Sulfur-resistant and water-resistant low-temperature denitration composite molecular sieve catalyst and preparation method thereof

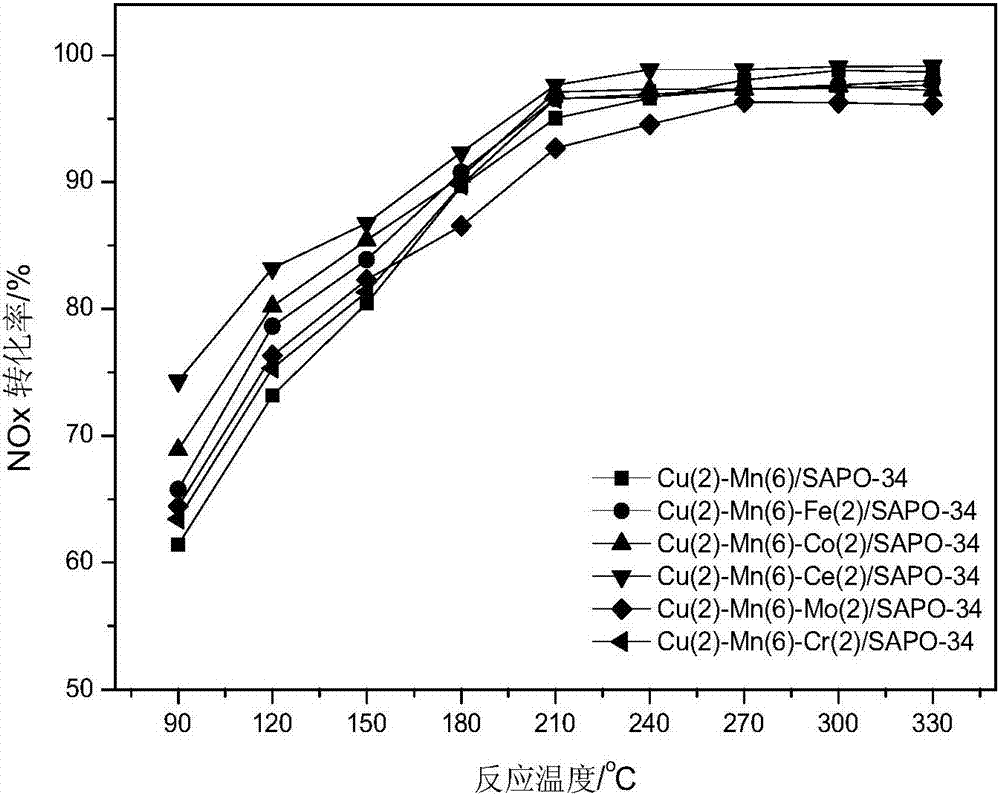

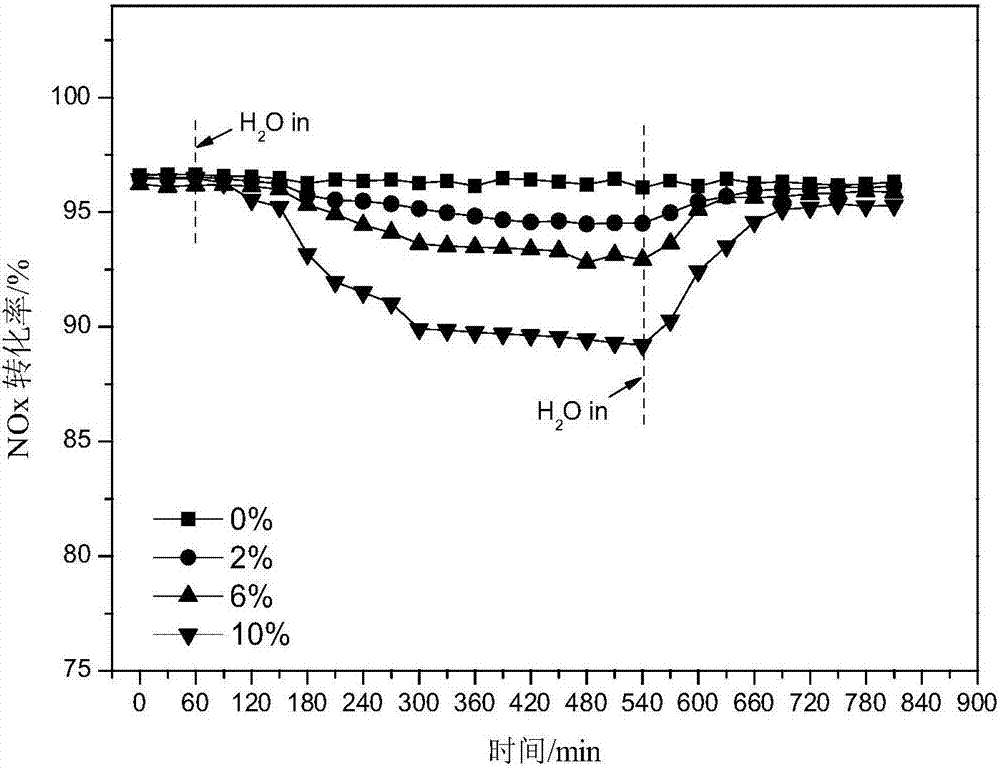

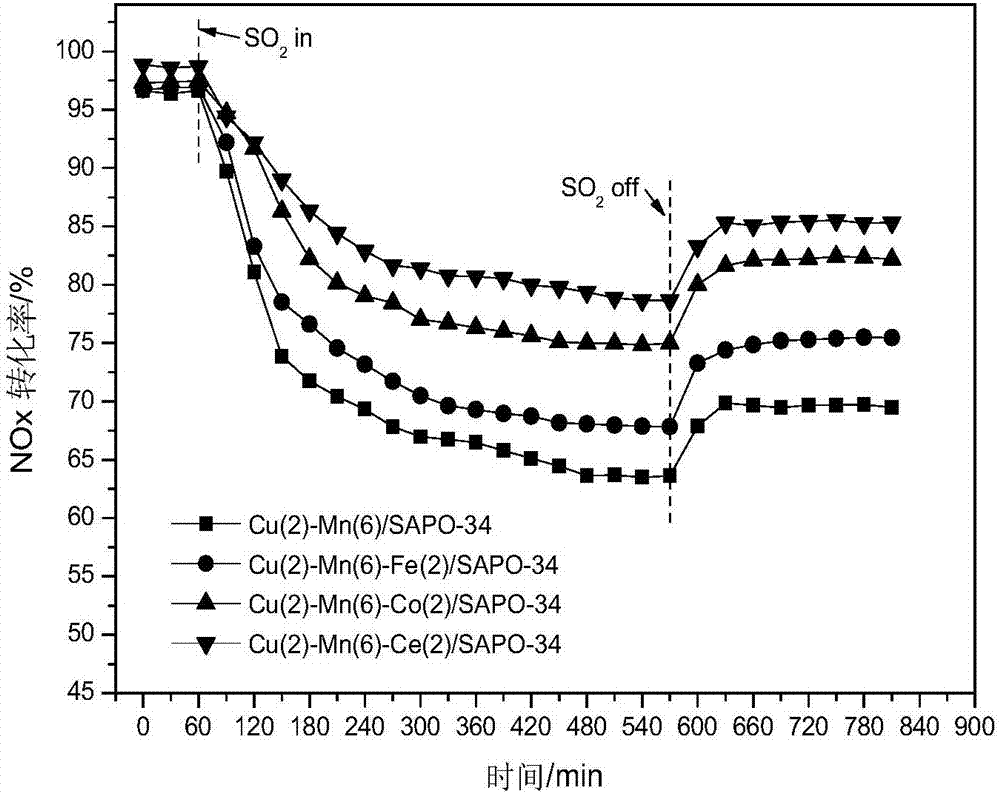

A composite molecular sieve and low-temperature denitrification technology, which is applied in the field of low-temperature denitrification composite molecular sieve catalyst and its preparation, can solve the problems of unfavorable ecological environment and human health, the toxicity of active component vanadium, and the space behind the large furnace, etc., and achieve low activation temperature , wide temperature window, and the effect of widening the temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 8g of the original powder of chabazite molecular sieve (H-SAPO-34), put it into an ark made of corundum, and place it together in a blast drying oven at 100°C for 25 minutes for later use;

[0026] (2) Weigh 0.3775gCu(NO 3 ) 2 ·3H 2 O powder was dissolved in 30ml of deionized water, and after fully stirring evenly, 2.7412g of manganese nitrate solution with a concentration of 50% was added, and fully stirred to form a mixed solution containing two active components in different proportions.

[0027] (3) Take 5 g of the dried H-SAPO-34 molecular sieve former powder in step (1) and dissolve in the mixed solution prepared in step (2), and stir continuously for 8 hours in a water bath at 30° C. and a magnetic stirrer, fully After impregnation, heat it up to 75°C and continue stirring and impregnating for 2h. After the water is evaporated to dryness, put the evaporative crystallized product in an oven and dry it at 100°C for 8h, and then put it in a tube furnace....

Embodiment 2

[0030] (1) Weigh 8g of the original powder of chabazite molecular sieve H-SAPO-34, put it into an ark made of corundum, and place it together in a blast drying oven at 103°C for 30 minutes for later use;

