Vanadium-series loading type high-temperature SCR catalyst and preparation method thereof

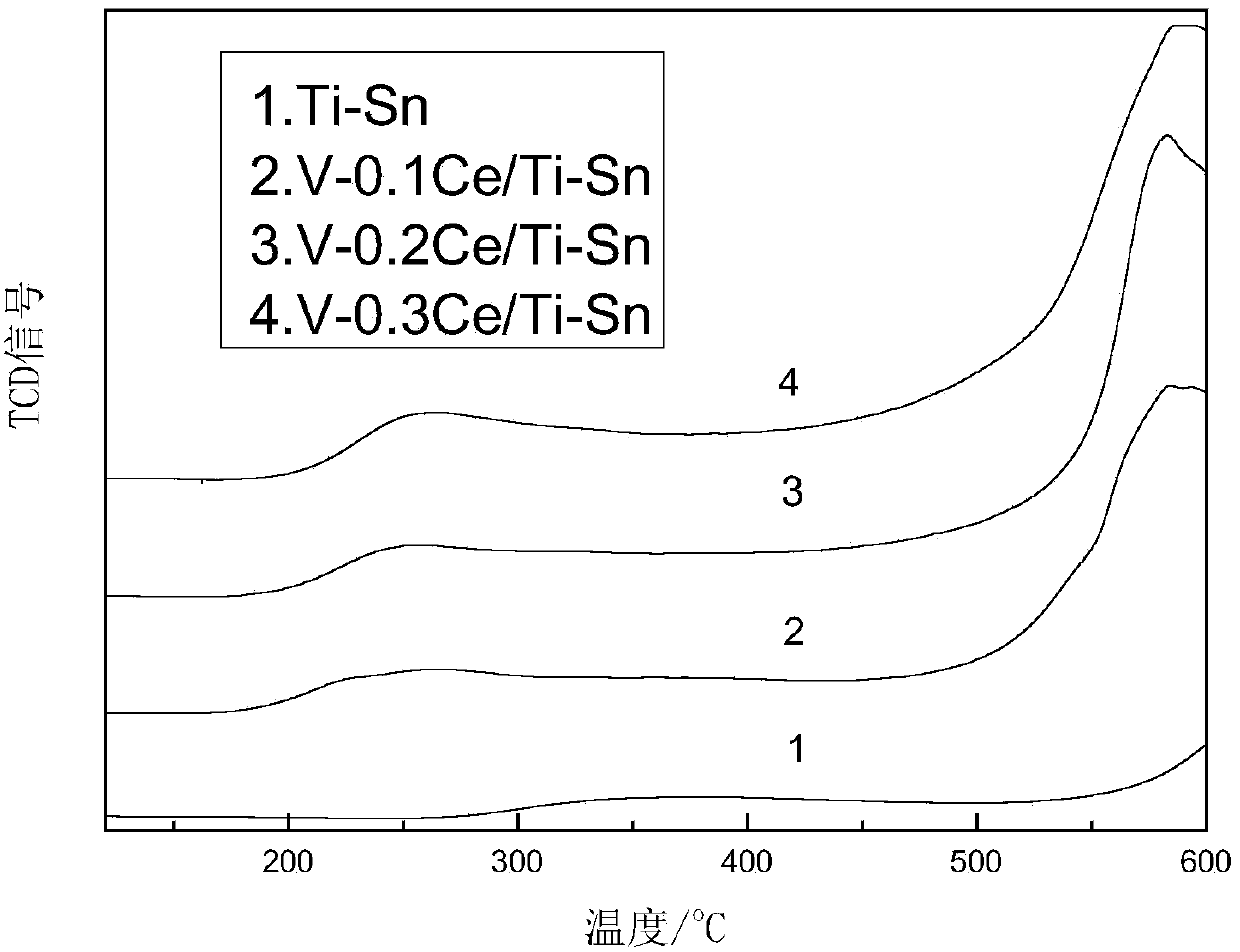

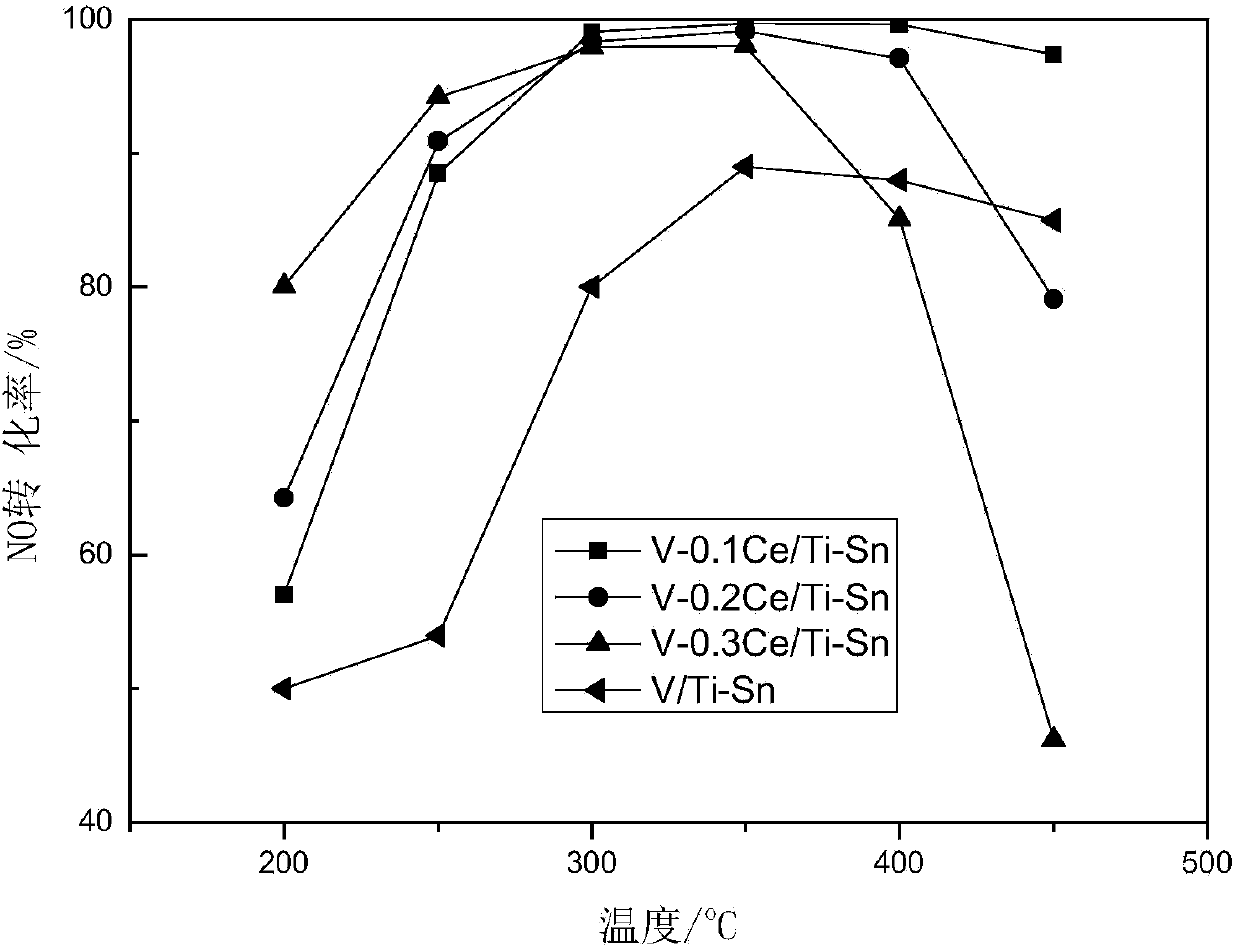

An SCR catalyst and supported technology, which is applied in the field of vanadium-based supported high-temperature SCR catalyst and its preparation, can solve the problems of low mechanical strength, high activation temperature, and narrow temperature window of the catalyst, so as to broaden the activation temperature window, start The effect of lowering the active temperature and improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: TiO 2 -SnO 2 Preparation of support (Ti-Sn).

[0028] TiO 2 -SnO 2 Carrier Preparation: Co-precipitation method was used to prepare TiO with a molar ratio of 1:1 2 -SnO 2 composite oxides. Tin tetrachloride pentahydrate (AR, produced by Sinopharm Chemical Reagent Co., Ltd.), titanium tetrachloride (TiCl 4 ) solution (AR, density 1.73g / ml, produced by Shanghai Lingfeng Chemical Reagent Co., Ltd.), ammonia water (AR, 28wt%, produced by Shanghai Pilot Chemical Corporation), and deionized water as raw materials. Weigh 15.2051g SnCl 4 ·5H 2 O, add a small amount of water to dissolve it and transfer it into a 400ml large beaker, measure 4.7558ml TiCl 4 , under an ice-water