High-selective catalyst for dehydrogenating cyclohexanol to produce cyclohexanone and preparation method thereof

A high-selectivity, catalyst technology, applied in the direction of dehydrogenation preparation, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of increasing burden, high operating temperature, and affecting the quality of caprolactam products, so as to improve selectivity and reduce The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

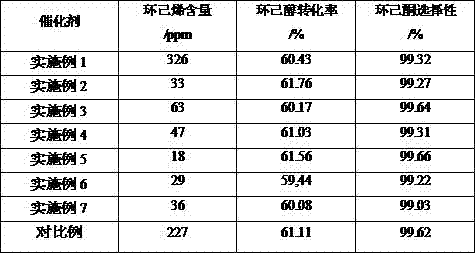

Examples

Embodiment 1

[0020] Catalyst preparation is carried out in an open reactor, according to the following steps to implement. Take 1000ml solution a of 1.0M copper nitrate solution; in a precipitation tank with stirring, at a precipitation temperature of 50°C, co-precipitate the sodium carbonate solution and 980 grams of silica sol, age for 5 minutes, and then add solution a In the above precipitation, the precipitation temperature is 50°C, the pH value of the end point of the precipitation is 8.4, and the catalyst is aged at 60°C for 60 minutes, washed, dried, crushed, roasted at 420°C, and pressed into tablets to obtain a usable catalyst.

Embodiment 2

[0022] Catalyst preparation is carried out in an open reactor, according to the following steps to implement. Take 100ml of 1.0M copper nitrate solution and 16ml of 1.0M manganese nitrate solution to prepare mixed solution a; in a sedimentation tank with stirring, the precipitation temperature is 50°C, co-precipitate the sodium carbonate solution and 1048 grams of silica sol, Precipitation temperature is 50°C, age for 5 minutes, then add solution a to the above precipitation, control the precipitation temperature at 50°C, the pH value of the end point of precipitation is 8.1, age at 60°C for 60 minutes, wash, dry, Granulating, calcining at 450°C, and pressing into tablets to obtain a usable catalyst.

Embodiment 3

[0024] Catalyst preparation is carried out in an open reactor, according to the following steps to implement. Take 1000ml of 1.0M copper nitrate solution and 12ml of 1.0M cerium nitrate solution to prepare mixed solution a; in a precipitation tank with stirring, at a precipitation temperature of 50°C, co-precipitate potassium carbonate solution and 1048 grams of silica sol , aged for 5 minutes, then added solution a to the above precipitation, controlled the precipitation temperature to 50°C, the pH value of the end point of the precipitation was 7.9, aged at 60°C for 60 minutes, washed, dried, granulated, and 450°C Roasting, tablet molding, that is, a usable catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com