Fluorine modified lanthanum manganese composite oxide SCR denitration catalyst and preparation method thereof

A composite oxide and denitration catalyst technology, which is applied in the field of fluorine-modified lanthanum-manganese composite oxide SCR denitration catalyst and its preparation, can solve the problems of poor sulfur and water resistance, and achieve good sulfur and water resistance and a wide range of sources , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

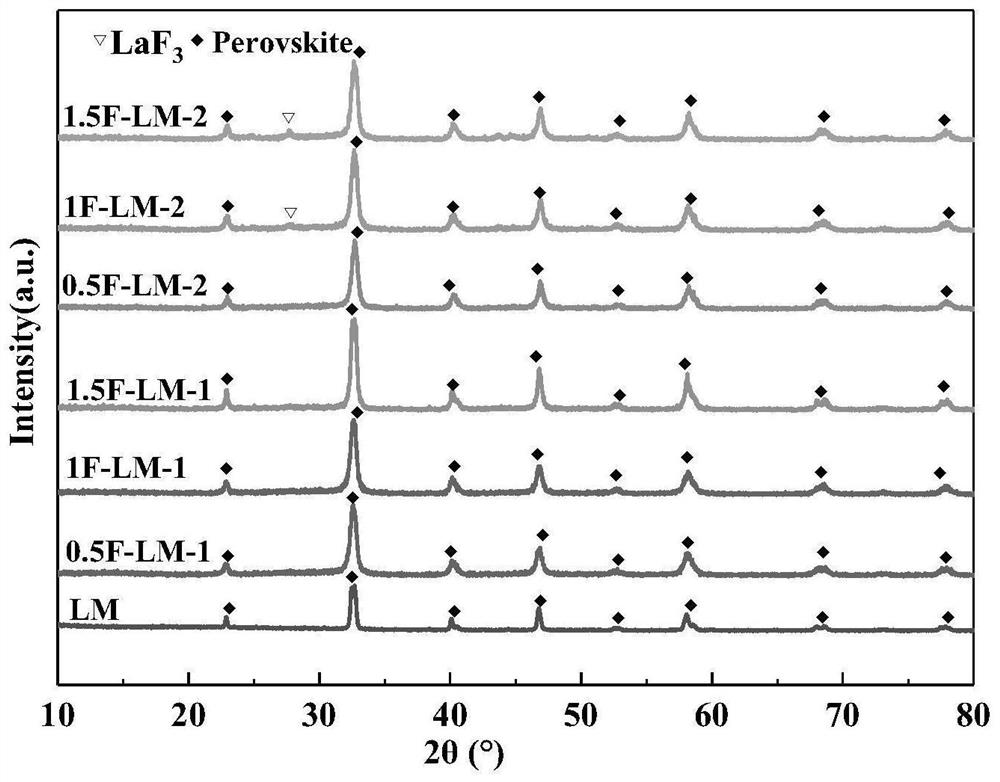

Embodiment 1

[0036] Get 8.66g of lanthanum nitrate and 4.65ml of 50% manganese nitrate solution, dissolve them in 100ml of distilled water, then add 15.37g of anhydrous citric acid, stir until completely mixed and dissolved, slowly add the pH regulator ammonia water and keep stirring, adjust the pH= 8. Then stir and evaporate the water in a water bath at 90°C, then age and dry at 120°C for 24 hours, and roast the product at 400°C for 3 hours, then raise the temperature to 800°C for 3 hours to obtain product 1, which is denoted as LM.

Embodiment 2

[0038] 10g of LM and 0.0978g of ammonium fluoride were mechanically stirred, mixed evenly, placed in a muffle furnace and calcined at 360°C for 2h at a heating rate of 5°C / min to obtain product 2, which was designated as 0.5F-LM-1.

Embodiment 3

[0040] 10g LM and 0.197g ammonium fluoride were mechanically stirred, mixed evenly, placed in a muffle furnace and calcined at 360°C for 2h at a heating rate of 5°C / min to obtain product 3, which was designated as 1F-LM-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com