Mixer and application thereof

A mixer and slurry mixing technology, which is applied to fluid mixers, mixers, mixing methods, etc., can solve the problems of high impact force at the outlet of the mixed liquid, high flow rate at the outlet of the mixed liquid, and large flow rate of the mixed liquid, and achieve a stable Effect of mixing, fast and efficient mixing, and slowing down of flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

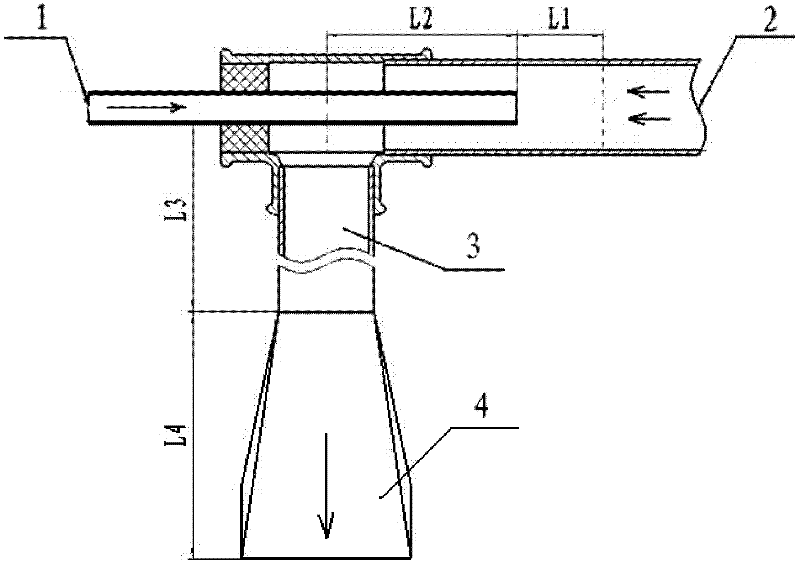

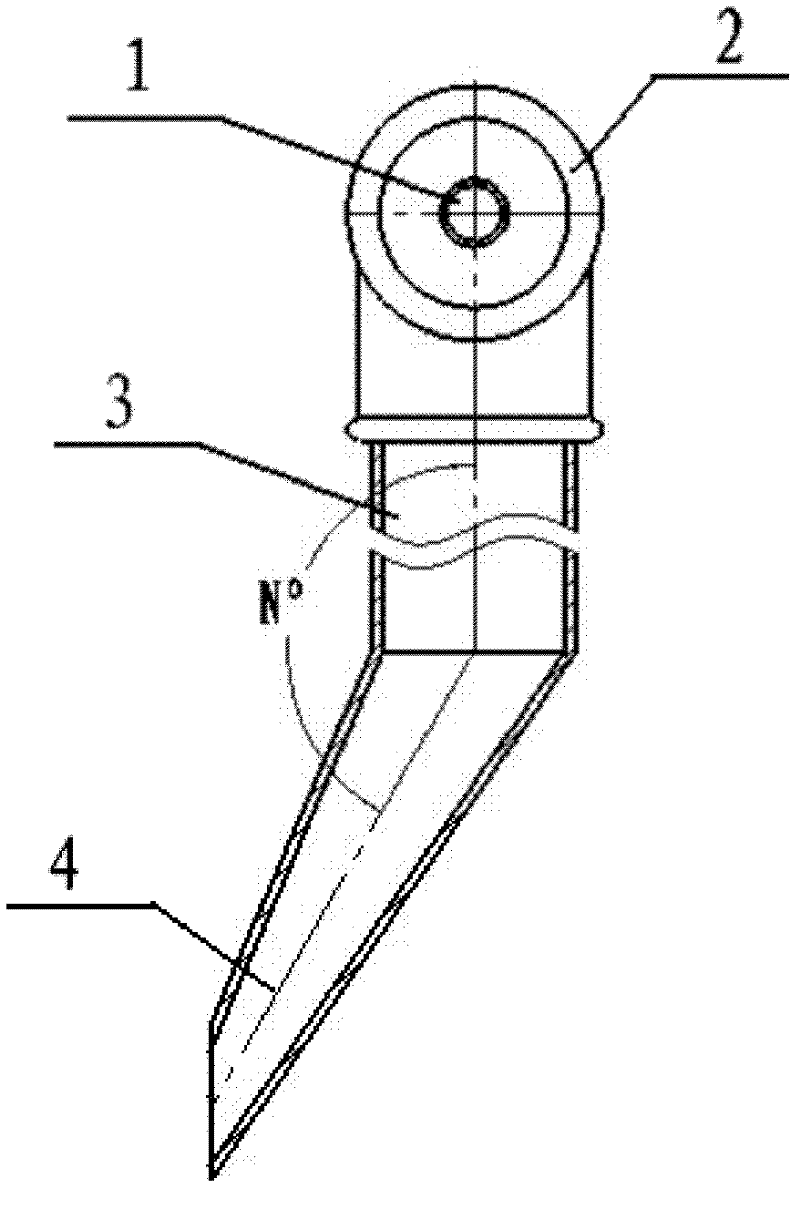

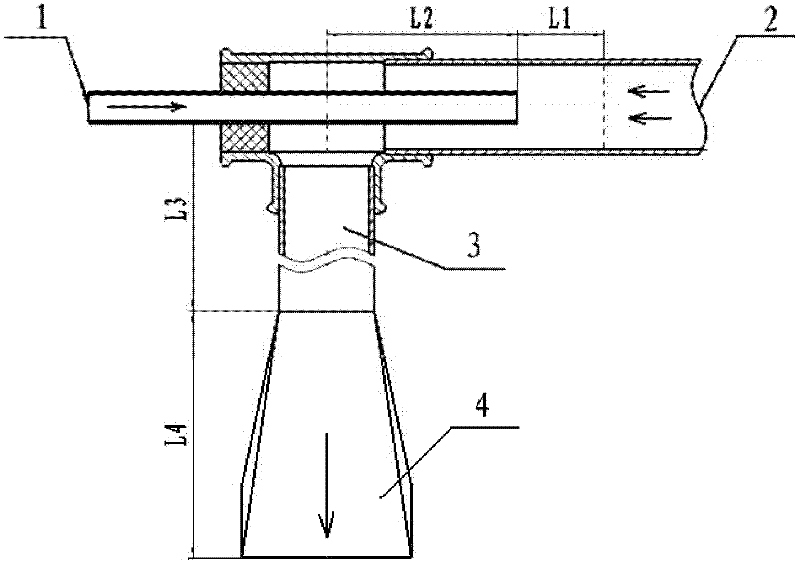

[0026] figure 1 This is the front view of the mixer of the present invention; figure 2 for figure 1 Left view.

[0027] Such as figure 1 , figure 2 As shown, the mixer disclosed in this embodiment includes: a thin conveying pipe 1, a thick conveying pipe 2 whose pipe diameter is larger than that of the thin conveying pipe 1 and one end closed, and the side wall of the thick conveying pipe 2 close to the closed end communicating and making The mixed slurry output pipe 3 whose material flow direction has changed. The thin conveying pipe 1 extends from the closed end of the thick conveying pipe 2, and the amount of the thin conveying pipe 1 in the thick conveying pipe 2 exceeds that of the thick conveying pipe. The connecting port between the pipe 2 and the mixed slurry output pipe 3 forms a partial overlap with the coarse conveying pipe 2, and the mixed slurry output pipe 3 forms an increased diameter from the connecting port with the coarse conveying pipe 2 to the discharge por...

Embodiment 2

