Catalyst for concurrently and efficiently removing soot and NOx under oxygen-enriched, sulfur-containing and water-containing conditions, and preparation method thereof

The technology of a catalyst and a precious metal catalyst is applied in the field of simultaneous efficient removal of soot and NOx from diesel vehicle exhaust gas and the field of catalyst preparation thereof, and achieves the effects of high sulfur resistance and water resistance and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Catalyst of the present invention and preparation method thereof

[0042] A soot and NO x Simultaneously, the catalyst is efficiently removed, comprising: preparing two kinds of precious metals loaded on the catalyst support by an equal-volume impregnation method, and the total mass fraction of the precious metals is 1%.

[0043] Among them, a precursor of the double noble metal catalyst is H 2 IrCl 6 ·6H 2 O, another precursor is H 2 PtCl 6 ·6H 2 O, RhCl 3 ·nH 2 O, AgNO 3 , Pd(NH 4 )NO 3 、RuCl 3 ·3H 2 O or HAuC 4 4H 2 O, the two noble metals were supported on the catalyst support ZrO by the equal volume impregnation method 2 Above, the total mass fraction of precious metals is 1%, the weight ratio range R of double precious metals is 5:5, and the loading sequence is simultaneous loading.

[0044] The catalyst was prepared by the equal volume impregnation method. The double precious metal was impregnated on the catalyst carrier, and after st...

Embodiment 2

[0046] Embodiment 2 Catalyst of the present invention and preparation method thereof

[0047] According to the catalyst composition and preparation method thereof of the embodiment, the carrier is replaced by TiO 2 、Al 2 o 3 , ZSM-5 or SiO 2 .

