Low temperature high activity carbon dioxide methanation catalyst and preparation method thereof

A methanation catalyst, carbon dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrocarbon production from carbon oxides, etc. It is suitable for large-scale production and other problems, and achieves good hydrothermal stability and prevents hydrothermal oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

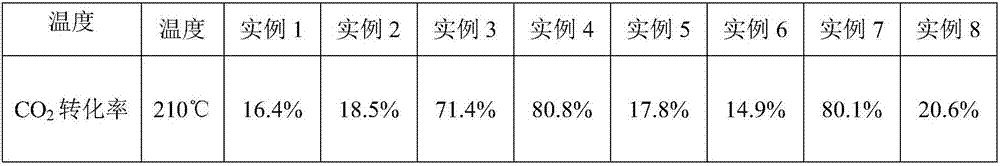

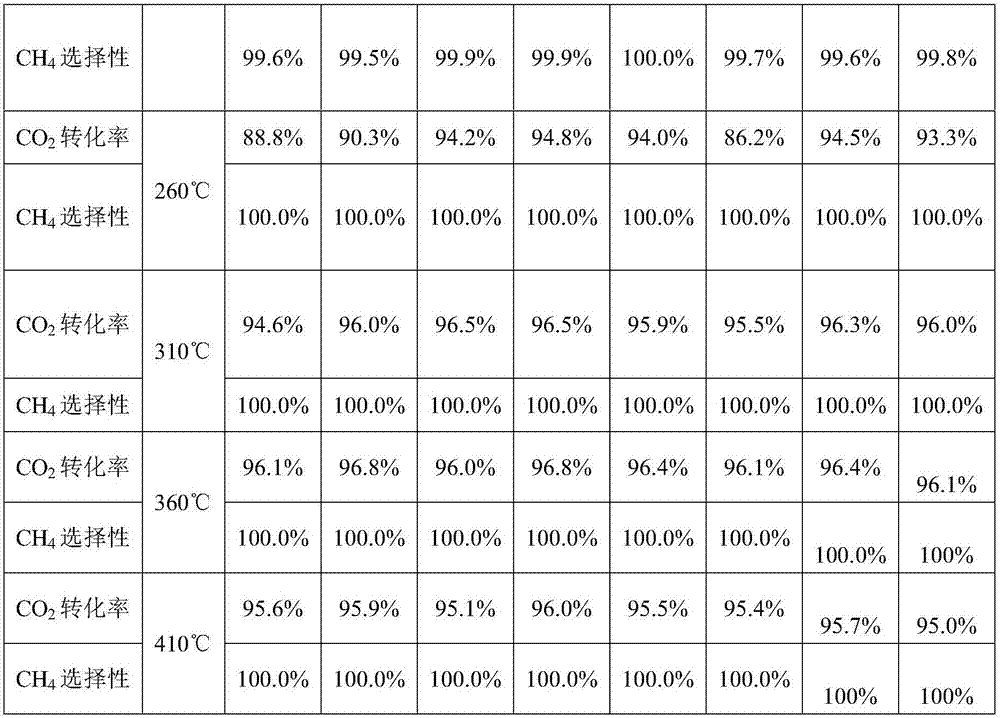

Examples

Embodiment 1

[0022] A preparation method of a low-temperature high-activity carbon dioxide methanation catalyst in this embodiment comprises the following steps:

[0023] Step A, preparation of nickel-aluminum hydrotalcite catalyst precursor:

[0024] Weigh 136.27g of Ni(NO 3 ) 2 ·6H 2 O, 316.4g of Al(NO 3 ) 3 9H 2 O, 6.06g of Fe(NO 3 ) 3 9H 2 O, 19.08g of Mg(NO 3 ) 2 ·6H 2 O, 2.66g of La(NO 3 ) 3 ·nH 2 O and 5.05g of Ce(NO 3 ) 2 ·8H 2 O, 168.22g of CO(NH 2) 2 , were added to a 500ml three-neck flask in turn, and then 300ml deionized water was added, stirred to dissolve into a mixed solution. With simethicone oil as the heating medium, reflux heating is carried out with a magnetic stirring heater. Control the temperature of the solution at 101°C, add 0.10 mol / L ammonia water drop by drop and maintain the pH value of the mother liquor at 7.5 to carry out the precipitation reaction; Excessive ammonium salt; the obtained filter cake was dried in a drying oven at 80°C for ...

Embodiment 2

[0028] In this embodiment, a method for preparing a low-temperature high-activity carbon dioxide methanation catalyst comprises the following steps:

[0029] Step A, preparation of nickel-aluminum hydrotalcite catalyst precursor:

[0030] Weigh 144.06g of Ni(NO 3 ) 2 ·6H 2 O, 294.33g of Al(NO 3 ) 3 9H 2 O, 3.03g of Fe(NO 3 ) 3 9H 2 O, 31.81g of Mg (NO 3 ) 2 ·6H 2 O, 1.33g of La(NO 3 ) 3 ·nH 2 O and 1.26g of Ce(NO 3 ) 2 ·8H 2 O, 180.21g of CO(NH 2 ) 2 , were added to a 500ml three-neck flask in turn, and then 300ml deionized water was added, stirred to dissolve into a mixed solution. With simethicone oil as the heating medium, reflux heating is carried out with a magnetic stirring heater. Control the temperature of the solution at 110°C, add 0.10 mol / L ammonia water drop by drop and maintain the pH value of the mother liquor at 8.0 to carry out the precipitation reaction; Excessive ammonium salt; the obtained filter cake was dried in a drying oven at 90°C f...

Embodiment 3

[0034] In this embodiment, a method for preparing a low-temperature high-activity carbon dioxide methanation catalyst comprises the following steps:

[0035] Step A, preparation of nickel-aluminum hydrotalcite catalyst precursor:

[0036] Weigh 155.74g of Ni(NO 3 ) 2 ·6H 2 O, 235.47g of Al(NO 3 ) 3 9H 2 O, 9.09g of Fe(NO 3 ) 3 9H 2 O, 12.73g of Mg(NO 3 ) 2 ·6H 2 O, 3.99g of La(NO 3 ) 3 ·nH 2 O and 3.78g of Ce(NO 3 ) 2 ·8H 2 O, 210.22g of CO(NH 2 ) 2 , were added to a 500ml three-neck flask in turn, and then 300ml deionized water was added, stirred to dissolve into a mixed solution. With simethicone oil as the heating medium, reflux heating is carried out with a magnetic stirring heater. Control the temperature of the solution at 100°C, add 0.10 mol / L ammonia water drop by drop and maintain the pH value of the mother liquor at 7.5 to carry out the precipitation reaction; Excessive ammonium salt; the obtained filter cake was dried in a drying oven at 90°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com