Composite Ti-Si-molecular sieve coating integral denitration catalyst and preparation method thereof

A denitration catalyst, ti-si-technology, applied in the field of composite Ti-Si-molecular sieve coating integral denitration catalyst and its preparation, can solve the problems of poor anti-poisoning performance, single catalyst carrier composition, etc. The ability to resist H2O vapor and SO2 poisoning, the effect of enhancing surface acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

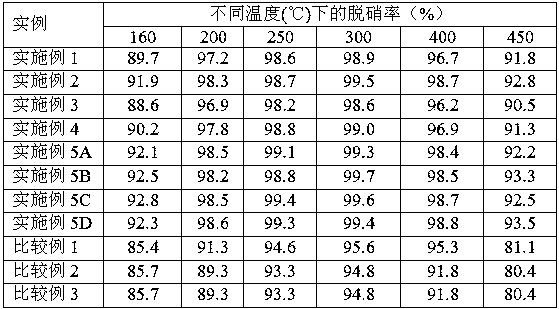

Embodiment 1

[0029] (1) Preparation of Ti-Si-molecular sieve composite sol: Add 450g of titanium sulfate and 300g of silica sol to 1800mL of nitric acid solution with a concentration of 0.6 mol / L, add 20g of urea, 20g of polyacrylamide and 15g of acetyl acetone. After stirring for a certain period of time, 60 grams of ZSM-5 molecular sieve was added and aged for 24 hours to obtain a transparent Ti-Si-molecular sieve composite sol.

[0030] (2) Preparation of Ti-Si-molecular sieve composite coating: Immerse the cordierite honeycomb matrix in the Ti-Si-molecular sieve composite sol prepared in step (1), take it out, blow off the residual liquid in the channel with compressed air, and Dry at 100°C for 12 hours, and bake at 600°C for 2 hours to obtain a carrier coated with a Ti-Si-molecular sieve composite coating.

[0031] (3) Loading active components: immerse the honeycomb ceramic carrier obtained in step (2) in a solution of 20g / L cerium nitrate, 30g / L ammonium molybdate and 4g / L tin tetr...

Embodiment 2

[0034] (1) Preparation of Ti-Si-molecular sieve composite sol: Add 450g of titanium sulfate and 400g of silica sol into 1800mL of 2mol / L nitric acid solution, add 40g of urea, 30g of polyacrylamide and 30g of acetylacetone while stirring . After stirring for a certain period of time, 70 grams of ZSM-5 molecular sieves were added and aged for 24 hours to obtain a transparent Ti-Si-molecular sieve composite sol.

[0035] (2) Preparation of Ti-Si-molecular sieve composite coating: Immerse the cordierite honeycomb matrix in the Ti-Si-molecular sieve composite sol prepared in step (1), take it out, blow off the residual liquid in the channel with compressed air, and Drying at 120°C for 8 hours and sintering at 550°C for 4 hours can obtain a carrier coated with a Ti-Si-molecular sieve composite coating.

[0036] (3) Loading active components: immerse the honeycomb ceramic carrier obtained in step (2) in a solution of 30g / L cerium nitrate, 50g / L ammonium molybdate and 6g / L tin tetra...

Embodiment 3

[0039] (1) Preparation of Ti-Si-molecular sieve composite sol: Take 450 g of titanium sulfate and 100 g of silica sol and add it to 1800 mL of nitric acid solution with a concentration of 4 mol / L, add 80 g of urea, 40 g of polyethylene glycol and 40 g of acetylene while stirring acetone. After stirring for a certain period of time, 50 grams of ZSM-5 molecular sieves were added and aged for 24 hours to obtain a transparent Ti-Si-molecular sieve composite sol.

[0040] (2) Preparation of Ti-Si-molecular sieve composite coating: Immerse the cordierite honeycomb matrix in the Ti-Si-molecular sieve composite sol prepared in step (1), take it out, blow off the residual liquid in the channel with compressed air, and Dry at 100°C for 12 hours, and bake at 400°C for 5 hours to obtain a carrier coated with a Ti-Si-molecular sieve composite coating.

[0041] (3) Loading active components: immerse the honeycomb ceramic carrier obtained in step (2) in a solution of 40g / L cerium nitrate, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com