Synthesis method of copper-cerium co-doped CNT-coated SAPO-34 composite denitration catalyst

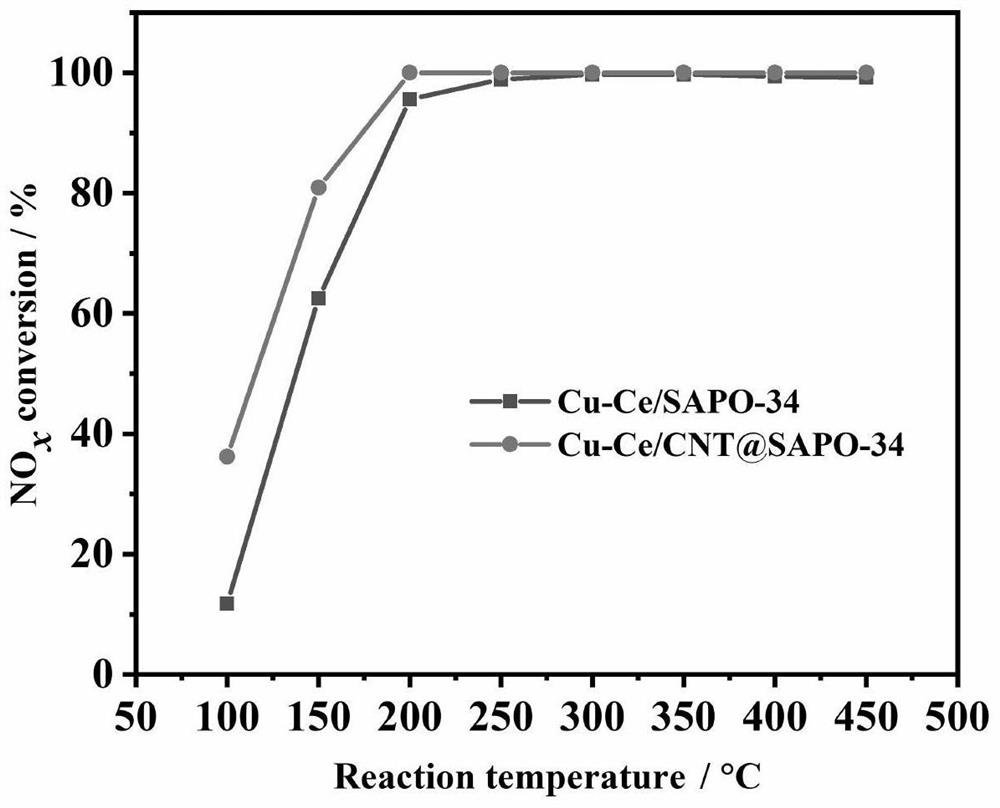

A technology of denitration catalyst and synthesis method, which is applied in the field of synthesis of copper and cerium co-doped CNT@SAPO-34 composite denitration catalyst, can solve the problems of poor water resistance and sulfur resistance, low loading of active components, etc., and achieve good water resistance Sulfur resistance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

