Cerium supported medium temperature SCR (selective catalytic reduction) catalyst and preparation method thereof

An SCR catalyst, supported technology, applied in the field of catalysts, can solve the problems of shortening the catalyst life, high investment cost of transformation, increasing denitration cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

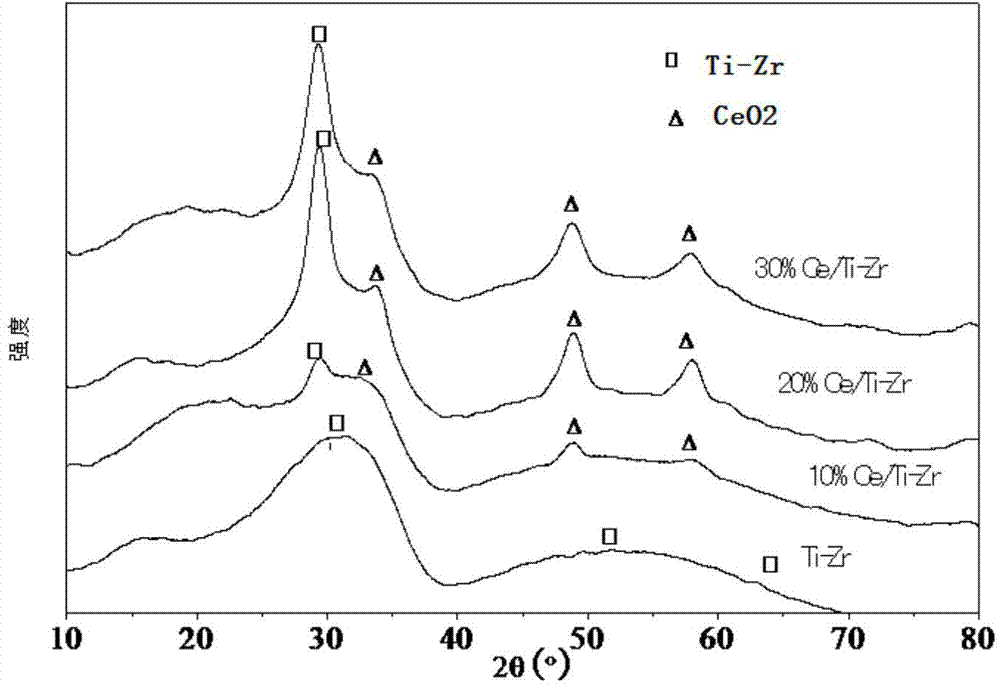

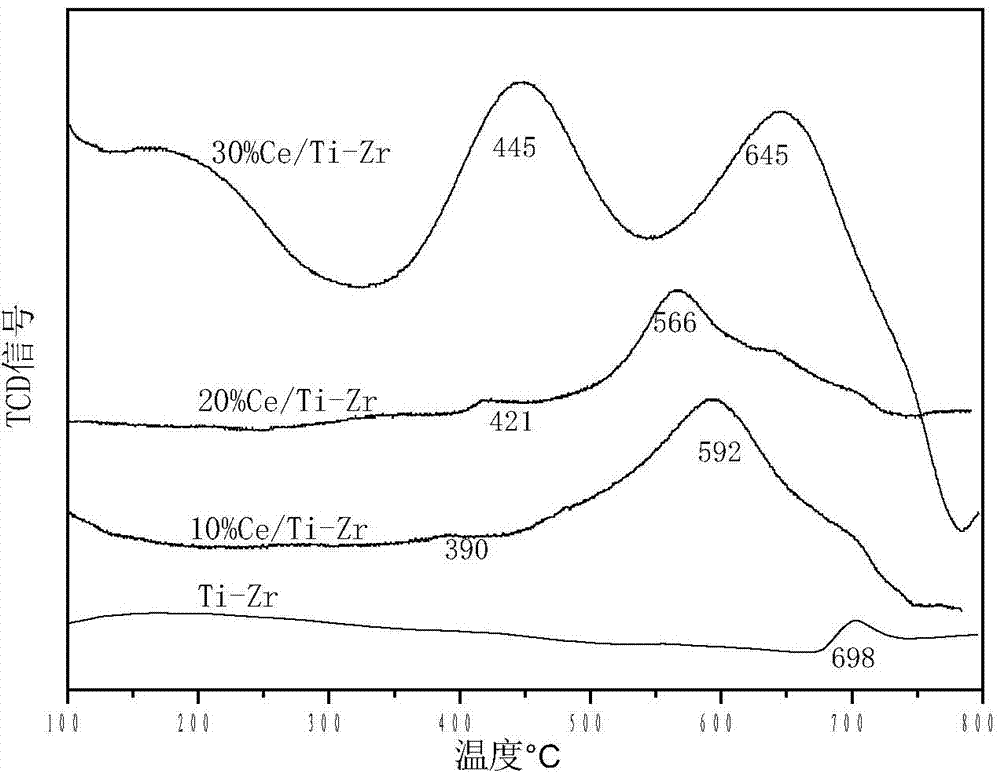

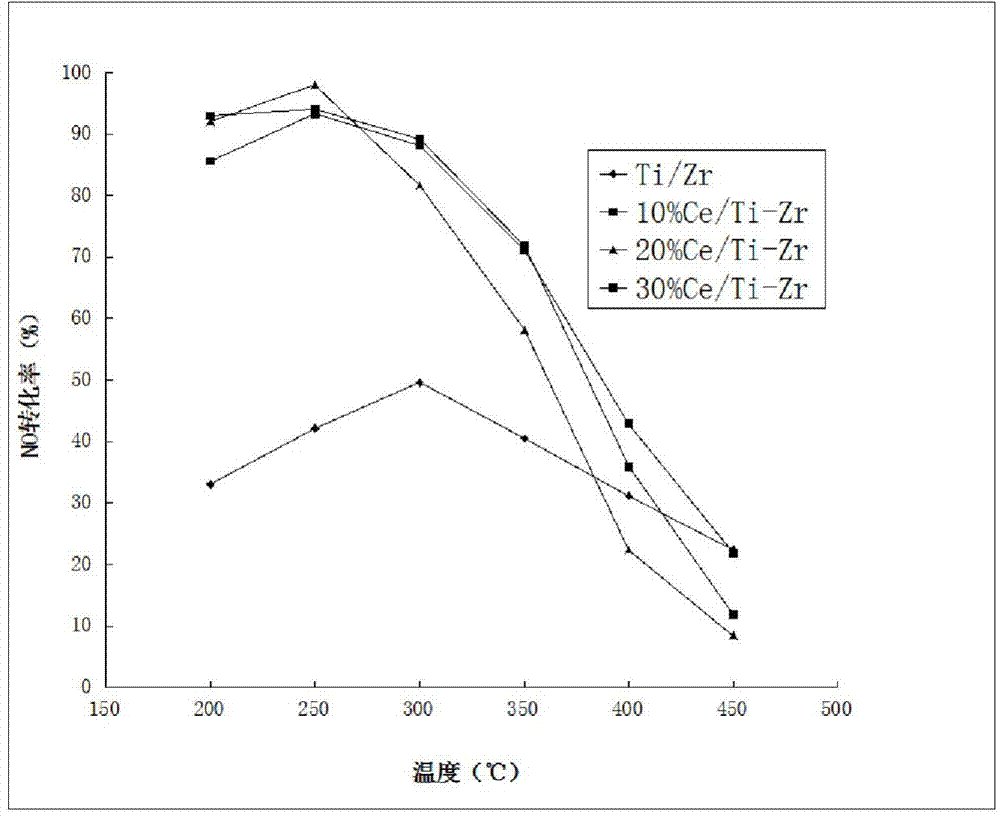

[0025] Example 1 Titanium-zirconium solid solution (TiO 2 -ZrO 2 preparation of the carrier).

[0026] Preparation of TiO with a molar ratio of 1:1 by co-precipitation 2 -ZrO 2 Composite oxide: zirconium oxychloride octahydrate ZrOCl 2 ·8H 2 O (AR, produced by Sinopharm Chemical Reagent Co., Ltd.), titanium tetrachloride (TiCl 4 ) solution (density 1.73g / ml, AR, produced by Shanghai Lingfeng Chemical Reagent Co., Ltd.), ammonia water (AR, 28wt%, produced by Shanghai Pilot Chemical Corporation) and deionized water as raw materials. First use a clean graduated cylinder to measure 5.3995ml of TiCl 4 , Put the beaker with 300-400ml deionized water into the ice water bath, then add TiCl to the beaker at a rate of 1ml / min 4 . During the addition process, the beaker was mechanically stirred at a stirring speed of 45r / s, and then 15.8673g of ZrOCl was added 2 ·8H 2 O until the solution is clear. Then dropwise add 28wt% ammonia water to the solution at a rate of 3-5ml / min, a...

Embodiment 2

[0027] Example 2 10% CeO 2 / TiO 2 -ZrO 2 Preparation of (10%Ce / Ti-Zr) catalyst.

