Low-temperature cerium-based sulfur-resistant and water-resistant denitration catalyst and preparation method thereof

A denitrification catalyst, cerium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as increased energy consumption and equipment investment, physical damage to catalysts, poor resistance to sulfur and water, and achieve Reproducible, performance-boosting, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

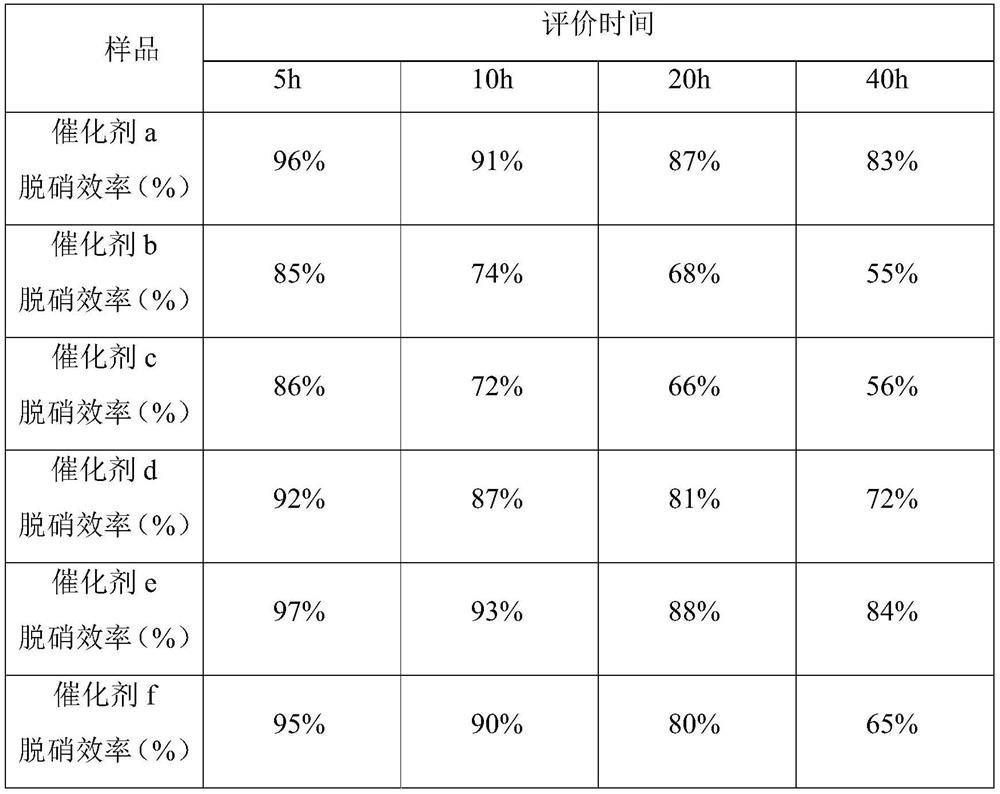

Examples

Embodiment 1

[0027] (1) A kind of preparation of cerium oxide

[0028] ①Dissolve 13.95g of cerium nitrate in 45mL of deionized water, and magnetically stir for 30 minutes at room temperature to obtain a cerium nitrate solution;

[0029] ②Dissolve 4.05g of cetyltrimethylammonium bromide in 30mL of deionized water, then add 36mL of ammonia water, and stir for 30 minutes;

[0030] ③ Slowly add the cerium nitrate solution prepared in step ① into the solution prepared in step ②, stir magnetically for 30 minutes at room temperature, transfer it to a 200mL hydrothermal reaction kettle, place it in an oven with a heating condition of 130°C, and a synthesis time of 15 hours;

[0031] ④The sample obtained in step ③ is subjected to suction filtration and water washing to remove other impurity ions. The obtained solid sample is placed in an oven with a heating condition of 80°C and a drying time of 5 hours. The dried sample is placed in a muffle furnace for roasting. The temperature is 500°C, the cal...

Embodiment 2

[0038] (1) A kind of preparation of cerium oxide

[0039] ①Dissolve 13.95g of cerium nitrate in 45mL of deionized water, and magnetically stir for 30 minutes at room temperature to obtain a cerium nitrate solution;

[0040] ②Dissolve 4.05g of cetyltrimethylammonium bromide in 30mL of deionized water, then add 36mL of ammonia water, and stir for 30 minutes;

[0041] ③ Slowly add the cerium nitrate solution prepared in step ① into the solution prepared in step ②, stir magnetically for 30 minutes at room temperature, transfer it to a 200mL hydrothermal reaction kettle, place it in an oven with a heating condition of 130°C, and a synthesis time of 15 hours;

[0042] ④The sample obtained in step ③ is subjected to suction filtration and water washing to remove other impurity ions. The obtained solid sample is placed in an oven with a heating condition of 80°C and a drying time of 5 hours. The dried sample is placed in a muffle furnace for roasting. The temperature is 500°C, the cal...

Embodiment 3

[0049] (1) A kind of preparation of cerium oxide

[0050] ①Dissolve 13.95g of cerium nitrate in 45mL of deionized water, and magnetically stir for 30 minutes at room temperature to obtain a cerium nitrate solution;

[0051] ②Dissolve 4.05g of cetyltrimethylammonium bromide in 30mL of deionized water, then add 36mL of ammonia water, and stir for 30 minutes;

[0052] ③ Slowly add the cerium nitrate solution prepared in step ① into the solution prepared in step ②, stir magnetically for 30 minutes at room temperature, transfer it to a 200mL hydrothermal reaction kettle, place it in an oven with a heating condition of 130°C, and a synthesis time of 15 hours;

[0053] ④The sample obtained in step ③ is subjected to suction filtration and water washing to remove other impurity ions. The obtained solid sample is placed in an oven with a heating condition of 80°C and a drying time of 5 hours. The dried sample is placed in a muffle furnace for roasting. The temperature is 500°C, the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com