A supported manganese-based medium and low temperature denitrification catalyst, its preparation method and its application

A supported manganese-based, low-temperature denitrification technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor low-temperature activity of manganese-based denitrification catalysts, and achieve enhanced medium-low temperature Effects of catalytic activity and excellent low-temperature denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

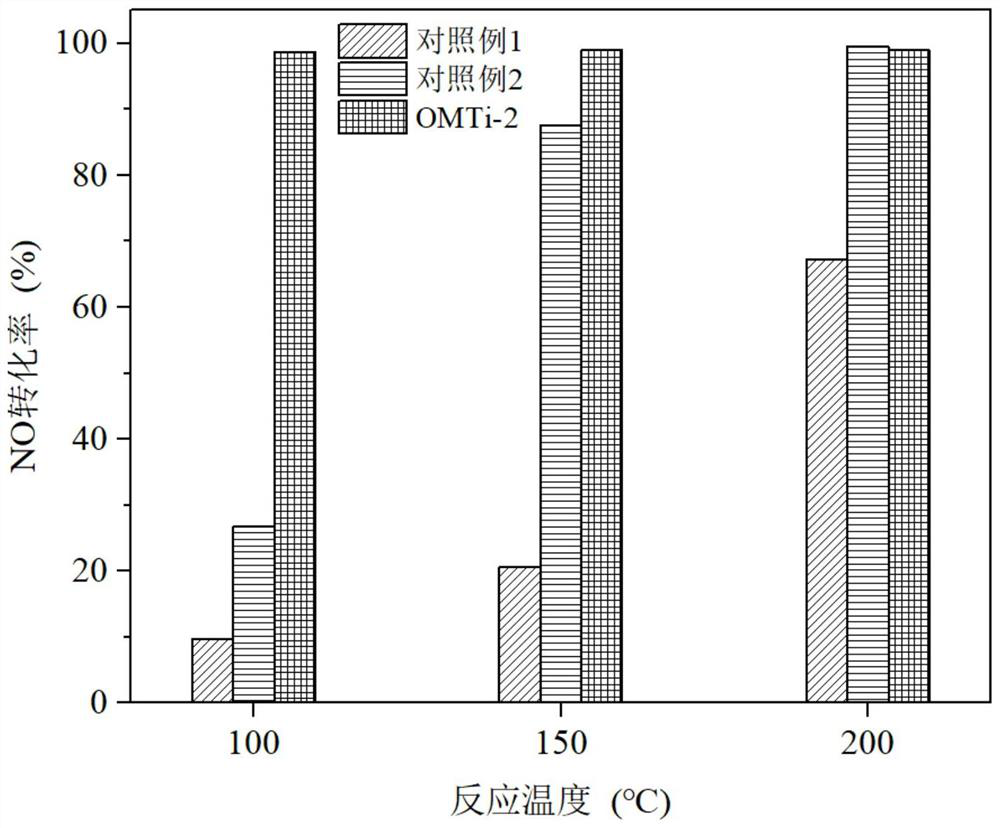

Embodiment 1

[0052] The sample of supported manganese-based low-temperature denitration catalyst in this example was prepared by the following steps:

[0053] (1) Impregnation: Weigh 1.01g of manganese acetate and dissolve it in 8mL of deionized water, add 2.4g of carrier titanium dioxide, stir at room temperature for 6h, mix evenly, transfer to an oven at 80°C for 12h, grind to powder, and obtain bivalent The initial sample of manganese salt;

[0054] (2) Grinding and mixing and solid-phase interface reaction: add potassium permanganate solid to the initial sample of divalent manganese salt, and carry out sufficient grinding and mixing and solid-phase interface reaction for 20 minutes to obtain a manganese-containing precursor; wherein, potassium permanganate The molar ratio of Mn to the divalent manganese salt is 1:5, and the total mass of the divalent manganese salt and potassium permanganate is 27% of the mass of the carrier.

[0055] (3) Aging: Aging the manganese-containing precurso...

Embodiment 2

[0060] The sample of supported manganese-based low-temperature denitration catalyst in this embodiment was prepared by the following steps:

[0061] (1) Impregnation: Weigh 0.51g of manganese acetate and dissolve it in 8mL of deionized water, add 2.7g of carrier titanium dioxide, stir at room temperature for 6h, mix evenly, transfer to an oven at 80°C for 12h, grind to powder, and obtain divalent The initial sample of manganese salt;

[0062] (2) Grinding and mixing and solid-phase interface reaction: add potassium permanganate solid to the initial sample of divalent manganese salt, and carry out sufficient grinding and mixing and solid-phase interface reaction for 20 minutes to obtain a manganese-containing precursor; wherein, potassium permanganate The molar ratio of Mn to the divalent manganese salt is 2:3, and the total mass of the divalent manganese salt and potassium permanganate is 60% of the mass of the carrier.

[0063] (3) Aging: Aging the manganese-containing precu...

