Core-shell catalyst for denitration of FCC regeneration flue gas and preparation method of core-shell catalyst

A technology for core-shell catalysts and flue gas regeneration, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor water and sulfur resistance, easy deactivation, and short life, and achieve high The effects of water and sulfur resistance, high and low temperature activity, and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

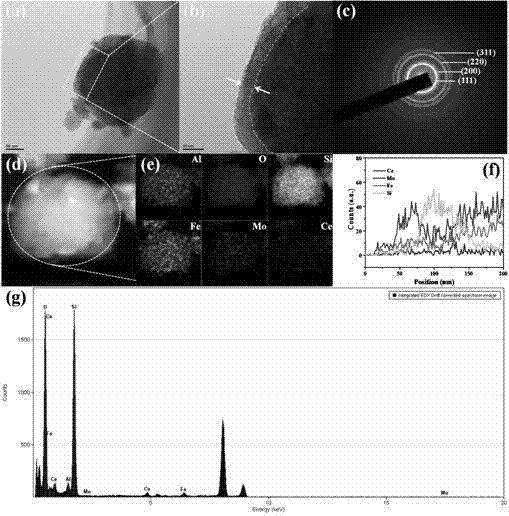

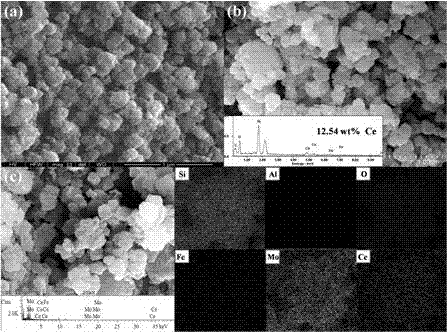

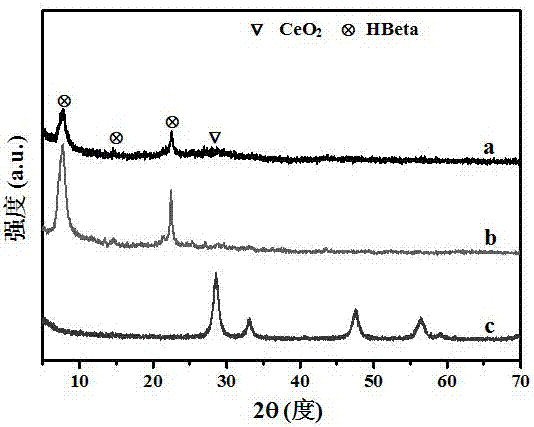

Method used

Image

Examples

Embodiment 1

[0039] Step 1) Preparation of small grain H-Beta (Si / Al 2 =30)

[0040] First, 90g of tetrapropylammonium hydroxide (25wt%) was added to 25g of deionized water, fully stirred for 2-4 hours, then 1.74g of aluminum isopropoxide was added to the solution, and after stirring for 30-60min, 63.8g Add silica sol (40wt%) into the solution, stir for 2-4 hours, then add 0.48g of NaOH solid powder, stir for 24 hours, put it into a crystallization kettle, crystallize at 100°C for 3 days, and then centrifuge the reaction product , and then wash the lower solid with alcohol, repeat twice, dry at 100°C for 12h, and roast at 550°C for 6h to obtain nano-sized Na-Beta. Subsequently, at 80°C with 0.1mol / L NH 4 NO 3 Treated for 8 hours, fully washed, dried, and calcined at 450°C for 3 hours to obtain small-grain H-Beta molecular sieve powder with a particle size of about 100nm.

[0041] Step 2) MoFe / Beta sample preparation (the loadings of Mo and Fe are 0.2wt% and 2.0wt%) based on Beta.

[0...

Embodiment 2

[0056] Step 1) Preparation of small grain H-Beta (Si / Al 2 =30)

[0057]First, 90g of tetrapropylammonium hydroxide (25wt%) was added to 25g of deionized water, fully stirred for 2-4 hours, then 1.74g of aluminum isopropoxide was added to the solution, and after stirring for 30-60min, 63.8g Add silica sol (40wt%) into the solution, stir for 2-4 hours, then add 0.48g NaOH solid powder, stir for 24 hours, put it into a crystallization kettle, crystallize at 100°C for 5 days, and then centrifuge the reaction product , and then wash the lower solid with alcohol, repeat twice, dry at 100°C for 12h, and roast at 550°C for 6h to obtain nano-sized Na-Beta. Then, at 60°C, 0.1mol / L NH 4 NO 3 Treated for 12 hours, fully washed, dried, and calcined at 450°C for 3 hours to obtain small-grain H-Beta molecular sieve powder with a particle size of about 100nm.

[0058] Step 2) MoFe / Beta sample preparation (the loadings of Mo and Fe are 0.2wt% and 2.0wt%) based on Beta.

[0059] First take...

Embodiment 3

[0063] Step 1) Preparation of small grain H-Beta (Si / Al 2 =30)

[0064] First, 90g of tetrapropylammonium hydroxide (25wt%) was added to 25g of deionized water, fully stirred for 2-4 hours, then 1.74g of aluminum isopropoxide was added to the solution, and after stirring for 30-60min, 63.8g Add silica sol (40wt%) into the solution, stir for 2-4 hours, then add 0.48g of NaOH solid powder, stir for 24 hours, put it into a crystallization kettle, crystallize at 100°C for 3 days, and then centrifuge the reaction product , and then wash the lower solid with alcohol, repeat twice, dry at 100°C for 12h, and roast at 550°C for 6h to obtain nano-sized Na-Beta. Then, at 80°C with 0.1mol / L NH 4 NO 3 Treated for 8 hours, fully washed, dried, and calcined at 450°C for 3 hours to obtain small-grain H-Beta molecular sieve powder with a particle size of about 100nm.

[0065] Step 2) MoFe / Beta sample preparation (the loadings of Mo and Fe are 0.2wt% and 2.0wt%) based on Beta.

[0066] Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com