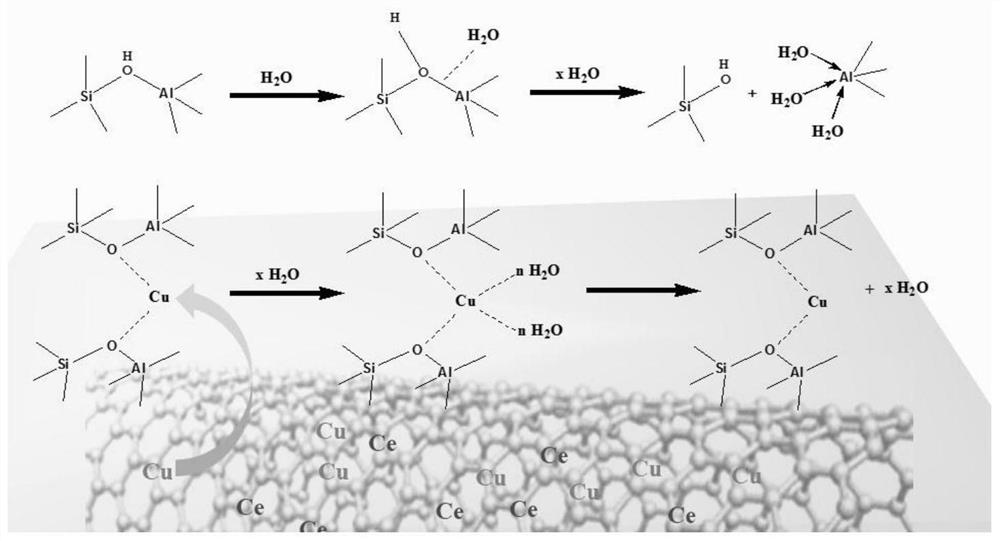

Method used

Image

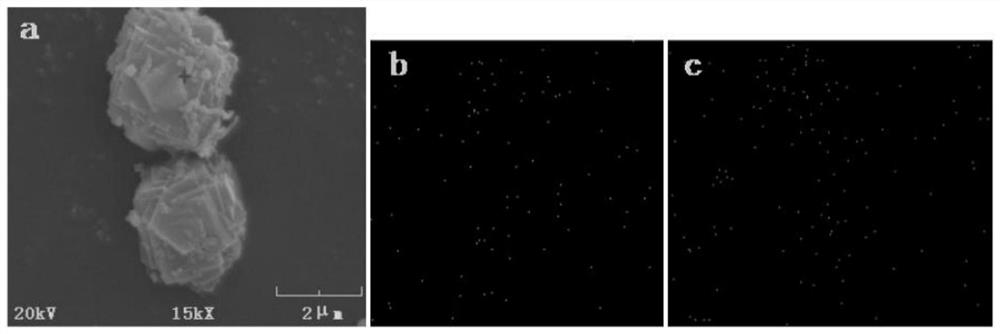

Examples

Embodiment 1

[0028] Example 1: The synthesis method of a copper-cerium co-doped CNT@SAPO-34 composite denitration catalyst in this example is carried out according to the following steps:

[0029] Step 1: 1.56g Ce(NO 3 ) 3 ·6H 2 O and 2.2g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 20.1 mL of water, then 1.0 mL of tetraethylenepentamine (TEPA) and 0.72 g of carbon nanotube (CNT) powder were added, and stirred until uniformly mixed to obtain a mixed solution;

[0030] Step 2: Dissolve 12.5g of aluminum isopropoxide in 22.9mL of deionized water, then add 6.3mL of diethylamine (DEA), stir at room temperature for 1 hour, then add 4mL of tetraethyl orthosilicate (TEOS), continue at room temperature Stir for 4h, then slowly add 4mLH to the system at a rate of 0.5mL / min 3 PO 4 (85wt%), continue to stir until forming sol, obtain sol;

[0031] Step 3: Add the mixed solution obtained in Step 1 to the sol obtained in Step 2, stir for 2 hours and then ultrasonicate at 40 kHz for 1 hour to obtain ...

Embodiment 2

[0032] Example 2: The synthesis method of a copper-cerium co-doped CNT@SAPO-34 composite denitration catalyst of this example is carried out according to the following steps:

[0033] Step 1: 0.78g Ce(NO 3 ) 3 ·6H 2 O and 0.44g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 9 mL of water, then 0.34 mL of tetraethylenepentamine (TEPA) and 0.18 g of carbon nanotube (CNT) powder were added, and stirred until uniformly mixed to obtain a mixed solution;

[0034] Step 2: Dissolve 6.13g of aluminum isopropoxide in 10mL of deionized water, then add 3.1mL of diethylamine (DEA), stir at room temperature for 1 hour, then add 2mL of tetraethyl orthosilicate (TEOS), and continue stirring at room temperature 4h, then slowly add 2.0mLH to the system at a rate of 0.5mL / min 3 PO 4 (85wt%), continue to stir until forming sol, obtain sol;

[0035] Step 3: Add the mixed solution obtained in Step 1 to the sol obtained in Step 2, stir for 2 hours and then ultrasonicate at 40 kHz for 1 hour to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com