Sulfur-resistant and water-resistant manganese-based low-temperature denitration catalyst as well as preparation method and application thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of poor sulfur and water resistance and high operating temperature. Achieve the effects of good sulfur and water resistance, high low temperature activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

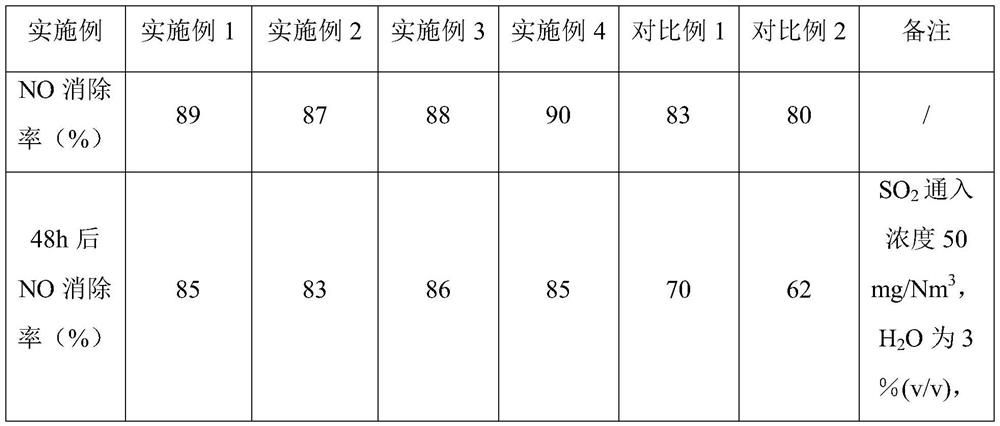

Examples

Embodiment 1

[0030] (1) 1000 g of titanium dioxide powder was weighed, washed twice with deionized water, and dried at 80° C. for 5 hours to obtain carrier powder for later use.

[0031] (2) Weigh 30.28g of cerium nitrate, 9.39g of zirconium oxynitrate and 5.27g of nickel nitrate and add a certain amount of deionized water to prepare a 300ml solution, impregnate the single volume on the carrier powder, let stand for 8h, and dry at 100°C for 5h , placed in a muffle furnace and calcined at 350° C. for 5 h with a heating rate of 2° C. / min to obtain carrier powder supported by cerium oxide, zirconium oxide and nickel oxide.

[0032] (3) Take a certain amount of the above-mentioned modified carrier powder and grind it evenly, put it into a polytetrafluoroethylene hydrothermal reaction kettle, add 2.57g ammonium metavanadate and 3.95g oxalic acid, 40.36g potassium permanganate, 114.30g manganese nitrate Solution, 1ml of dilute nitric acid with a concentration of 1% and a certain amount of deioni...

Embodiment 2

[0035] (1) Weigh 1000g of titanium-tungsten powder, wash with deionized water three times, and dry at 90°C for 8 hours to obtain carrier powder for later use.

[0036] (2) Weigh 39.87g of lanthanum nitrate, 5.63g of zirconium oxynitrate and 6.05g of copper nitrate and add a certain amount of deionized water to prepare a 300ml solution, impregnate the single volume on the carrier powder, let stand for 8h, and dry at 100°C for 5h , placed in a muffle furnace and calcined at 350° C. for 5 h, with a heating rate of 2° C. / min, to obtain carrier powder supported by lanthanum oxide, zirconium oxide and copper oxide.

[0037] (3) Take a certain amount of the above-mentioned modified carrier powder and grind it evenly, put it into a polytetrafluoroethylene hydrothermal reaction kettle, add 6.43g ammonium metavanadate and 9.98g oxalic acid, 24.21g potassium permanganate, 46.96g manganese acetate , 3ml of 0.2% dilute nitric acid and a certain amount of deionized water, sealed in an autoc...

Embodiment 3

[0040](1) Weigh 400g of titanium dioxide powder and 600g of titanium-tungsten powder and mix evenly, wash with deionized water twice, and dry at 90°C for 8 hours to obtain carrier powder for later use.

[0041] (2) Weigh 32.80g of cerium nitrate, 30ml of zirconium acetate solution, 10.05g of ferric nitrate and 3.51g of cobalt nitrate and add a certain amount of deionized water to prepare a 300ml solution, impregnate the single volume on the carrier powder, let it stand for 8h, and place it at 100 ℃ drying for 5 hours, placed in a muffle furnace and calcined at 350 ℃ for 5 hours with a heating rate of 2 ℃ / min to obtain carrier powder loaded with cerium oxide, zirconia, iron oxide and cobalt oxide.

[0042] (3) Take a certain amount of the above-mentioned modified carrier powder and grind it evenly, put it into a polytetrafluoroethylene hydrothermal reaction kettle, add 3.86g ammonium metavanadate and 6.05g oxalic acid, 32.29g potassium permanganate, 62.61g manganese acetate , 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com