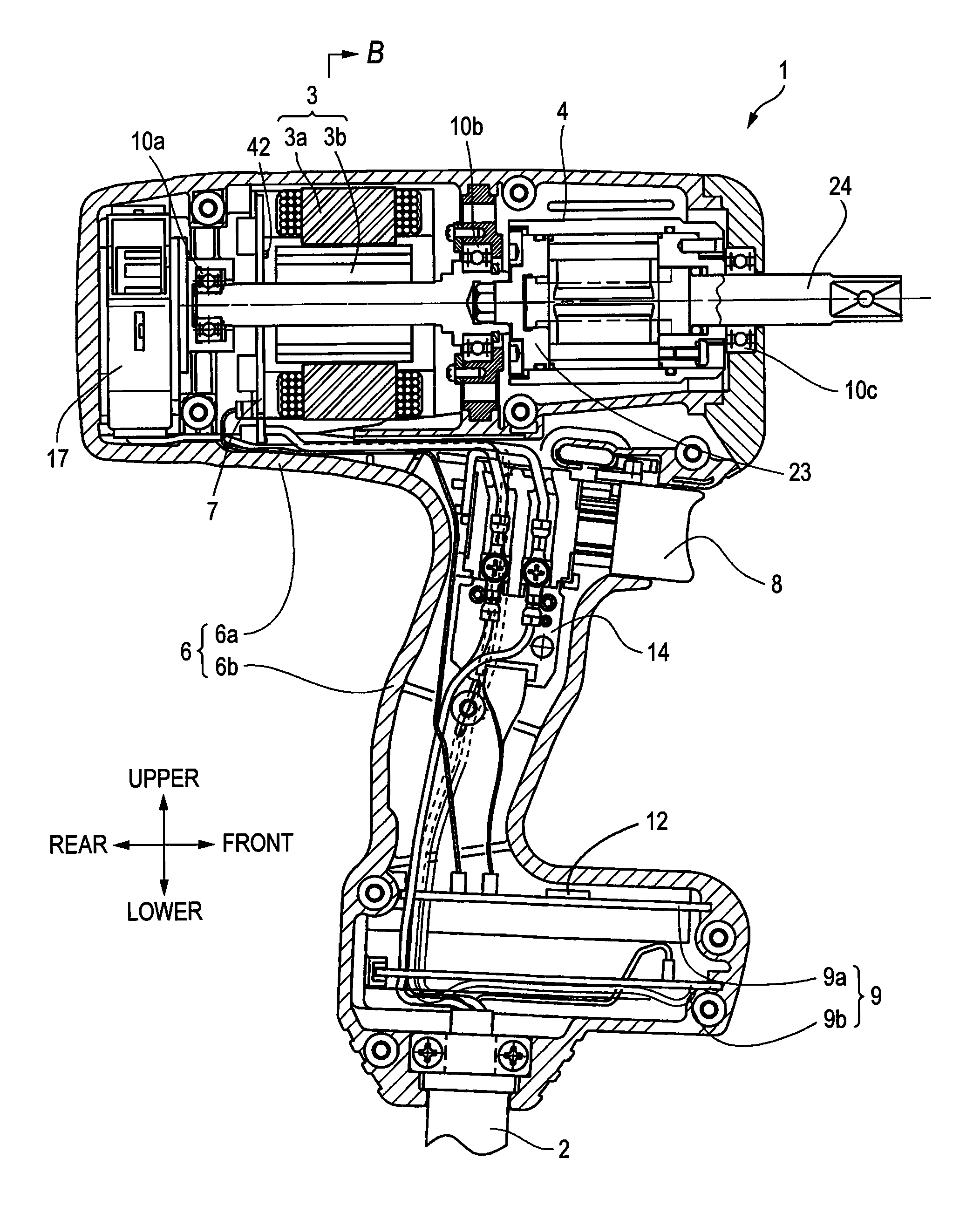

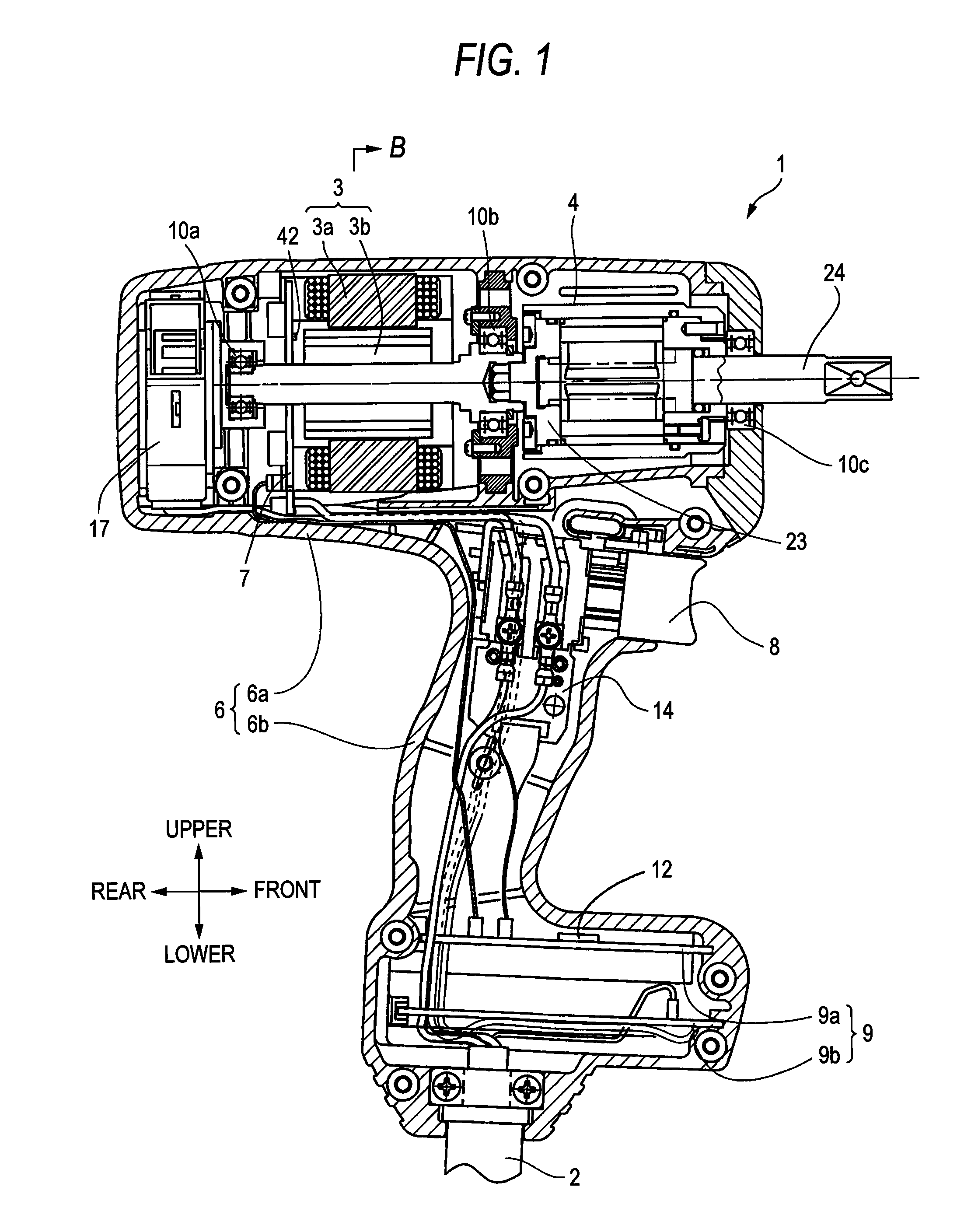

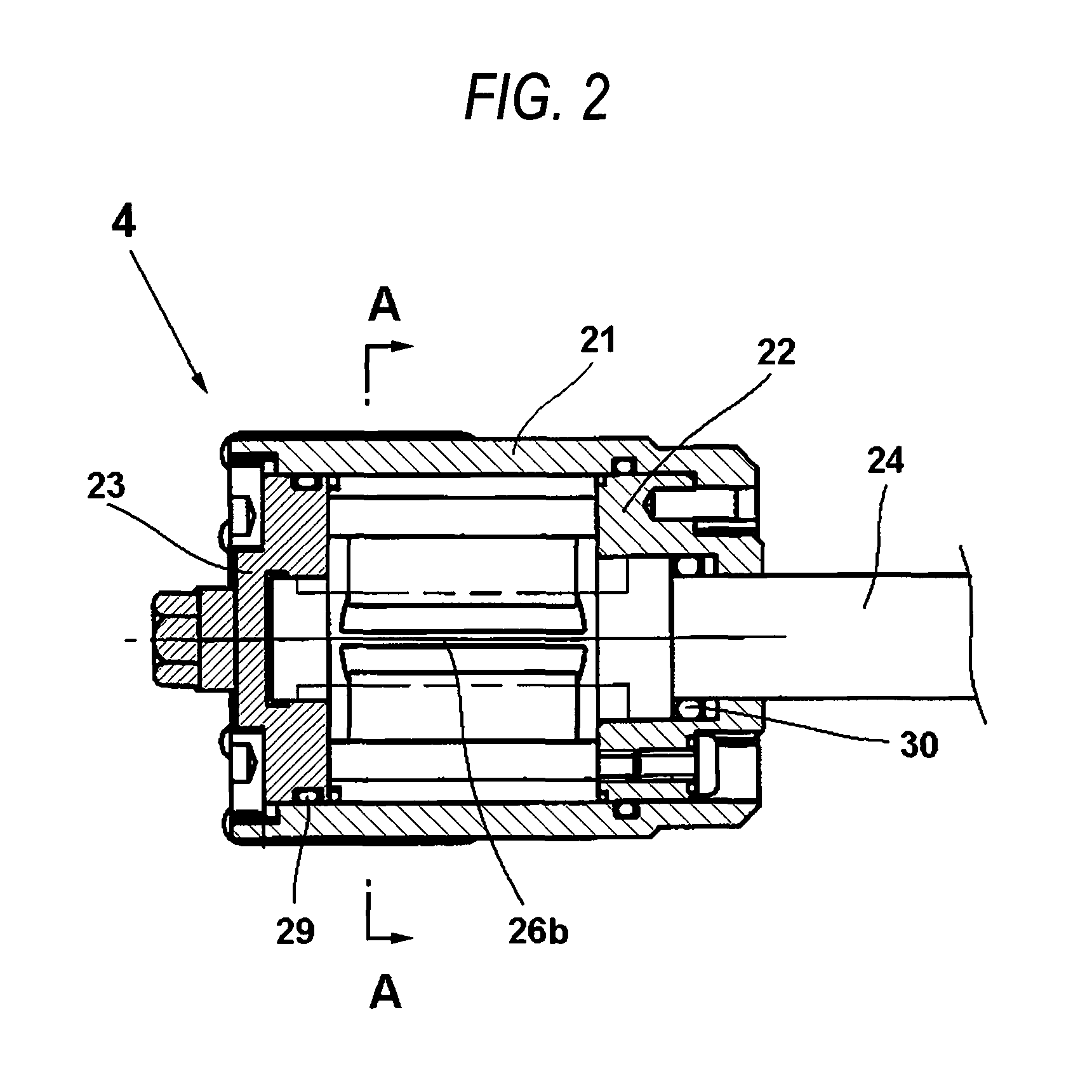

An electric boring tool comprises an electric motor, a switch trigger, a tip tool driven by driving force of the electric motor, a power transmission mechanism for transmitting the driving force of the electric motor to the tip tool as rotational force and / or hammer force, and a motor control unit for controlling speed of the electric motor in response to an extent of pulling of the switch trigger. The motor control unit subjects the electric motor to low speed control after the electric motor is started up, and controls the speed of the electric motor in response to the extent of pulling of the switch trigger when the load current of the electric motor is set value or greater during the low speed control.

Owner:KOKI HLDG CO LTD

Rotary striking tool

According to an aspect of the present invention, there is provided a rotary striking tool, including: a motor; an impact unit having a driving part being driven by the motor and an output part; a tip-tool side output shaft that is coupled to the output part; an impact detection unit that detects an impact generated at the impact unit; and a control unit programmed to: control the impact unit to perform a confirmation striking when the impact detected by the impact detection unit reaches a prescribed value, detect a rotation angle of the output shaft at the confirmation striking, determine whether a fastening operation is completed when the detected rotation angle is equal to or smaller than a predetermined angle, and continue the fastening operation when the detected rotation angle is larger than the predetermined angle.

Owner:HITACHI KOKI CO LTD

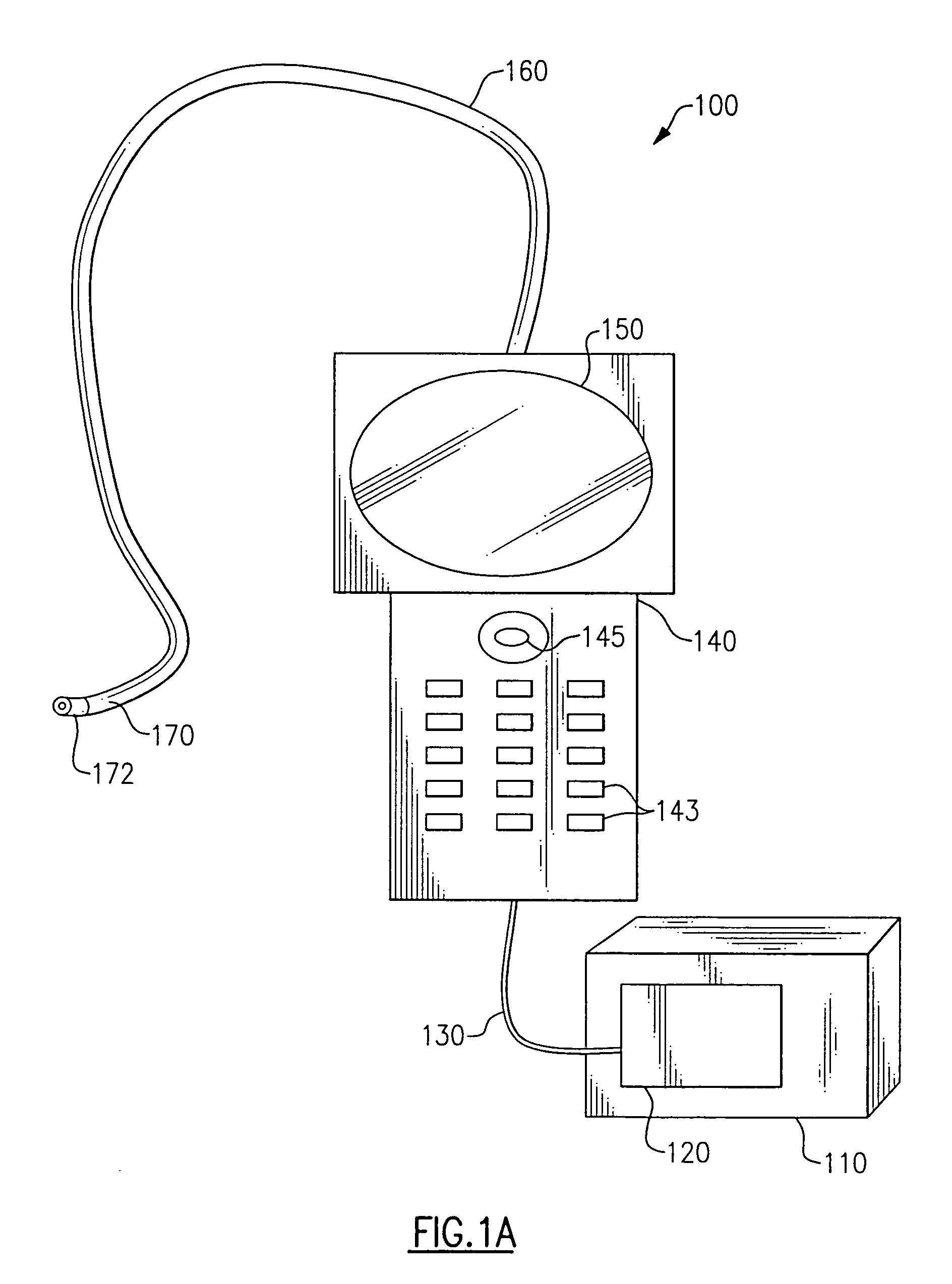

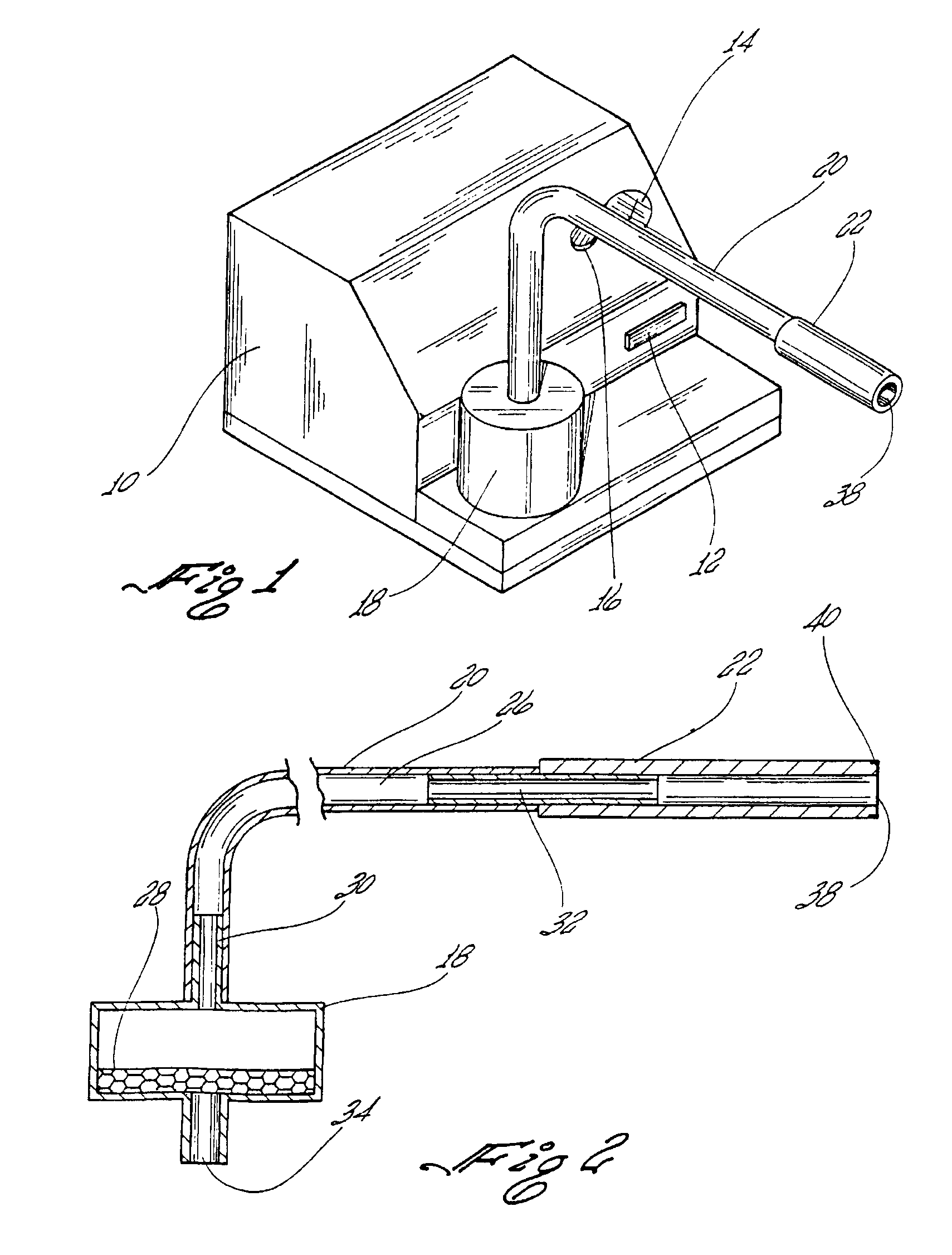

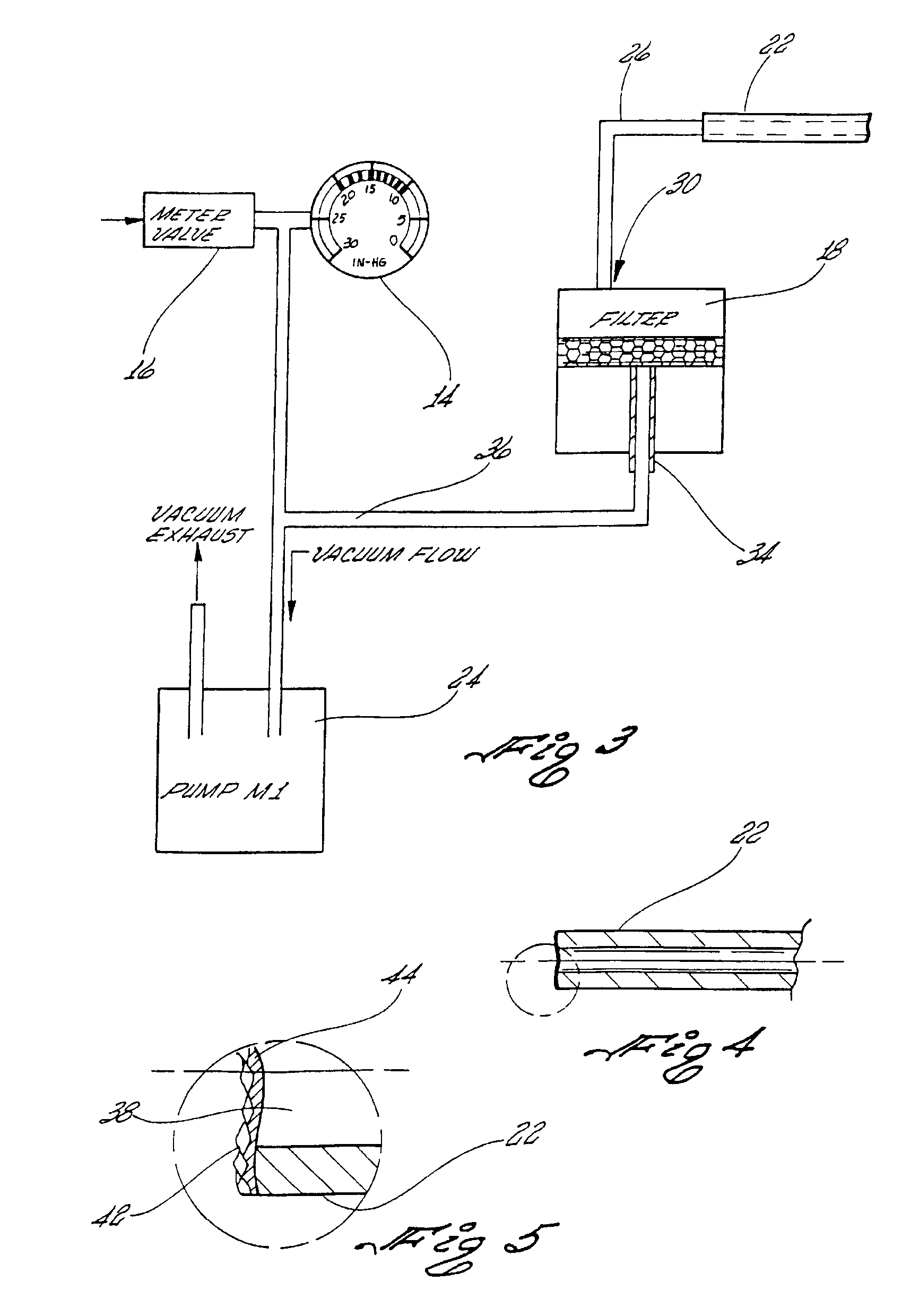

Microdermabrasion device

A treatment tool and tissue collection system, for removal of outer layers of skin to provide a revitalized, fresh skin surface, and a method of using same, comprising a abrasive tipped tool mounted on the end or within the end of a hollow tube, said tube being connected to a source of vacuum. The vacuum aids in maintaining intimate contact between the abrasive tip and the skin during the treatment process and transports the removed tissue to a collection container. The abrasive surface within the tube is a motor driven abrasive pad. Contact between the pad and the abrasive disk is brought about or increased by application of a vacuum through the tube to the skin surface.

