Preparation method for high-efficiency Ce1-xMnxO2-delta solid solution low-temperature denitration catalyst and application thereof

A low-temperature denitration, solid solution technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Water resistance requirements and other issues, to achieve the effect of broad industrial application prospects, less pollution, and rich raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

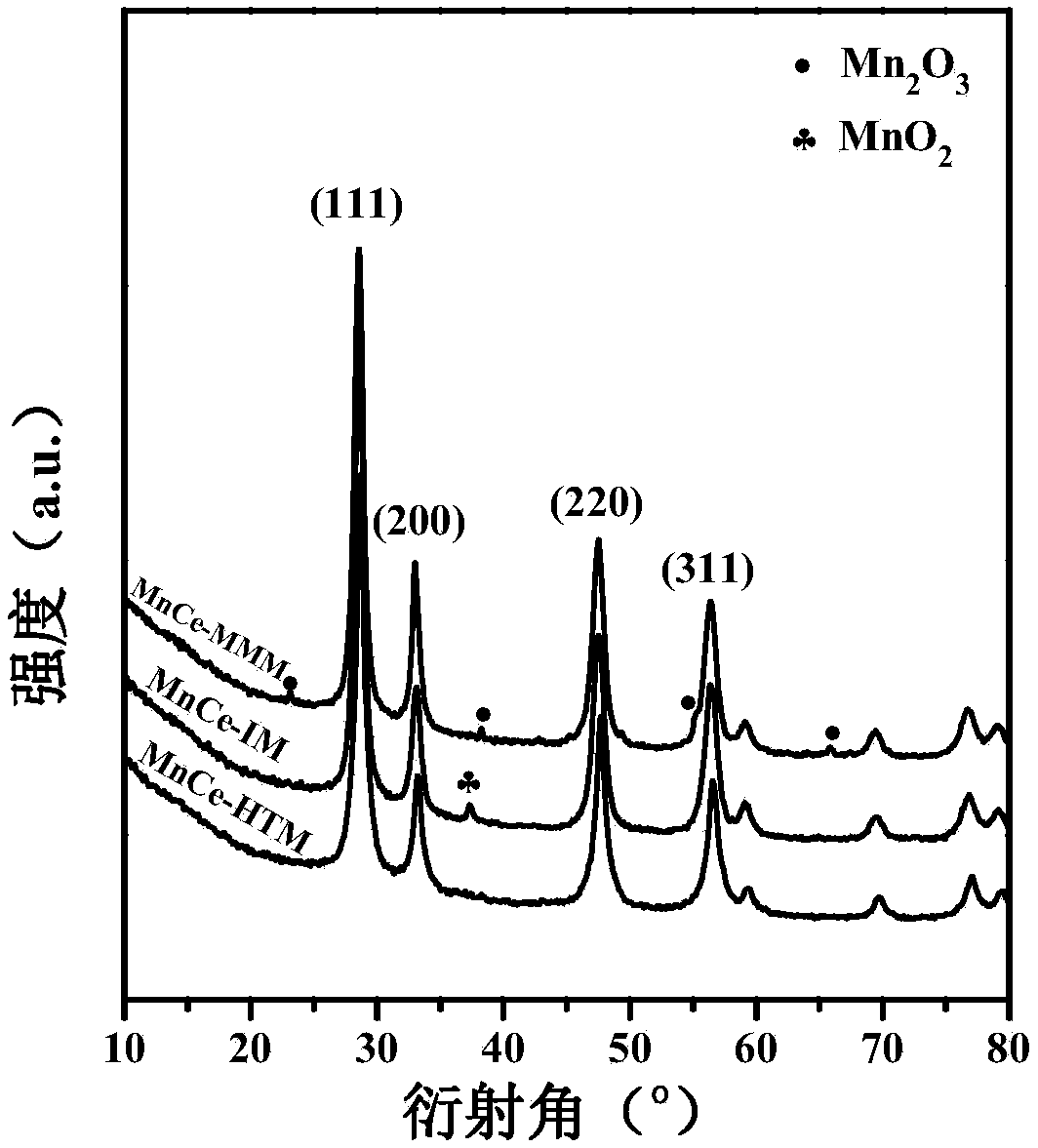

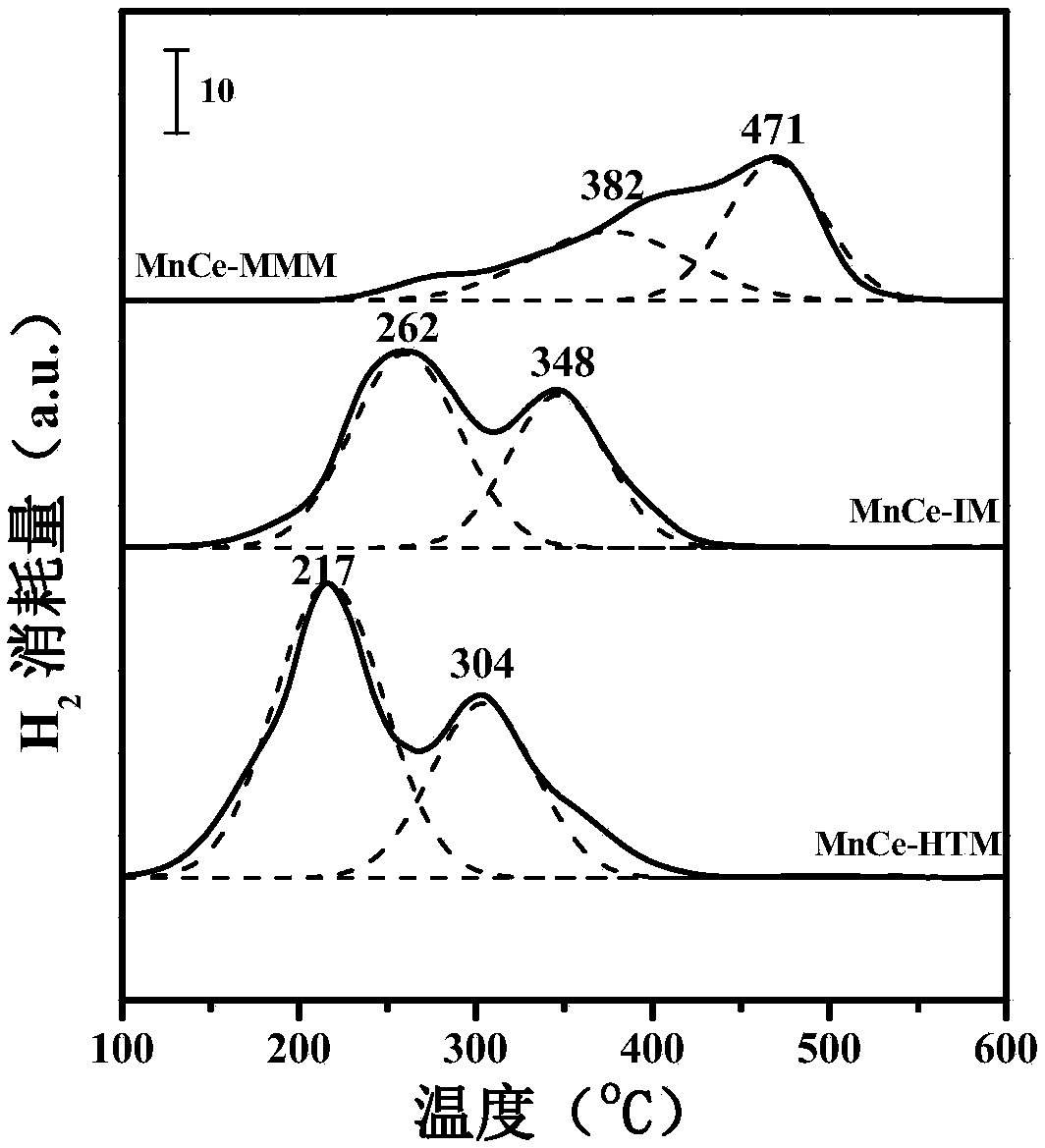

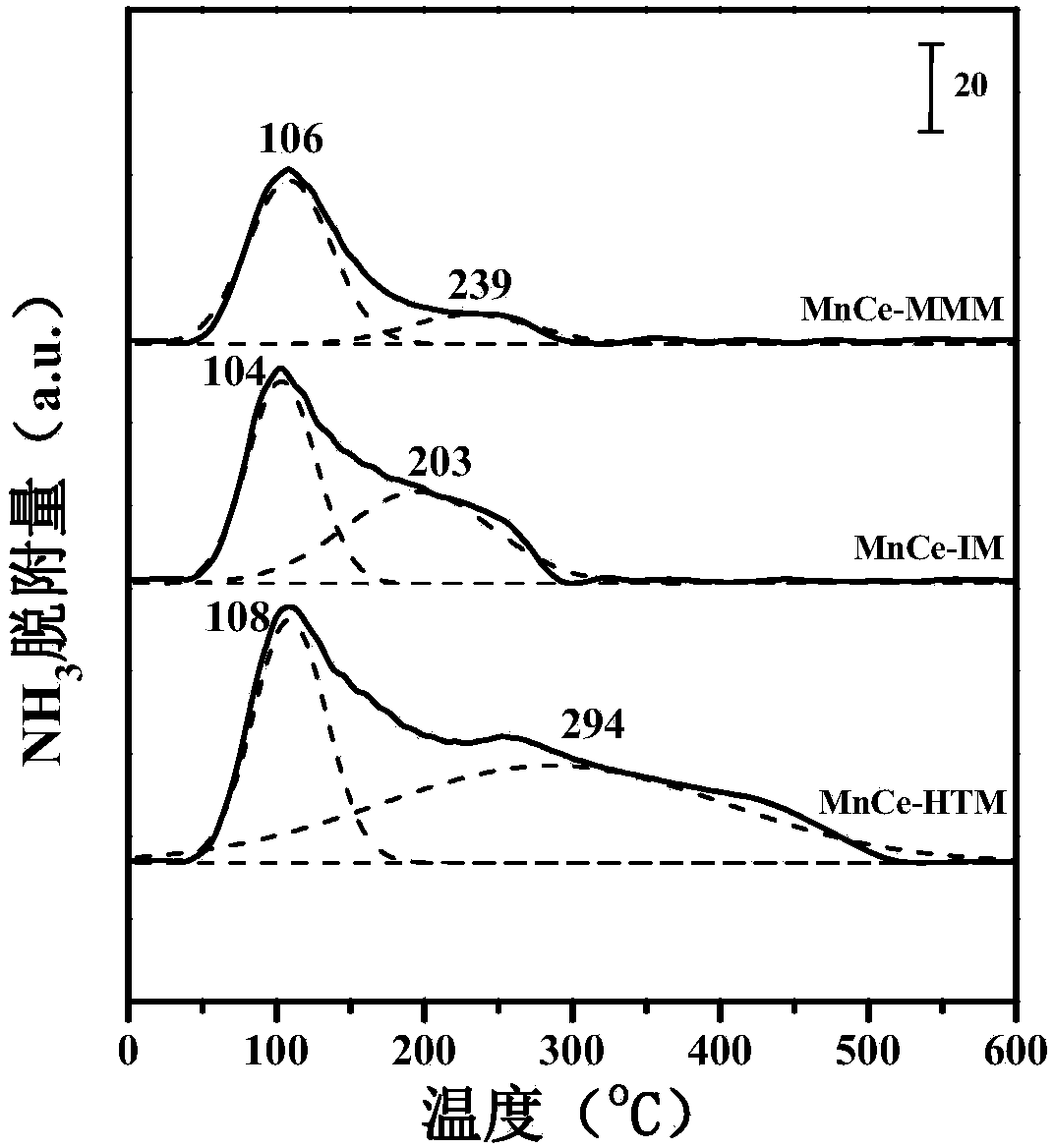

[0036] 1. Preparation of MnO by mechanical mixing method x -CeO 2 Catalyst (abbreviated as MnCe-MMM catalyst)

[0037] Accurately weigh 8.9575g50%Mn(NO 3 ) 2 , placed in a ceramic crucible, and then put the ceramic crucible into the muffle furnace, under the flowing air atmosphere of 100mL / min, the temperature was raised from room temperature to 500 °C at a rate of 2 °C / min, and then naturally cooled to room temperature, then taken out, placed in agate Grinding in a mortar for 30 min to obtain MnO x ; Similarly, accurately weigh 25.3237gCe (NO 3 ) 3 ·6H 2 O, after grinding in an agate mortar for 30 min, place it in a ceramic crucible, then