Catalyst prepared from red mud for removing volatile organic compound and preparation method of catalyst

A catalyst and red mud technology, applied in the field of solid waste treatment and application, to reduce production costs and solve environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

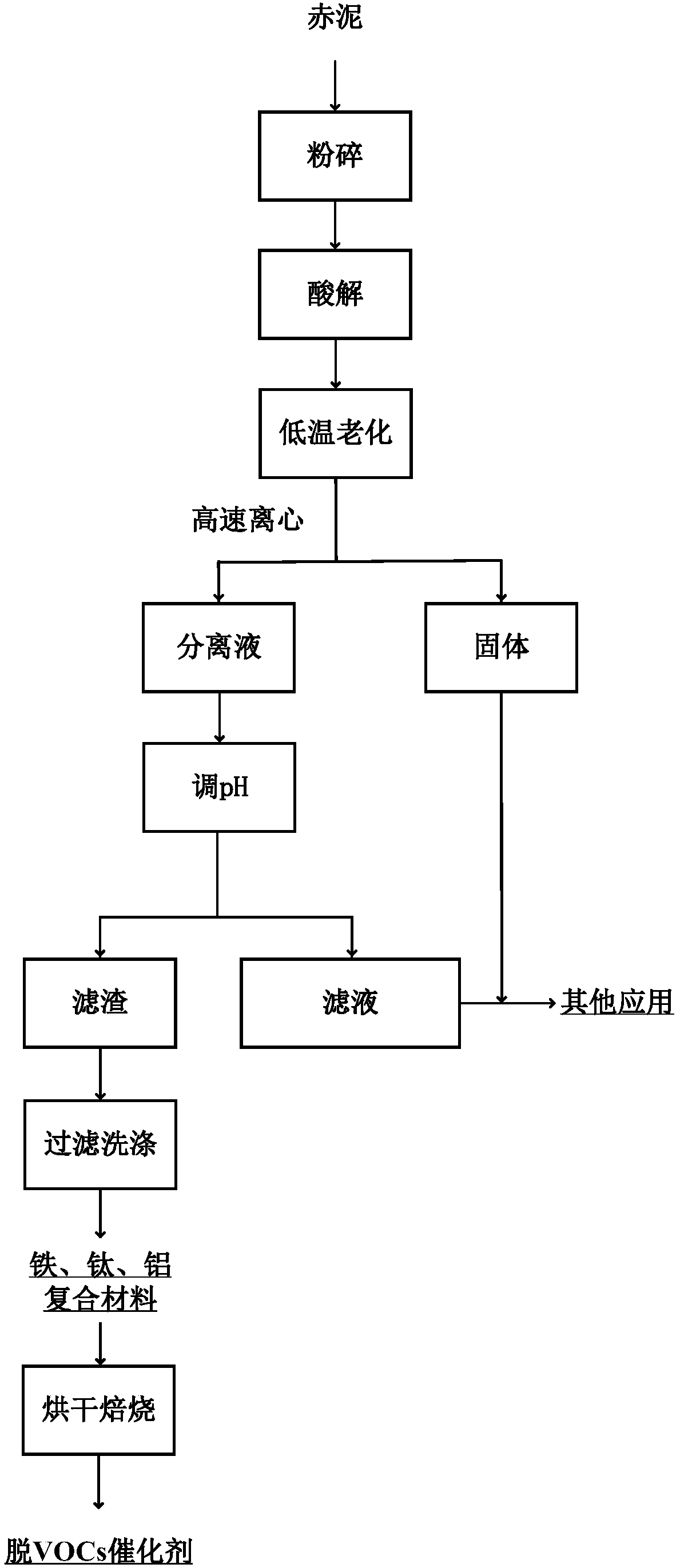

[0071] This example provides a method for preparing a catalyst for removing volatile organic compounds from red mud, and the specific method is as follows:

[0072](a) 100g of red mud is pulverized and added to 300g of dilute sulfuric acid with a concentration of 50%. It is reacted at 80°C for 12h for acidolysis. The hydrogen ion concentration of the reaction system is 28.9mol / L. After the acidolysis reaction is completed, The resulting slurry was aged at a low temperature of 5°C for 24 hours, and the aged slurry was subjected to high-speed centrifugation at a speed of 20,000 r / min to obtain a separated liquid and a solid, which was then washed 3 times with 50% dilute sulfuric acid for use in other apps;

[0073] (b) Add ammonia water dropwise to the separation liquid, adjust the pH value of the solution to be about 9, filter and separate the obtained slurry to obtain filtrate and filter residue, the filtrate is used for other applications, and filter, wash and dry the filter ...