bath, transfer to a 400ml large beaker at a rate of 1ml / min while stirring. Turn on the mechanical stirring at a stirring rate of 45 r / s, and slowly add ammonia water dropwise. After the drop is complete and stir for 30 minutes, the measured pH can be between 9 and 10. After the reacti...

Embodiment 2

[0029] Example 2: 1%V 2 o 5 / TiO 2 -SnO 2 Preparation of catalyst (V / Ti-Sn).

[0030] Carrier pretreatment: take 2 g of the titanium-tin solid solution prepared in Example 1 and dissolve it in 50 ml of deionized water to obtain an aqueous solution of the titanium-tin solid solution;

[0031] The loading of vanadium oxide with a mass percentage of 1.00%: add 0.0260g NH to the aqueous solution of the above-mentioned titanium-tin solid solution 4 VO 3 (ammonia metavanadate), 1~2g oxalic acid needs to be added during the preparation process to promote the dissolution of ammonium metavanadate; stir evenly at 40~50r / s for 2 hours at 20°C, then stir at 85°C until the water is basically evaporated to dryness ( It usually takes about 4 hours); after the water is basically evaporated to dryness, take it out, put it in an oven, dry it at 110°C for 12 hours, take it out, grind it and pass it through a 60 mesh sieve; put it in a muffle furnace and calcinate it at 450°C for 4h to obtai...

