Cu-based low-temperature water gas conversion catalyst under hydrogen rich reformed gas and preparation method thereof

A technology for converting catalysts and catalysts, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., and can solve the problem of insufficient conversion efficiency, narrow active temperature range, and high activation temperature. problem, to achieve the effect of strong interaction, high copper dispersion and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

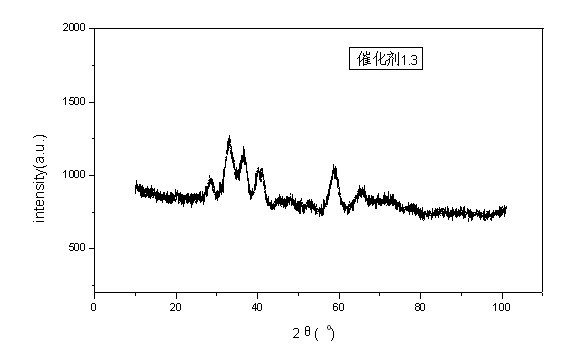

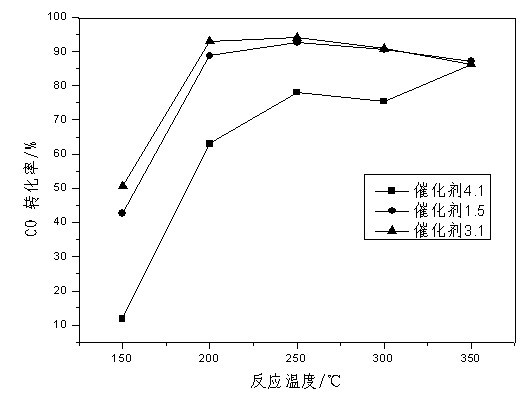

[0030] Embodiment 1: preparation catalyst CuO / ZrO 2

[0031] Preparation of ZrO 2 Carrier: Take 60mL of 0.2g / mL ZrOCl 2 ·8H 2 Put O aqueous solution into 100mL high-pressure polytetrafluoroethylene lining, then put the inner lining into the stainless steel outer lining, screw it tightly, and put it into the blast drying oven. At 150°C, heat for 6h. After the hydrothermal kettle is lowered to room temperature, pour out the emulsion in the lining, add 25% concentrated ammonia water dropwise to the emulsion, adjust the pH of the system to 9, then centrifuge and wash the precipitate with water for 5 times, and use AgNO 3 Detection without Cl - until. The resulting precipitate was dried at 80°C for 6h, and then fired in a muffle furnace at 350°C for 6h to obtain the desired ZrO 2 carrier.

[0032] Take 4.50g ZrO 2 Support preparation of CuO / ZrO 2 catalyst. ZrO 2 Grind into powder, add 9g of water, and disperse under 1400W for 10 minutes with ultrasonic assistance to for...

Embodiment 2

[0037] Embodiment 2: Adding method 1 of auxiliary agent

[0038] Preparation of ZrO 2 Carrier: Take 60mL of 0.2g / mL ZrOCl 2 ·8H 2 Put O aqueous solution into 100mL high-pressure polytetrafluoroethylene lining, then put the inner lining into the stainless steel outer lining, screw it tightly, and put it into the blast drying oven. At 150°C, heat for 6h. After the hydrothermal kettle dropped to room temperature, pour out the emulsion in the inner lining, add 25% concentrated ammonia water dropwise to the emulsion, adjust the pH of the system to 9, and then wash the precipitate by centrifugation for 6 times, and wash it with AgNO 3 Detection without Cl - until. The resulting precipitate was dried at 80°C for 6h, and then fired in a muffle furnace at 350°C for 6h to obtain the desired ZrO 2 carrier.

[0039] Take 4.45 g ZrO 2 Carrier for catalyst preparation. ZrO 2 Grind into powder, add 13g of water, disperse under 1600W for 20 minutes with ultrasonic assistance, and fo...

Embodiment 3

[0042] Embodiment 3: Adding method 2 of auxiliary agent

[0043] Preparation of doped ZrO 2 Carrier: Take 0.56g of La(NO 3 ) 3 ·6H 2 O solid with 10.46g ZrOCl 2 Dissolve the 8H2O solid in 60mL of water and put it into a 100mL high-pressure polytetrafluoroethylene lining, then put the inner lining into a stainless steel outer lining, screw it tightly, and put it into a blast drying oven. At 150°C, heat for 6h. After the hydrothermal kettle dropped to room temperature, pour out the emulsion in the inner lining, add 25% concentrated ammonia water dropwise to the emulsion, adjust the pH of the system to 9, and then wash the precipitate by centrifugation for 6 times, and wash it with AgNO 3 Detection without Cl- until. The resulting precipitate was dried at 80°C for 6h, and then fired in a muffle furnace at 350°C for 6h to obtain the desired doped ZrO 2 carrier.

[0044] Get 4.50g doped ZrO 2 Support preparation of CuO / ZrO 2 catalyst. ZrO 2 Grind into powder, add 10g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com