[0028] Carrier pretreatment: Take 2 g of the titanium-zirconium solid solution prepared in Example 1 and add it to 50 ml of deionized water to obtain an aqueous solution of the titanium-zirconium solid solution;

[0029] The loading of cerium oxide with a molar percentage of 10%: add 0.4275g Ce(NO 3 ) 3 ·6H 2 O, Stir evenly at 40~50r / s at 20°C for 2~2.5h, then stir at 80~90°C until the water evaporates to dryness (usually about 4 hours), put it in an oven and dry at 110°C for 12 hours Take out and grind until the particle size is greater than or equal to 60 mesh; finally put it into a muffle furnace and calcinate at 450°C for 4 hours to obtain 10% CeO 2 / TiO 2 -ZrO 2 Catalyst, wherein, 10% represents n(Ce):n(Ti):n(Zr)=0.1:1:1 in the prepared catalyst, n is the number of moles.

Embodiment 3

[0030] Example 3 20% CeO 2 / TiO 2 -ZrO 2 Preparation of (20%Ce / Ti-Zr) catalyst.

[0031] Carrier pretreatment: Take 2 g of the titanium-zirconium solid solution prepared in Example 1 and add it to 50 ml of deionized water to obtain an aqueous solution of the titanium-zirconium solid solution;

[0032] The loading of cerium oxide with a molar percentage of 20%: add 0.8550g Ce(NO 3 ) 3 ·6H 2 O, Stir evenly at 40~50r / s at 20°C for 2~2.5h, then stir at 80~90°C until the water evaporates to dryness (usually about 4 hours), put it in an oven and dry at 110°C for 12 hours Take it out and pass through a 60-mesh sieve after grinding; put it into a muffle furnace and calcinate at 450 ° C for 4 hours to obtain 20% CeO 2 / TiO 2 -ZrO 2 Catalyst, wherein 20% represents n(Ce):n(Ti):n(Zr)=0.2:1:1 in the prepared catalyst, n is the number of moles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com