Owner:ALTAIR INSTR

Rotary striking tool

According to an aspect of the present invention, there is provided a rotary striking tool, including: a motor; an impact unit having a driving part being driven by the motor and an output part; a tip-tool side output shaft that is coupled to the output part; an impact detection unit that detects an impact generated at the impact unit; and a control unit programmed to: control the impact unit to perform a confirmation striking when the impact detected by the impact detection unit reaches a prescribed value, detect a rotation angle of the output shaft at the confirmation striking, determine whether a fastening operation is completed when the detected rotation angle is equal to or smaller than a predetermined angle, and continue the fastening operation when the detected rotation angle is larger than the predetermined angle.

Owner:KOKI HLDG CO LTD

Impact tool

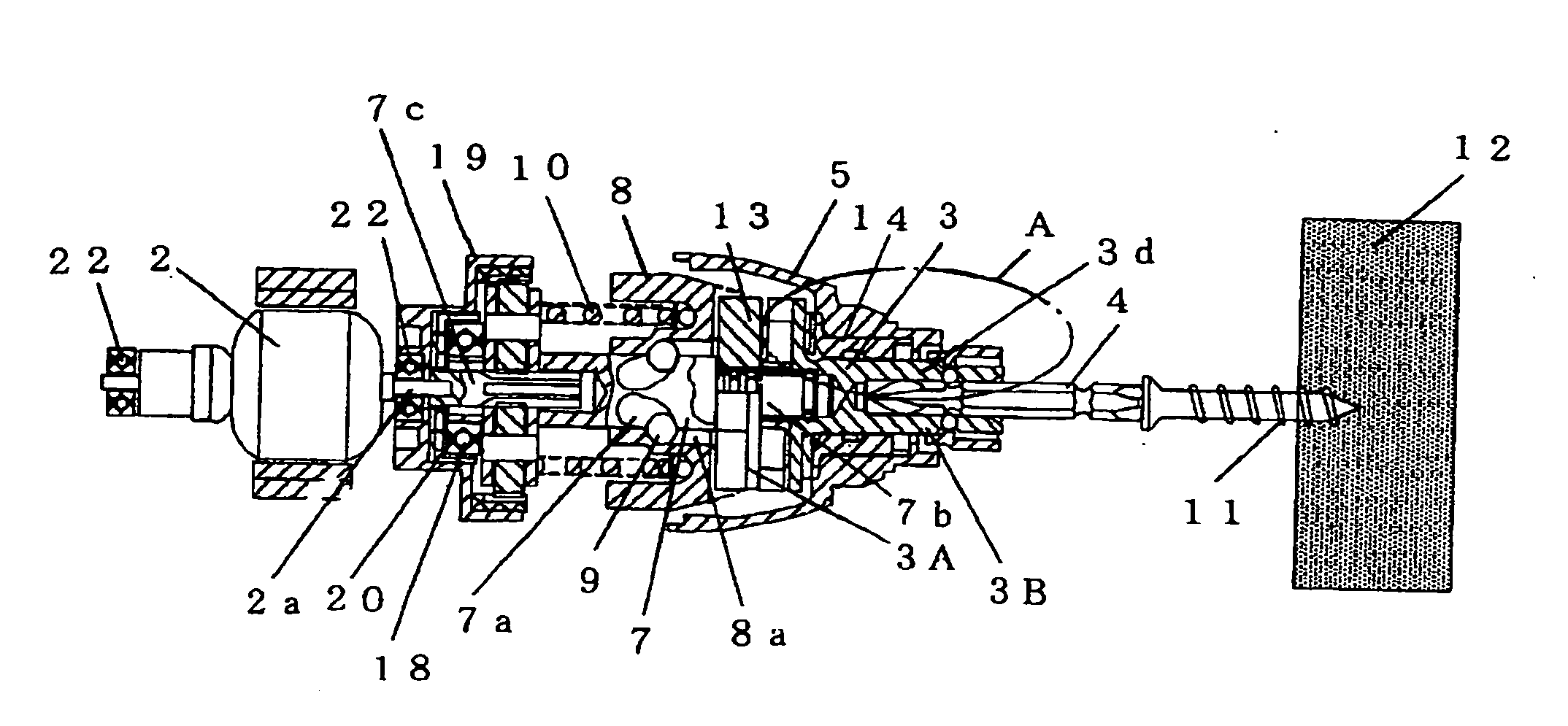

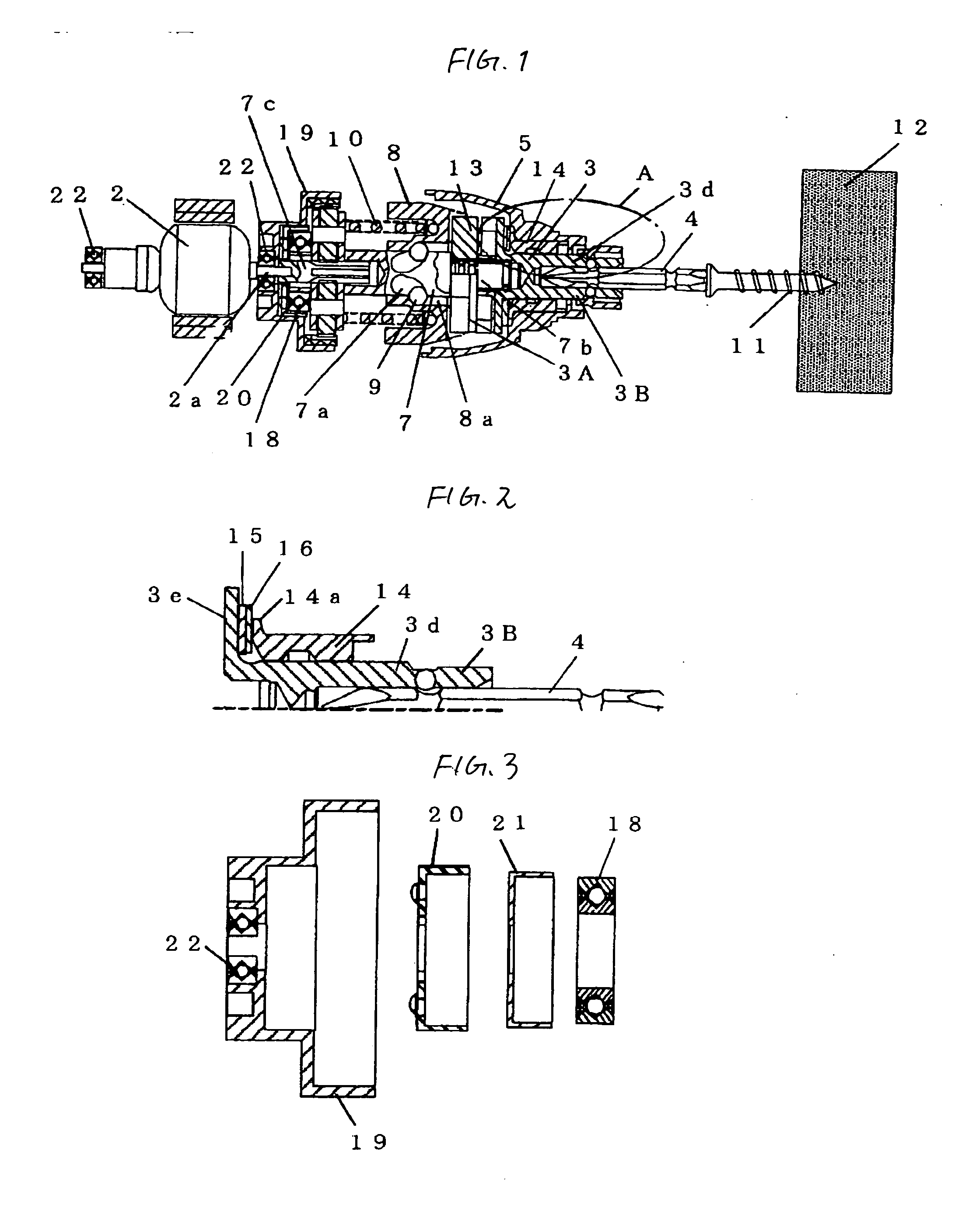

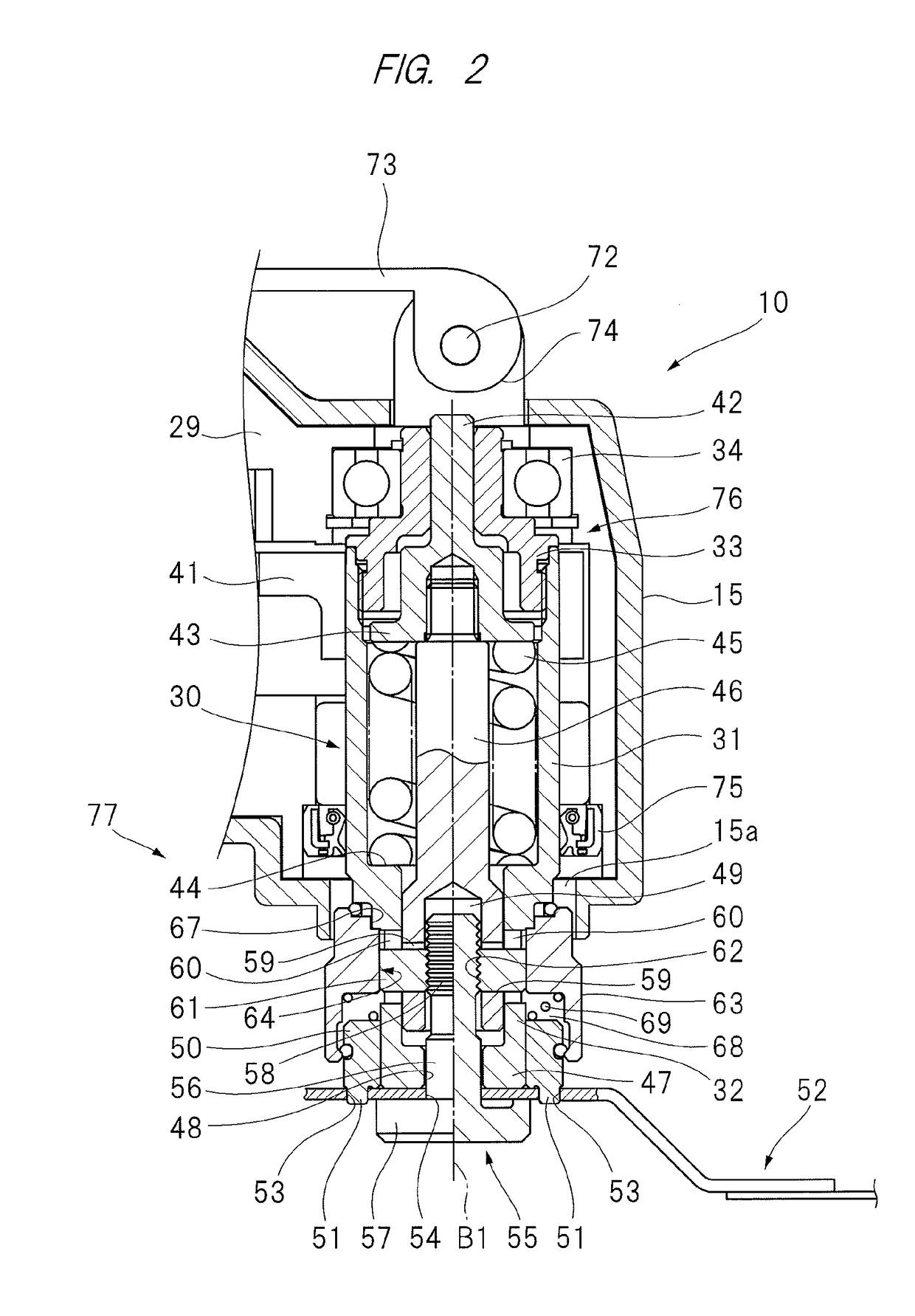

InactiveUS20070034398A1Improve noiseEffective absorptionReciprocating drilling machinesConstructionsEngineeringMechanical engineering

An impact tool for reducing noise without lowering the tightening ability. The impact tool gives a rotary blow force to a tip tool by mounting a rotary blow mechanism on a spindle rotatably driven by a motor and intermittently transferring the rotary blow force generated by the rotary blow mechanism from a hammer to the tip tool via an anvil, damping materials absorbing at least the vibration in the radial direction are arranged on at least one side of both supports of the axial direction of the spindle 7. The damping material is interposed between a bearing that rotatably supports the rear end portion of the spindle and an inner cover that holds the same, and an O-ring is interposed as a damping material between the front end portion of the spindle and an anvil that rotatably supports the same.

Owner:HITACHI KOKI CO LTD

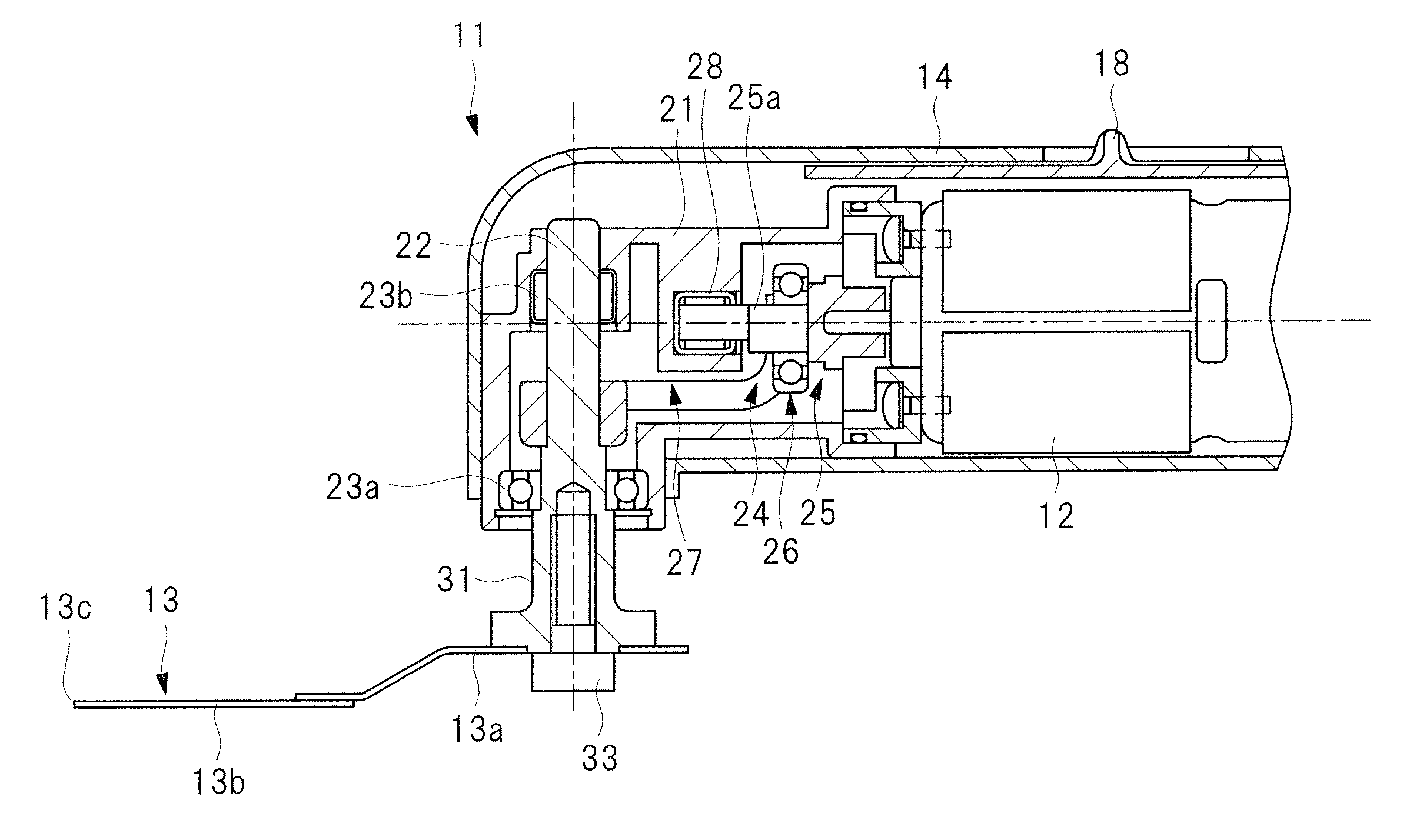

Electric power tool

ActiveUS20140352995A1Reduce stepsAutomatic controlAutomatic control devicesDC motor speed/torque controlElectric power systemPower tool

An object of the present invention is to provide an electric power tool capable of automatically changing the rotating speed of an electric motor in accordance with operation conditions. The electric power tool 11 which carries out an operation of polishing, peel-off, cutting, or the like by swinging a tip tool 13 attached to a tool retaining part 31 within the range of predetermined angles by the drive power of the electric motor 12, wherein the electric power tool has a control device configured to indirectly detect the load of the tip tool from a current value, and to control the rotating speed of the electric motor 12 to a maximum rotating speed and a minimum rotating speed on the basis of the load of the tip tool 13.

Owner:HITACHI KOKI CO LTD

Impact tool

According to an aspect of the present invention, there is provided an impact tool (1) (including: a motor (3)drivable in an intermittent driving mode; a hammer (41) connected to the motor; an anvil (16) to be struck by the hammer (41) to thereby rotate / strike a tip tool; and a control unit that controls a rotation of the motor (3)by switching a driving pulse supplied to the motor (3) in accordance with a load applied onto the tip tool.

