Co-In/Hbeta catalyst and preparation method and application thereof

A catalyst and co-in technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of high pipeline equipment requirements, poor water resistance and sulfur resistance, easy leakage reaction, etc., to achieve catalytic The active effect is obvious, the effect of improving water and sulfur resistance and reducing the active temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the Co-In / Hbeta catalyst is to co-impregnate cobalt nitrate and indium nitrate solutions with a molar concentration of 0.05-0.2mol / L on the H-beta molecular sieve, leave it at room temperature for 20-26 hours, and bake it at 100-120°C. 3-6 hours, then calcined at 400-600° C. for 2-6 hours, finally pressed into tablets, pulverized and sieved with 40-60 mesh to obtain Co-In / Hbeta catalyst.

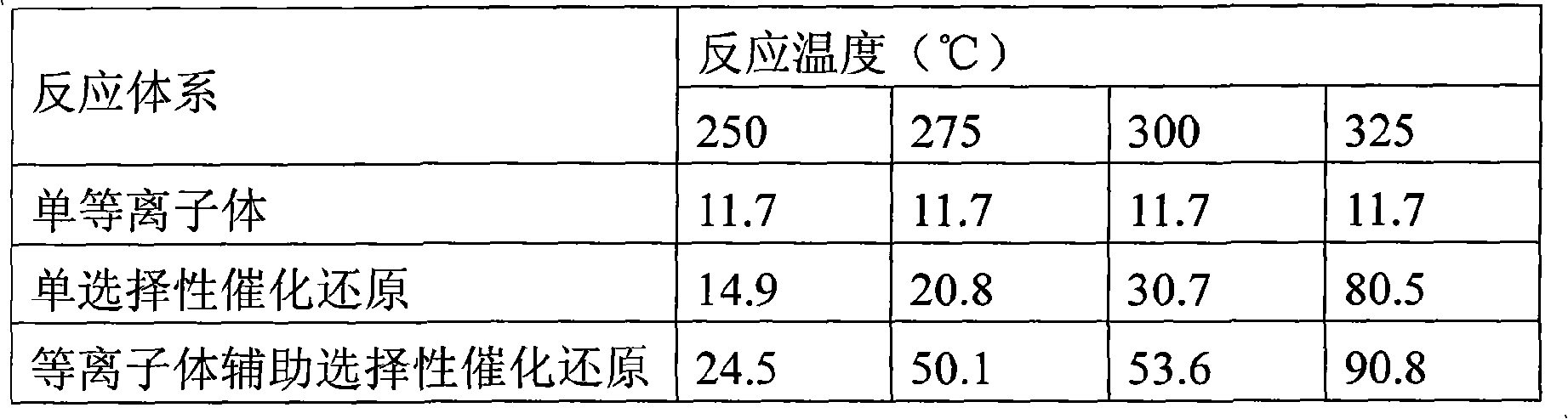

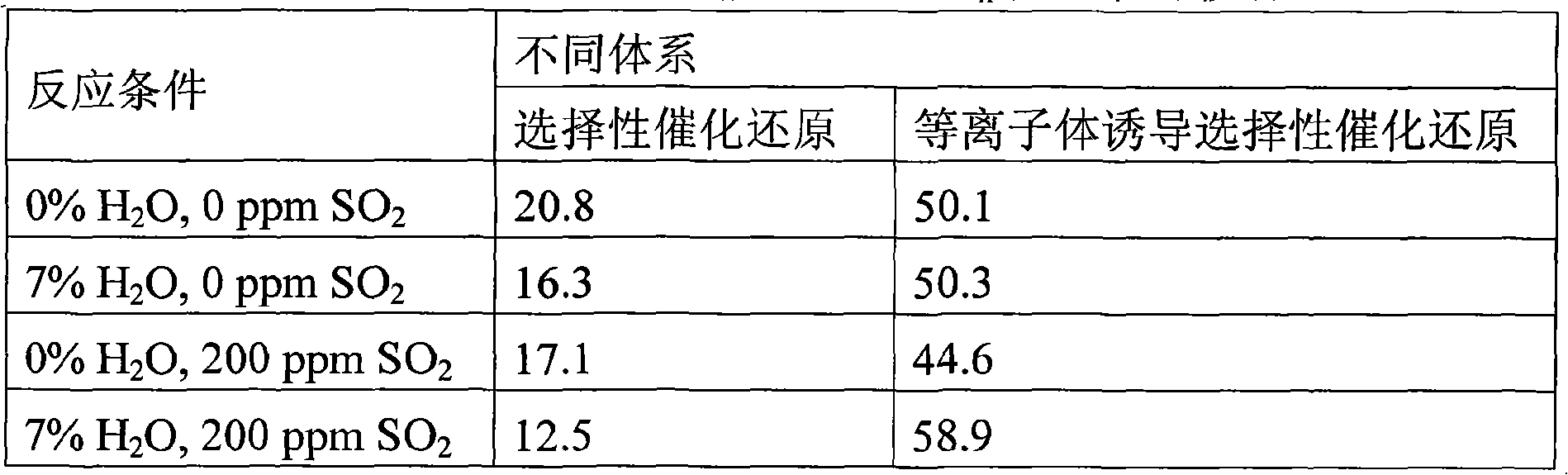

[0018] The Co-In / Hbeta catalyst can be applied to pulse plasma synergistic catalytic purification of nitrogen oxides in coal-fired flue gas. The method for synergistic catalytic purification of nitrogen oxides in coal-fired flue gas is: in 10000h -1 Under the condition of space velocity, low-carbon hydrocarbons are used as reducing agents, and Co-In / Hbeta is used as catalyst to catalytically reduce nitrogen oxides in flue gas. The volume concentration ratio of low-carbon hydrocarbons and nitrogen oxides in flue gas is 0.5- 3. The reaction temperature is 200-...

