Sulfating modified iron-tungsten-titanium SCR (selective catalytic reduction) denitration catalyst as well as preparation method and application thereof

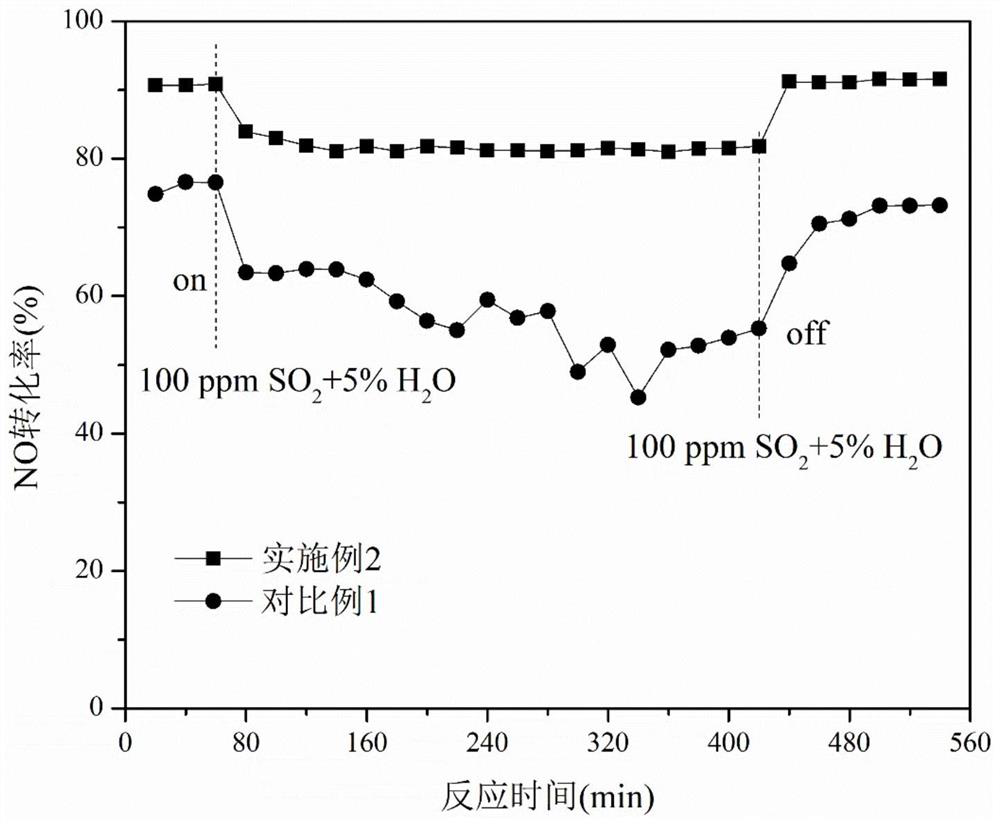

A denitrification catalyst and sulfation technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of poor denitrification catalytic performance, complicated preparation process, high production cost, etc., and achieve good application prospects, The preparation process is simple and the effect of high activation temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