Owner:KOKI HLDG CO LTD

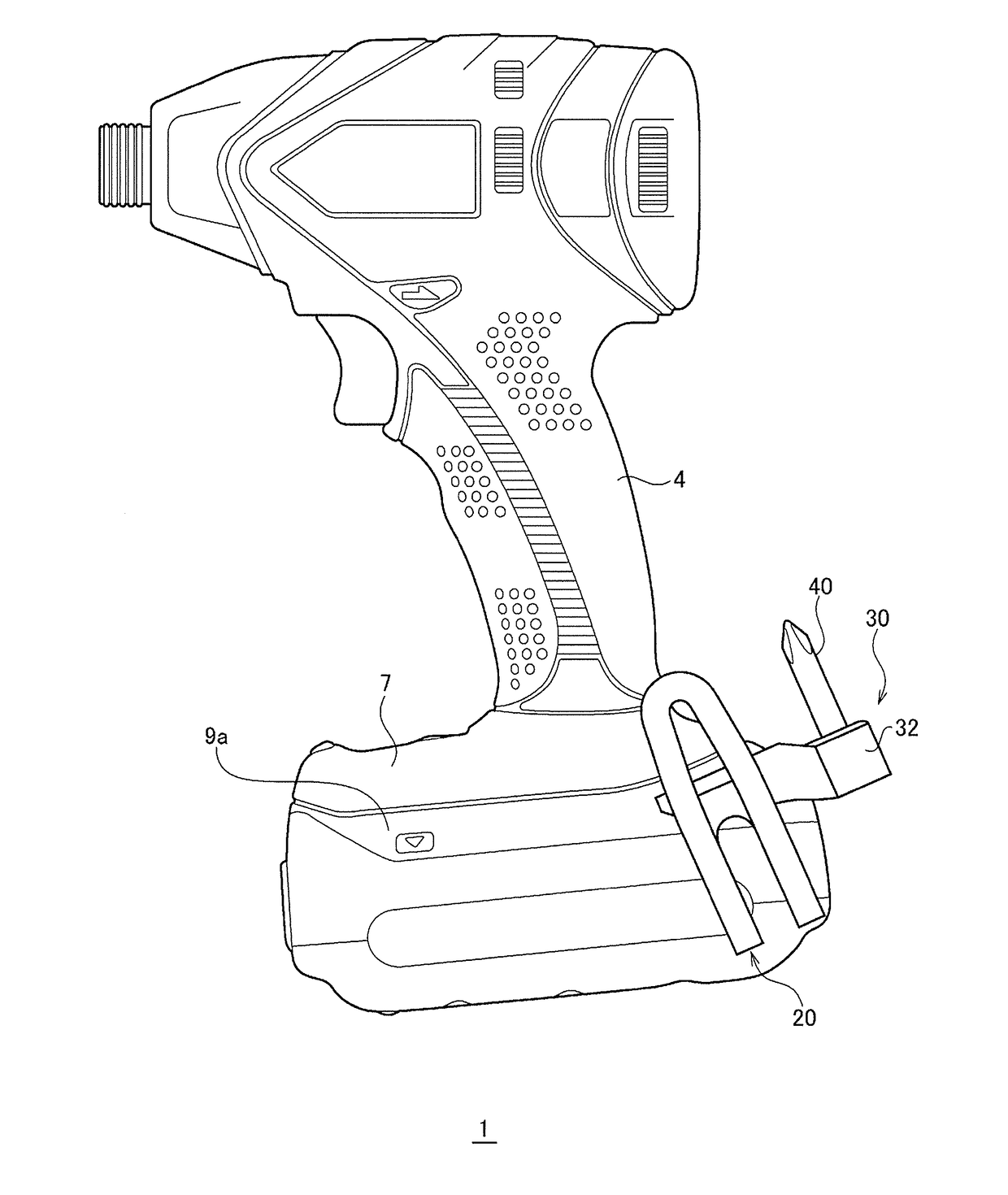

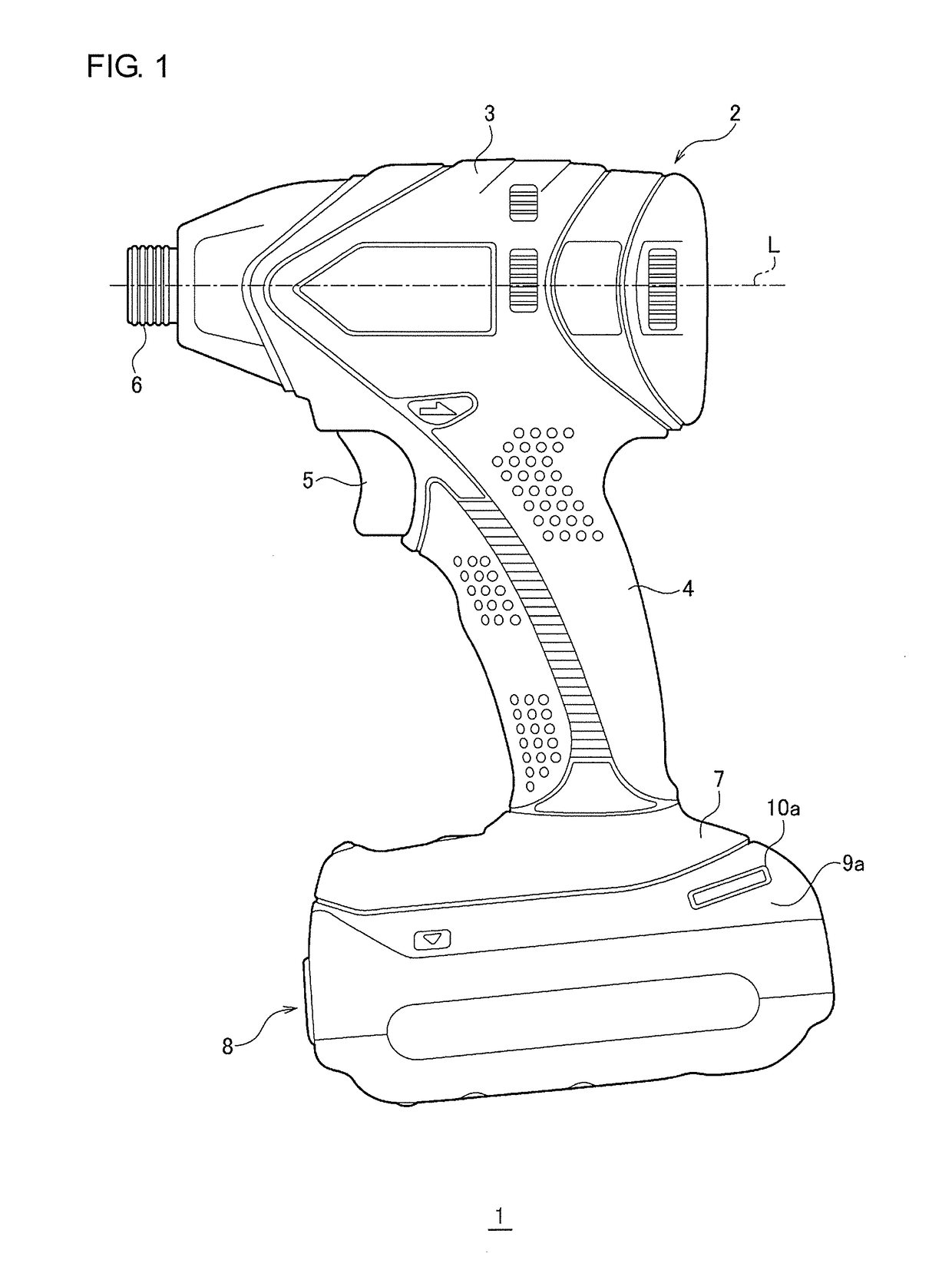

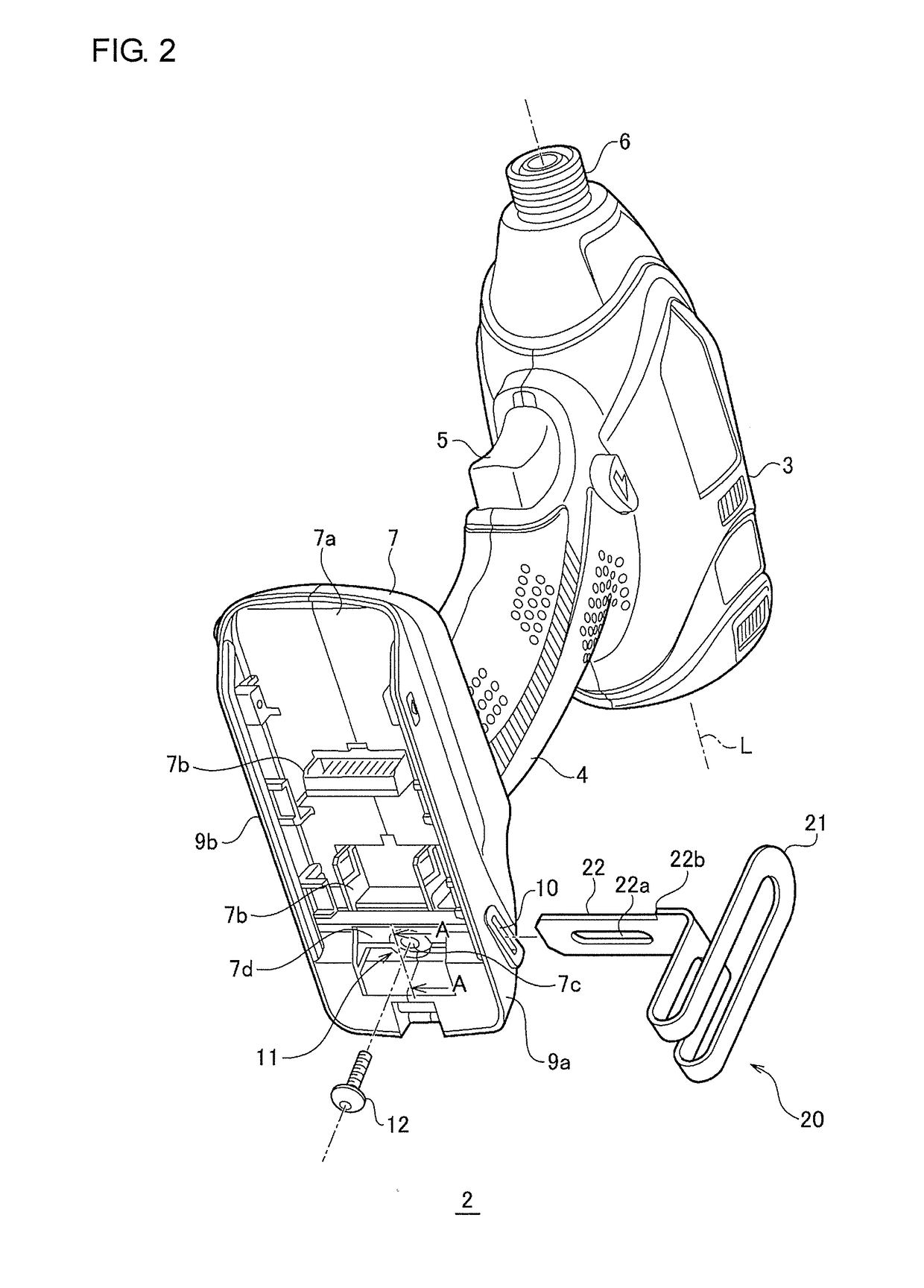

Tip tool holder and power tool

A tip tool holder includes a nail portion to be inserted in an attachment hole formed in a power tool, an accommodation portion capable of accommodating a tip tool, and an opening opposite to the nail portion. The accommodation portion accommodates the tip tool such that an axis of the tip tool is substantially perpendicular to a direction in which the nail portion and the opening face each other. The tip tool holder includes a first arm and a second arm opposite to each other. The opening is included in the first arm while the nail portion is provided to the second arm.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Electric tool

InactiveUS20080302551A1Easily identifiableImprove cooling effectDrilling rodsConstructionsPower toolTipped tool

According to an aspect of the present invention, there is provided an electric tool including: a housing; a motor that is housed in the housing; a tip tool; a rotation transmission mechanism that transmits a rotation of the motor to the tip tool; an air inlet that is disposed on the housing to introduce a cooling air for cooling the motor from an outside of the housing; an air outlet that is disposed to discharge the cooling air; and a cover that is slidable along an inner wall or an outer wall of the housing and that is movable in a first position where the air inlet and the air outlet are opened and a second position where the air inlet and the air outlet are closed.

Owner:HITACHI KOKI CO LTD

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

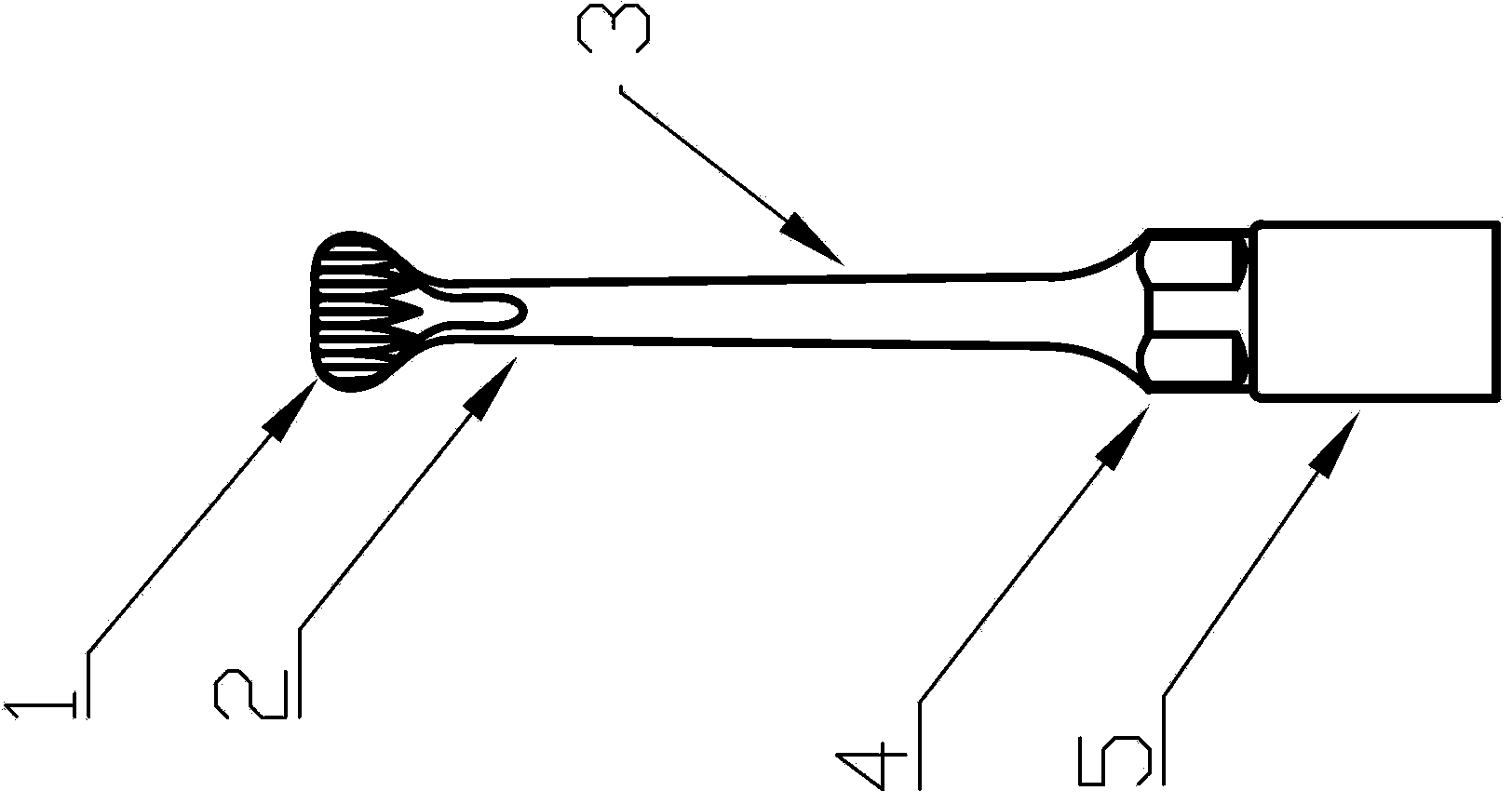

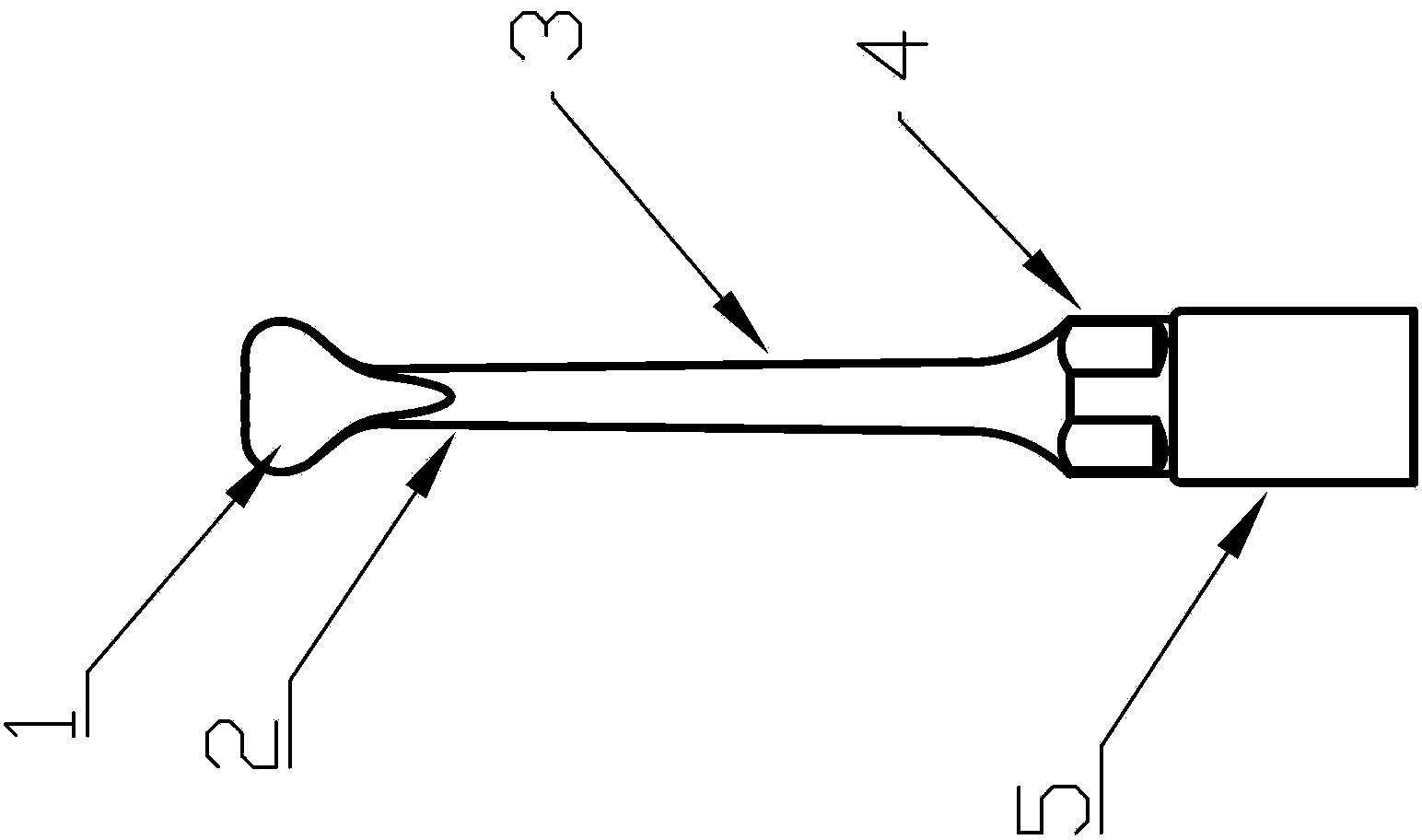

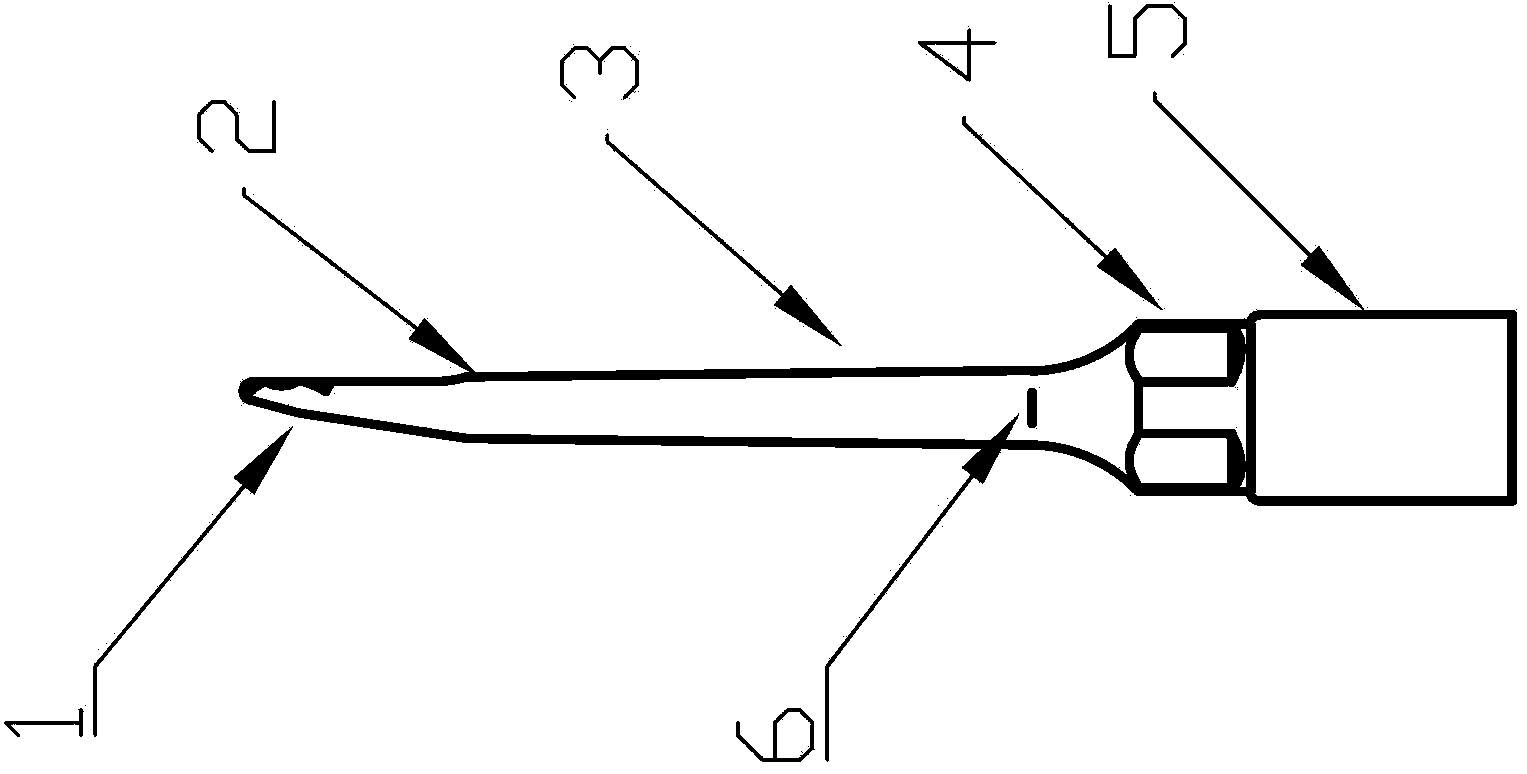

Piezosurgery machine working tip

The invention relates to a piezosurgery machine working tip, which consists of a working tip tool bit (1), a working tip head part (2), a working tip neck part (3) and a working tip connection part (5), wherein the working tip tool bit (1) is of a flat-spoon shaped plane; one surface is extruded in a wave shape; and the other surface is a smooth surface. According to the piezosurgery machine working tip disclosed by the invention, the edge of an orthopedic surgery can be subjected to bone surface expansion and grinding. The piezosurgery machine working tip has the advantages of convenience in use and simpleness in operation, and meanwhile, damage on an adjacent bone surface is reduced.

