Preparation method of NH3-SCR flue gas desulfurization catalyst and catalyst thereof

A NH3-SCR, denitration catalyst technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of poor thermal stability, harm, toxic environment of active component vanadium and human health, etc. Water and sulfur resistance, low price, and the effect of increasing catalyst active sites and surface acid sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the parts not described in detail below are all existing technologies or can be realized by using existing technologies.

[0019] a NH 3 -The preparation method of SCR flue gas denitrification catalyst, comprises the steps:

[0020] Step 1. Material preparation:

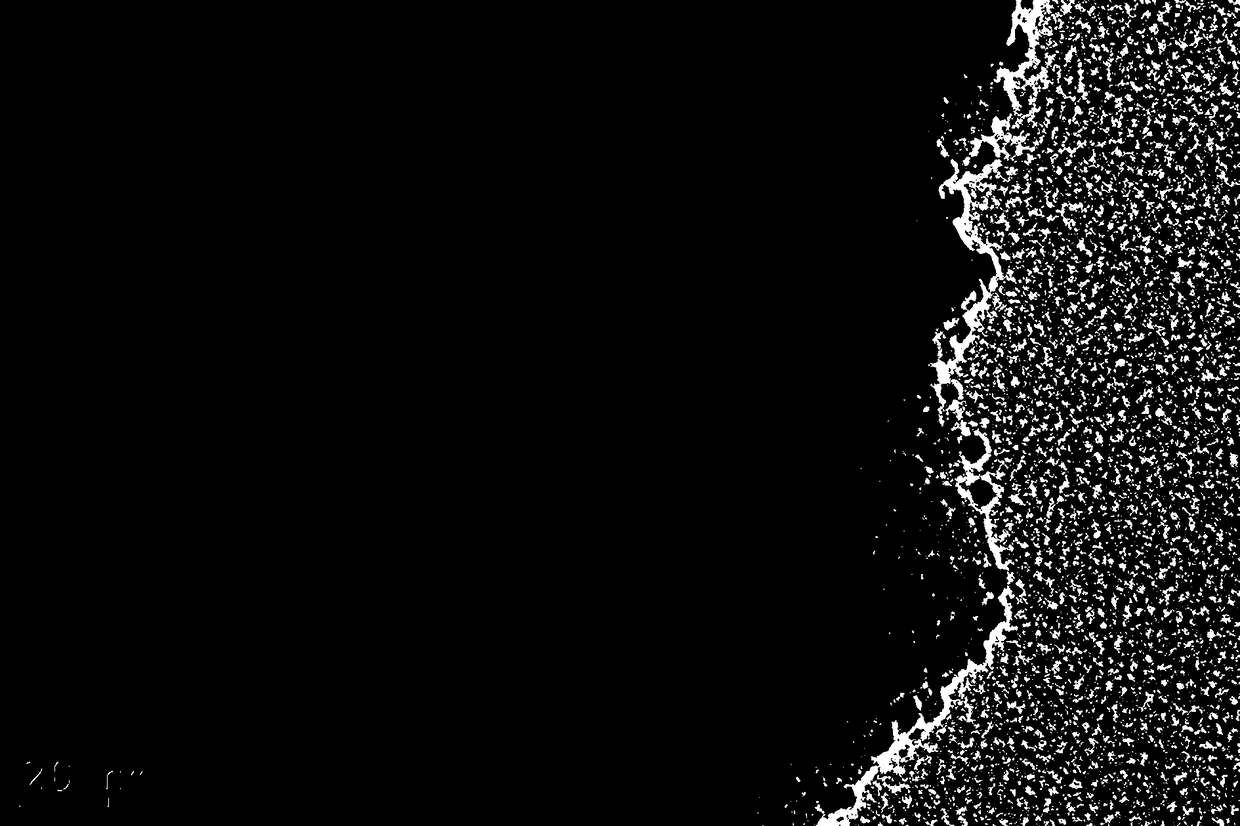

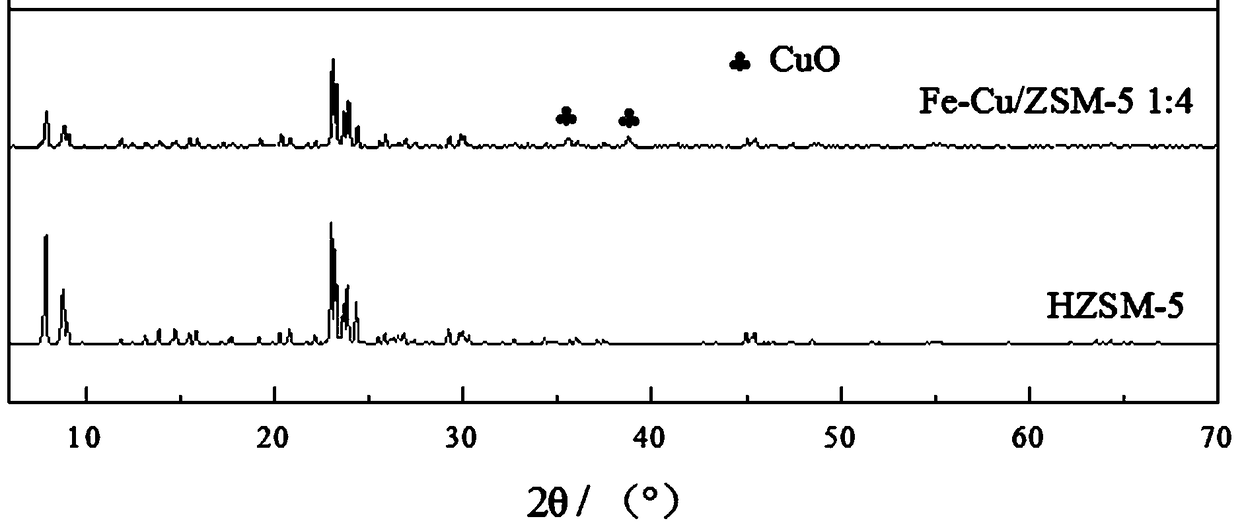

[0021] 1) Take H-ZSM-5 zeolite molecular sieve (SiO 2 / Al 2 o 3 =27, Tianjin Nankai University Chemical Reagent Factory), using a muffle furnace at 500 ° C for 3 h to remove water and impurities, cooled to room temperature, as a carrier;

[0022] 2) Weigh 40.4g of iron nitrate Fe(NO 3 ) 2 •9H 2 O (Tianjin Damao Chemical Reagent Factory, analytically pure) was fully dissolved in 500mL distilled water to prepare 0.2mol / L ferric nitrate solution;

[0023] 3) Weigh 24.16g copper nitrate Cu(NO 3 ) 2 •3H 2 O (Tianjin Damao Chemical Reagent Factory, analytically pure) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com