Catalyst used for removing dioxins and NO<x> in flue gas, and preparation method and applications thereof

A catalyst and flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as ineffective coordination and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present invention, MnCeO is prepared by sol-gel method x / TiO 2 Composite catalyst, the preparation process is as follows: Take 34ml tetrabutyl titanate solution, 30ml absolute ethanol and 20ml glacial acetic acid according to the proportion and stir at room temperature until they are evenly mixed to form solution A; take 3ml manganese nitrate, 4.3g cerium nitrate, Absolute ethanol and 5-10ml deionized water are stirred at room temperature until they are evenly mixed to form solution B; drop solution B into solution A under vigorous stirring to form solution C; keep stirring solution C until the solution turns transparent Then put the sol at room temperature for 24 hours to form a gel, then place the gel in an oven at 105°C for 8 hours and then place it in a muffle furnace for calcination; the muffle furnace rises from room temperature at a rate of 10°C / min Stay at 300°C for 30 minutes, continue to raise the temperature to 550°C and stay for 3 hours, then cool d...

Embodiment 2

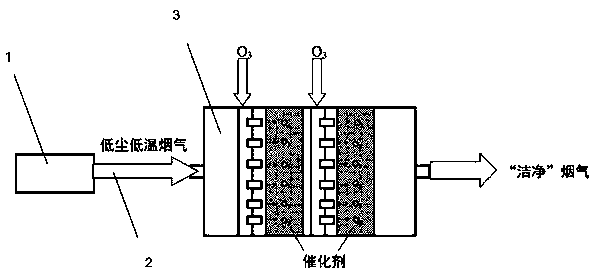

[0033] Such as figure 1 As shown, the low-dust and low-temperature flue gas after dedusting by the dedusting device 1 is input from the pipeline 2 into a MnCeO x / TiO 2 In the device 3 of composite catalyst; Ozone is sprayed into MnCeO through special-purpose pipeline (this pipeline contains some injection apertures) x / TiO 2 Inside the composite catalyst, the two are fully mixed (5min) to achieve ozone and MnCeO x / TiO 2 Composite catalyst coupling; flue gas passing through ozone and MnCeO x / TiO 2 In the pre-coupled device of the composite catalyst (the residence time of the flue gas flow on the surface of the catalyst is 1s; the total residence time of the flue gas flow in the catalytic device is less than 5s), remove dioxin and NO x The final "clean" flue gas is exhausted.

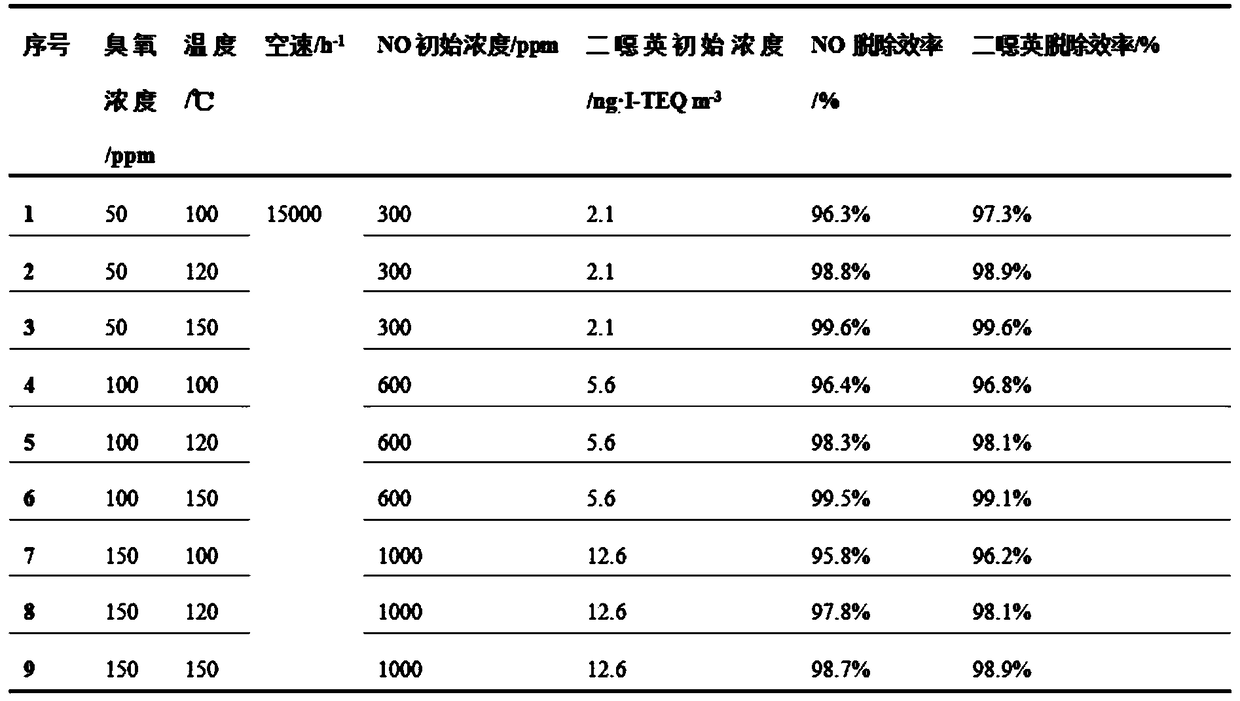

[0034] In the above flue gas, NO / NH 3 The molar ratio of = 0.8-1, the initial concentration of NO is 300-1000ppm, the initial concentration of dioxin is 2.0-12.6ng I-TEQ / m 3 .

[0035] Furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com