Denitration catalyst containing tungsten-tin-manganese-cerium composite oxide as well as preparation and application of denitration catalyst

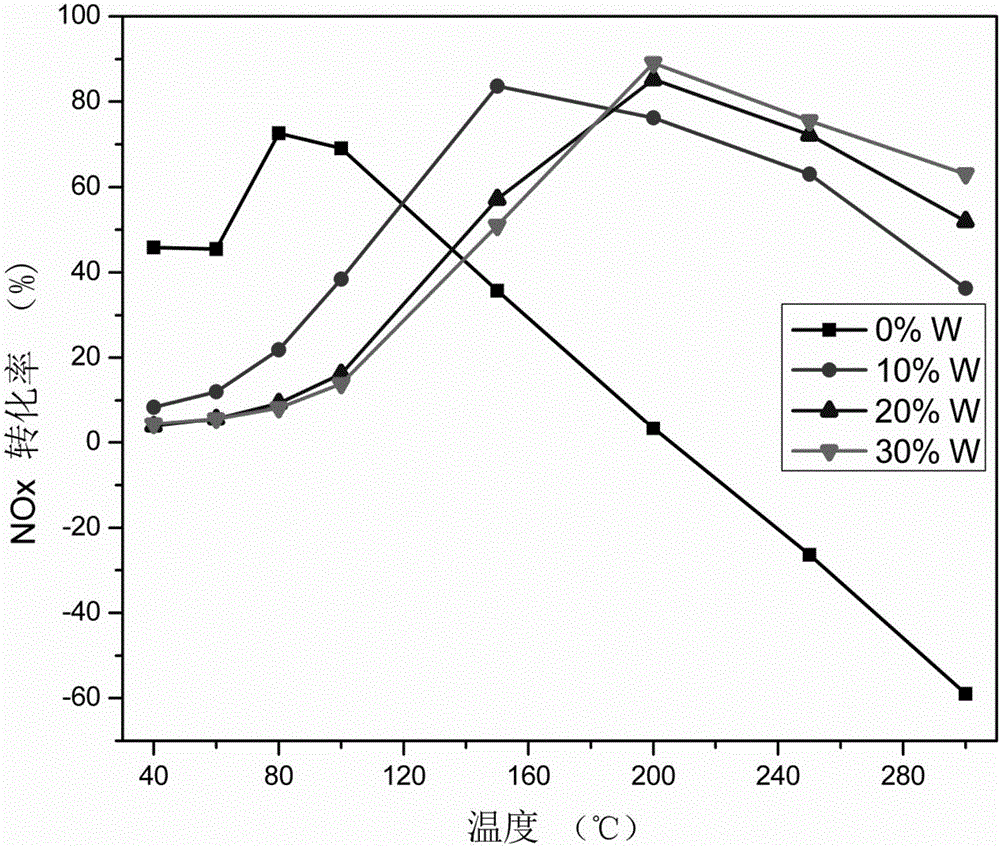

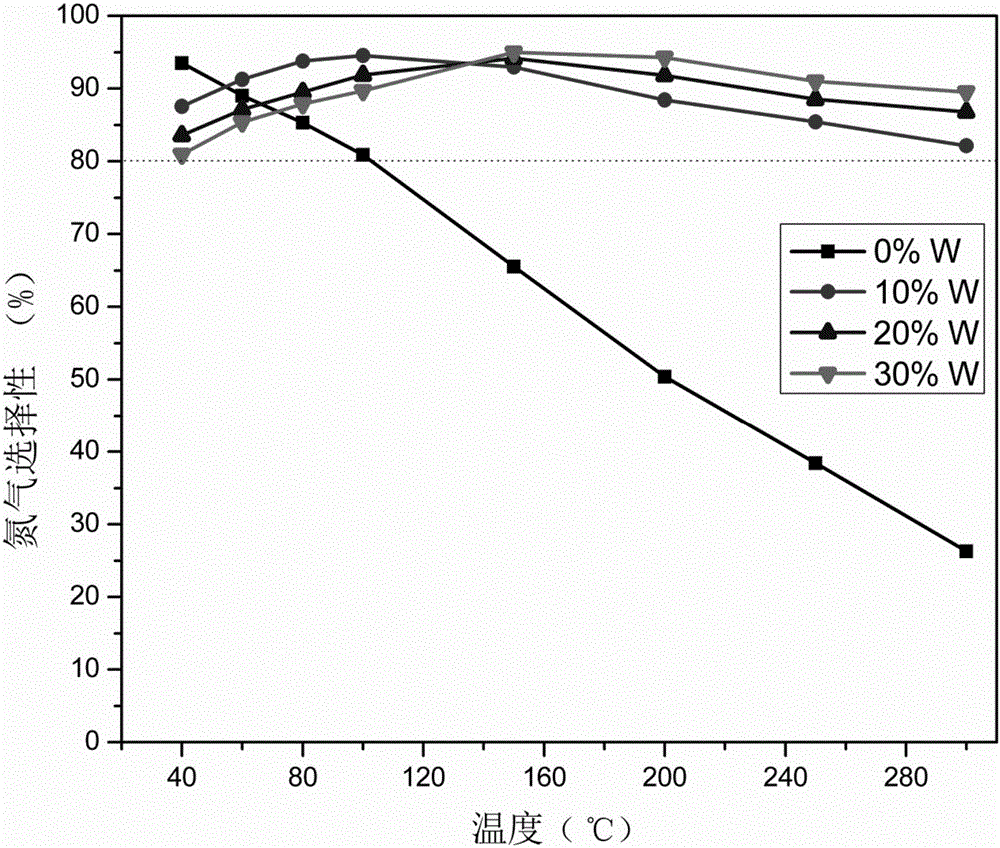

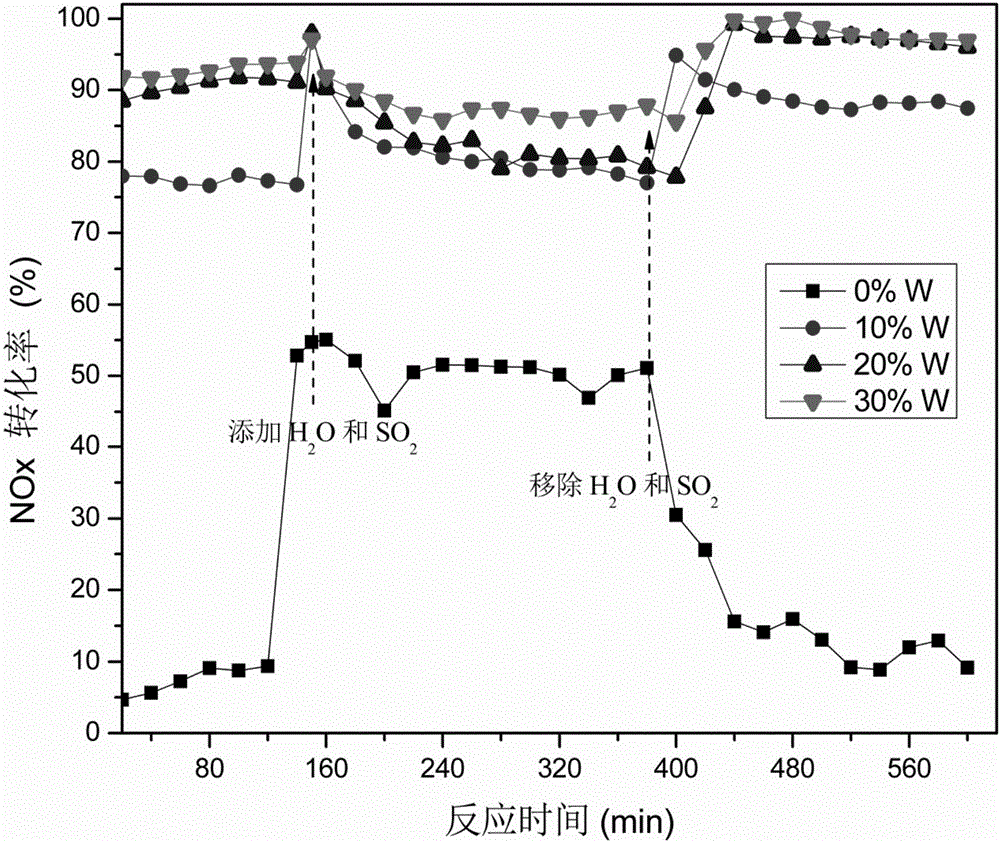

A composite oxide and denitrification catalyst technology, which is applied in the field of tungsten-tin-manganese-cerium composite oxide denitration catalyst and its preparation and application, can solve the problems of poor sulfur resistance, impact, and reduced nitrogen selectivity, etc., to improve water resistance and sulfur resistance resistance, high tolerance, and the effect of improving nitrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] W 0.3 sn 0.1 mn 0.4 Ce 0.5 o y sample preparation

[0029] (1) Take by weighing 4.044g ammonium metatungstate, 1.753g stannous chloride, 3.579g manganese nitrate solution (50%), 10.856g cerium nitrate hexahydrate for subsequent use;

[0030] (2) Weigh 4.044g oxalic acid, dissolve oxalic acid and ammonium metatungstate in 50mL deionized water;

[0031] (3) dissolving the weighed cerium nitrate hexahydrate in a small amount of deionized water;

