Ammonia scr catalyst and method of using the catalyst

A catalyst, ammonia source technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve public health problems and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

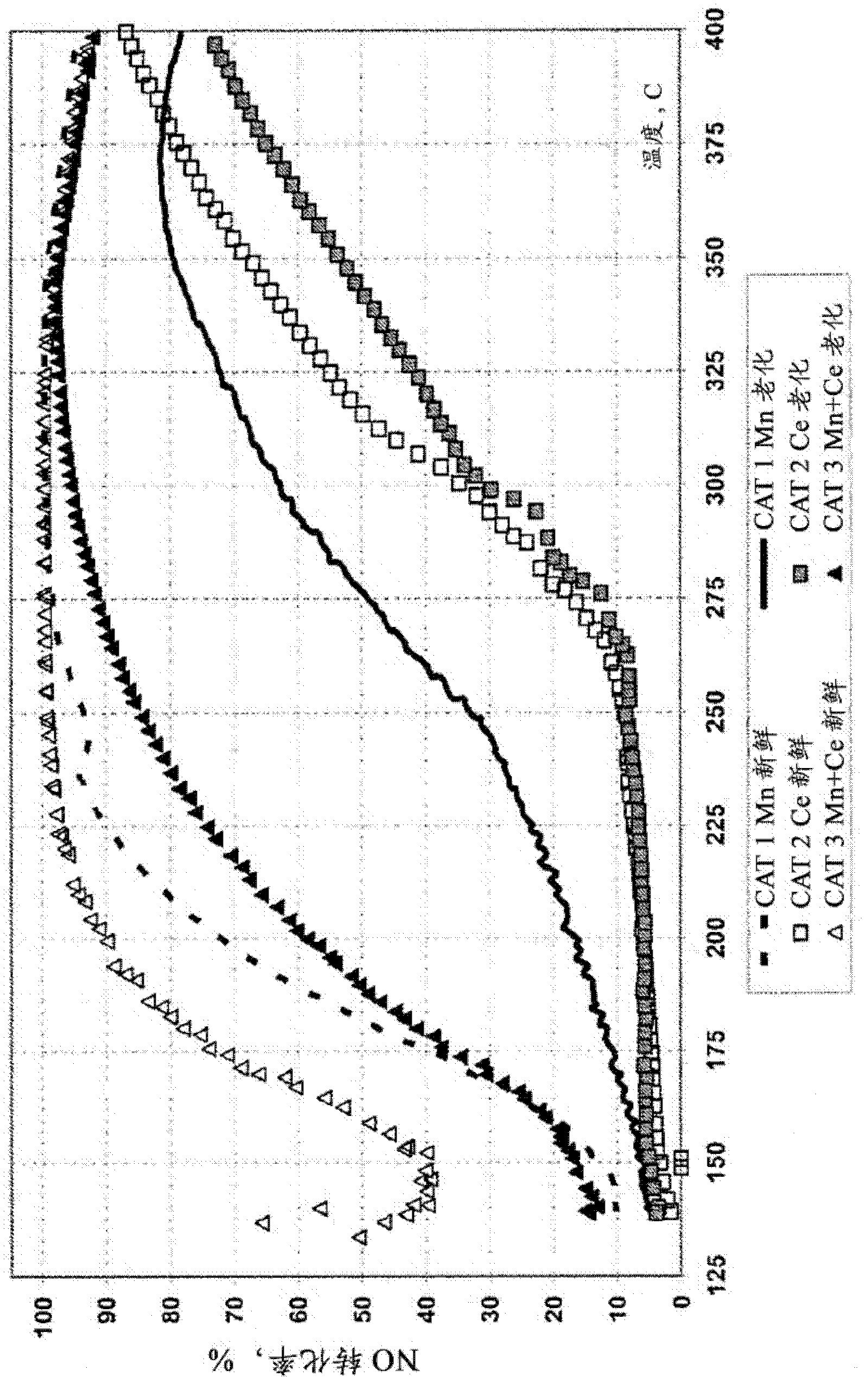

[0148] Synergy between manganese first component and cerium second component

[0149] Catalysts with the compositions shown in Table 1 were prepared and tested for ammonia SCR reduction of nitrogen oxides. The weight percents of manganese and cerium are given on an oxide and metal basis, respectively, with metal-based weight percents placed in parentheses in the table.

[0150] Table 1

[0151] Composition of Mn and Ce catalysts

[0152]

[0153] Zeolite and OSM were placed on the substrate as an eluting coating at a loading of about 150 g / L. The eluate coating was dried at room temperature and then calcined at 550 °C for 4 hours. The aqueous solutions of manganese nitrate and cerium nitrate are combined and dipped into the stripped coating on the substrate. The catalyst was dried and calcined at 550 °C for 2 hours. The OSM contains the formula Ce 0.24 Zr 0.66 La 0.04 Y 0.06 o 2 CZLY, and the zeolite consists of ZSM-5.

