Preparation method of catalyst for denitration and dioxin degradation

A catalyst and denitrification technology, applied in chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of inability to remove dioxins, low denitrification efficiency, and low denitrification efficiency. Achieve high dioxin removal rate, increase NO conversion rate, and reduce the effect of denitrification reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

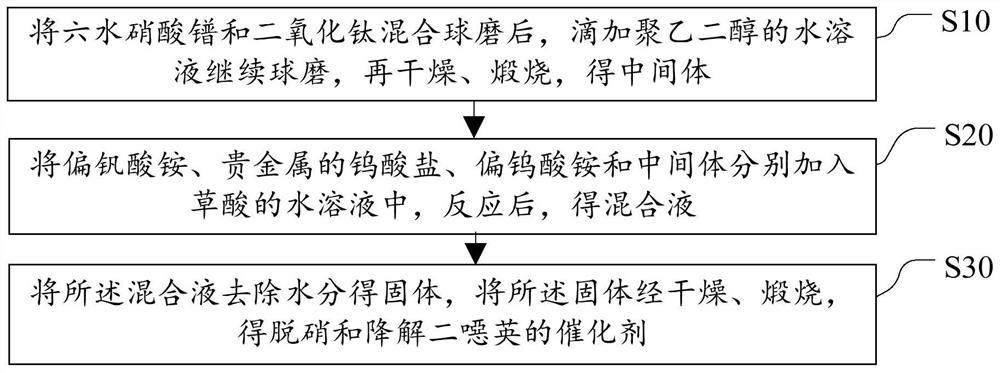

[0026] see figure 1 , the present invention proposes a preparation method of a catalyst for denitrification and degradation of dioxins, comprising the following steps:

[0027] S10. After ball-milling praseodymium nitrate hexahydrate and titanium dioxide, dropwise adding an aqueous solution of polyethylene glycol to continue ball-milling, then drying and calcining to obtain an intermediate.

[0028] This step mainly prepares the intermediate praseodymium / titanium oxide carrier, polyethylene glycol is preferably polyethylene glycol 4000, and its function is a dispersant, that is, it can stabilize some small particles of the intermediate that have just been ground in time during the ball milling process. In the embodiment of the present invention, the amount of polyethylene glycol 4000 added is relatively small, and the mass fraction of the aqueous solution of polyethylene glycol 4000 is 10%.

[0029] The conditions of drying and calcination are not limited in the present inven...

Embodiment 1

[0052] (1) After 4.35 parts of praseodymium nitrate hexahydrate and 32 parts of titanium dioxide were placed in a ball mill and mixed for 30 minutes, the aqueous solution (10wt.%) of 0.05 parts of polyethylene glycol 4000 was added dropwise to the ball mill to continue ball milling for 30 minutes. drying at 450°C for 1 hour and calcining at 450°C for 3 hours to obtain an intermediate;

[0053] (2) Under stirring conditions, add 1.25 parts of oxalic acid to 40 parts of water to form an aqueous solution of oxalic acid, mix 0.58 parts of ammonium metavanadate, 0.01 part of silver tungstate, and 1.1 parts of ammonium metatungstate (tungsten content 65wt. %) and 14.3 parts of intermediates were added to the aqueous solution of oxalic acid, and after reacting for 2 hours, a mixed solution was obtained;

[0054] (3) Remove moisture from the mixed solution to obtain a solid, dry the solid at 110°C for 1 hour, calcinate at 250°C for 1 hour, and then calcinate at 450°C for 3 hours to ob...

Embodiment 2

[0056] (1) After 4.35 parts of praseodymium nitrate hexahydrate and 32 parts of titanium dioxide were placed in a ball mill and mixed for 30 minutes, the aqueous solution (10wt.%) of 0.05 parts of polyethylene glycol 4000 was added dropwise to the ball mill to continue ball milling for 30 minutes. drying at 450°C for 1 hour and calcining at 450°C for 3 hours to obtain an intermediate;

[0057] (2) Under stirring conditions, 1.25 parts of oxalic acid are added to 40 parts of water to form an aqueous solution of oxalic acid, 0.58 parts of ammonium metavanadate, 0.05 parts of silver tungstate, 1.1 parts of ammonium metatungstate (tungsten content 65wt.%) ) and 14.3 parts of intermediates were added to the aqueous solution of oxalic acid respectively, and after 2 hours of reaction, a mixed solution was obtained;

[0058] (3) Remove moisture from the mixed solution to obtain a solid, dry the solid at 110°C for 1 hour, calcinate at 250°C for 1 hour, and then calcinate at 450°C for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com