Electric power tool

A technology of electric tools and electric motors, applied in the direction of manufacturing tools, electric components, electrical components, etc., can solve the problems of large power loss, heat damage, damage, etc., and achieve the effect of shortening the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. In addition, in all the drawings for explaining the embodiment, the members or elements having the same functions are assigned the same reference numerals, and overlapping descriptions are omitted.

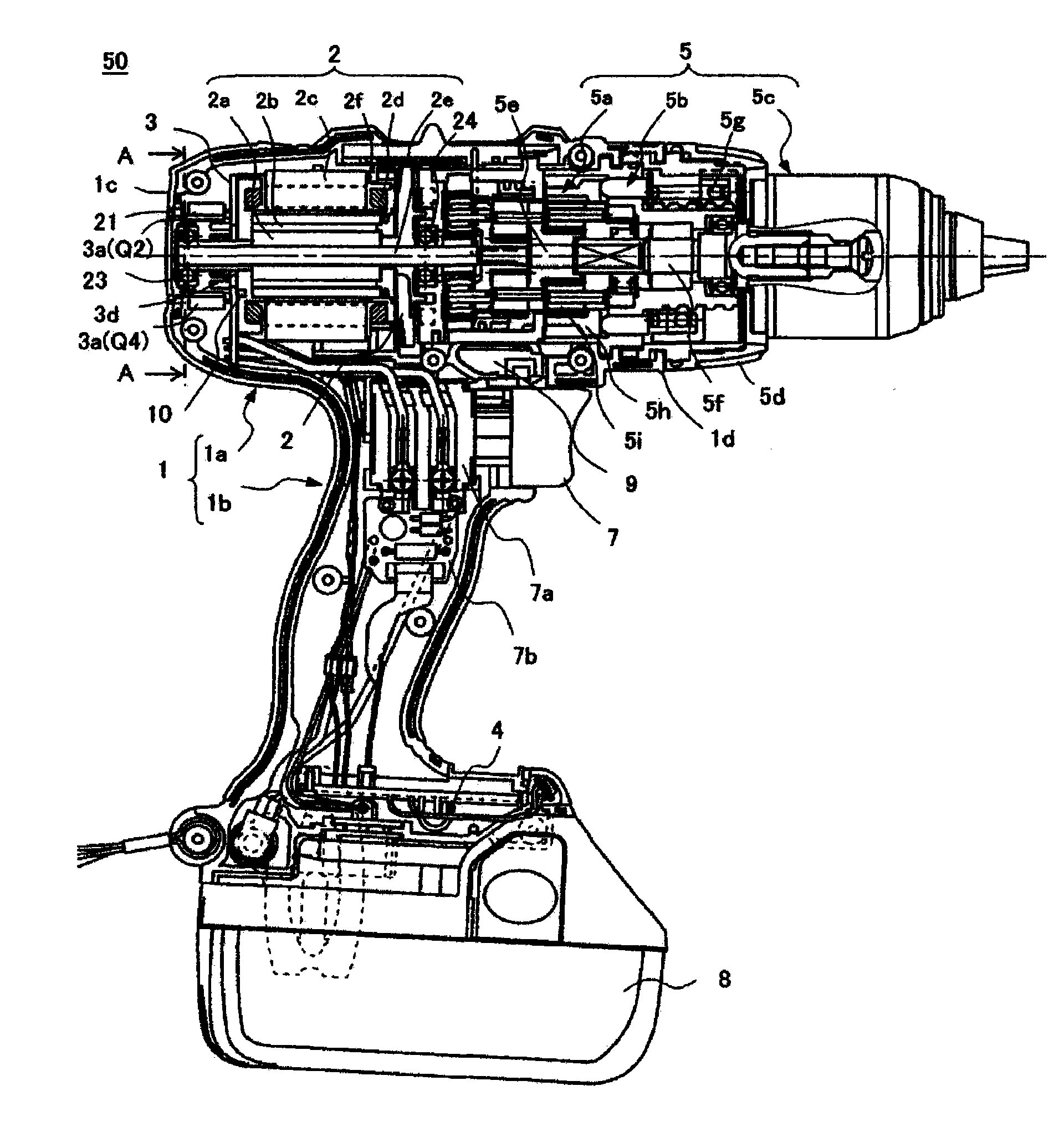

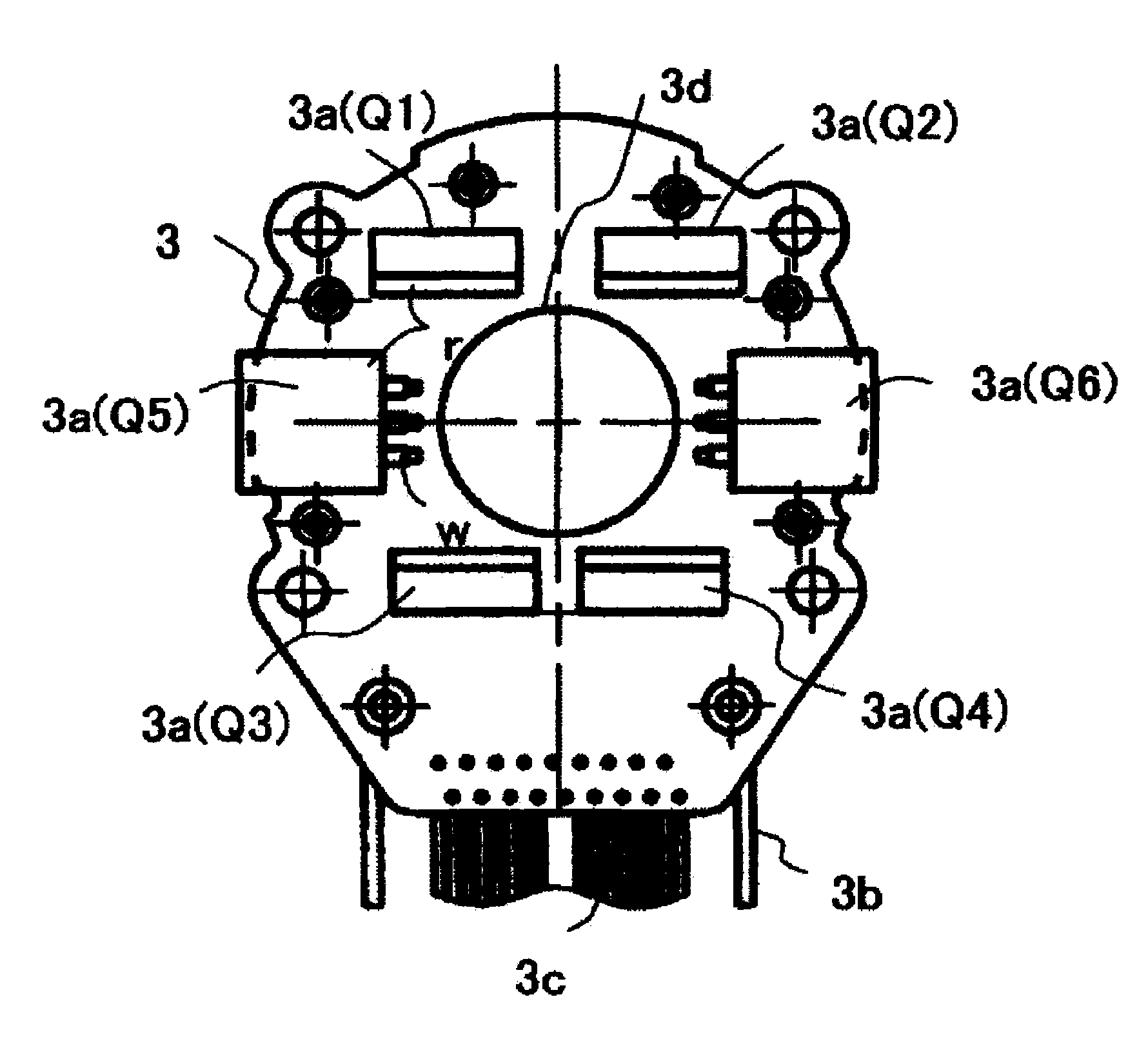

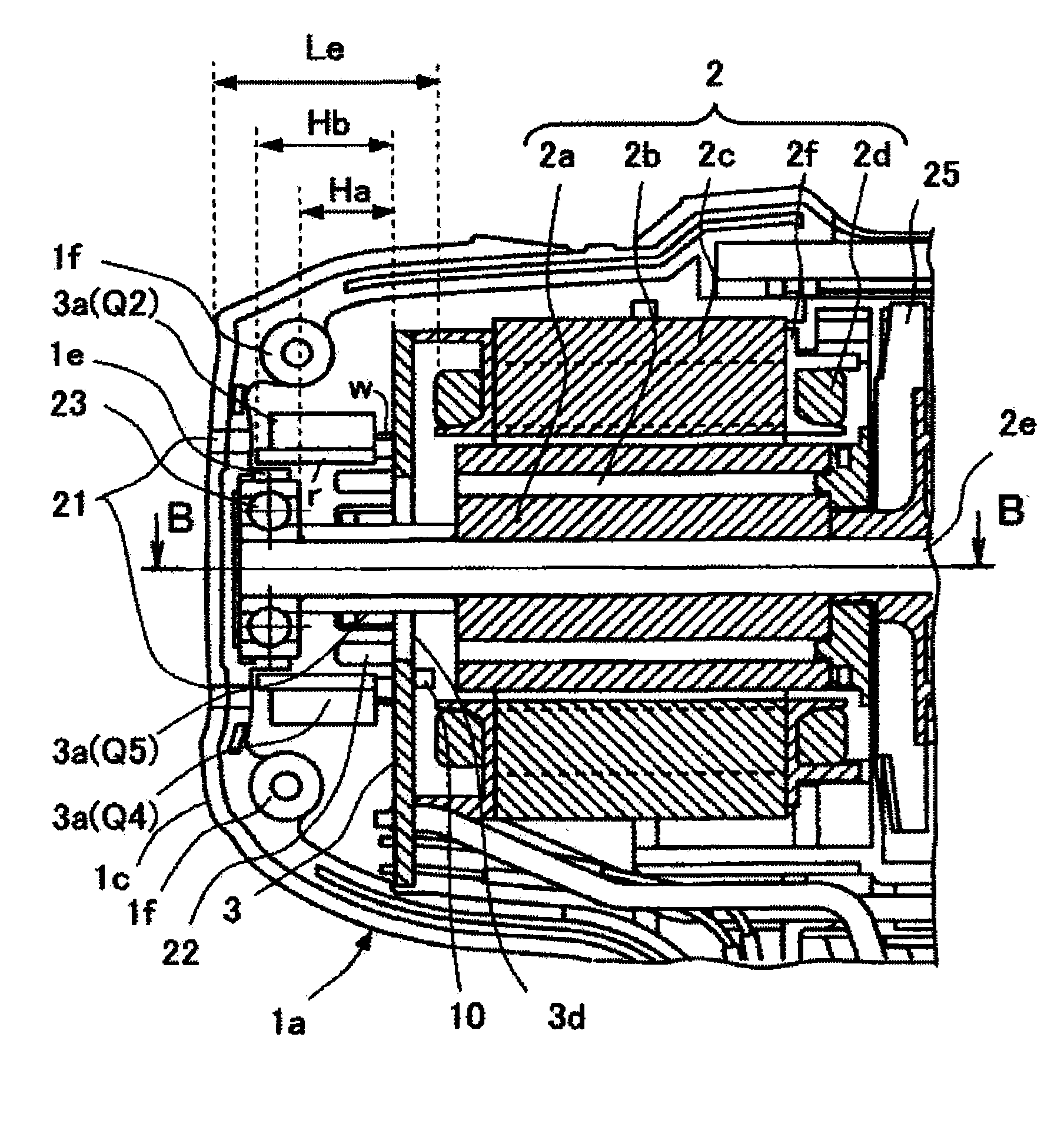

[0046] figure 1 It is a cross-sectional part showing the overall structure of the internal power type electric screwdriver drill according to one embodiment of the present invention, figure 2 is directed at figure 1 The top view of the inverter circuit substrate viewed from the A-A line of the driver electric drill shown, image 3 yes figure 1 The enlarged structural diagram of the key parts of the screwdriver electric drill shown, Figure 4 yes image 3 The B-B line sectional view of the enlarged structural diagram of the main part shown, Figure 5 From Figure 4 The top view of the inverter circuit substrate observed by the D-D line, Figure 6 yes figure 1 Functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com