Owner:GUILIN WOODPECKER MEDICAL INSTR

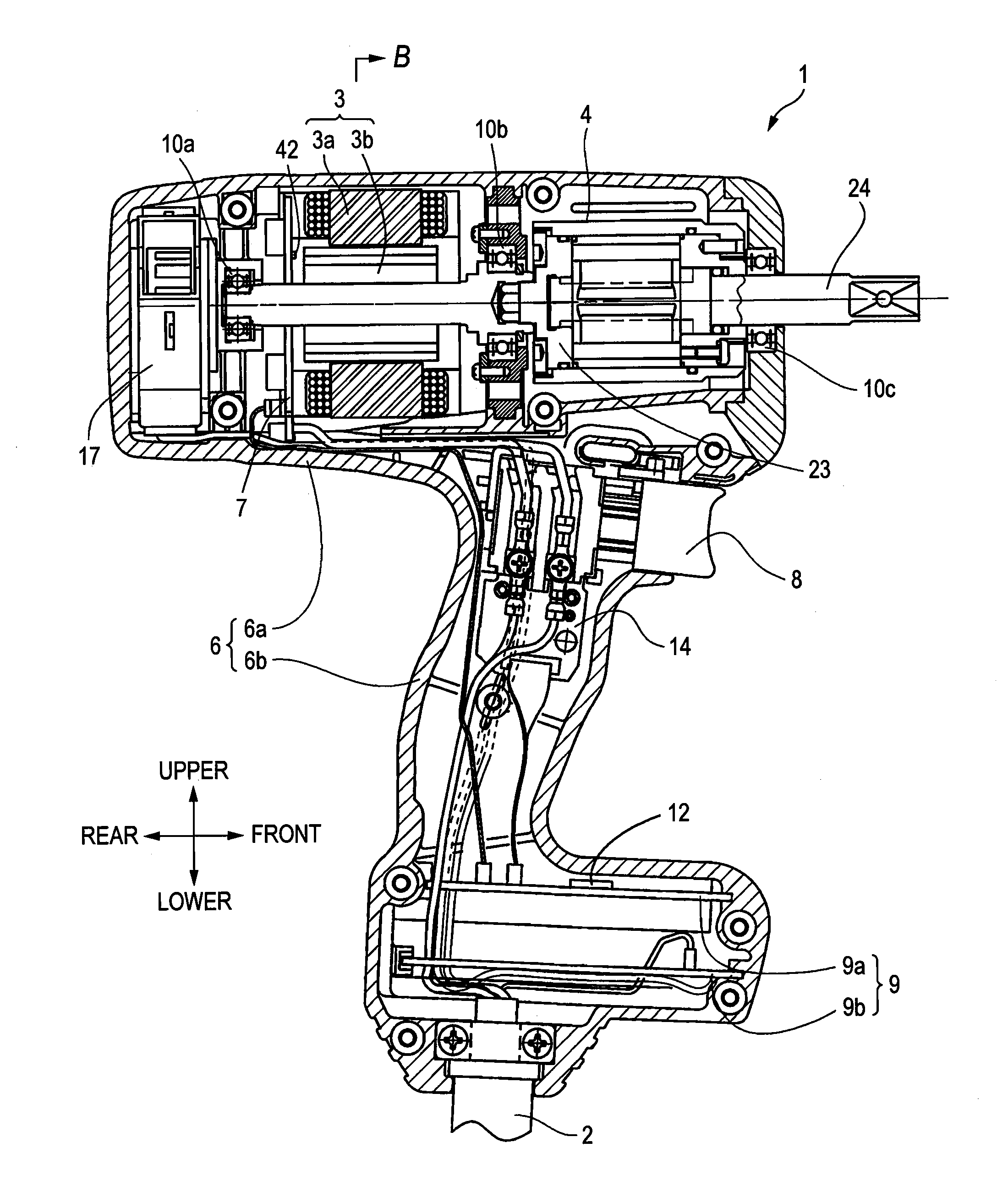

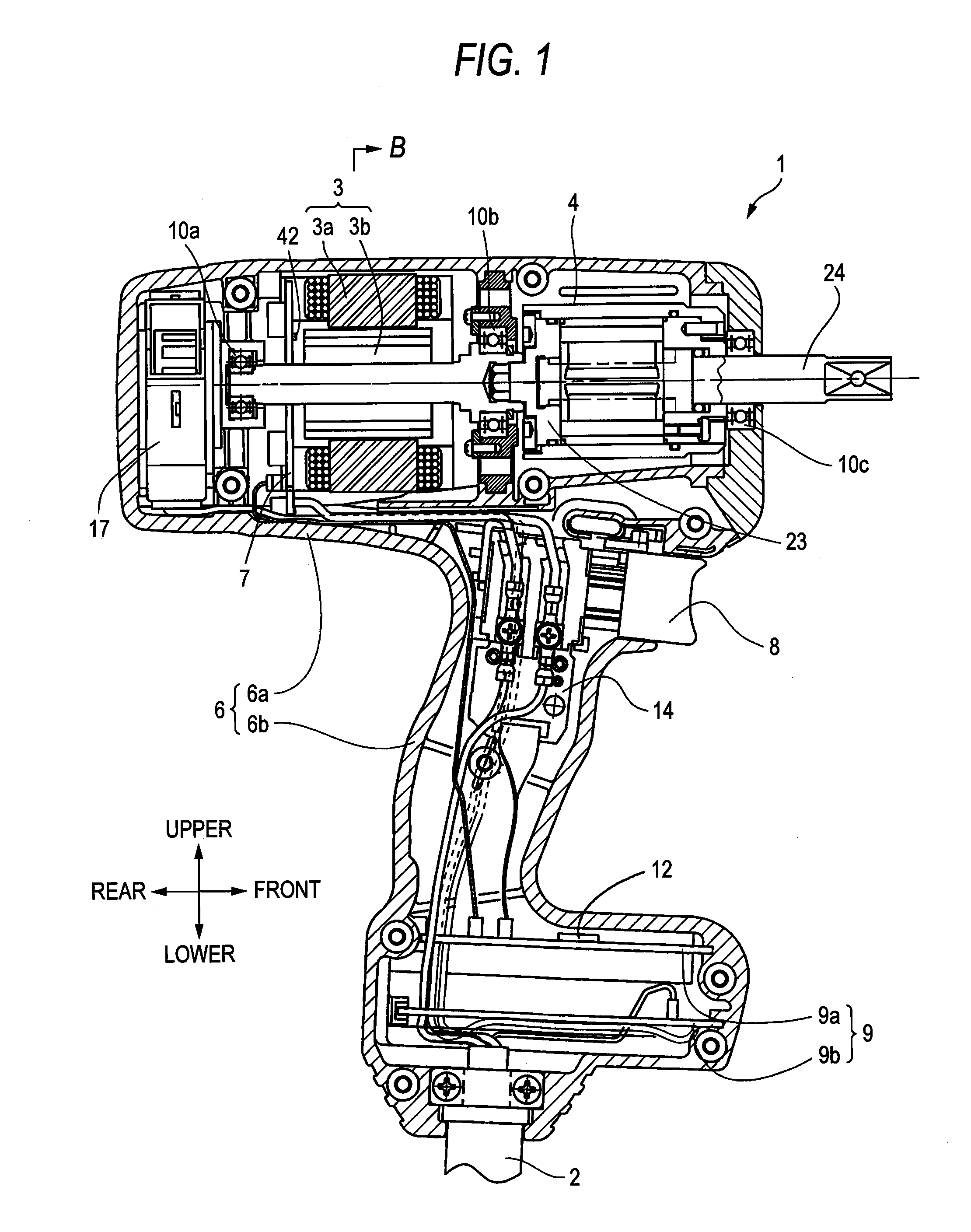

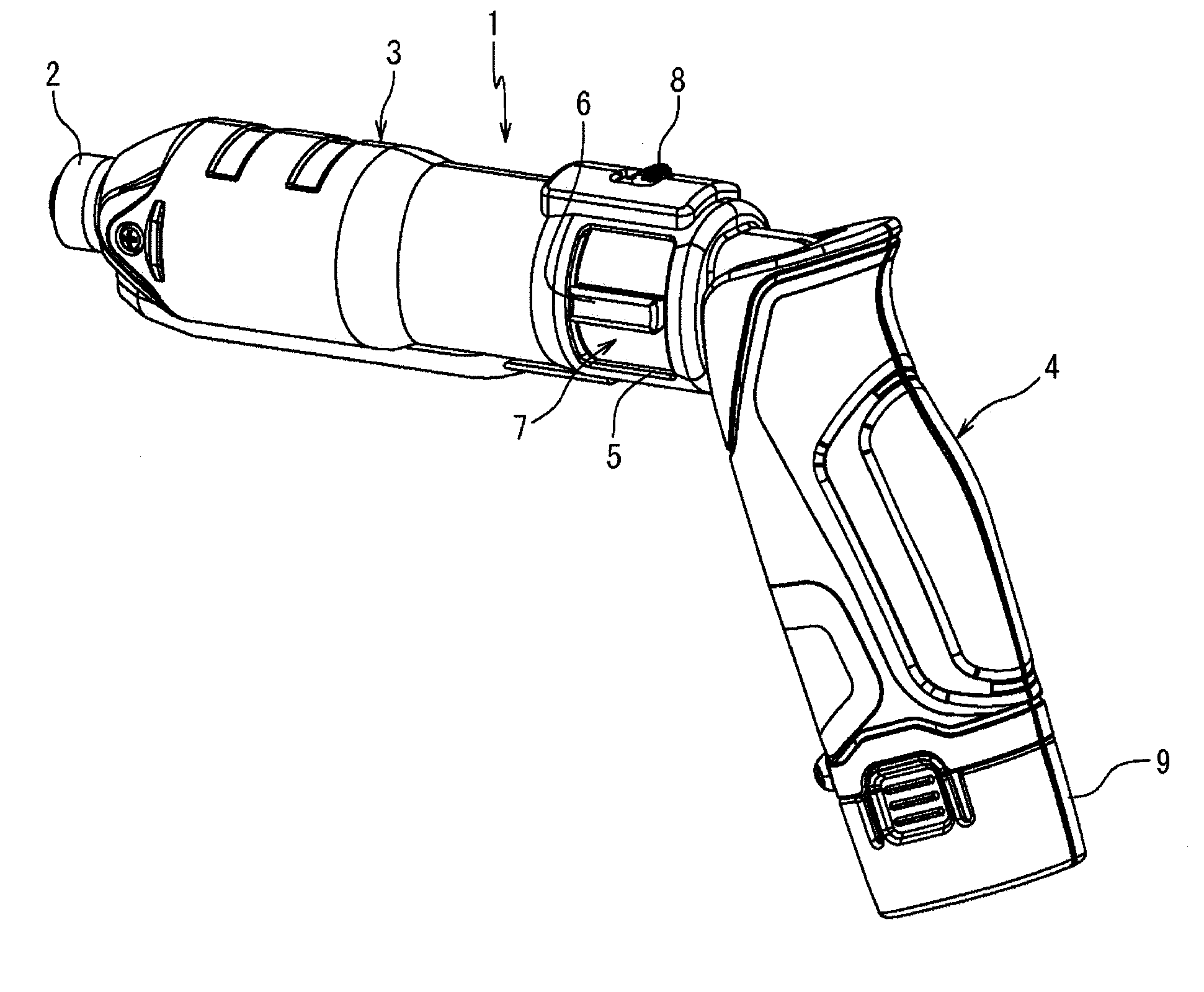

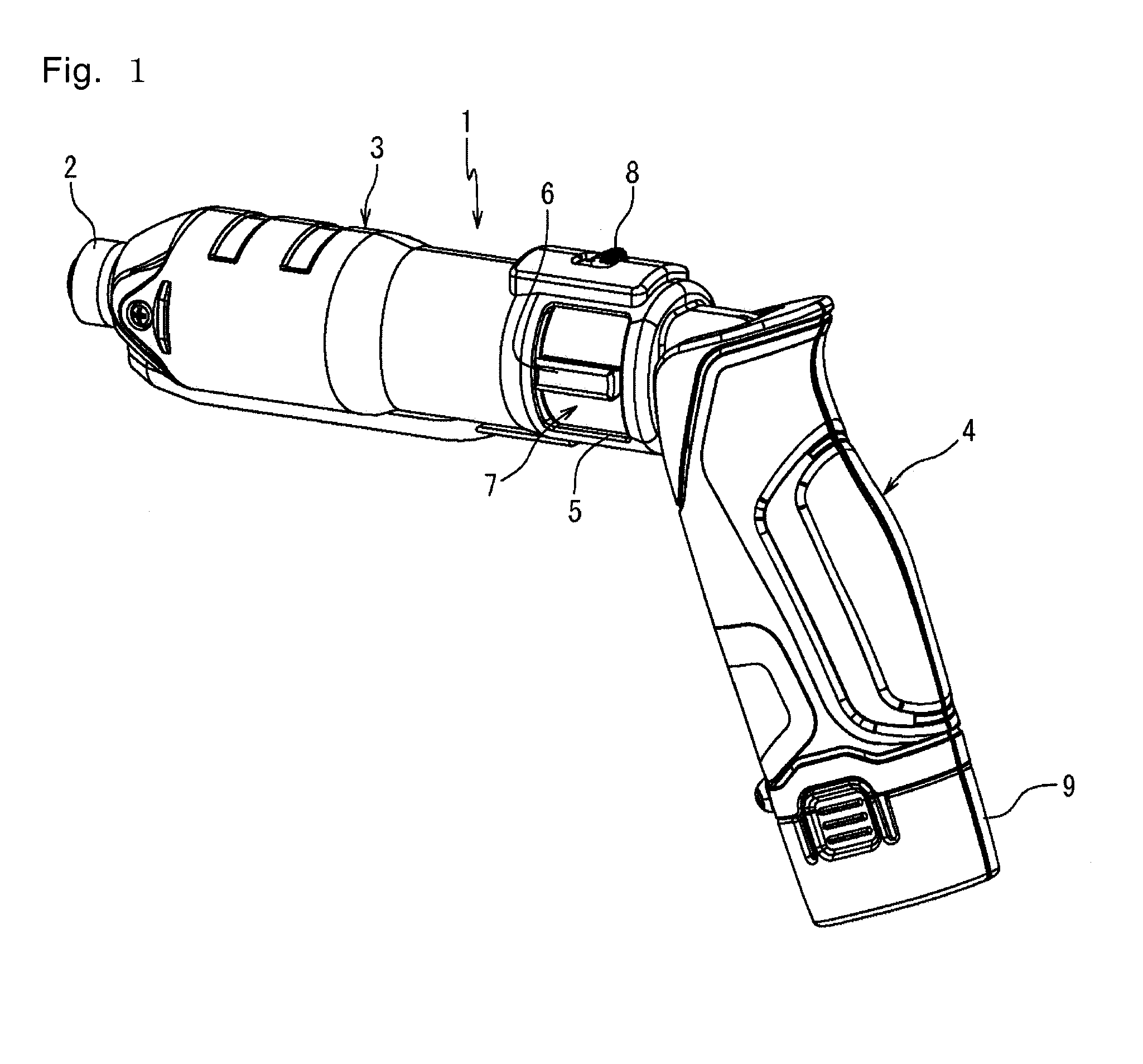

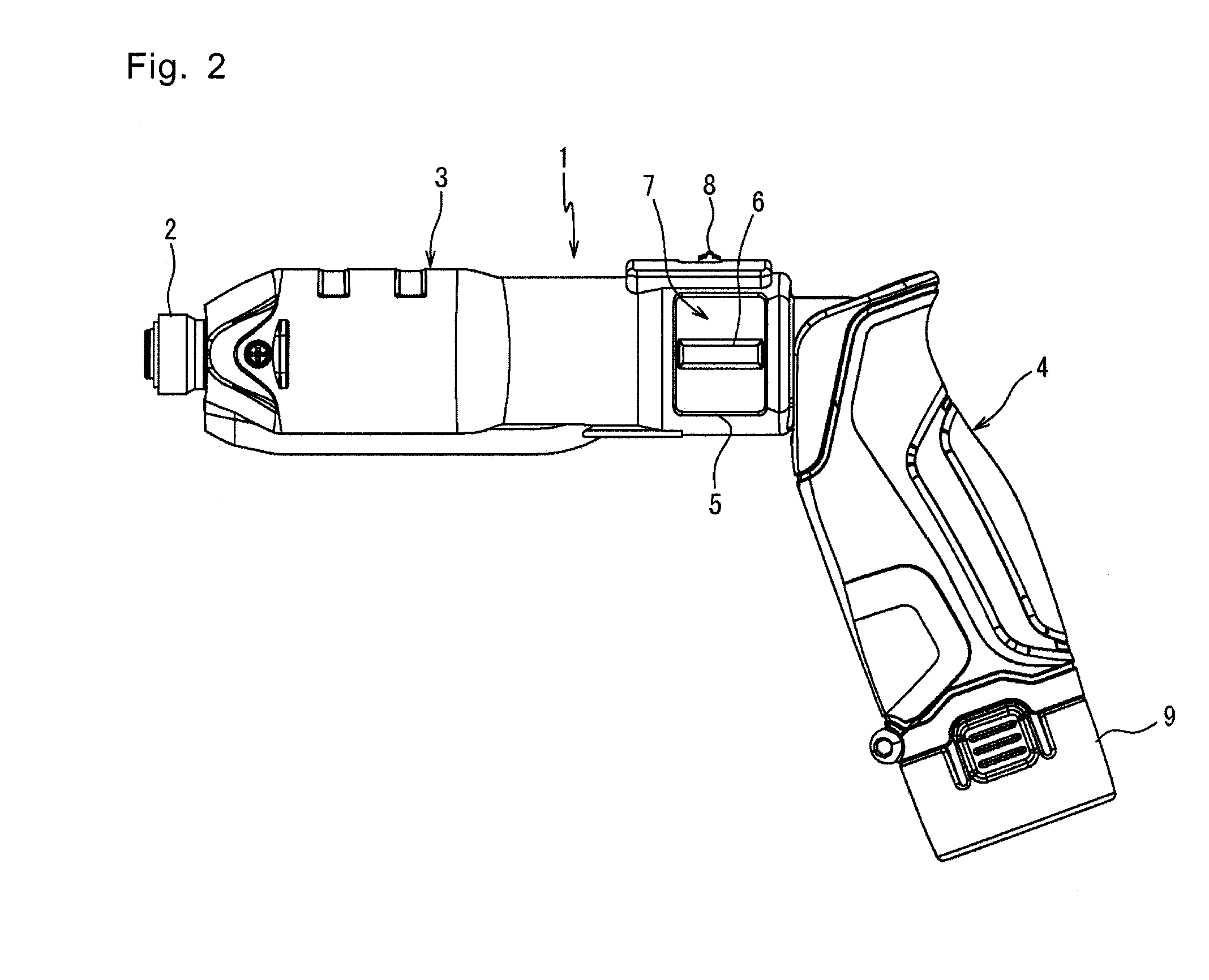

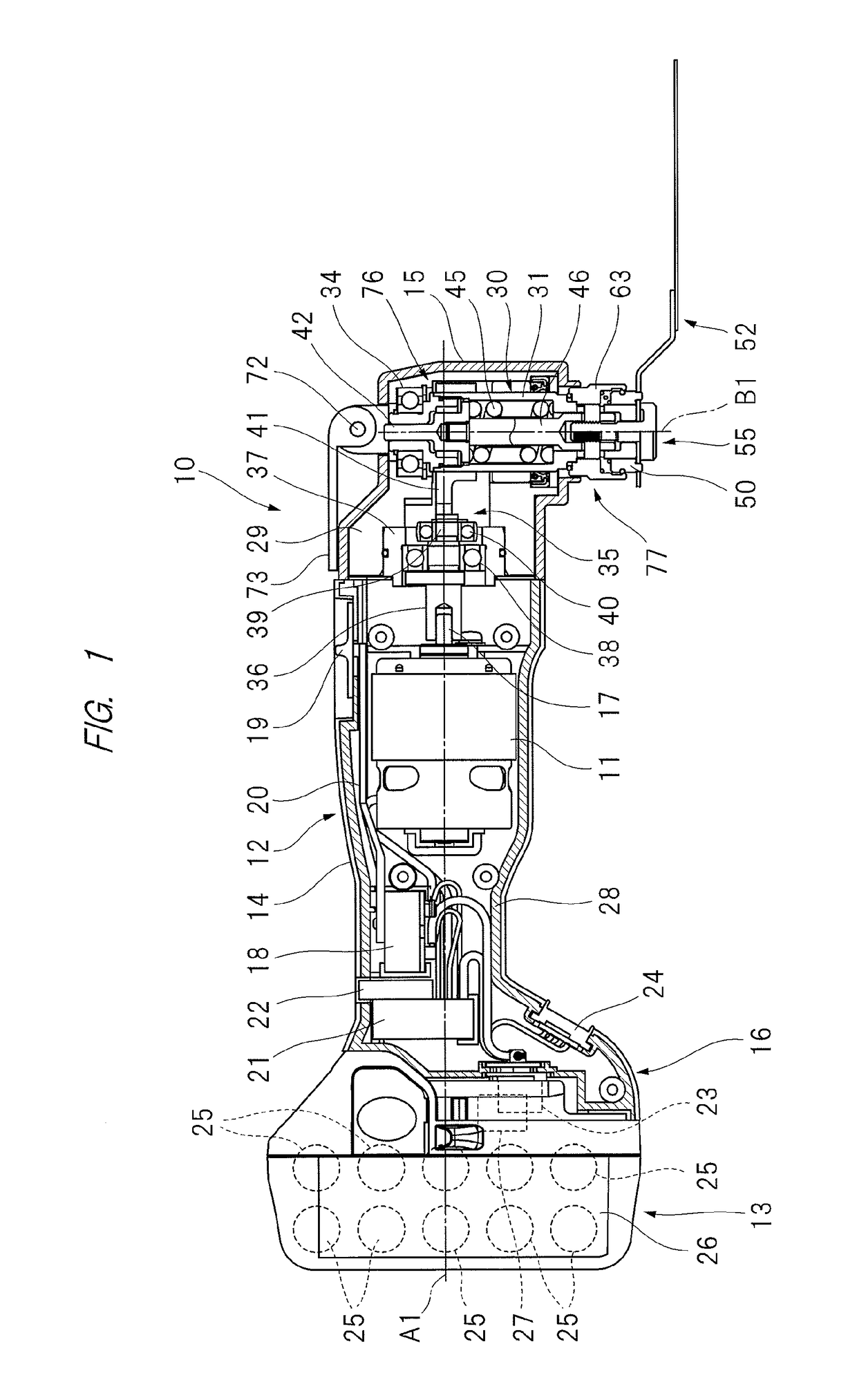

Electrical power tool

ActiveUS20100163265A1Finely control speedEasy to controlDrilling rodsConstructionsPower toolNeutral position

In view of the above problem, the present invention is to provide an electrical power tool which enables a user to intuitively grasp a rotation direction and a rotation speed of a tip tool. The electrical power tool 1 comprises a chuck 2 provided at a tip of a tool body 3, and rotatable with a tip tool held, and an operation switch 7 having operation protrusions 6 exposed to both side surfaces of a tool body 3 so as to be able to operate, respectively bilaterally symmetrically protruded with a rotation axis of the chuck 2 therebetween, coaxially rotatable with the chuck 2, and urged so as to be self-restored to a neutral position. The chuck 2 is rotated in a direction according to a rotation direction of the switch 7 at a speed according to a rotation angle from the neutral position of the operation switch 7.