Embodiment 2

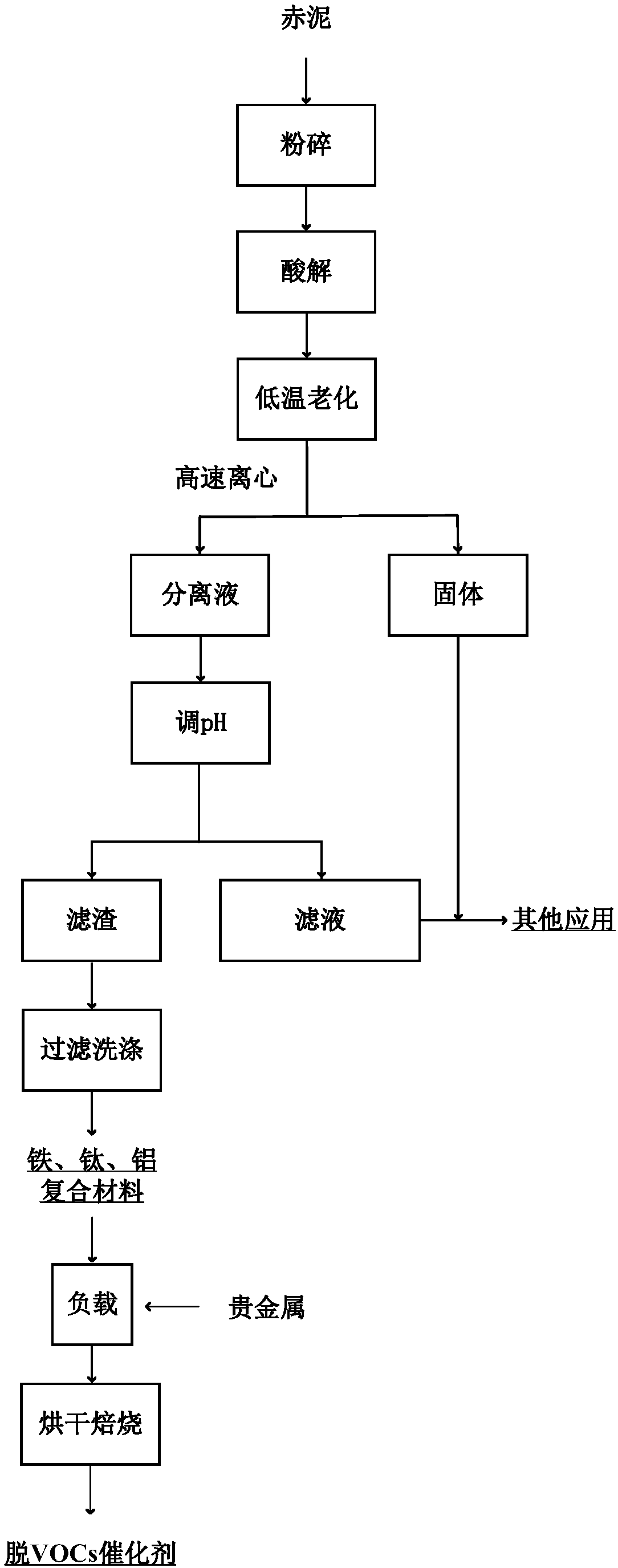

[0081] This example provides a method for preparing a catalyst for removing volatile organic compounds from red mud, and the specific method is as follows:

[0082] (a) 100g of red mud is pulverized and added to 300g of dilute sulfuric acid with a concentration of 50%. It is reacted at 80°C for 12h for acidolysis. The hydrogen ion concentration of the reaction system is 28.9mol / L. After the acidolysis reaction is completed, The resulting slurry was aged at a low temperature of 5°C for 24 hours, and the aged slurry was subjected to high-speed centrifugation at a speed of 20,000 r / min to obtain a separated liquid and a solid, which was then washed 3 times with 50% dilute sulfuric acid for use in other apps;

[0083] (b) Add ammonia water dropwise to the separation liquid to adjust the pH value of the solution to about 9, filter and separate the obtained slurry to obtain a filtrate and a filter residue, the filtrate is used for other applications, filter, wash and dry the filter ...

Embodiment 3

[0092] This example provides a method for preparing a catalyst for removing volatile organic compounds from red mud, and the specific method is as follows:

[0093] (a) 300g of red mud is pulverized and added to 300g of dilute sulfuric acid with a concentration of 80%. It is reacted at 70°C for 12h for acidolysis. The hydrogen ion concentration of the reaction system is 35.14mol / L. After the acidolysis reaction is completed, The resulting slurry was aged at a low temperature of 10°C for 5 hours, and the aged slurry was subjected to high-speed centrifugation at a speed of 20,000 r / min to obtain a separated liquid and a solid, and the solid was washed three times with 50% dilute sulfuric acid for use in other apps;

[0094] (b) Add ammonia water dropwise to the separating liquid, adjust the pH value of the solution to be about 8.5, filter and separate the obtained slurry to obtain filtrate and filter residue, the filtrate is used for other applications, and obtain iron-titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com