[0032] (4) After (2) and (3) are completely dissolved, sequentially add the tin salt and manganese salt solutions weighed in (1) to (2), and add (3) to the system drop by drop;

[0033] (5) Measure about 50 mL of ammonia water and add it dropwise to the solution obtained in (4), so that the pH value in the final system is 10±0.5, and stir and age at room temperature for about 2 hours;

[0034] (6) After stopping stirring in (5), let it stand for 2 to 4 hours to allow the precipitated grains to aggregate and grow;

[0035] ...

Embodiment 2

[0039] W 0.2 sn 0.1 mn 0.4 Ce 0.5 o y sample preparation

[0040] (1) Take by weighing 2.696g ammonium metatungstate, 1.753g stannous chloride, 3.579g manganese nitrate solution (50%), 10.856g cerium nitrate hexahydrate for subsequent use;

[0041] (2) Weigh 2.696g of oxalic acid, and dissolve oxalic acid and ammonium metatungstate in 50mL of deionized water;

[0042] (3) dissolving the weighed cerium nitrate hexahydrate in a small amount of deionized water;

[0043] (4) After (2) and (3) are completely dissolved, sequentially add the tin salt and manganese salt solutions weighed in (1) to (2), and add (3) to the system drop by drop;

[0044] (5) Measure about 50 mL of ammonia water and add it dropwise to the solution obtained in (4), so that the pH value in the final system is 10±0.5, and stir and age at room temperature for about 2 hours;

[0045] (6) After stopping stirring in (5), let it stand for 2 to 4 hours to allow the precipitated grains to aggregate and grow; ...

Embodiment 3

[0050] W 0.1 sn 0.1 mn 0.4 Ce 0.5 o y sample preparation

[0051] (1) Take by weighing 1.348g ammonium metatungstate, 1.753g stannous chloride, 3.579g manganese nitrate solution (50%), 10.856g cerium nitrate hexahydrate for subsequent use;

[0052] (2) Weigh 1.348g oxalic acid, dissolve oxalic acid and ammonium metatungstate in 50mL deionized water;

[0053] (3) dissolving the weighed cerium nitrate hexahydrate in a small amount of deionized water;

[0054] (4) After (2) and (3) are completely dissolved, sequentially add the tin salt and manganese salt solutions weighed in (1) to (2), and add (3) to the system drop by drop;

[0055] (5) Measure about 50 mL of ammonia water and add it dropwise to the solution obtained in (4), so that the pH value in the final system is 10±0.5, and stir and age at room temperature for about 2 hours;

[0056] (6) After stopping stirring in (5), let it stand for 2 to 4 hours to allow the precipitated grains to aggregate and grow;

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com