Core-shell nanoparticles prepared by heterogeneous precipitation method and method for preparing nano ceramic

A nanoparticle and nanoceramic technology, applied in the field of multifunctional materials, can solve the problems of difficult repeated batch preparation and high preparation cost, and achieve the effects of omitting the calcination step, simple preparation method and less operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

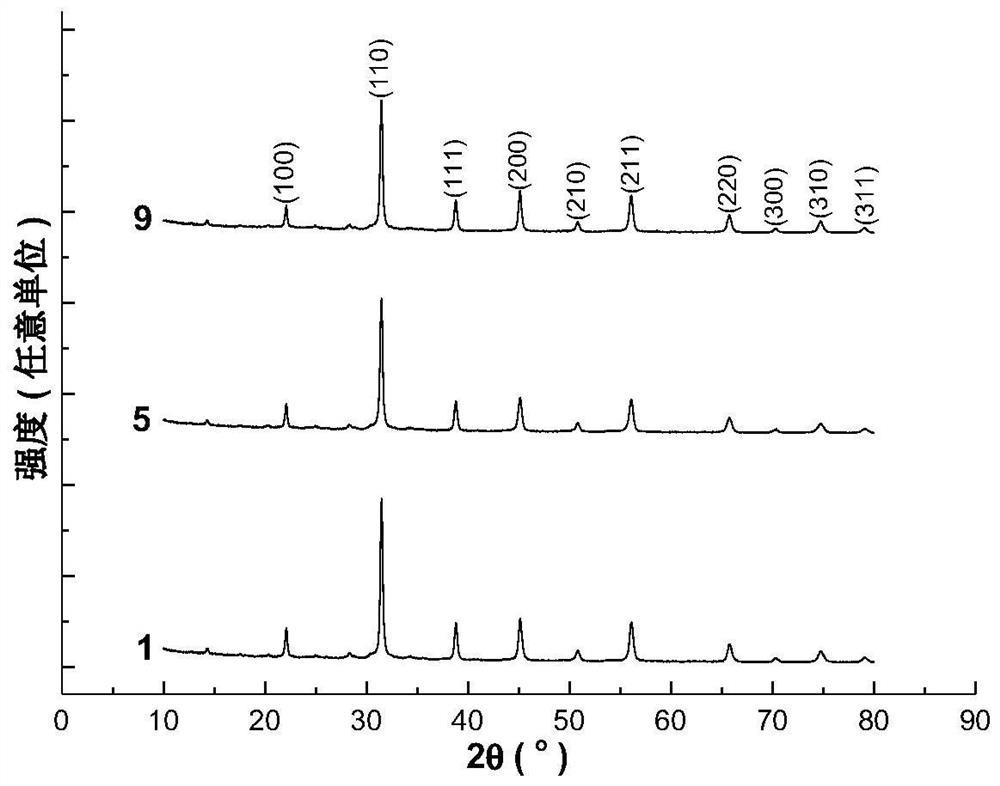

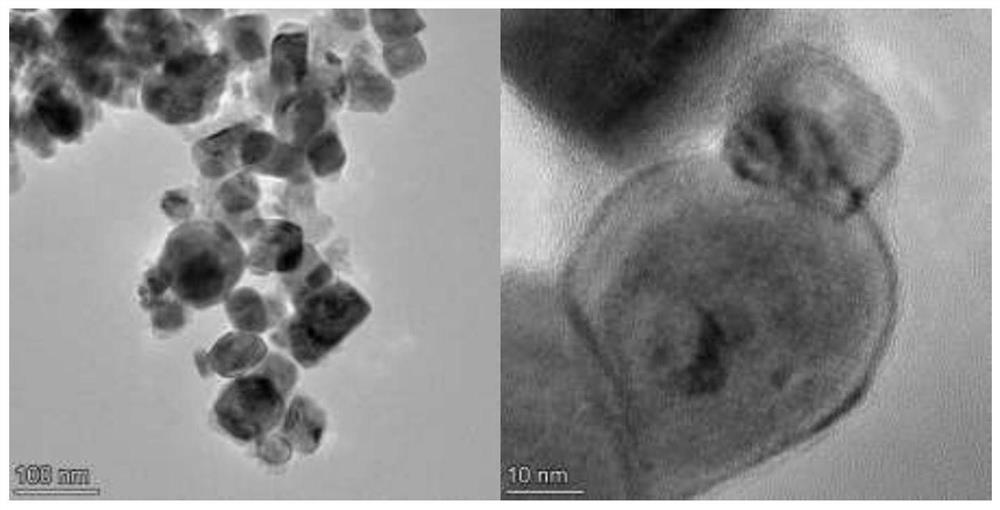

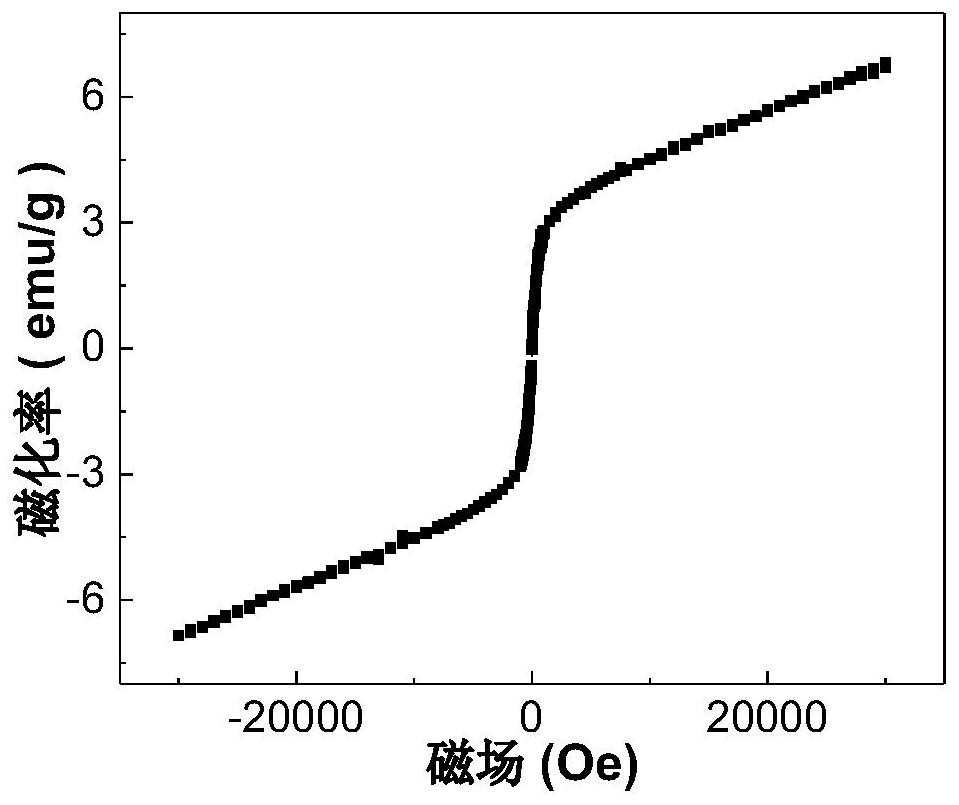

[0036] A kind of core-shell nanoparticles prepared by heterogeneous precipitation method, the chemical formula is [(BaCa) 1-x Nd x ](TiHf)O 3 (BCTH-xNd), where Ba / Ca=0.8-0.9 / 0.2-0.1, Ti / Hf=0.85-0.95 / 0.15-0.05, x=0.001-0.05.

[0037] Its preparation method is as follows:

[0038] S1. Weigh BaCl according to the stoichiometric ratio 2· 2H 2 O, CaCl 2 、TiCl 4 , HfO 2 、Nd 2 o 3 ;

[0039]S2. Put the raw materials weighed in step S1 into a hydrothermal kettle, add deionized water and mix evenly, add NaOH to form a supersaturated solution, and prepare perovskite structure BCTH-xNd nanopowder by hydrothermal reaction. The temperature is 160°C, the filling rate is less than 75%, the reaction time is 16h, and the concentration of NaOH is 14M;

[0040] S3. BCTH-xNd core-shell nanoparticles were prepared by using the point charge defects generated by asymmetric doping combined with electric field to induce heterogeneous precipitation. The electric field was an alternating elec...

Embodiment 2~9

[0043] The experimental method and material of embodiment 2~9 are all identical with embodiment 1, and its experimental condition sees the following table:

[0044] The experimental condition of table 1 embodiment 1~9

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com