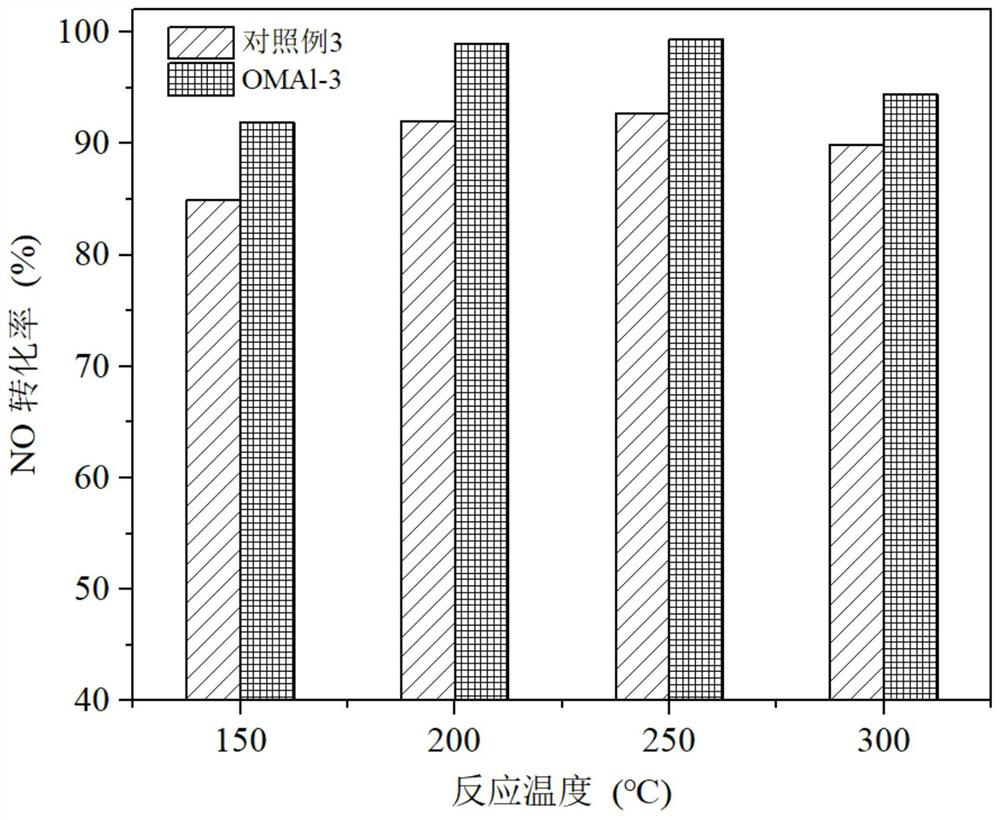

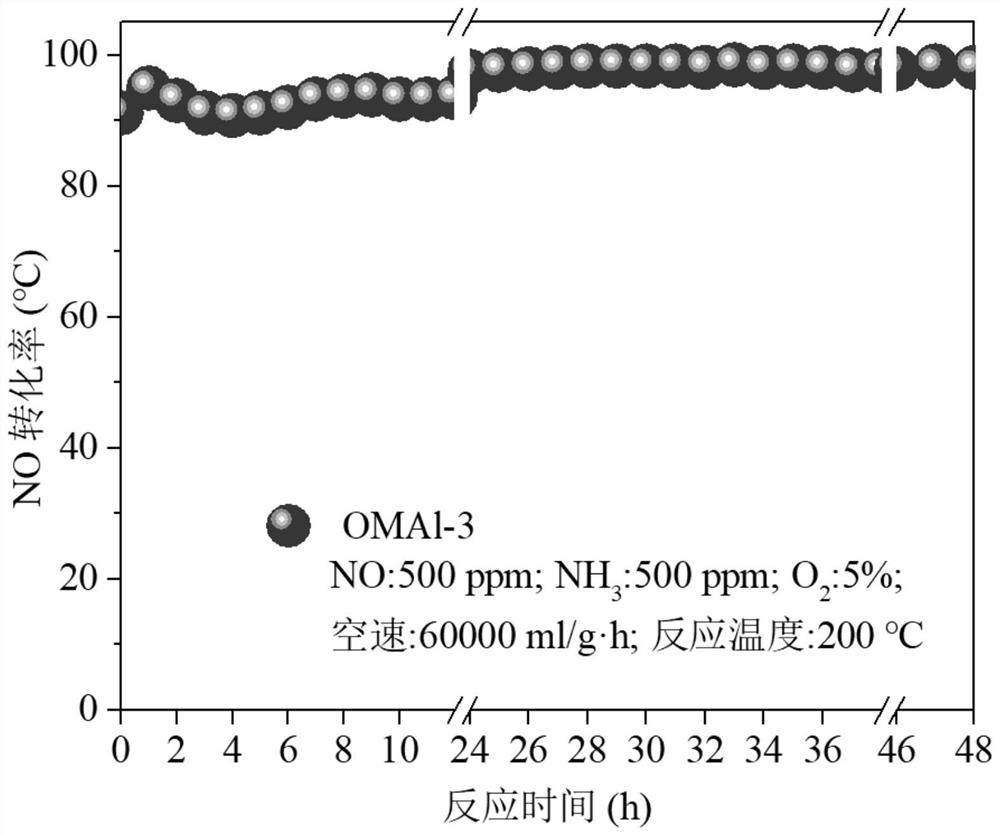

Embodiment 3

[0069] The sample of supported manganese-based medium-low temperature denitration catalyst in this example was prepared by the following steps:

[0070] (1) Impregnation: Weigh 0.05g of manganese acetate and dissolve it in 8mL of deionized water, and add carrier γ-Al 2 o 3 2.97 g was stirred at room temperature for 6 hours to mix evenly, then transferred to an oven at 80°C to dry for 12 hours, and then ground to powder to obtain the initial sample of divalent manganese salt;

[0071] (2) Grinding and mixing and solid-phase interface reaction: add potassium permanganate solid to the initial sample of divalent manganese salt, and carry out sufficient grinding and mixing and solid-phase interface reaction for 20 minutes to obtain a manganese-containing precursor; wherein, potassium permanganate The molar ratio of Mn to the divalent manganese salt is 2:3, and the total mass of the divalent manganese salt and potassium permanganate is 2% of the mass of the carrier.

[0072] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com