A system and method for wet desulfurization and denitrification

A desulfurization, denitrification and wet desulfurization technology, applied in the field of flue gas purification, can solve the problems of lack of denitration function, etc., and achieve the effects of low investment cost, inhibition of ammonia escape and aerosol generation, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

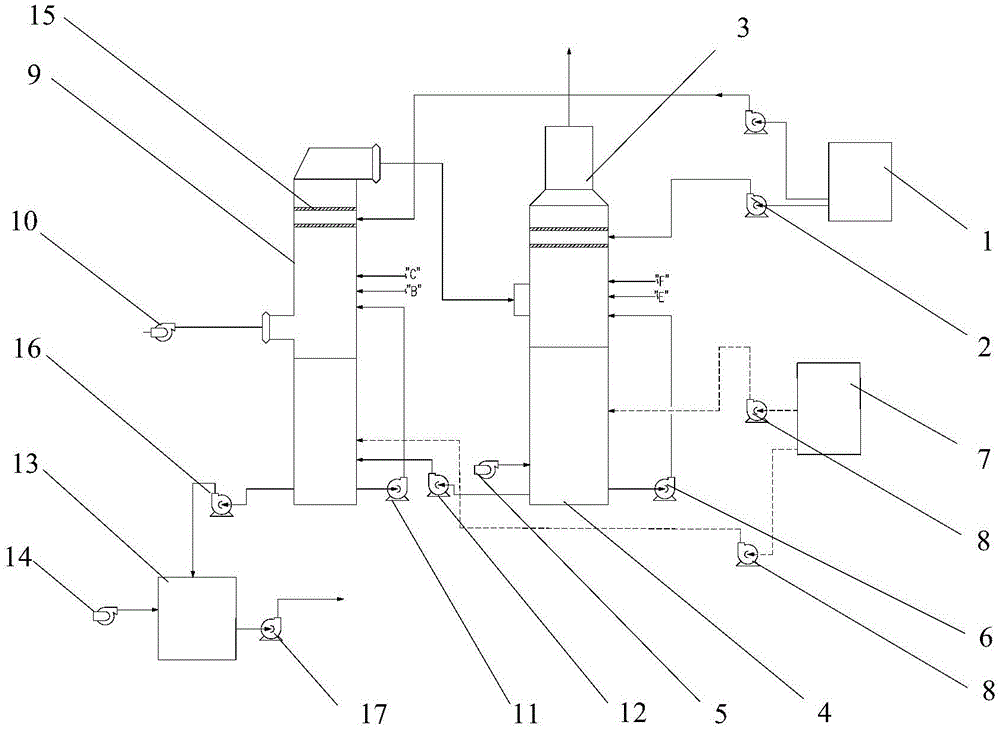

[0047] Desulfurization and denitrification system ( figure 1 ), including desulfurization and denitrification tower 9 and desulfurization tower 4, the two towers are connected by pipelines;

[0048] A desulfurization tower oxidation blower 5 is arranged outside the desulfurization tower 4, which is connected with the desulfurization tower through pipelines. The air intake position of the oxidation fan is below the liquid level.

[0049] The desulfurization and denitrification tower 9 is provided with a flue gas inlet in the middle (entered through the booster fan 10) and an outlet at the top of the tower, which are connected to the flue gas inlet in the middle of the desulfurization tower through pipes; Connect ammonia storage tank 7 with ammonia delivery pump 8; the ammonium sulfate absorption solution outlet at the bottom of the desulfurization tower is connected with the ammonium sulfate absorption solution inlet at the bottom of the desulfurization and denitrification tow...

Embodiment 2

[0054] A certain sintering flue gas temperature is 120°C, where SO 2 The concentration is 1200mg / Nm 3 , NO x The concentration is 130mg / Nm 3 , after entering the desulfurization and denitrification system of embodiment 1, it first enters the desulfurization and denitrification tower 9 from the middle, and the flue gas to be purified is in contact with the three-layer spray absorption liquid from bottom to top, and then purified by the demister 15, from The discharge from the top of the desulfurization and denitrification tower 9 enters the middle of the desulfurization tower 4 through the connecting pipe between the desulfurization and denitrification tower 9 and the desulfurization tower 4 . The absorption liquid in the desulfurization and denitrification tower 9 is mainly a mixture of ammonium sulfite and ammonium sulfate, and the pH is adjusted to 5.0 with ammonia water. The liquid-gas ratio is controlled to be 4L / m by the circulation pump 11 of the desulfurization and d...

Embodiment 3

[0058] A certain sintering flue gas temperature is 145°C, where SO 2 The concentration is 3400mg / Nm 3 , NO x The concentration is 280mg / Nm 3 After entering the desulfurization and denitrification system (Example 1), it first enters the desulfurization and denitrification tower 9 from the middle, and the flue gas to be purified is in contact with the three-layer spray absorption liquid from bottom to top, and then purified by the demister 15. It is discharged from the top of the desulfurization and denitrification tower 9, and enters the middle part of the desulfurization tower 4 through the connecting pipe between the desulfurization and denitrification tower 9 and the desulfurization tower 4. The absorption liquid in the desulfurization and denitrification tower 9 is mainly a mixture of ammonium sulfite and ammonium sulfate, and the pH is adjusted to 4.8 with ammonia water. The gas ratio is controlled to 8L / m by the circulation pump 11 of the desulfurization and denitrific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com