[0052] The difference between the mixer of this embodiment and the first embodiment is that the number of thin conveying pipes in this embodiment is two. The mixer of the embodiment is used as a mixing device for soy milk and coagulant during tofu production, and the coagulant is CaSO with a mass percentage of 10% 4 ·2H 2 O suspension. The storage tank is agitated by an electric agitator to maintain the suspended state, and the coagulant is transported using an adjustable speed gear pump (to achieve the pump pressure to 1.5Kg / cm 2 ). The mixing process is as follows: open the soymilk storage tank valve and gear pump, feed the coagulant and soy milk with a temperature above 85°C into the mixer from the thin conveying pipe and the coarse conveying pipe respectively, and adjust the flow rate of the coagulant to be greater than that of the soymilk, so that The two are mixed in the coarse conveying pipe, and the mixed slurry is injected into the holding container through the dischar...

Embodiment 3

[0055] This embodiment uses a mixer with the same structure as the first embodiment, in which φ1 is 0.6 mm, φ2 is 6 mm, and φ3 is 8 mm. The length L of the partial overlap is 8 times the diameter Φ1 of the thin conveying pipe. This embodiment is used as a mixing device for soy milk and coagulant when producing box tofu. Crush the soybeans into broken pieces, remove the germ, fine powder, and soybean hulls to obtain cotyledons; soak the broken soybean cotyledons in water for 30-60 minutes, then refining, and remove the bean dregs after refining to obtain raw soybean milk; heat the raw soybean milk to boil , And keep the temperature above 90℃ for 30-45min to obtain soy milk. The coagulant is glucono-delta-lactone with a mass concentration of 7.5%.

[0056] The method of using the mixer is as follows: the soy milk above 90°C flows from a 1.5m high-position heat preservation barrel through a valve into the entrance of the coarse conveying pipe at a flow rate of 25mL / s, and the coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com