[0031] (2) Weigh 0.3775g Cu(NO 3 ) 2 ·3H 2 O powder, be dissolved in the deionized water of 35ml, after fully stirring, add 0.9091g concentration and be the manganese nitrate solution of 50% and 0.1549g Ce(NO 3 ) 3 ·6H 2 O powder, fully stirred to make a mixed solution containing two active components and cerium-containing additives in different proportions.

[0032] (3) Take 5 g of the dried H-SAPO-34 molecular sieve former powder in step (1) and dissolve in the mixed solution prepared in step (2), and stir continuously for 6 hours in a water bath at 20° C. and a magnetic stirrer, fully After impregnation, heat it up to 85°C and continue to stir and impregnate for 4h. After the water is evaporated to dryness, put the evaporated and crystallized product in an oven and d...

Embodiment 3

[0035] (1) Weigh 8g of the original powder of chabazite molecular sieve H-SAPO-34, put it into an ark made of corundum, and place it together in a blast drying oven at 105°C for 30 minutes for later use;

[0036] (2) Weigh 0.3775g Cu(NO 3 ) 2 ·3H 2 O powder, dissolved in 40ml of deionized water, after fully stirring evenly, adding 2.7412g concentration of 50% manganese nitrate solution and 0.3099g Ce(NO 3 ) 3 ·6H 2 O powder, fully stirred to make a mixed solution containing two active components and cerium-containing additives in different proportions.

[0037] (3) Take 5 g of the dried H-SAPO-34 molecular sieve former powder in step (1) and dissolve in the mixed solution prepared in step (2), and stir continuously for 6 hours in a water bath at 20° C. and a magnetic stirrer, fully After impregnation, heat it up to 85°C and continue to stir and impregnate for 4h. After the water is evaporated to dryness, put the evaporated and crystallized product in an oven and dry it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com