put the ceramic crucible into a muffle furnace, and raise the temperature from room temperature to 500 °C at a rate of 2 °C / min under 100 mL / min flowing air atmosphere, and then After naturally cooling to room temperature, take it out and grind it in an agate mortar for 30 minutes to obtain CeO 2 ; Finally, the above MnO x and CeO ...

Embodiment 2

[0054] Accurately weigh 0.2986g50%Mn(NO 3 ) 2 and 35.8149gCe(NO 3 ) 3 ·6H 2 O, ultrasonically dissolved in 150mL of distilled water, magnetically stirred at room temperature for 2h to mix evenly, and then added dropwise to excess (5000mL) NaOH (0.05mol / L) solution, Mn(NO 3 ) 2 , Ce(NO 3 ) 3 The pH of the suspension mixed with the NaOH solution is ≥ 10.0, magnetically stirred at room temperature for 3 hours to make the precipitation complete, and then continued to stir for 2 hours, and the suspension was transferred to multiple 250mL hydrothermal reaction kettles, and then the airtight The hydrothermal reaction kettle was placed in an oven at 100°C for 48 hours, followed by centrifugation and solid-liquid separation, and the obtained solid phase was washed until the pH of the washing liquid no longer changed, then dried overnight in an oven at 100°C, and then naturally cooled to room temperature and taken out. Grind in an agate mortar for 30 minutes, and finally, place i...

Embodiment 3

[0056] Accurately weigh 11.9433g50%Mn(NO 3 ) 2 and 21.7060gCe(NO 3 ) 3 ·6H 2 O, ultrasonically dissolved in 150mL of distilled water, stirred magnetically at room temperature for 2h to make it evenly mixed, then added dropwise to excess (500mL) NaOH (0.5mol / L) solution, Mn(NO 3 ) 2 , Ce(NO 3 ) 3 The pH of the suspension mixed with the NaOH solution is ≥ 10.0, magnetically stirred at room temperature for 3 hours to make the precipitation complete, and then continued to stir for 4 hours, and the suspension was transferred to multiple 250mL hydrothermal reaction kettles, and then the airtight The hydrothermal reaction kettle was placed in an oven at 180°C for 6 hours, followed by centrifugation and solid-liquid separation, and the obtained solid phase was washed until the pH of the washing liquid no longer changed, then dried overnight in an oven at 120°C, and then naturally cooled to room temperature and taken out. Grind in an agate mortar for 30 minutes, and finally, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com