Owner:ORMON CORP +1

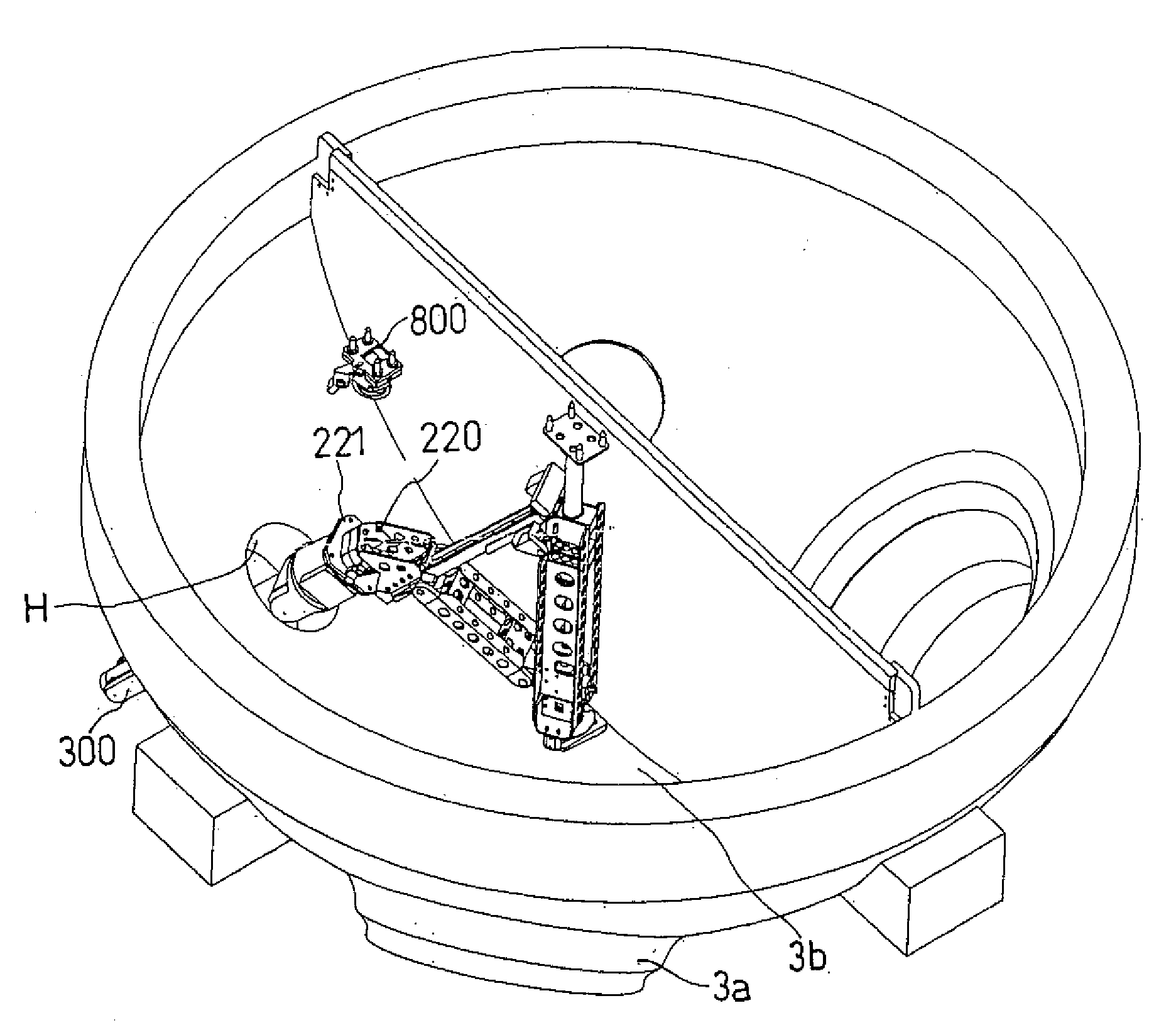

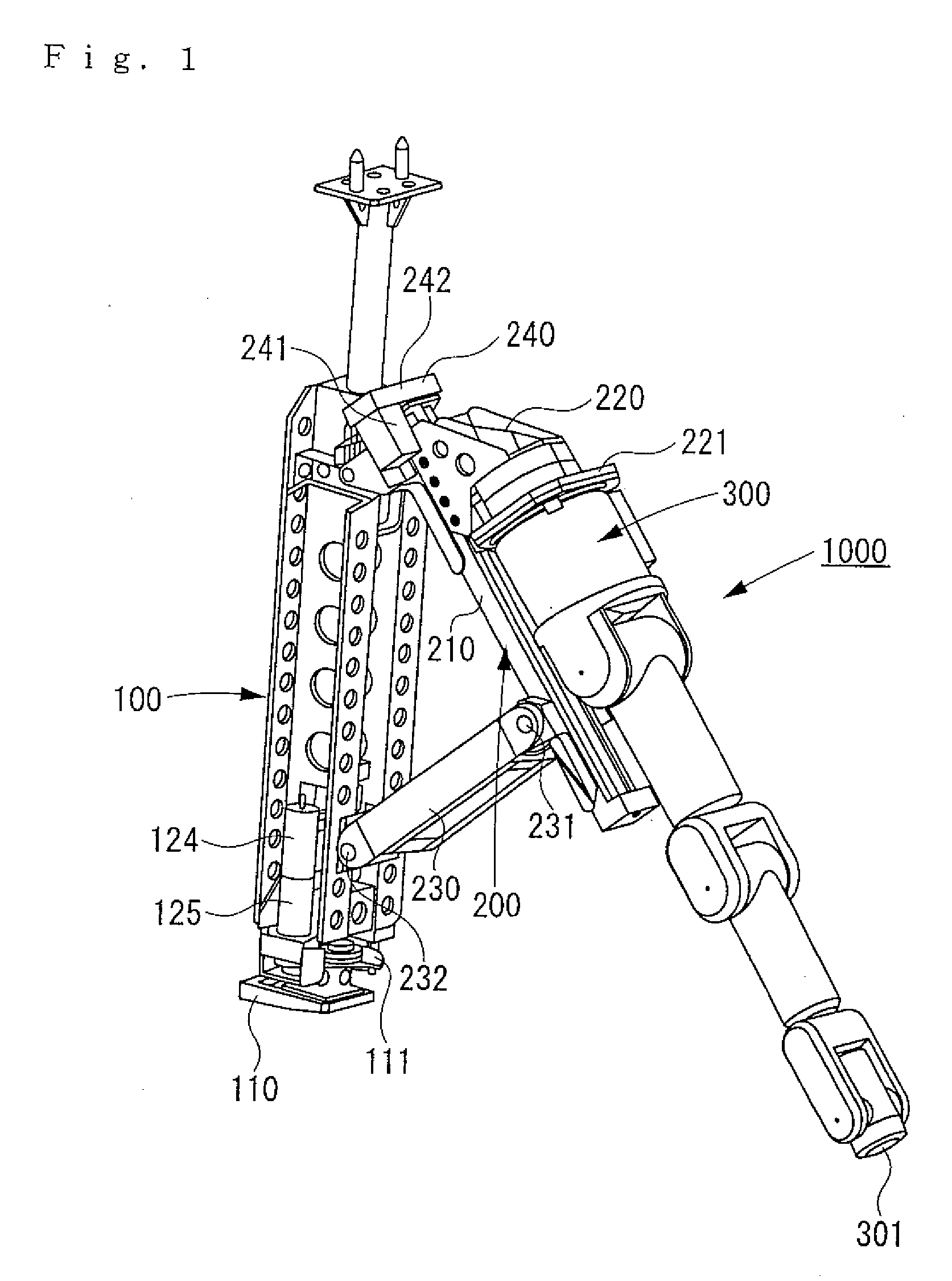

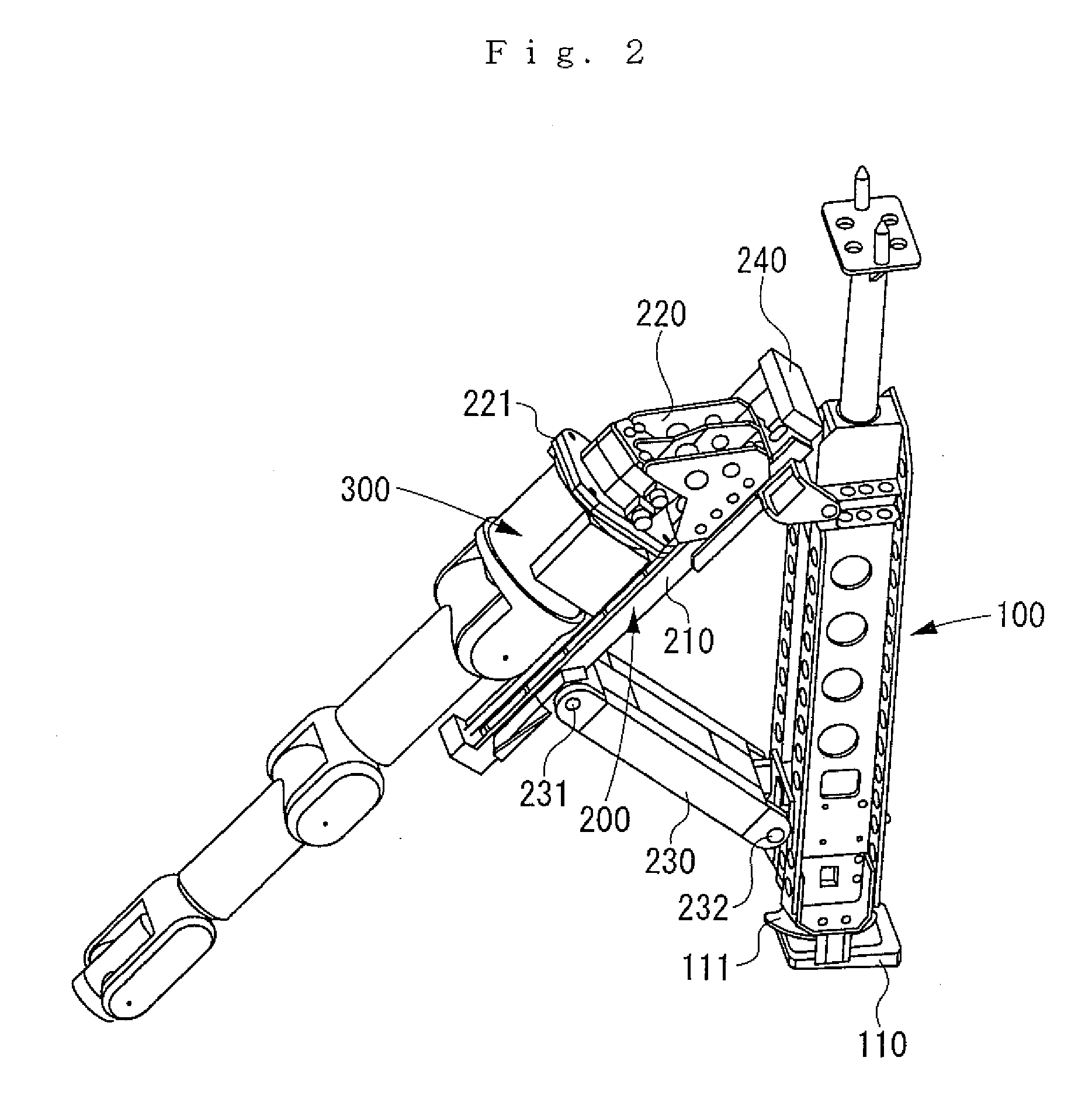

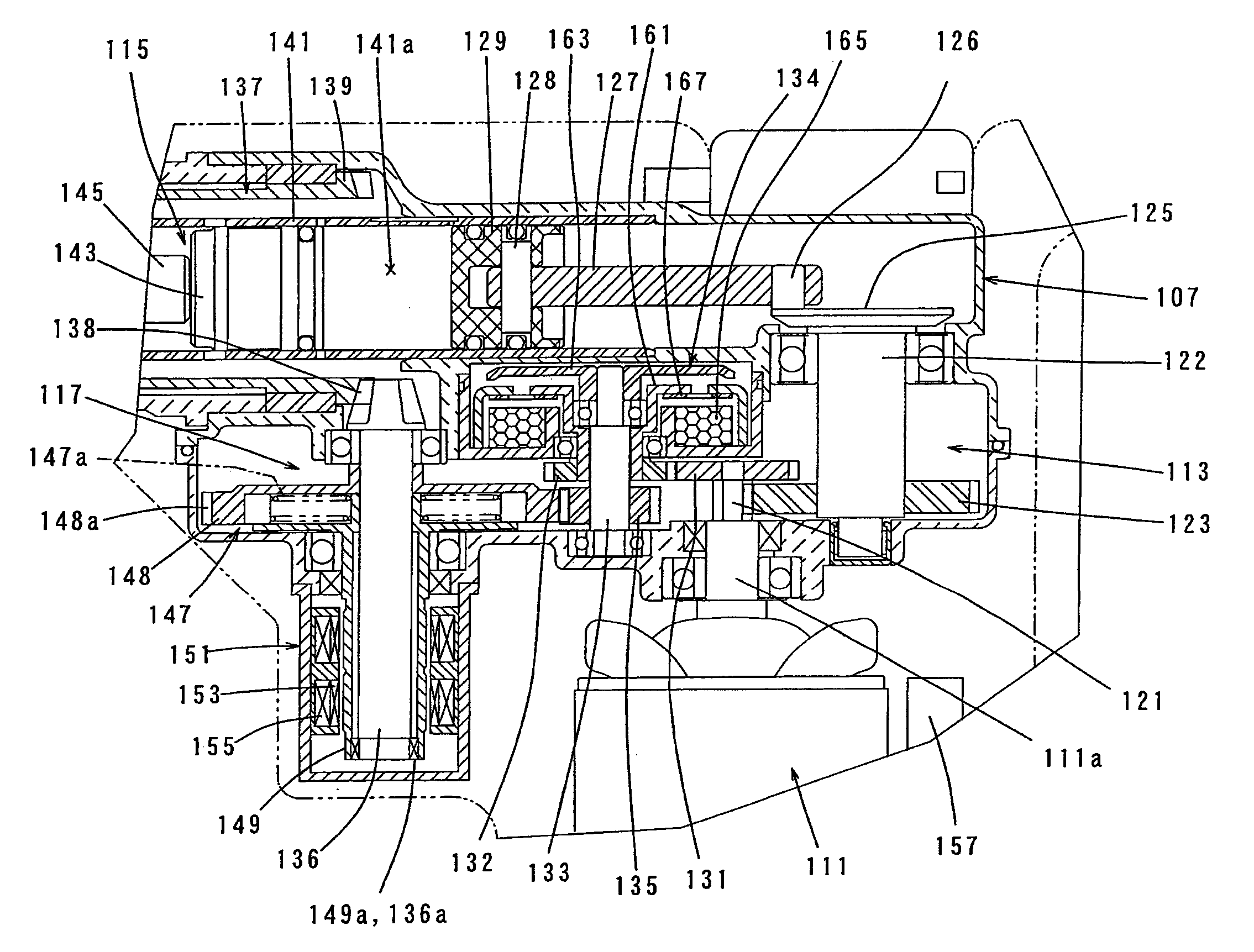

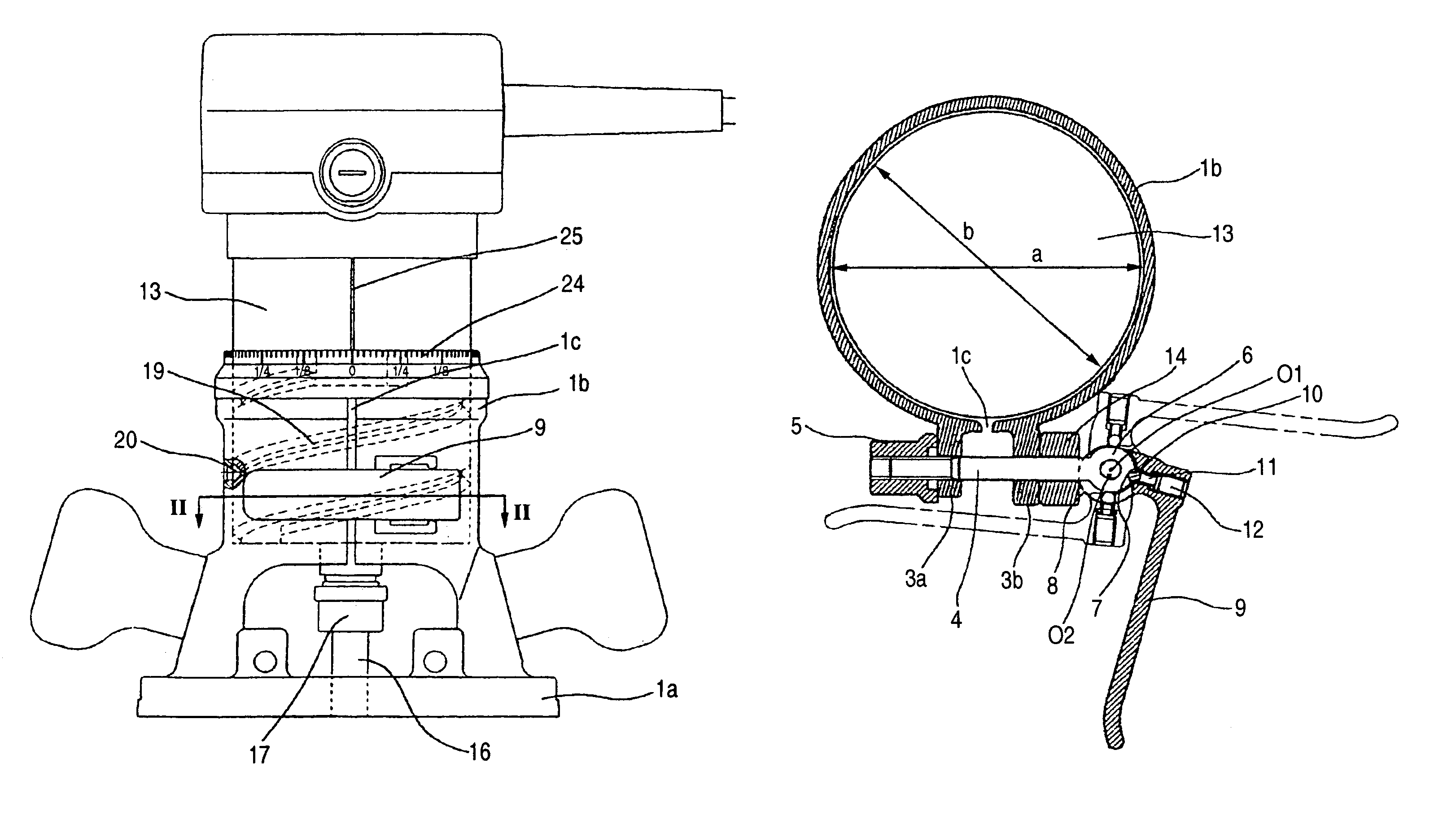

Tip tool guide apparatus and method for bringing in tip tool guide apparatus

ActiveUS20080223106A1Disassembled andShaping toolsForging/hammering/pressing machinesEngineeringManipulator

A tip tool guide apparatus is brought into a water chamber of a steam generator of nuclear power equipment, and guides a tip tool, such as a shot peening head, along a necessary region. For this purpose, a tip tool guide apparatus 1000 is composed of a swivel support portion 100, a slide table 200, and a manipulator 300. The swivel support portion 100 is self-supported and fixed within the water chamber, and turns the slide table 200 connected thereto. The slide table 200 connects the manipulator 300, and moves the manipulator 300 slidingly in a fore-and-aft direction. The manipulator 300 grasps the tip tool at its leading end. For bringing into the water chamber, the swivel support portion 100, the slide table 200, and the manipulator 300 are separated from each other, brought in individually, and assembled within the water chamber to constitute the tip tool guide apparatus 1000.