[0154] The catalysts in Table 1 were teste...

Embodiment 2

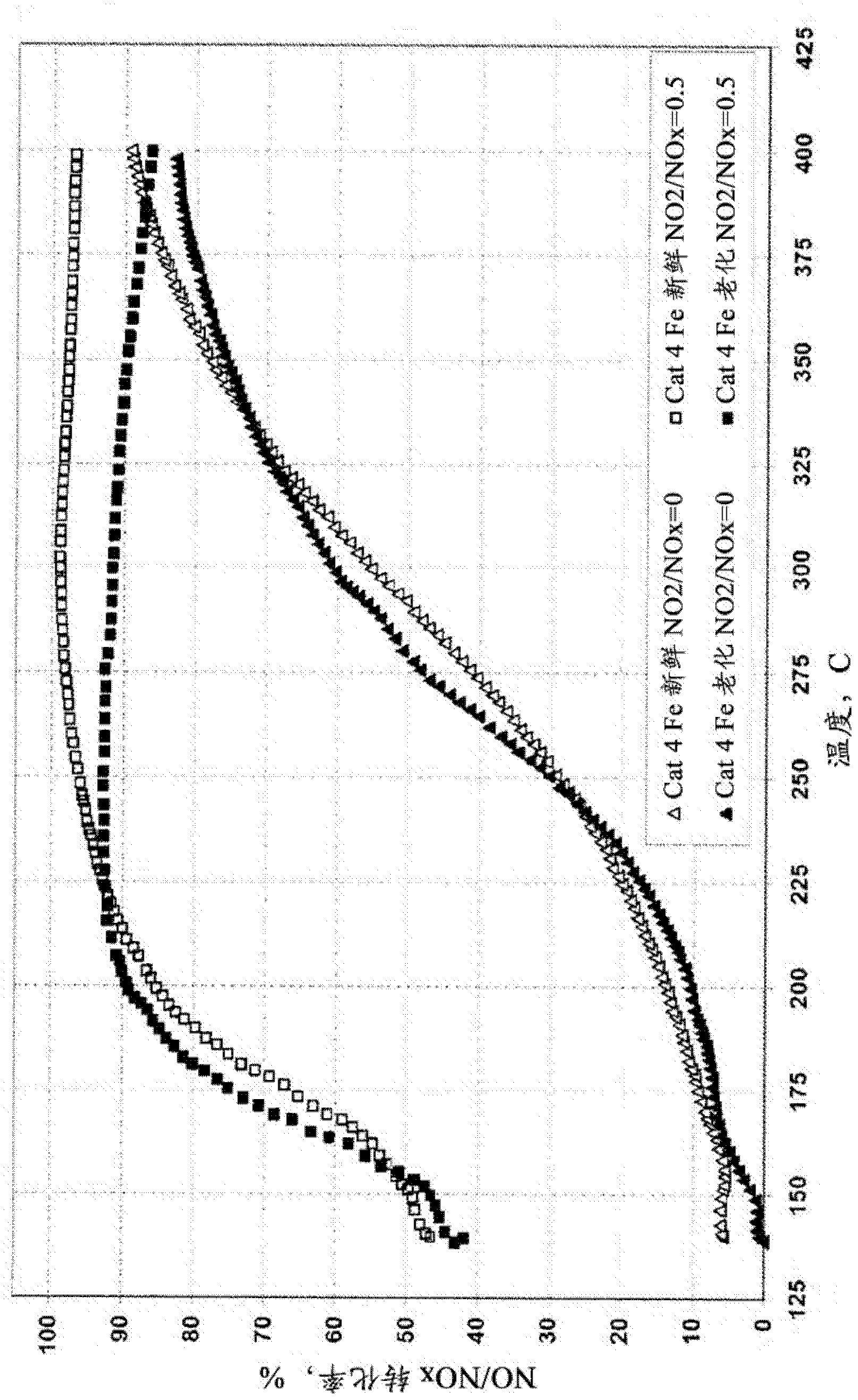

[0161] NO and NO / N0 2 Effect of Feed Gas on the Activity of Iron β-SCR

[0162] Iron-exchanged zeolite beta was supplied by Tricat GmbH, Bitterfeld, Germany. Catalyst 4 having the composition shown in Table 2 was prepared from iron-exchanged Beta zeolite.

[0163] Table 2

[0164] Composition of iron-exchanged β catalyst

[0165] Catalyst No.

wt% iron exchanged beta zeolite

wt % OSM

4

50

50

[0166] Catalyst 4 was tested with two different feed gases as fresh catalyst and after hydrothermal aging. The first feed gas contains 350ppm NO, no NO 2 . The second feed gas contains 175ppm NO and 175ppm NO 2 mixture. NO / NO of two feed gases x The graph of conversion rate versus temperature is shown in figure 2 shown.

