Molecular sieve loaded modified manganese-based catalyst used for diesel car tail gas denitration, and preparation method and applications thereof

A manganese-based catalyst, molecular sieve technology, applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve problems such as selectivity and poor sulfur resistance and water resistance, and achieve a wide active temperature window, high low temperature activity, and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] a. Calcining the HZSM-5 molecular sieve carrier at 550°C for 3-5 hours, then cooling it for later use;

[0046] B. take by weighing 12g manganese acetate and 7.8g cerium nitrate, both are dissolved in 258mL deionized water, fully stir and mix, obtain mixed salt solution;

[0047] c. Weigh 51.5g of HZSM-5 molecular sieve carrier in proportion, use equal volume impregnation method, add it to the mixed salt solution described in step b and stir for 0.5 hours at the same time, sonicate for 2 hours, and stand at room temperature for 32 hours Obtain catalyst precursor;

[0048] d. Place the catalyst precursor in an oven, dry it at a constant temperature at 100-110°C for 18 hours, and then roast it in an air atmosphere at 400°C for 3 hours, and grind and sieve the obtained catalyst to 40-60 mesh;

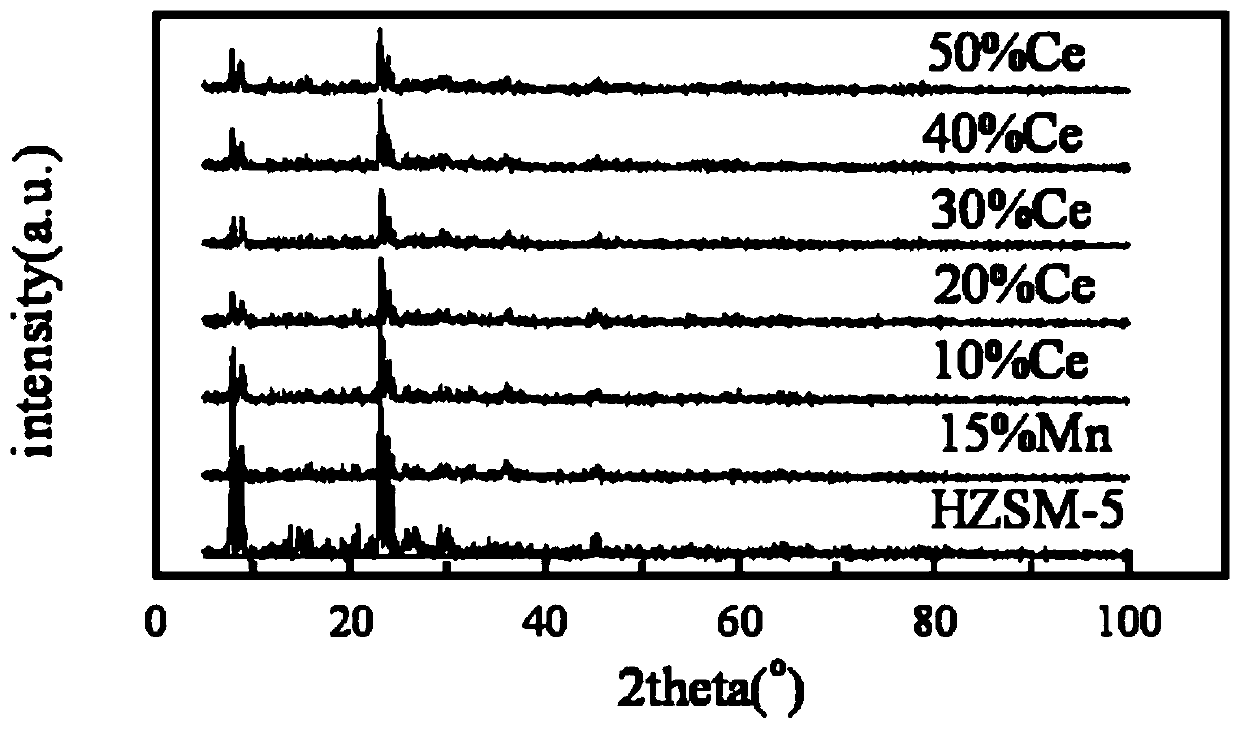

[0049] e. The catalyst of the present invention carries out XRD, SEM characterization and nitrogen adsorption-desorption experiment respectively, and XRD diffraction pattern is as ...

Embodiment 2

[0052] a. Calcining the HZSM-5 molecular sieve carrier at 550°C for 3-5 hours, then cooling it for later use;

[0053] B. take by weighing 5.5g manganese acetate and 4.5g cerium nitrate, both are dissolved in 118mL deionized water, fully stir and mix, obtain mixed salt solution;

[0054] c. Weigh 23.6g of HZSM-5 molecular sieve carrier in proportion, and use equal volume impregnation method, add it to the mixed salt solution described in step b and stir for 0.5 hours at the same time, sonicate for 3 hours, and stand at room temperature for 24 hours Obtain catalyst precursor;

[0055] d. Place the catalyst precursor in an oven, dry it at a constant temperature at 100-110°C for 18 hours, and then roast it in an air atmosphere at 400°C for 3 hours, and grind and sieve the obtained catalyst to 40-60 mesh;

[0056] e. The catalyst of the present invention was characterized and nitrogen adsorption and desorption experiments were carried out. The results of the nitrogen adsorption a...

Embodiment 3

[0059] a. Calcining the HZSM-5 molecular sieve carrier at 550°C for 3-5 hours, then cooling it for later use;

[0060] b. Weigh 18.5g manganese acetate and 10.5g cerium nitrate, dissolve the two in 397mL deionized water, fully stir and mix to obtain a mixed salt solution;

[0061] c. Weigh 79.5g of HZSM-5 molecular sieve carrier in proportion, use equal volume impregnation method, add it to the mixed salt solution described in step b and stir for 0.5 hours at the same time, sonicate for 3 hours, and stand at room temperature for 32 hours Obtain catalyst precursor;

[0062] d. Place the catalyst precursor in an oven, dry it at a constant temperature at 100-110°C for 18 hours, and then roast it in an air atmosphere at 400°C for 3 hours, and grind and sieve the obtained catalyst to 40-60 mesh;

[0063] e. The catalyst of the present invention is characterized and subjected to nitrogen adsorption and desorption experiments. The results of the nitrogen adsorption and desorption ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com