Embodiment 1

[0022] The catalyst of the present invention uses cobalt and indium as active components, and is carried on an artificially synthesized Hbeta molecular sieve with a silicon-to-aluminum ratio of 25. The weight percent of cobalt carried on the molecular sieve is 3%, and the weight percent of indium is 3%. %, namely: Co-In / Hbeta (3:3:100);

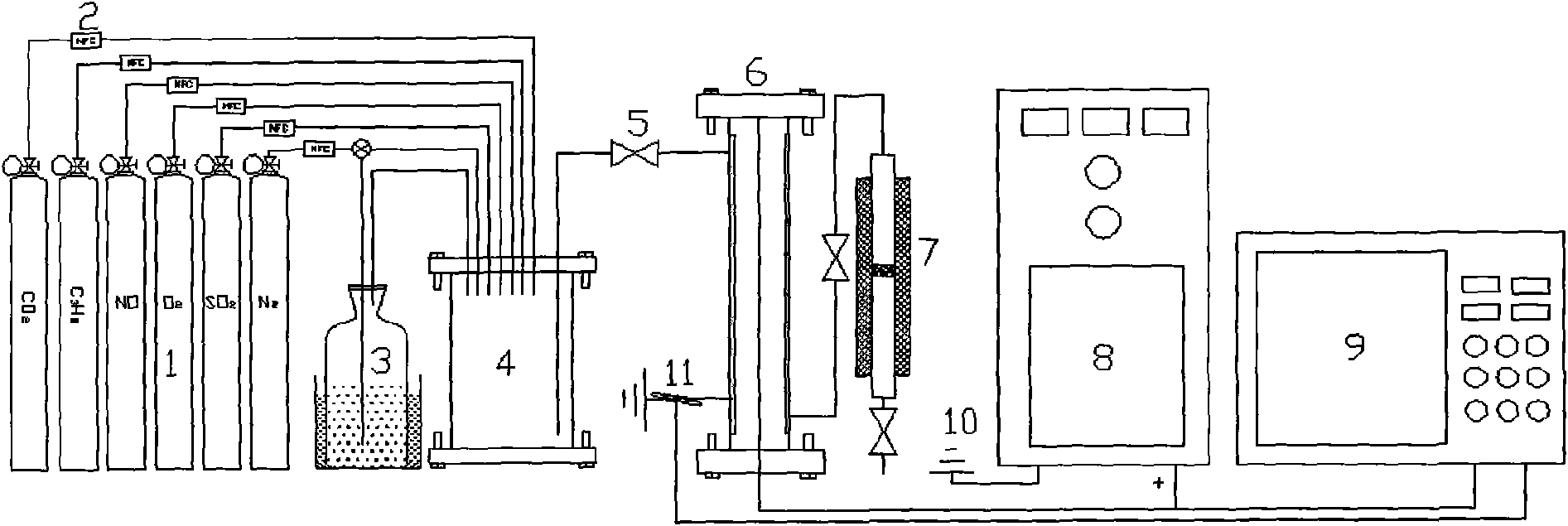

[0023] Now take the Co-In / H-beta catalyst (silicon-aluminum ratio is 25) that contains Co3%, In3% (percentage by weight) as an example to generally describe the use and effect thereof of process equipment among the present invention, specifically for:

[0024] Cobalt nitrate and indium nitrate were used to prepare In-containing 2+ and Co 2+ A solution of 0.1mol / L is used as the impregnation solution. Take 37ml of the solution and impregnate it on 10 grams of H-beta molecular sieve, let it stand for 24 hours, bake it at 120°C for 5 hours, put it in a muffle furnace and bake it at 500°C for 3 hours, and finally The catalyst was pressed into ...

Embodiment 2

[0030] The catalyst of the present invention uses cobalt and indium as active components, and is carried on an artificially synthesized Hbeta molecular sieve with a silicon-to-aluminum ratio of 25. The weight percent of cobalt carried on the molecular sieve is 3%, and the weight percent of indium is 3%. %, namely: Co-In / Hbeta (3:3:100);

[0031] Now take the Co-In / H-beta catalyst (silicon-aluminum ratio is 25) that contains Co2%, In2% (percentage by weight) as an example to generally describe the use and effect thereof of process equipment among the present invention, specifically for:

[0032] Cobalt nitrate and indium nitrate were used to prepare In-containing 2+ and Co 2+A solution of 0.1mol / L is used as the impregnation solution. Take 24.5ml of the solution and impregnate it on 10 grams of H-beta molecular sieve, let it stand for 24 hours, bake it at 120°C for 5 hours, and bake it in a muffle furnace for 3 hours at 500°C after drying. Finally, the catalyst was pressed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com