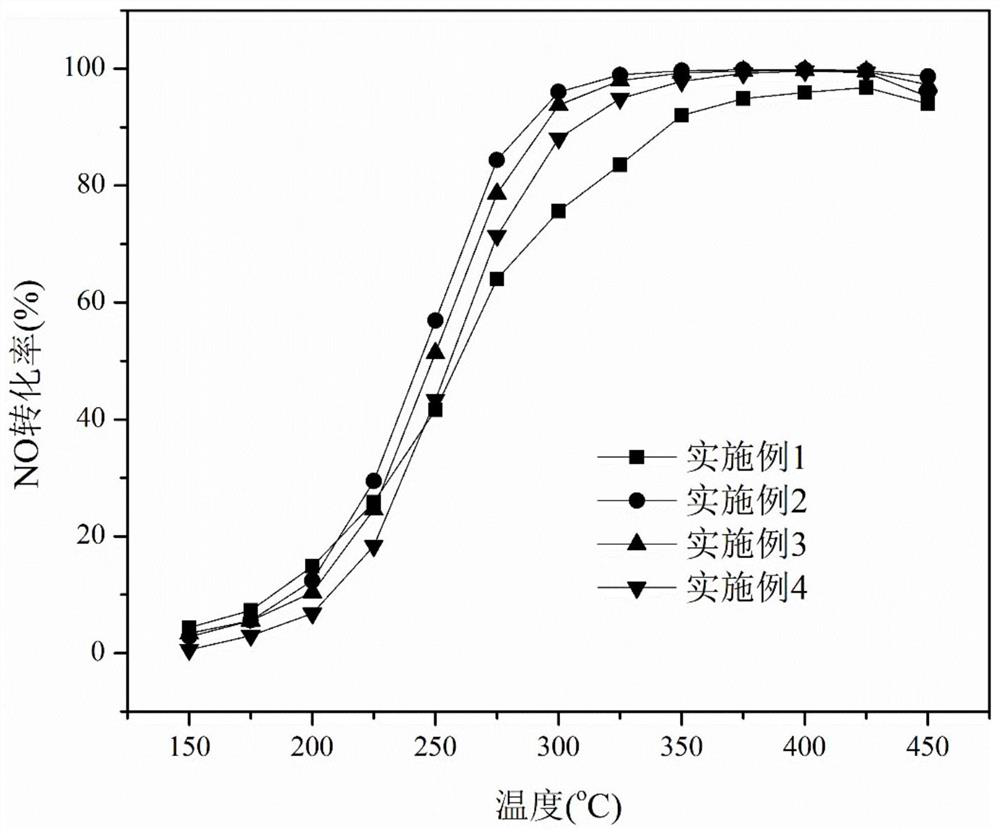

Examples

Embodiment 1

[0029] This example provides a method for preparing a sulfated modified iron-tungsten-titanium SCR denitration catalyst, the specific steps are:

[0030] (1) Tetrabutyl titanate, ethanol and nitric acid were mixed and stirred in a beaker at a volume ratio of 5:20:1 for 35 minutes.

[0031] (2) Mix ethanol and deionized water in a beaker at a volume ratio of 1:1, then add 0.067g of thiourea, 4.75g of Fe(NO 3 ) 3 ·9H 2 O, and 0.84g of ammonium tungstate were dissolved in the solution and stirred for 1h.

[0032] (3) The solution obtained in step (2) was slowly added dropwise to the solution obtained in step (1) under vigorous stirring, and the stirring was continued for 2.5 h to obtain a light yellow sol.

[0033] (4) Place the sol obtained in step (3) in an oven and dry it at 80° C. for 12 hours to remove water and organic solvents.

[0034] (5) The product obtained in step (4) is placed in a tube furnace, and heat-treated in still air at a treatment temperature of 450° C.,...

Embodiment 2

[0036] This example provides a method for preparing a sulfated modified iron-tungsten-titanium SCR denitration catalyst, the specific steps are:

[0037] (1) Tetrabutyl titanate, ethanol and nitric acid were mixed and stirred in a beaker at a volume ratio of 5:20:1 for 30 minutes.

[0038] (2) Mix ethanol and deionized water in a beaker at a volume ratio of 1:1, then add 0.134g of thiourea, 4.75g of Fe(NO 3 ) 3 ·9H 2 O, and 0.84g of ammonium tungstate were dissolved in the solution and stirred for 1.5h.

[0039] (3) The solution obtained in step (2) was slowly added dropwise to the solution obtained in step (1) under vigorous stirring, and the stirring was continued for 2 hours to obtain a light yellow sol.

[0040](4) The sol obtained in step (3) is placed in an oven, and dried at 80° C. for 12 hours to remove water and organic solvent.

[0041] (5) placing the product obtained in step (4) in a tube furnace, and performing heat treatment under still air at a treatment tem...

Embodiment 3

[0043] The present embodiment provides a preparation method of a sulfated modified iron-tungsten-titanium SCR denitration catalyst, the specific steps are:

[0044] (1) Mix and stir tetrabutyl titanate, ethanol and nitric acid in a beaker at a volume ratio of 5:20:1 for 25 minutes.

[0045] (2) Mix ethanol and deionized water in a beaker at a volume ratio of 1:1, then mix 0.225g thiourea, 4.75g Fe(NO 3 ) 3 ·9H 2 O, and 0.84g of ammonium tungstate were dissolved in the solution and stirred well for 2h.

[0046] (3) The solution obtained in step (2) was slowly added dropwise to the solution obtained in step (1) under vigorous stirring, and the stirring was continued for 1.5 h to obtain a pale yellow sol.

[0047] (4) The sol obtained in step (3) is placed in an oven, and dried at 80° C. for 12 hours to remove water and organic solvent.

[0048] (5) placing the product obtained in step (4) in a tube furnace, and performing heat treatment under still air at a treatment tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com