Owner:MITSUBISHI HEAVY IND LTD

Power tool

ActiveUS9364944B2Reliable detectionEasy to understandGrinding drivesPortable percussive toolsHand heldExercise state

Owner:MAKITA CORP

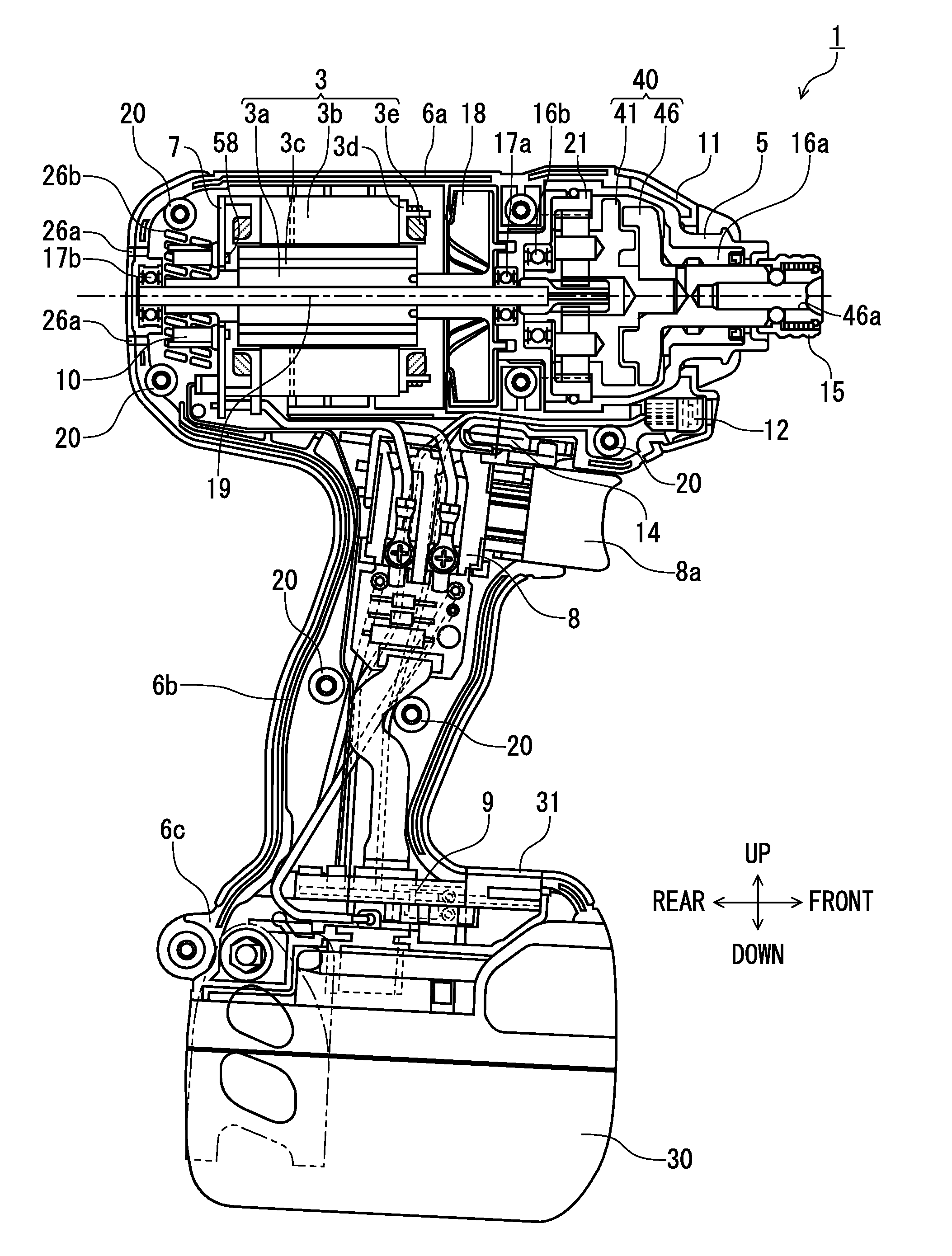

Electric power tool

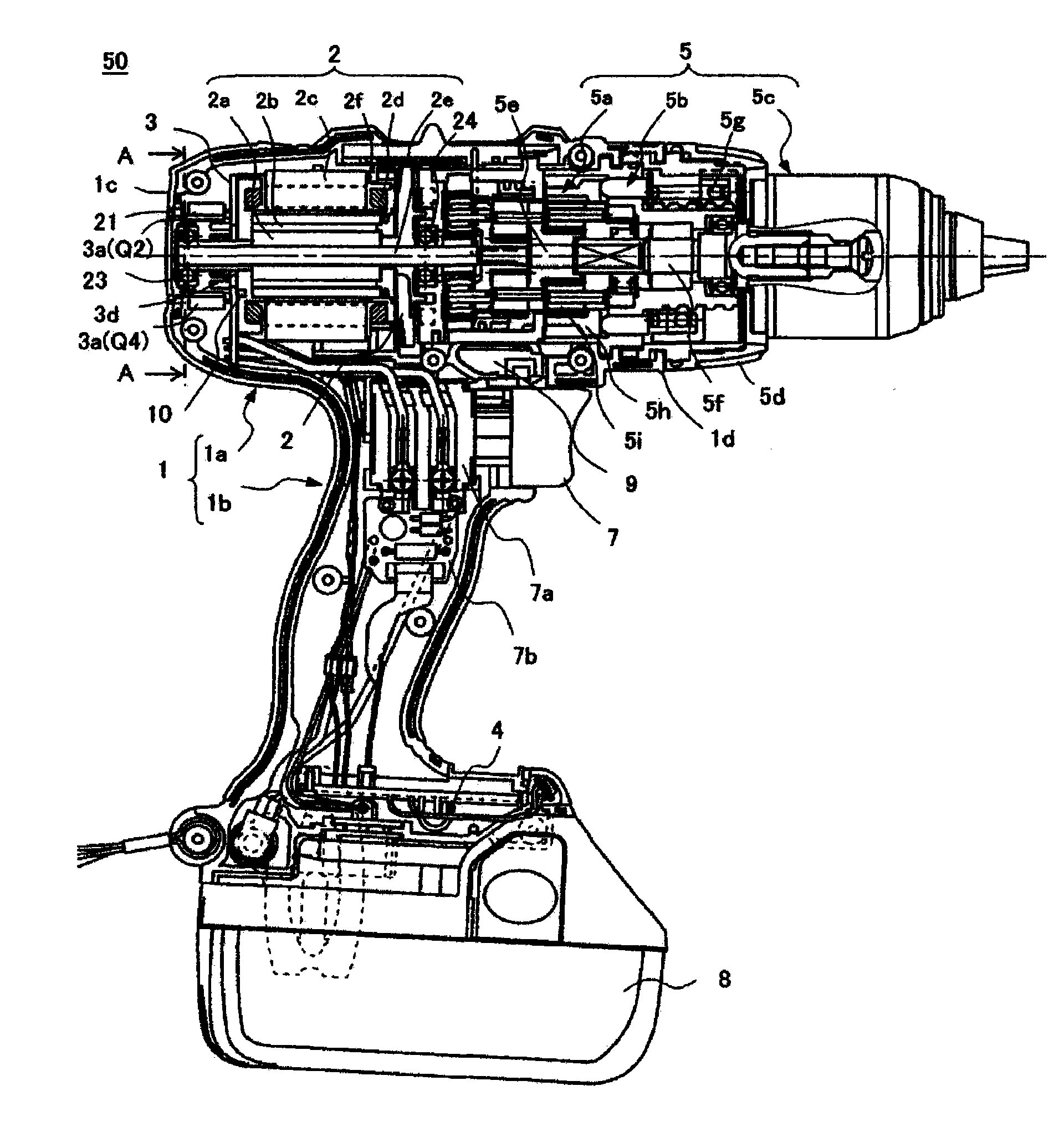

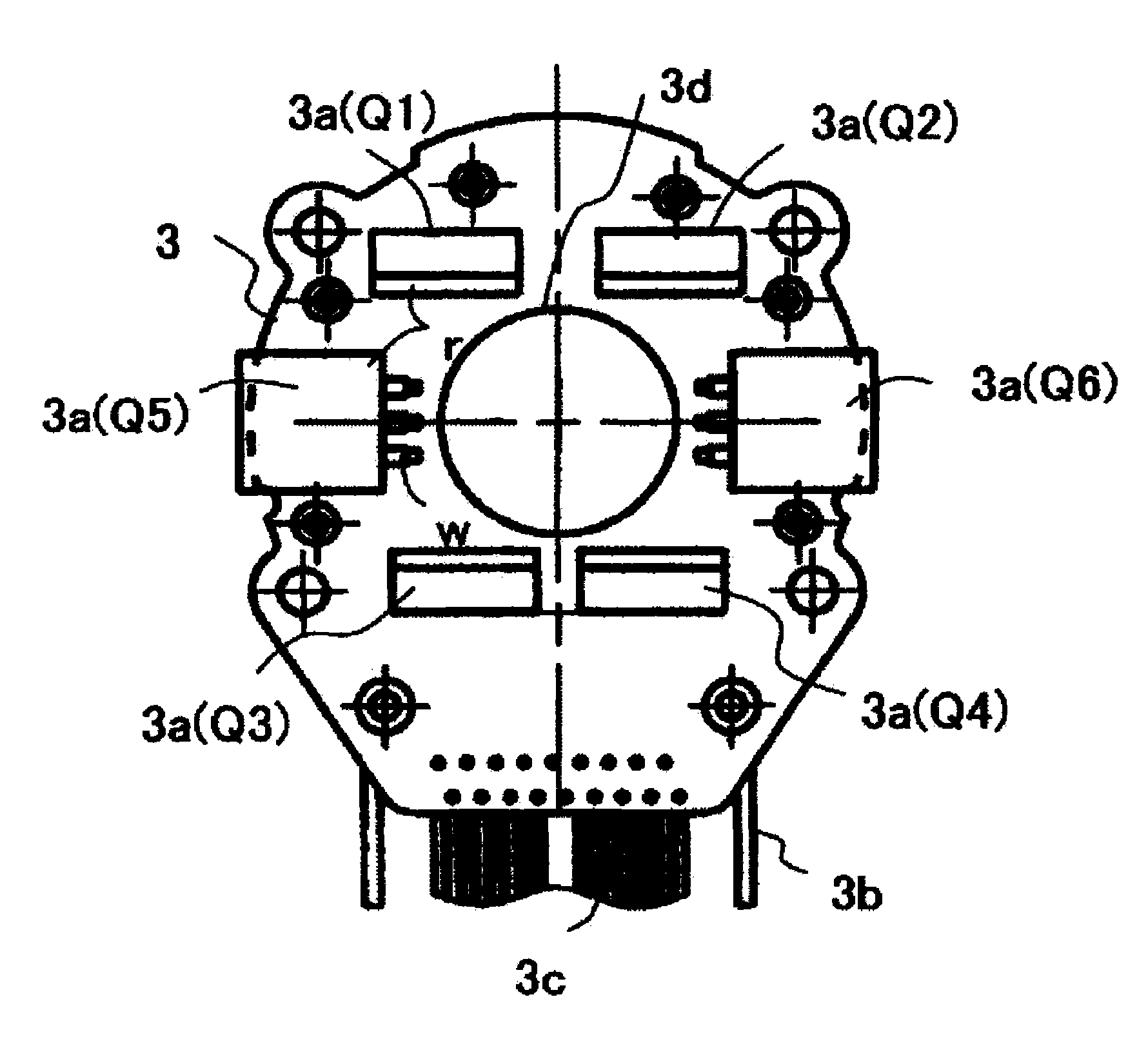

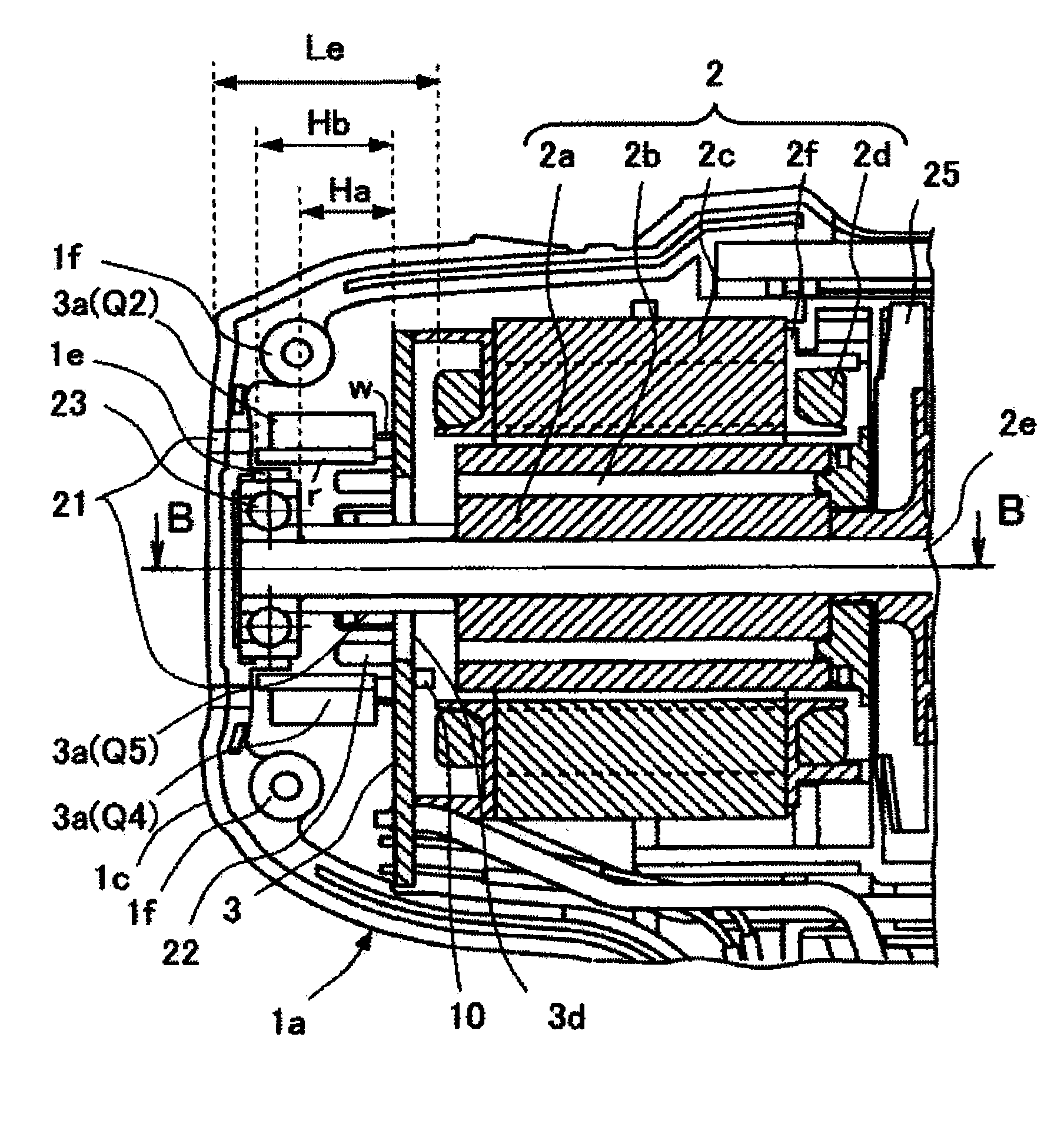

ActiveCN101885178AShorten the lengthSave installation spaceAssociation with control/drive circuitsPortable power-driven toolsElectric power systemEngineering

An electric power tool includes: a motor including a motor shaft; a tip tool driven by the motor; a housing that houses the motor; a switching element for driving the motor; and a bearing that can retain the motor shaft. The switching element is provided so as to overlap with the bearing in a direction of the motor shaft inside the housing.

Owner:HITACHI KOKI CO LTD

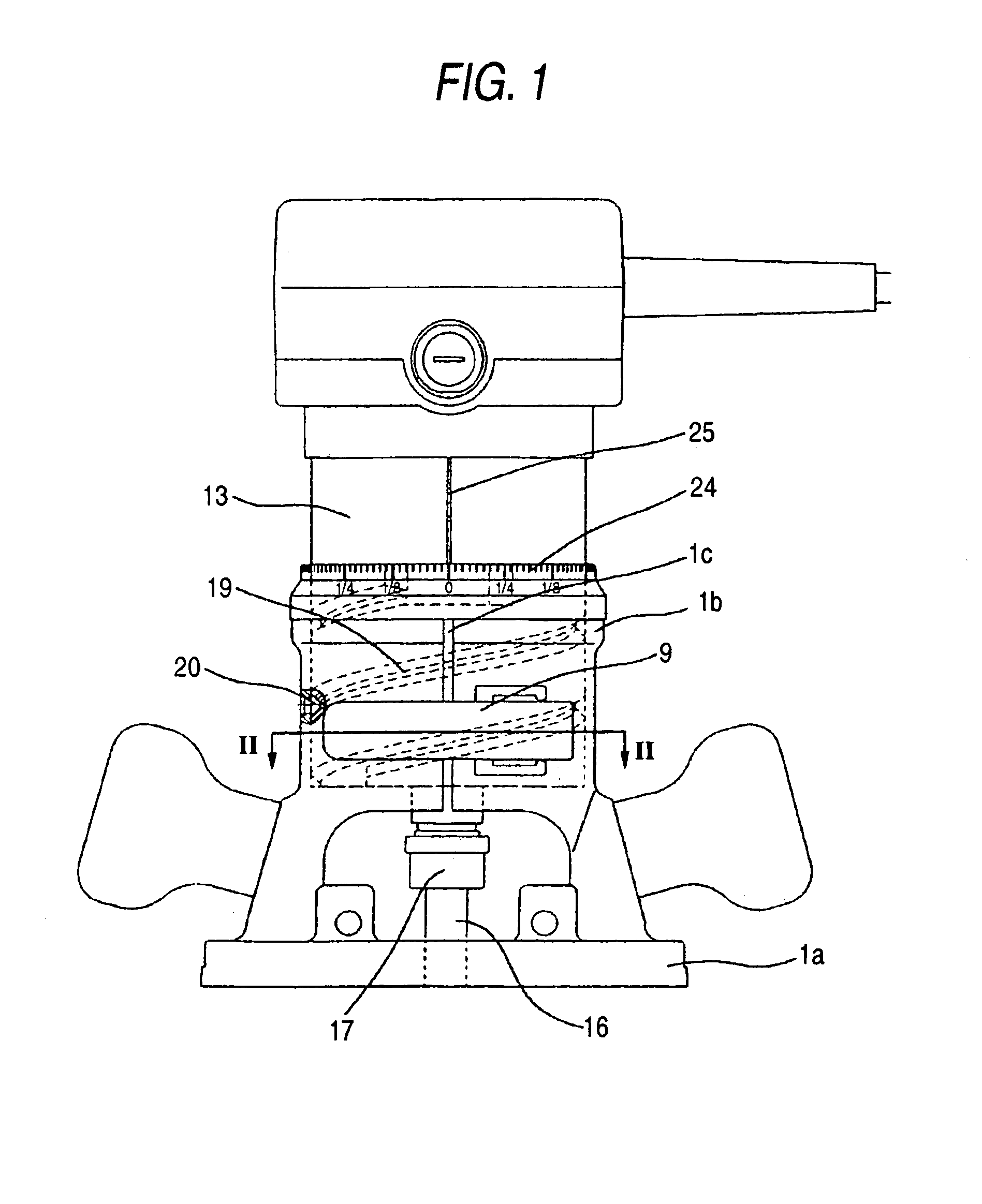

Portable electric tool

ActiveUS7121775B2Easy to operateAdjust the cutting depth accurately and easilyMetal sawing devicesMetal sawing accessoriesRotational axisEngineering

A portable electrical tool includes a tip tool; a cylindrical housing accommodating a motor including a chuck attachably and detachably holding the tip tool at tip end of a rotation shaft; a base including a surface plate which slides on an upper surface of work material, and which allows the tip tool to protrude from the surface plate downwardly, a cylindrical portion including a cutout portion, and a lever having a cam surface, and rotatable to a fixed position and a release position. When the lever is in the fixed position, a gap at the cutout portion is narrowed to stop movement of the cylindrical housing. When the lever is in the release position, the cylindrical housing is movable by weight in the cylindrical portion. The tool includes a stopper to stop a rotation of the lever between the fixed position and the release position.

