A method for removing dioxin and no from flue gas x Catalyst and preparation method and application of

A catalyst and flue gas technology, applied in the chemical industry, can solve the problems of ineffective coordination and removal, and achieve the effect of improving ozone utilization rate and low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present invention, MnCeO is prepared by sol-gel method x / TiO 2 Composite catalyst, the preparation process is as follows: take 34ml tetrabutyl titanate solution, 30ml absolute ethanol and 20ml glacial acetic acid according to the proportion and stir at room temperature until they are evenly mixed to form solution A; Absolute ethanol and 5-10ml deionized water are stirred at room temperature until they are evenly mixed to form solution B; drop solution B into solution A under vigorous stirring to form solution C; keep stirring solution C until the solution turns transparent Then put the sol at room temperature for 24 hours to form a gel, then place the gel in an oven at 105°C for 8 hours and then place it in a muffle furnace for calcination; the muffle furnace rises from room temperature at a rate of 10°C / min Stay at 300°C for 30 minutes, continue to raise the temperature to 550°C and stay for 3 hours, then cool down to room temperature, grind and sieve the calc...

Embodiment 2

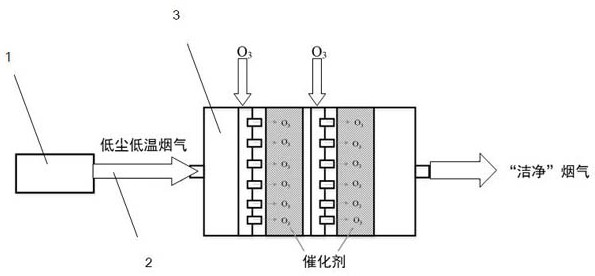

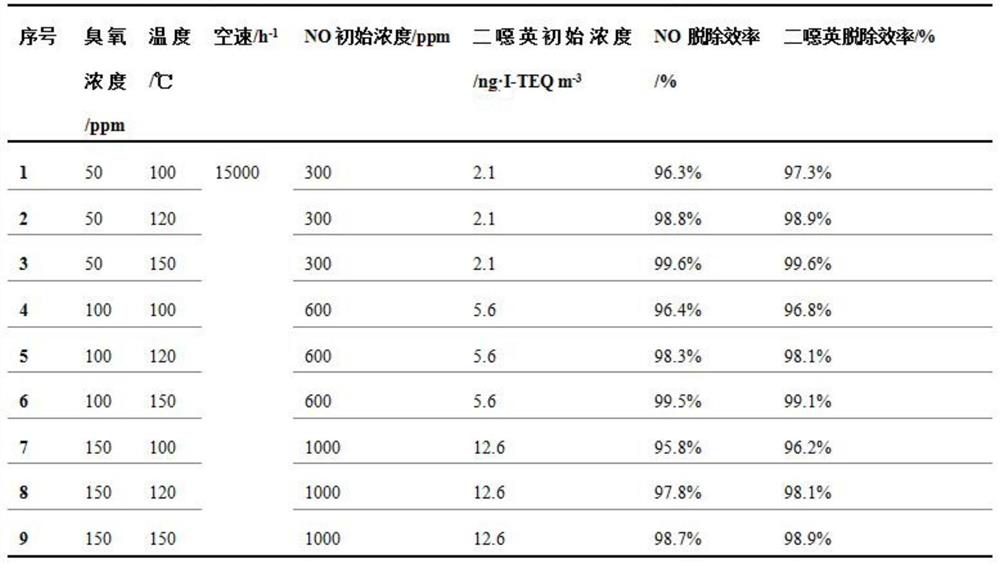

[0033] Such as figure 1 As shown, the low-dust and low-temperature flue gas after dedusting by the dedusting device 1 is input from the pipeline 2 into a MnCeO x / TiO 2 In the device 3 of composite catalyst; Ozone is sprayed into MnCeO through special-purpose pipeline (this pipeline contains some injection apertures) x / TiO 2 Inside the composite catalyst, the two are fully mixed (5min) to achieve ozone and MnCeO x / TiO 2 Composite catalyst coupling; flue gas into ozone and MnCeO x / TiO 2 In the pre-coupled device of the composite catalyst (the residence time of the flue gas flow on the surface of the catalyst is 1s; the total residence time of the flue gas flow in the catalytic device is less than 5s), remove dioxin and NO x The final "clean" flue gas is exhausted.

[0034] In the above flue gas, NO / NH 3 The molar ratio of = 0.8-1, the initial concentration of NO is 300-1000ppm, the initial concentration of dioxin is 2.0-12.6ng I-TEQ / m 3 .

[0035] Further, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com