Embodiment 3

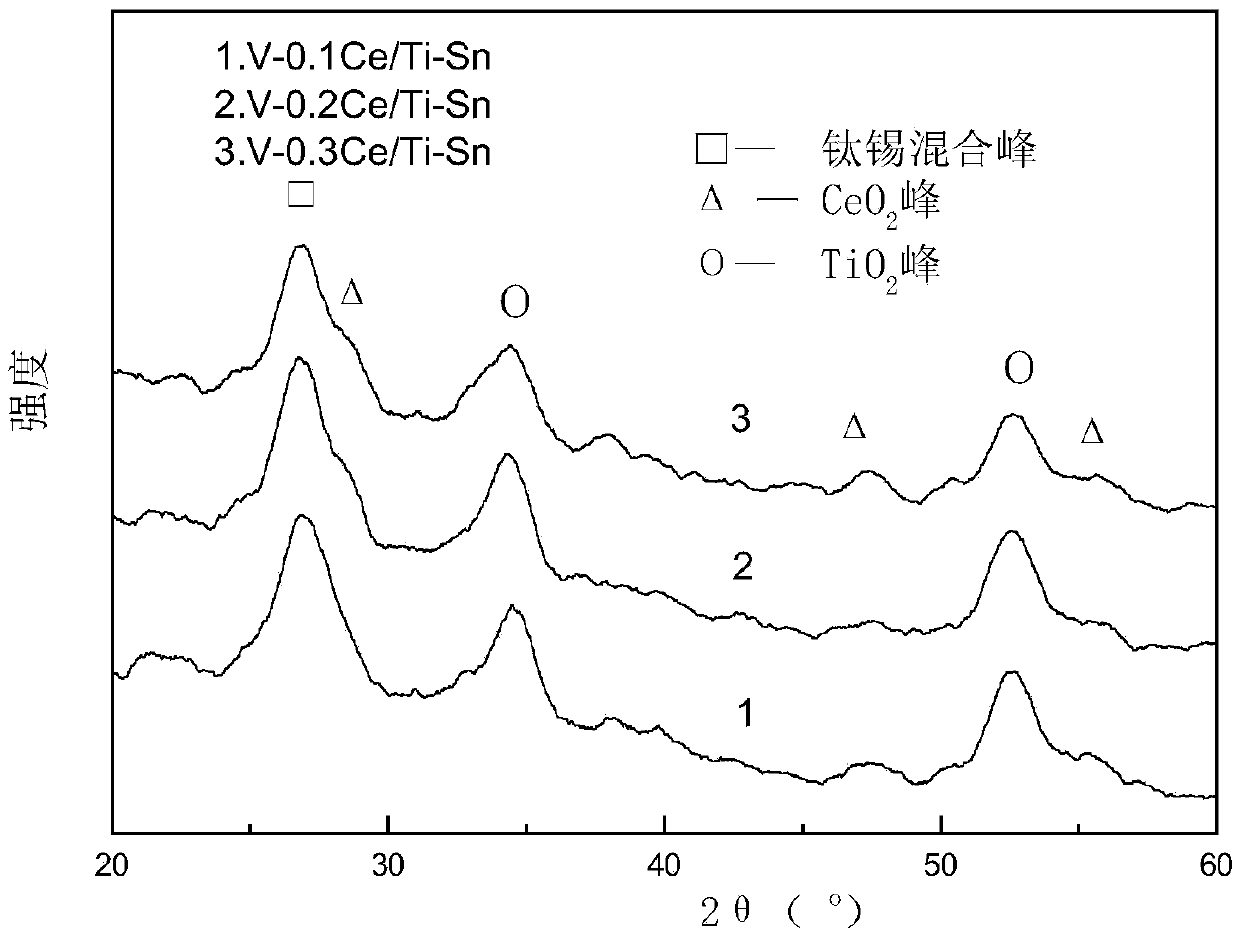

[0032] Example 3: 1% V 2 o 5 -0.1CeO 2 / TiO 2 -SnO 2 Preparation of catalyst (1%V-0.1Ce / Ti-Sn).

[0033] Carrier pretreatment: Carrier pretreatment: take 2 g of the titanium-tin solid solution prepared in Example 1 and dissolve it in 50 ml of deionized water to obtain an aqueous solution of the titanium-tin solid solution;

[0034] The loading of cerium oxide with a molar ratio of 0.1: add 0.3765g Ce(NO 3 ) 3 ·6H 2 O, stir evenly at 40~50r / s at 20°C for 2 hours, then stir at 85°C until the water is basically evaporated to dryness (usually about 4 hours); after the water is basically evaporated to dryness, take it out and put it in an oven at 110°C Dry at 450°C for 4 hours in a muffle furnace to obtain 0.1CeO 2 / TiO 2 -SnO 2 Catalyst, after grinding and passing through a 60-mesh sieve, it is standby, wherein, 0.1 represents CeO 2 / TiO 2 -SnO 2 CeO in the catalyst 2 with TiO 2 -SnO 2 The molar ratio is 0.1.

[0035] Loading of vanadium oxide with a mass percenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com