Owner:KOKI HLDG CO LTD

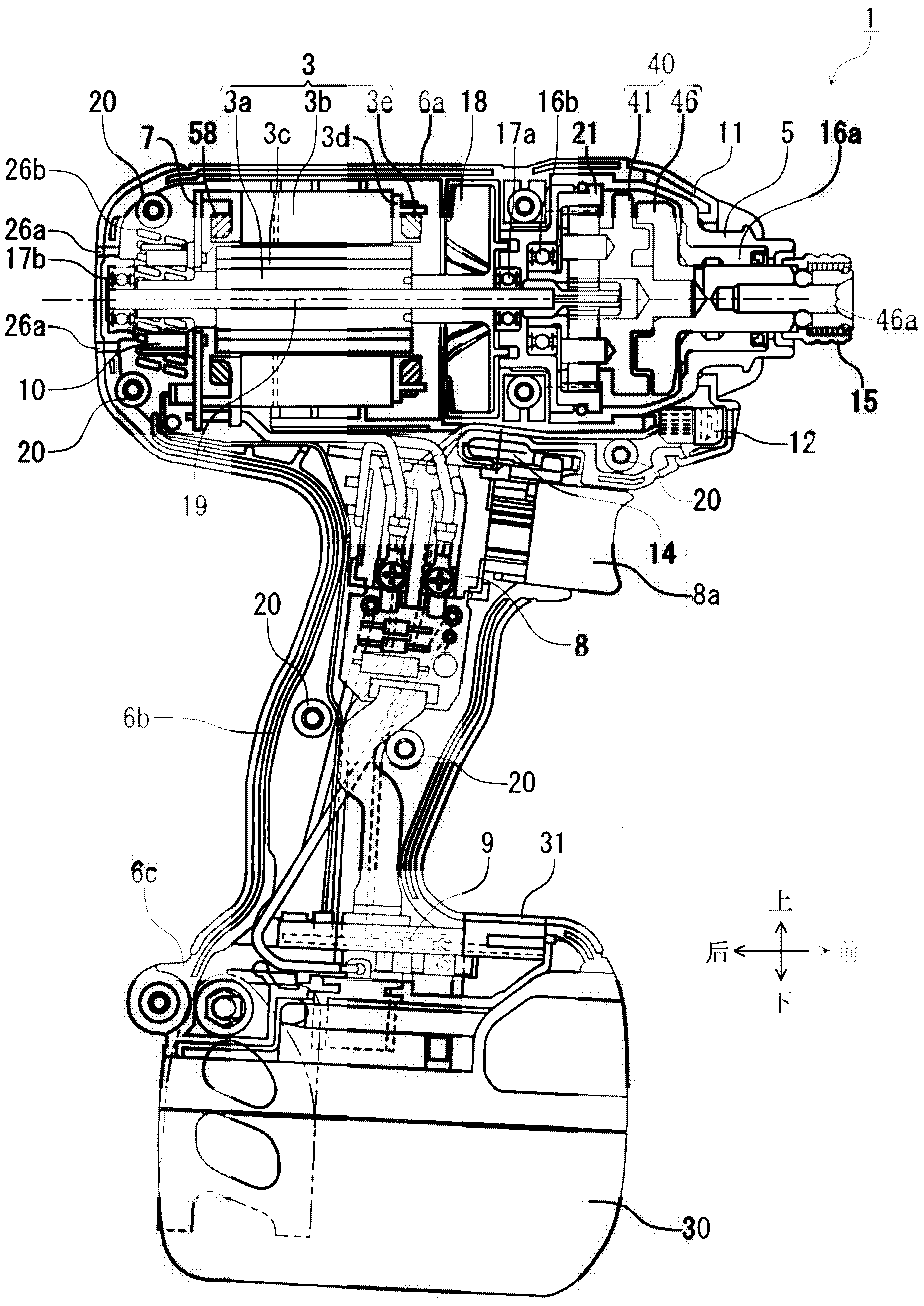

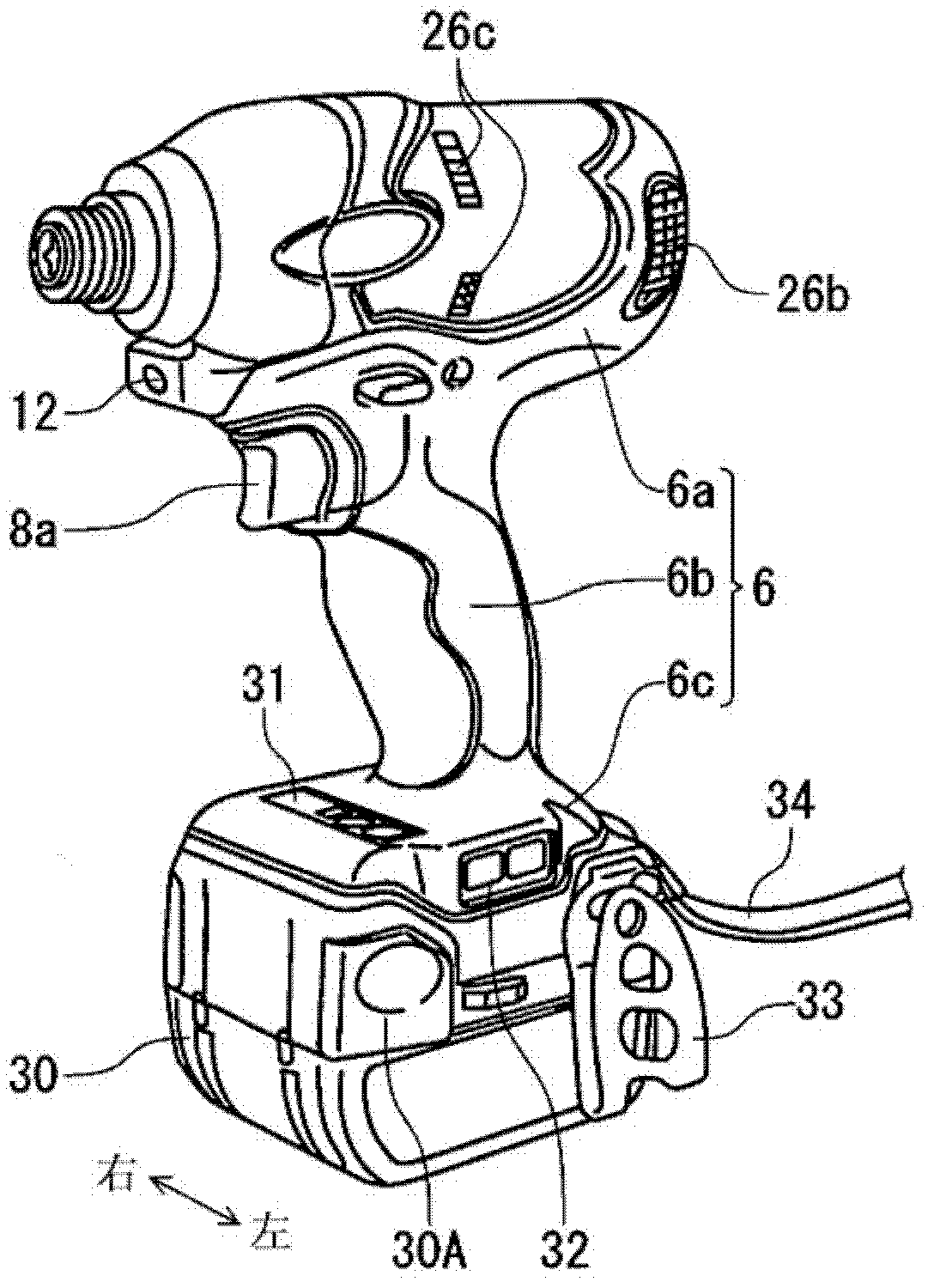

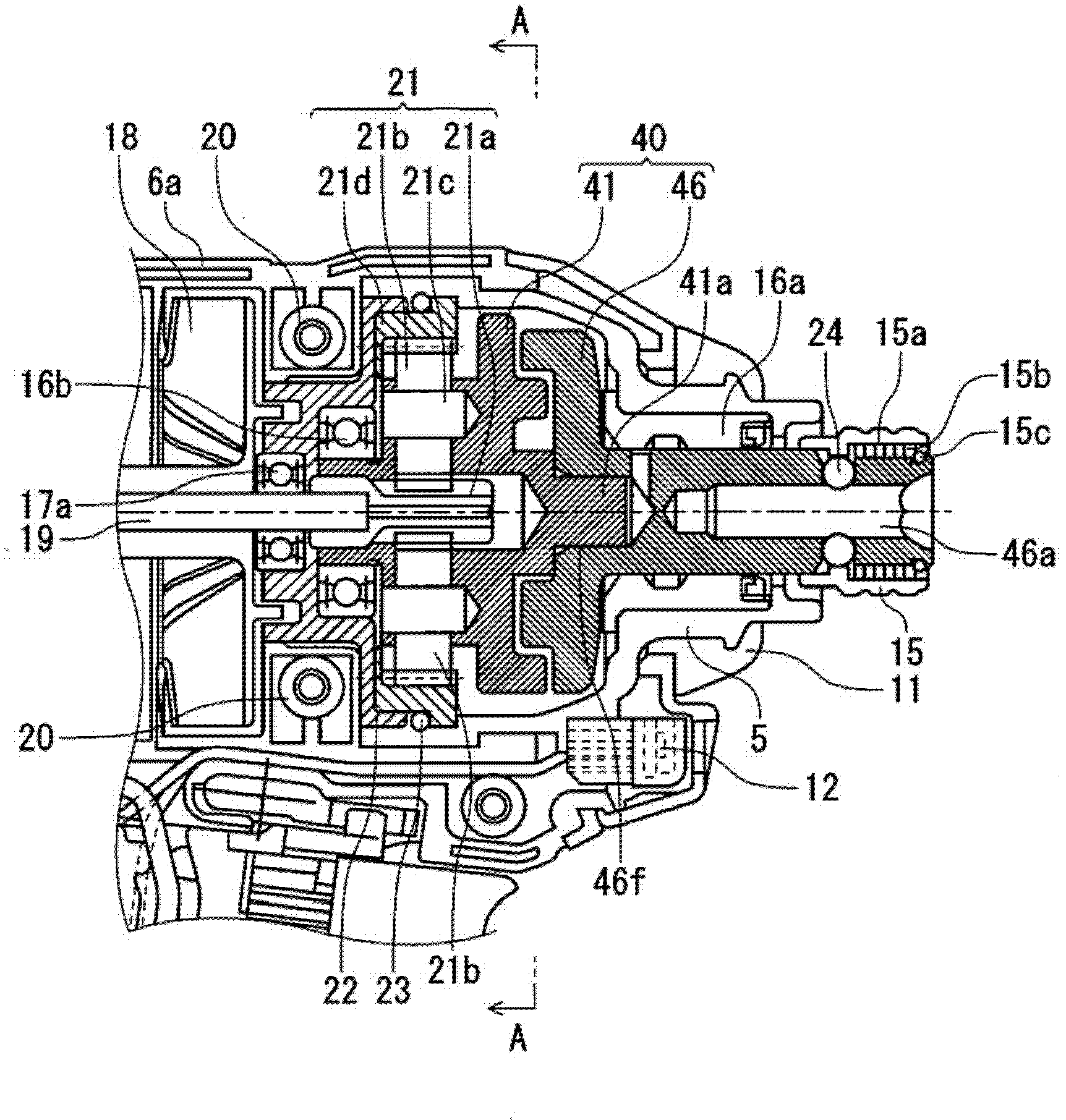

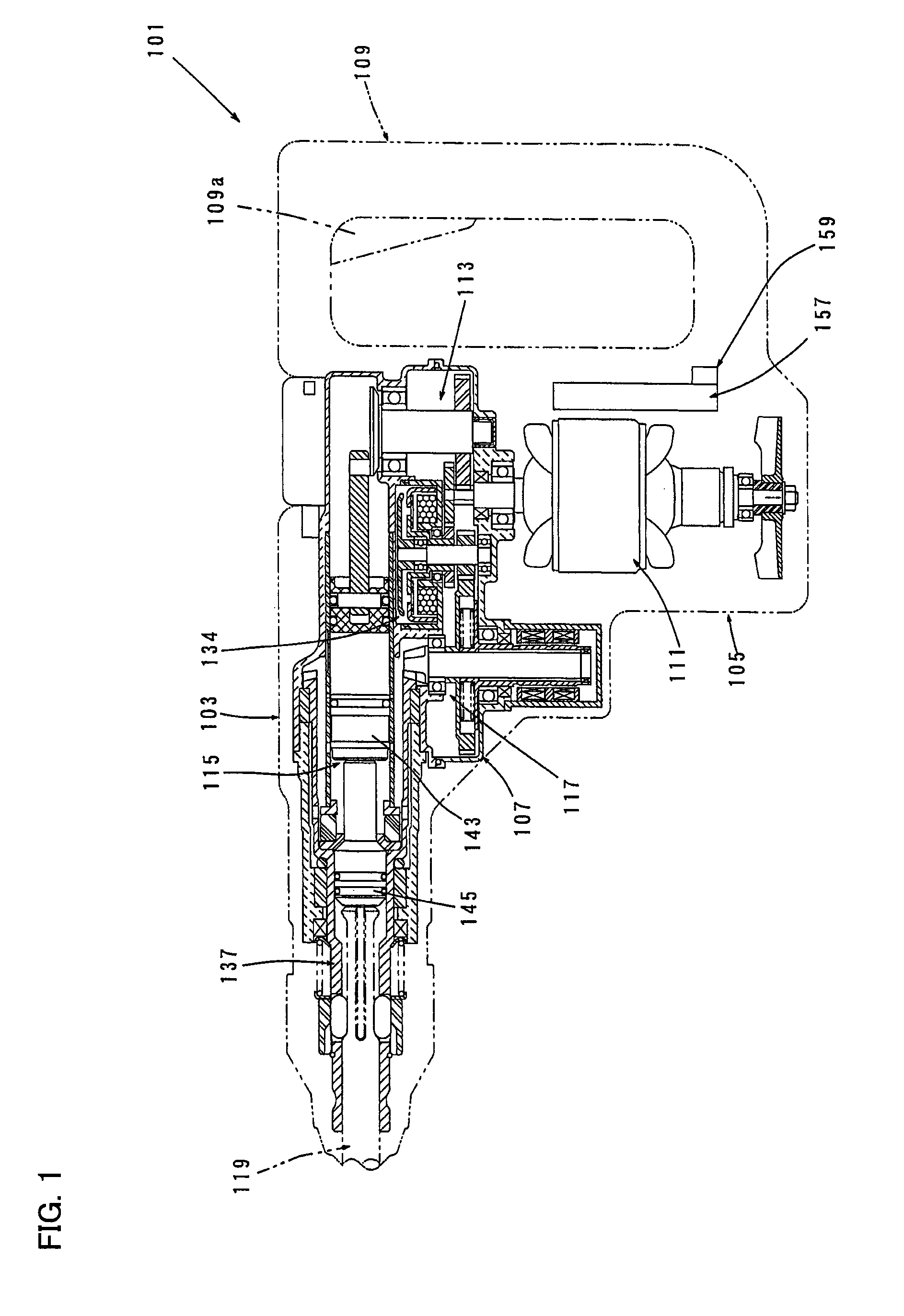

Power tool

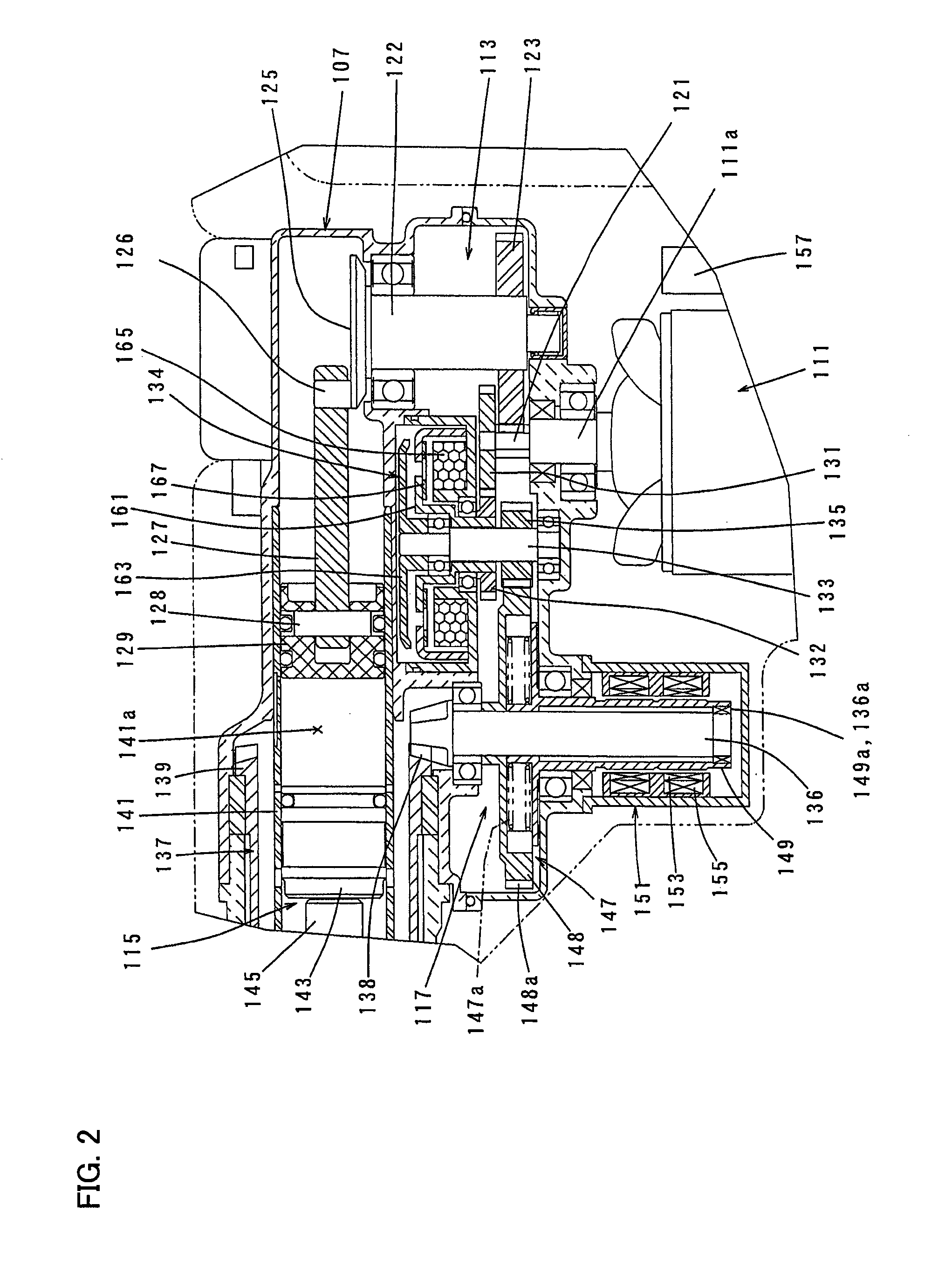

InactiveUS20130255982A1Reduced durabilityIncrease flow resistancePortable power-driven toolsPower driven toolsReduction driveReducer

A power tool, in which a case that is connected to a housing and the case houses a reducer mechanism that decelerates an output of an electric motor and an impact mechanism that transmits an output of the reducer mechanism to a tip tool, is provided. The power tool further includes an inner cover that covers an opening of the case, a ring gear included in the reducer mechanism, a spindle that is rotatably supported by a bearing, and a space portion that is placed between the inner cover and the ring gear and in a periphery of the bearing, and capable of stocking grease. A through hole, which communicates with the inside and outside of the case through the space portion, is formed in the inner cover.