[0167] Mixed NO / NO 2 For feed gas or feed gas containing only NO, hydrothermal aging has little effect on the activity of Catalyst 4.

[0168] Activity of fresh and hydrothermally aged Catalyst 4 for NO containing bu...

Embodiment 3

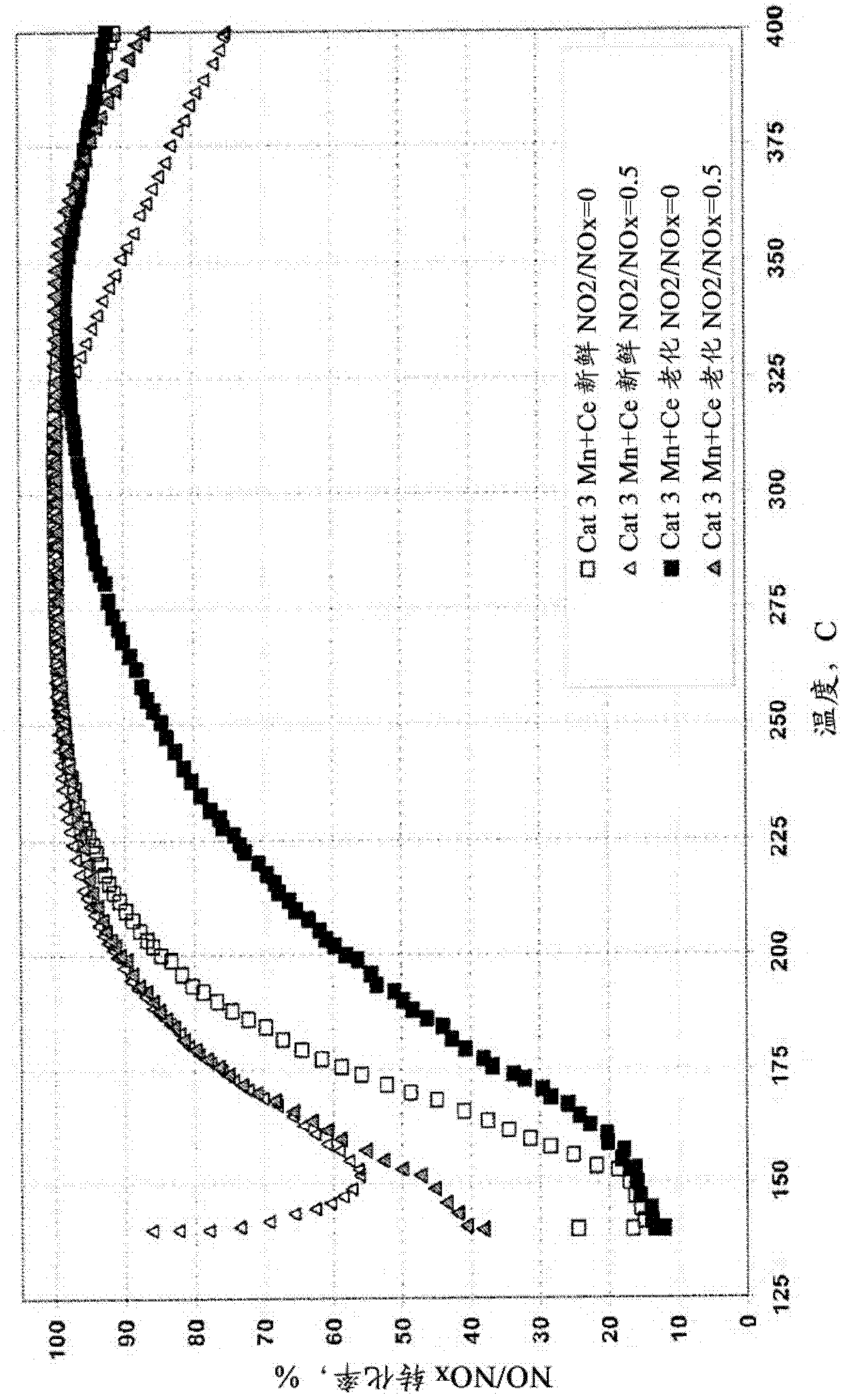

[0170] NO and NO / N0 2 Effect of Feed Gas on Activity of Mn / Ce / Zeolite / OSM Catalyst

[0171] In Example 3, with NO and NO / NO 2 The feed stream was tested for SCR activity of Catalyst 3, which is a Mn / Ce / Zeolite / OSM catalyst, a catalyst according to an embodiment of the present invention. The catalyst was tested as fresh catalyst and after hydrothermal aging. The result is as image 3 as shown.

[0172] Fresh and hydrothermally aged catalyst 3 for mixed NO / NO 2 Feed gas NO x The transforming activities were essentially the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com