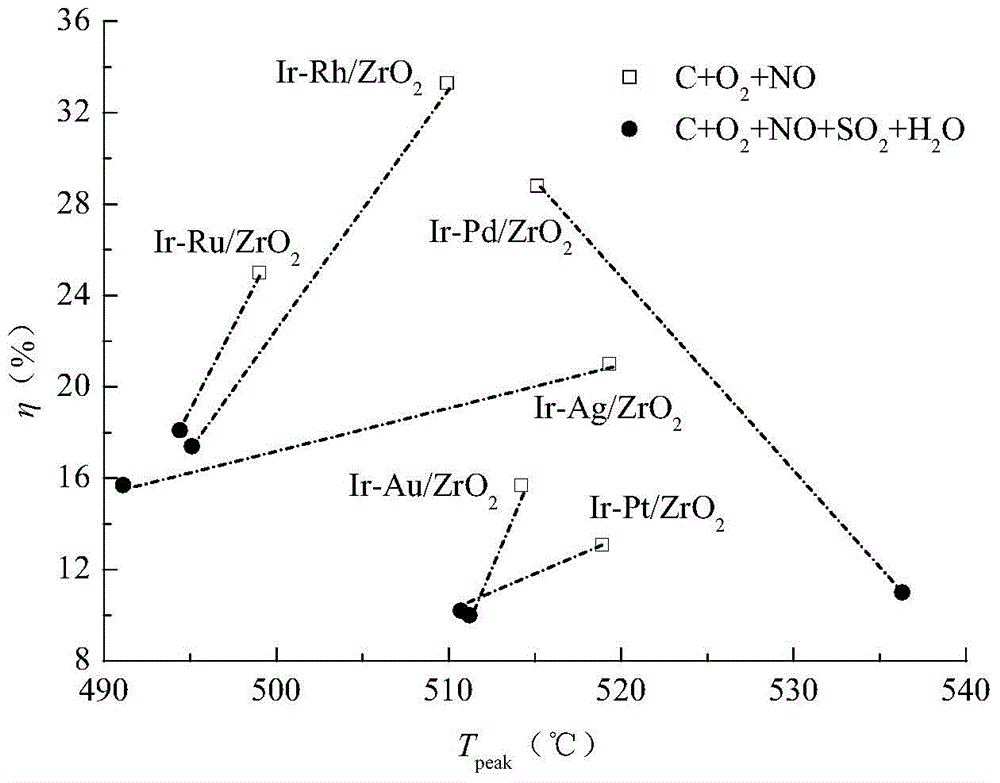

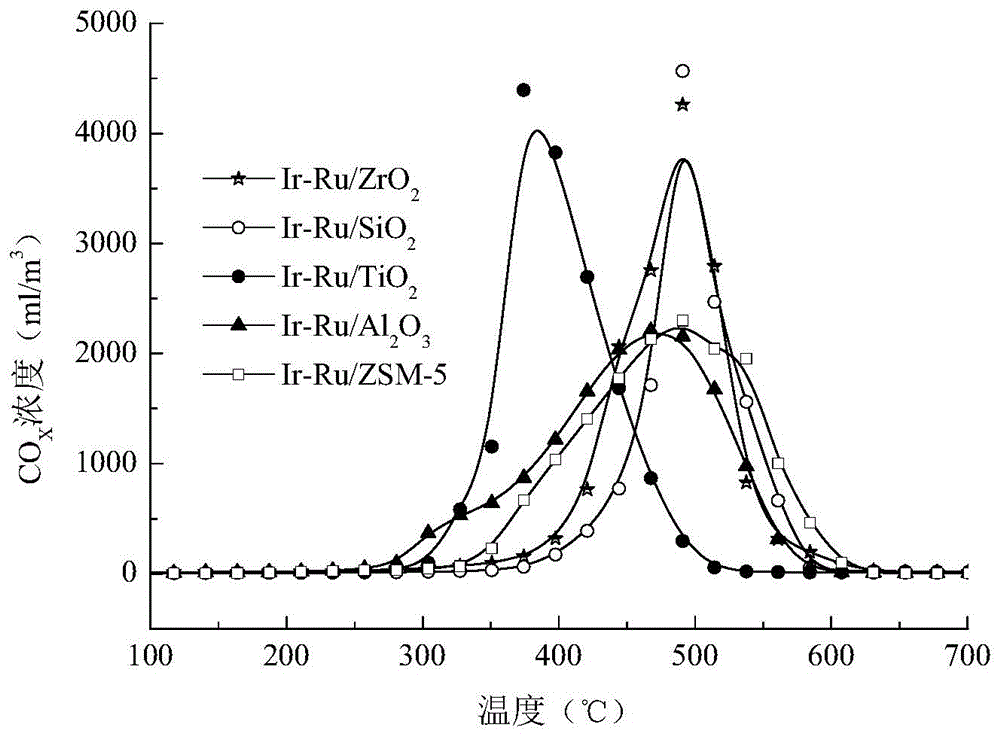

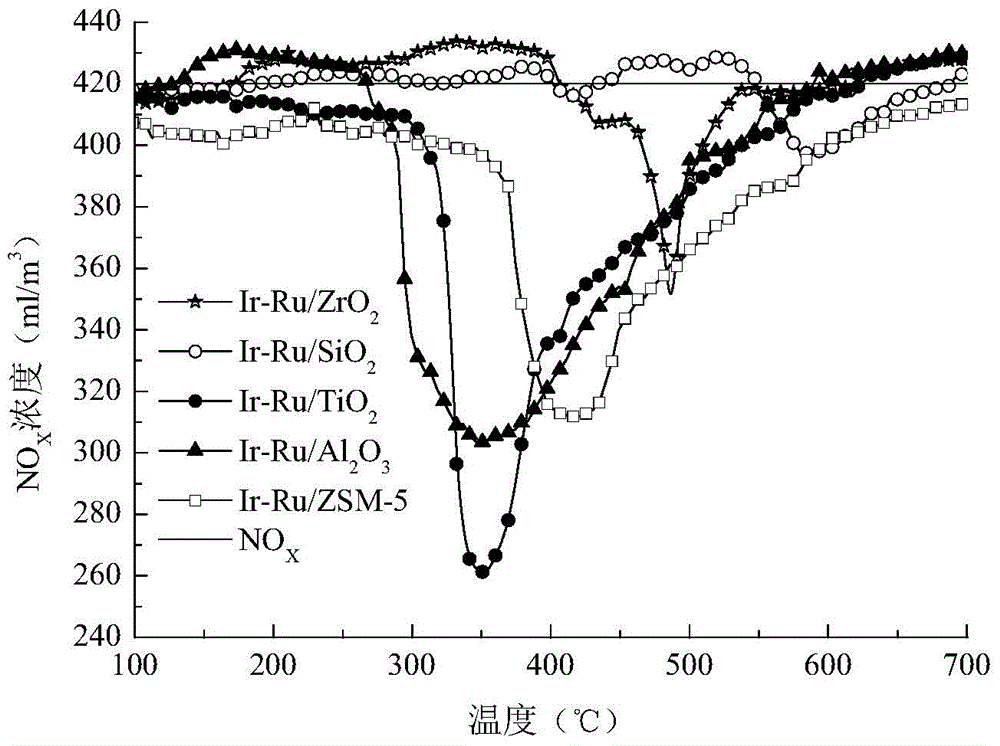

[0048] Using the catalyst evaluation method of the present invention, Ru-Ir loads different supports to simultaneously remove carbon particles and NO X Time CO X and NO X The TPR curves of figure 2 and 3 As shown, it can be seen that the dual-catalyst supports have good removal effects, and TiO 2 The carrier is optimal and has the best removal effect.

Embodiment 3

[0049] Embodiment 3 Catalyst of the present invention and preparation method thereof

[0050] According to the catalyst composition and preparation method thereof in the embodiment, the weight ratio R of Ru to Ir is replaced by 1:1, 3:7, 5:5, 7:3 respectively.

[0051] Using the catalyst evaluation method of the present invention, different Ru-Ir loading weight ratios R simultaneously remove carbon particles and NO X Time CO X and NO X The TPR curves of Figure 4 and 5 As shown, it can be seen that the weight ratio of Ru to Ir mentioned above has a good removal effect in the range of 1:1-9:1, and the weight ratio of Ru to Ir is 9:1, which has the best removal effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com