Owner:HITACHI KOKI CO LTD

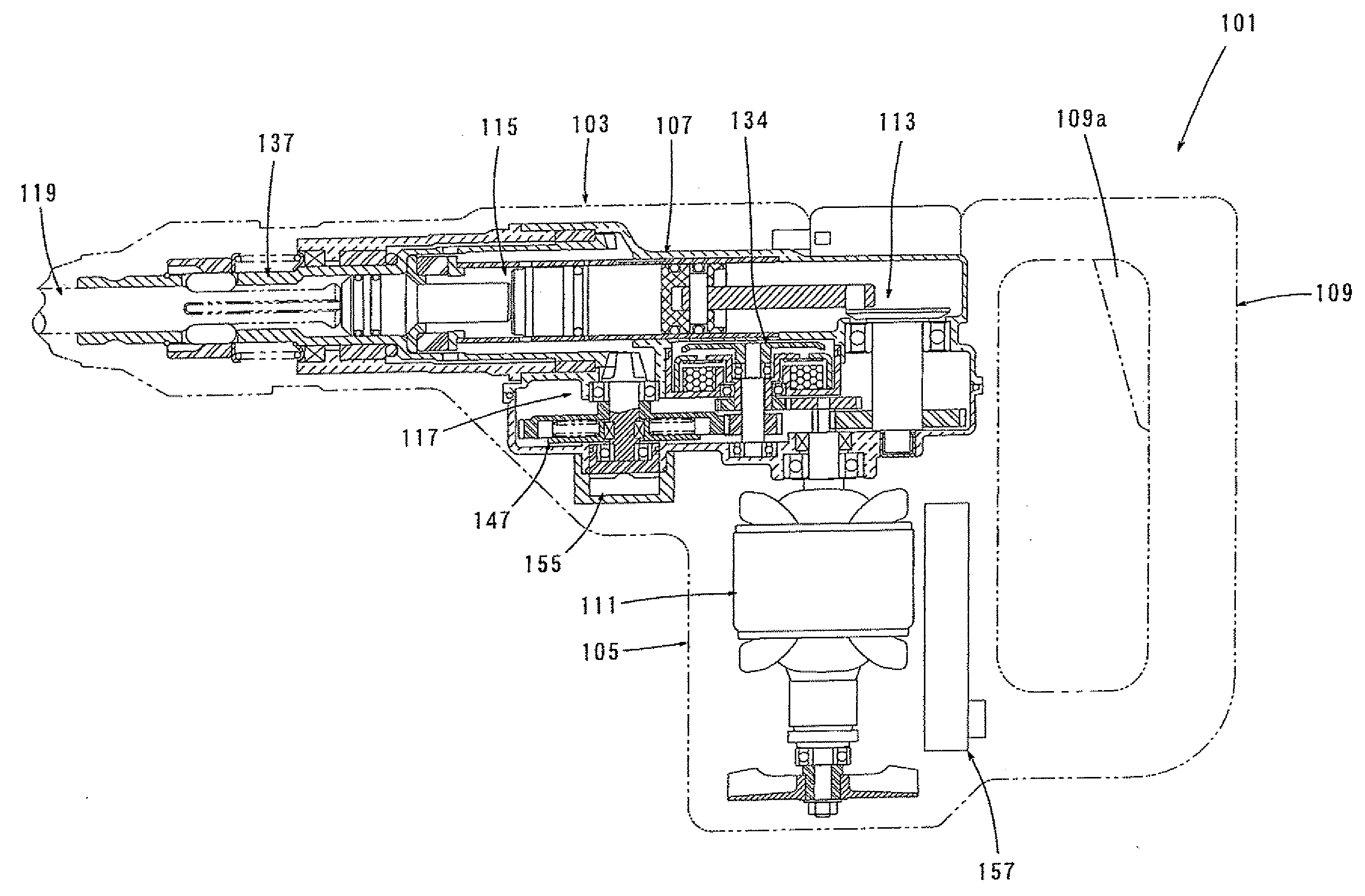

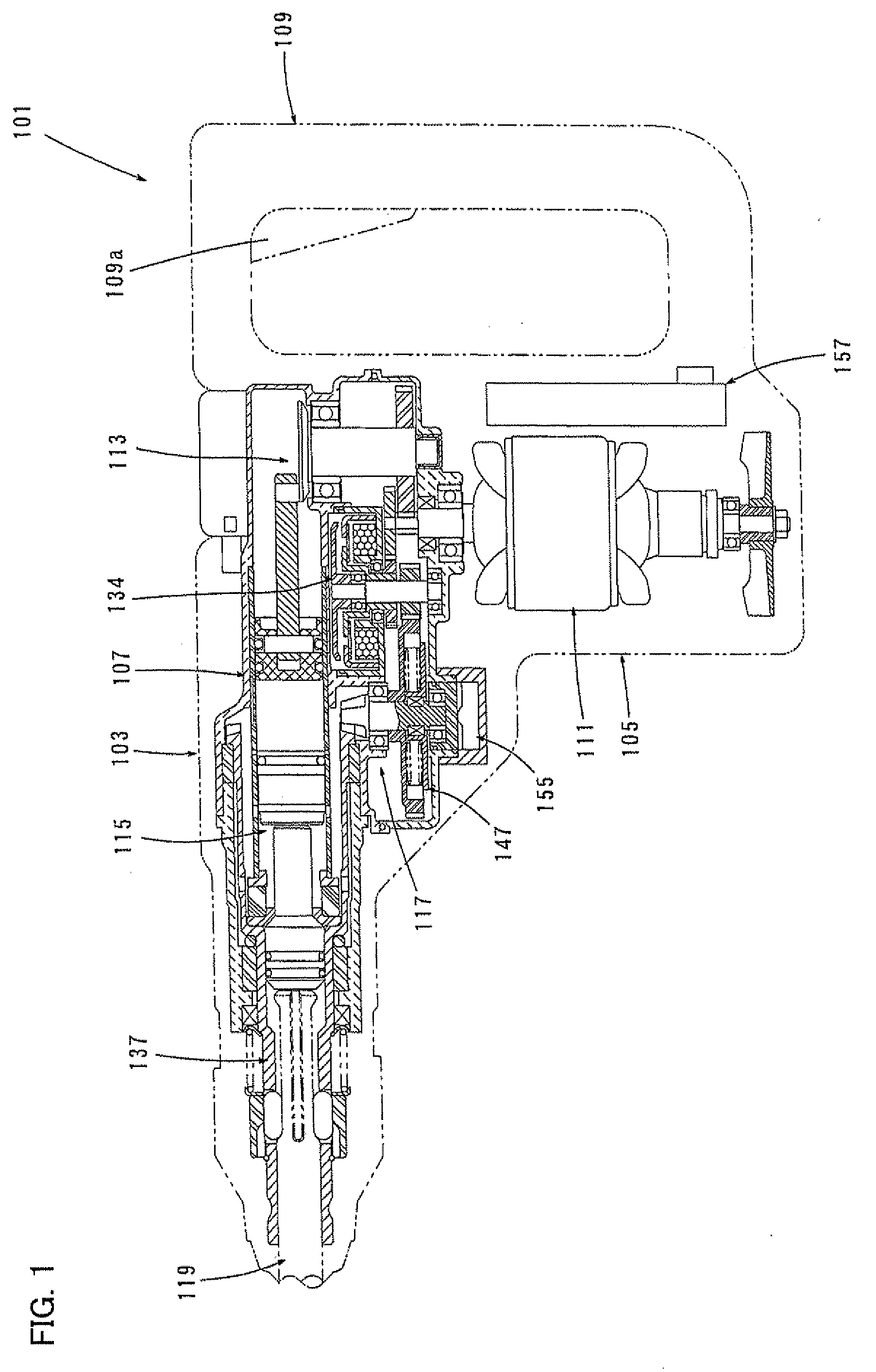

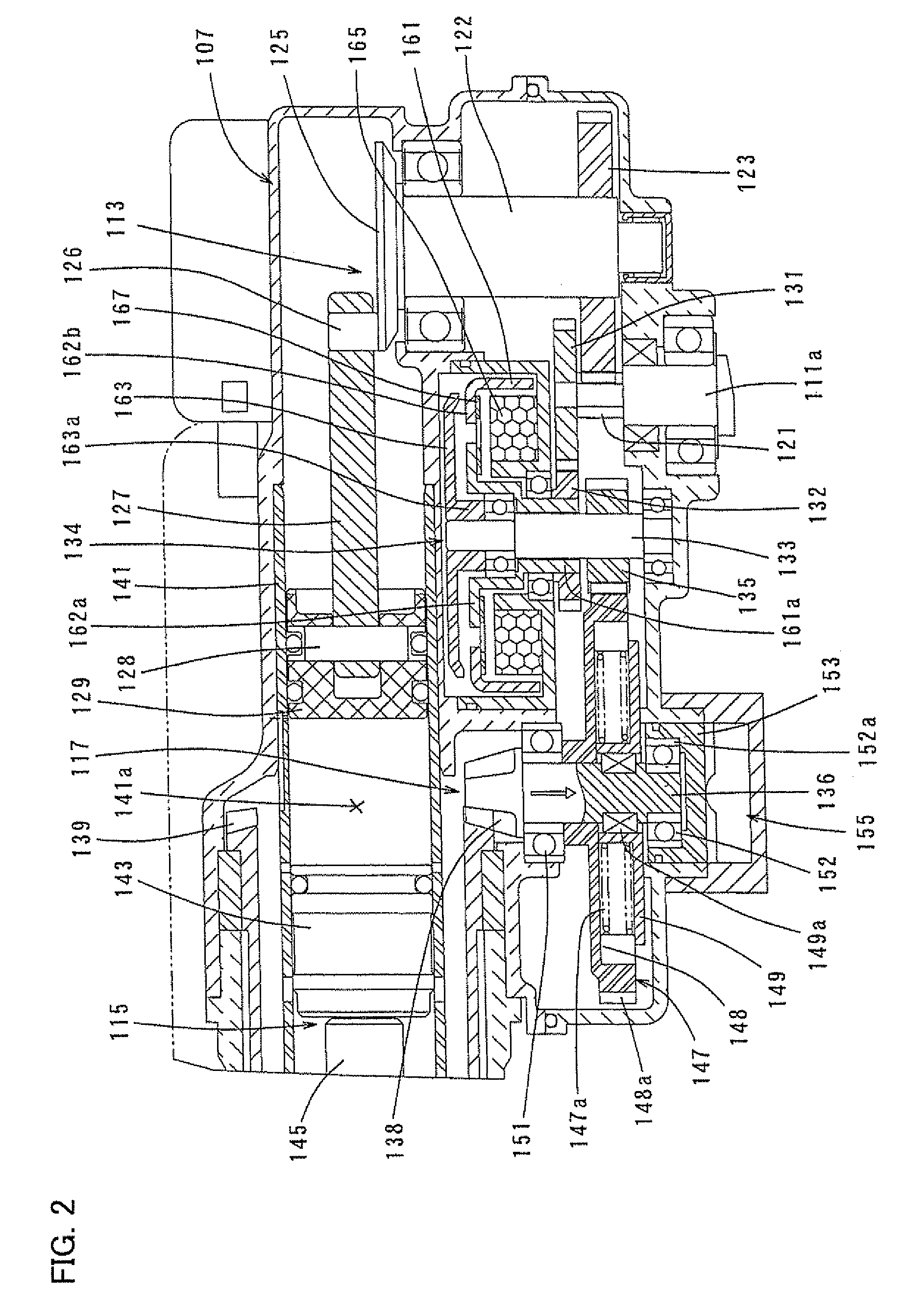

Powered working machine

ActiveUS9669536B2Convenience to workMetal sawing devicesSleeve/socket jointsEngineeringMechanical engineering

A powered working machine facilitating work of fixing a tip tool to a tool supporting member is provided. A powered working machine in which a tip tool is driven by power of an electric-powered motor includes: an output shaft to which the tip tool is attached; a tool fixing member which fixes the tip tool to the output shaft; a second shaft to / from which the tool fixing member is attached / detached; a clamp having a locked state in which a state of attachment of the tool fixing member to the second shaft is maintained and an unlocked state in which the tool fixing member can be detached from the second shaft; and a guide member having a first rotation position at which the clamp is in the locked state and a second rotation position at which the clamp is in the unlocked state.

Owner:KOKI HLDG CO LTD

Electric tool

ActiveUS20120289377A1Simple structureEasy to understandPortable percussive toolsElectric controllersEngineeringAxial force

An electric tool causes a drive mechanism to drive a tip tool to thereby cause the tip tool to perform predetermined work, and the drive mechanism is provided with a driving gear and a driven gear which meshes with the driving gear. The electric tool is configured in such a manner that an axial force or a radial force generated by the meshing between the driving gear and the driven gear is measured to detect the state of torque acting on the tip tool, and drive control of the drive mechanism is performed according to the detected state of torque.

Owner:MAKITA CORP

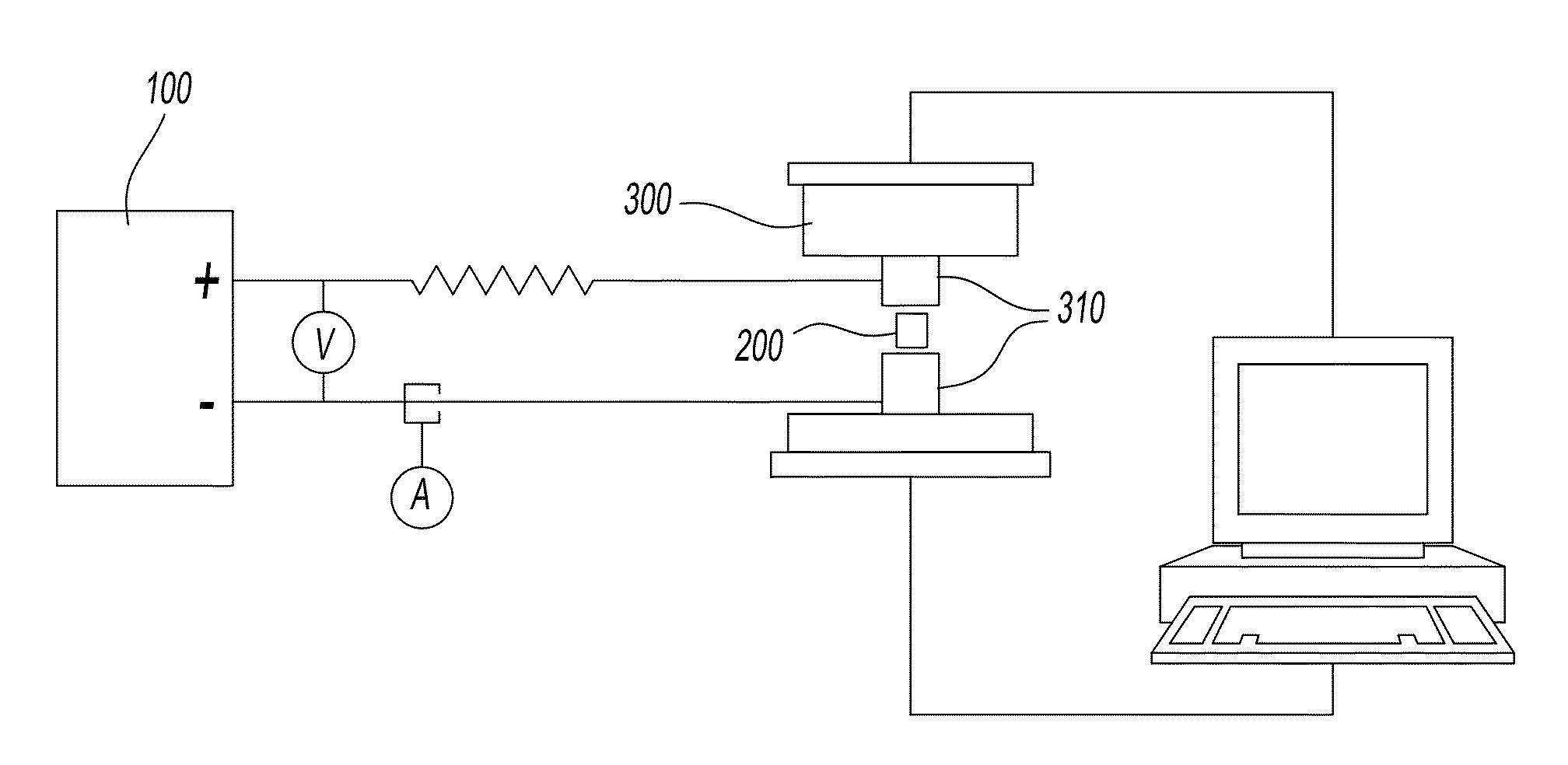

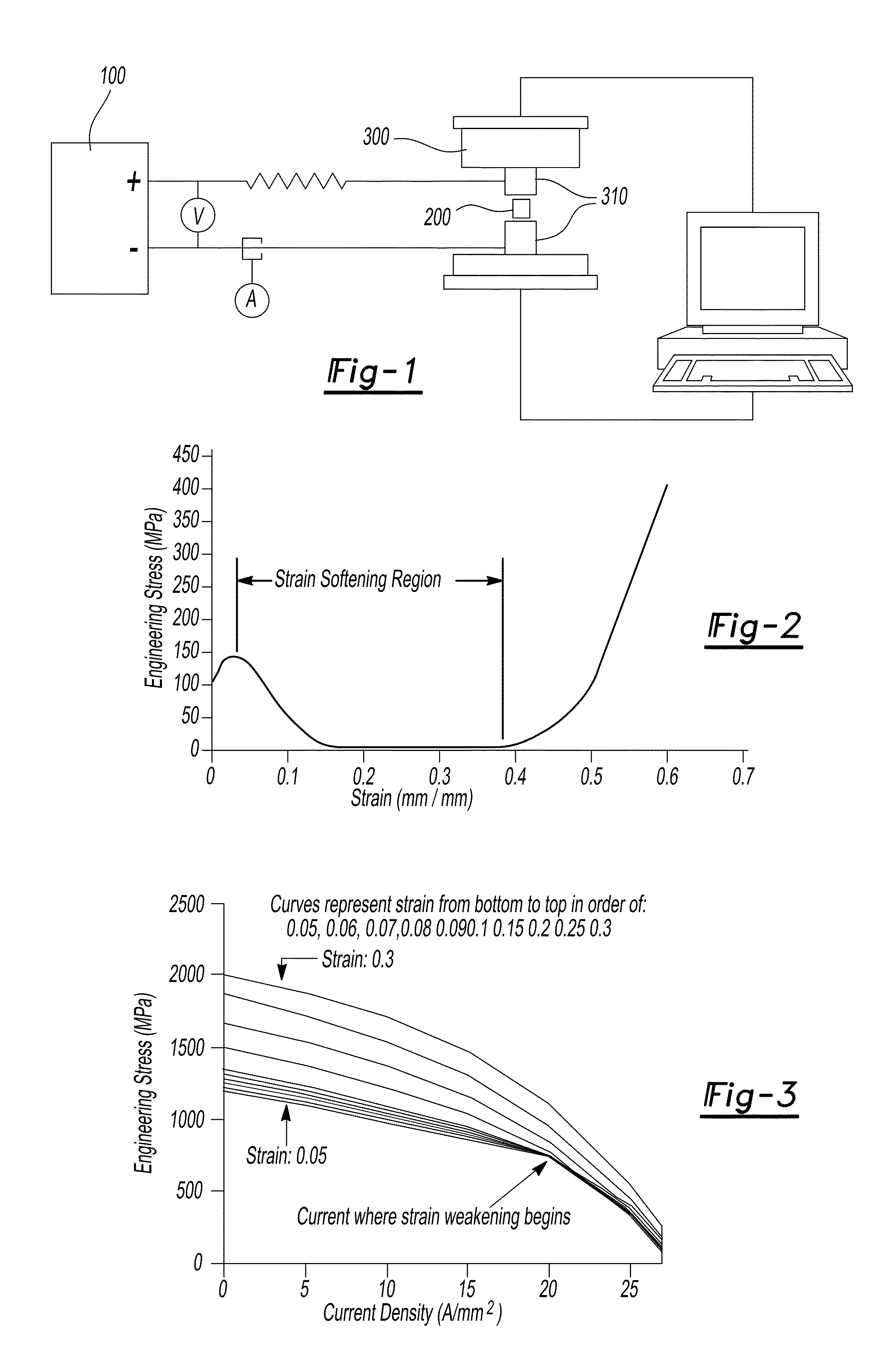

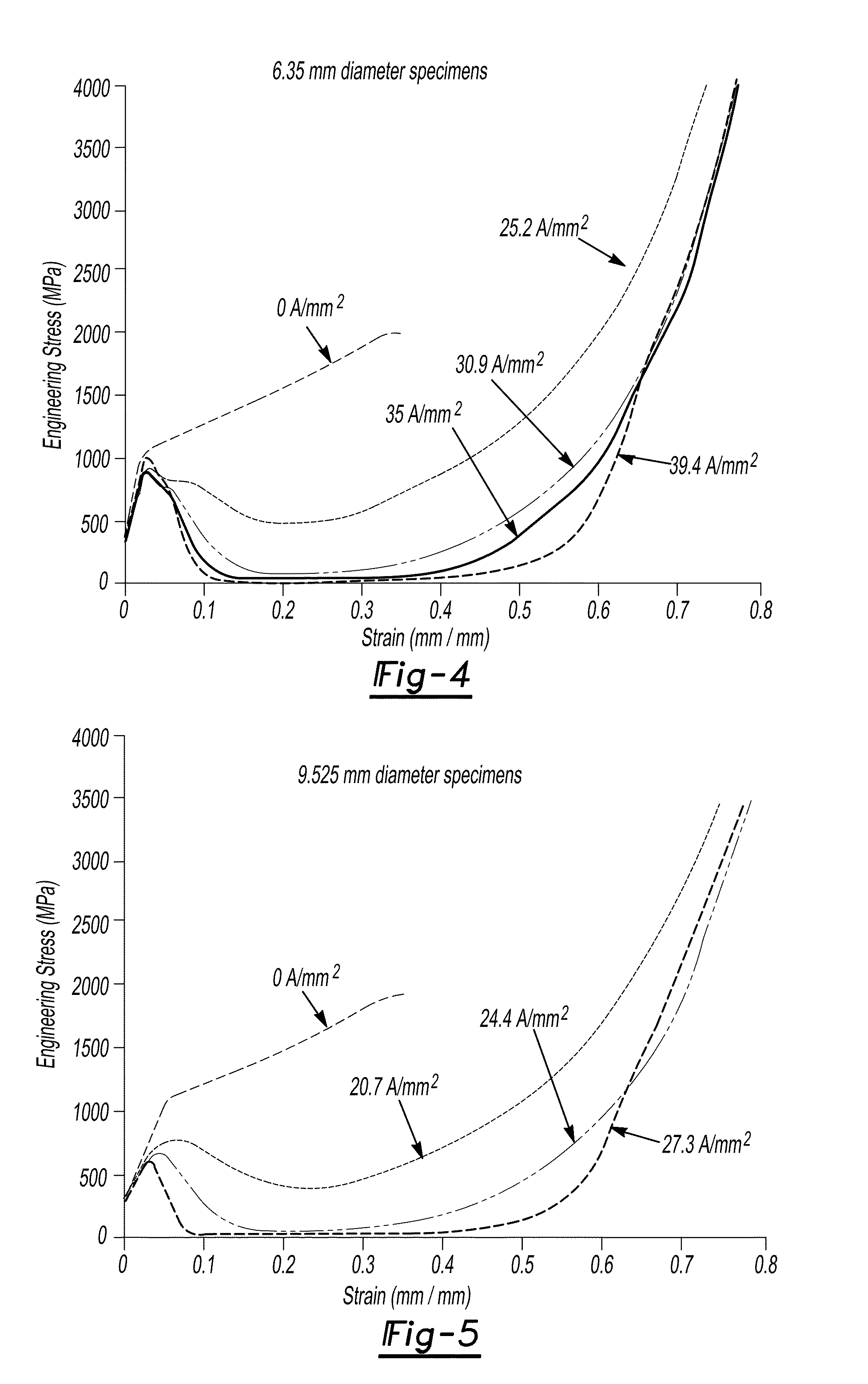

Apparatus for electrical-assisted incremental forming and process thereof

A process and apparatus for forming a sheet metal component using an electric current passing through the component. The process can include providing an incremental forming machine, the machine having at least one arcuate tipped tool and at least electrode spaced a predetermined distance from the arcuate tipped tool. The machine is operable to perform a plurality of incremental deformations on the sheet metal component using the arcuate tipped tool. The machine is also operable to apply an electric direct current through the electrode into the sheet metal component at the predetermined distance from the arcuate tipped tool while the machine is forming the sheet metal component.

Owner:PENN STATE RES FOUND +1

Electric tool

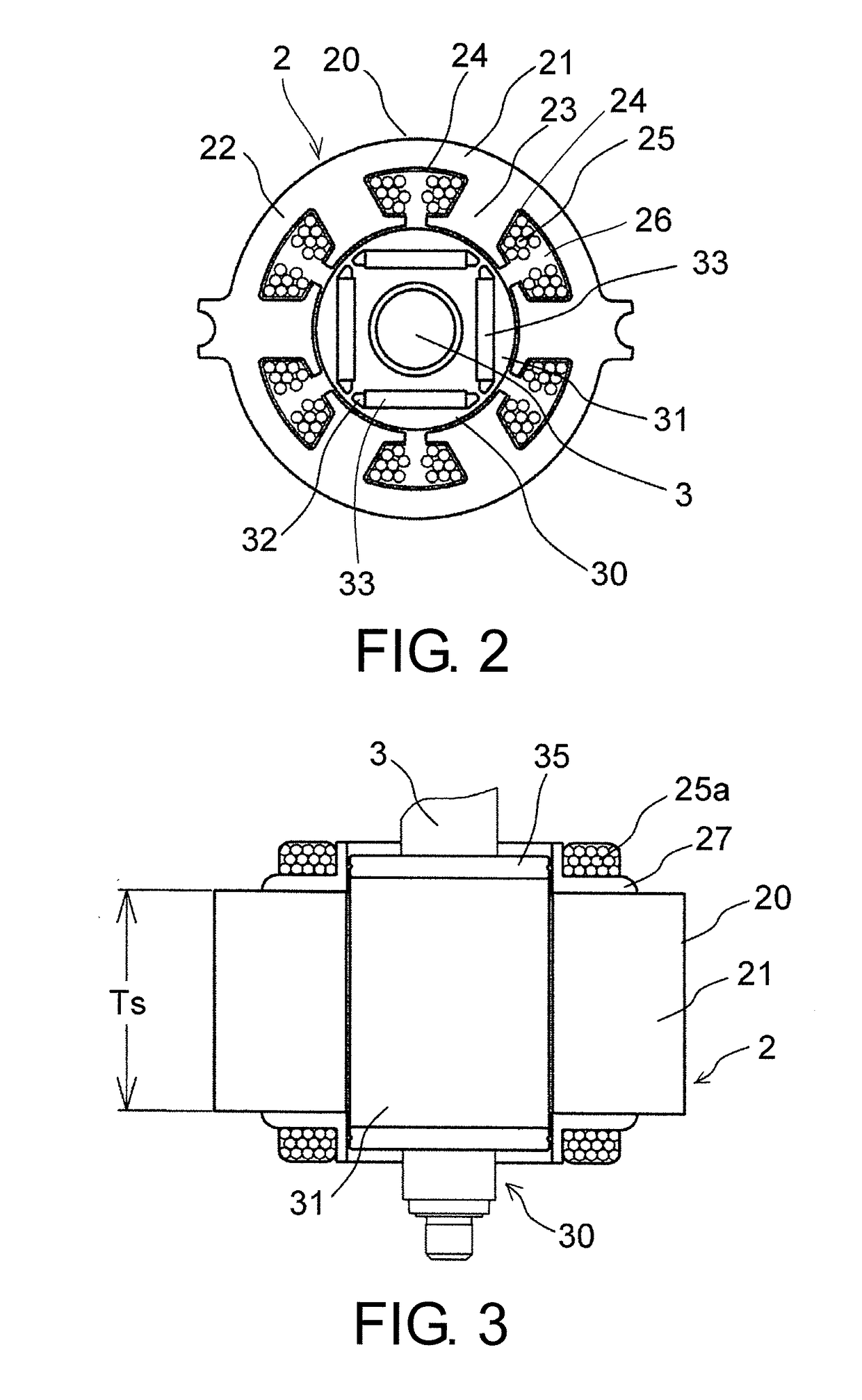

ActiveUS20170194846A1Magnetic circuit rotating partsMagnetic circuit stationary partsMotor speedBrushless motors

An electric tool is provided with a rotary striking mechanism unit converting the rotational force of a brushless motor to a striking force and applying the striking force to a tip tool. The required rated input of the motor is 1000-1300 W, the motor speed under fixed speed control is 16800±10% (min−1), and the variable Ku, which relates to the motor, is defined by the following expression Ku={(stator core outer diameter)2×(stator core lamination thickness)×(total tooth width)×(rotor outer diameter)}÷{(rated input)×(motor speed under fixed speed control)}, wherein the stator core outer diameter, the stator core lamination thickness, the total tooth width and the rotor outer diameter are shown in mm, the rated input is shown in W, the motor speed is shown in min−1, and the Ku value of the motor is set to 14.6←Ku←21.8.

Owner:HITACHI KOKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com