Anti-washing throttle valve sealing surface structure

A technology of sealing surface and throttle valve, which is applied in the direction of valve details, valve device, valve element and valve seat, etc. It can solve the problems of large front and rear pressure difference, high working pressure, internal leakage, etc., and achieve a solution Washout and inclusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

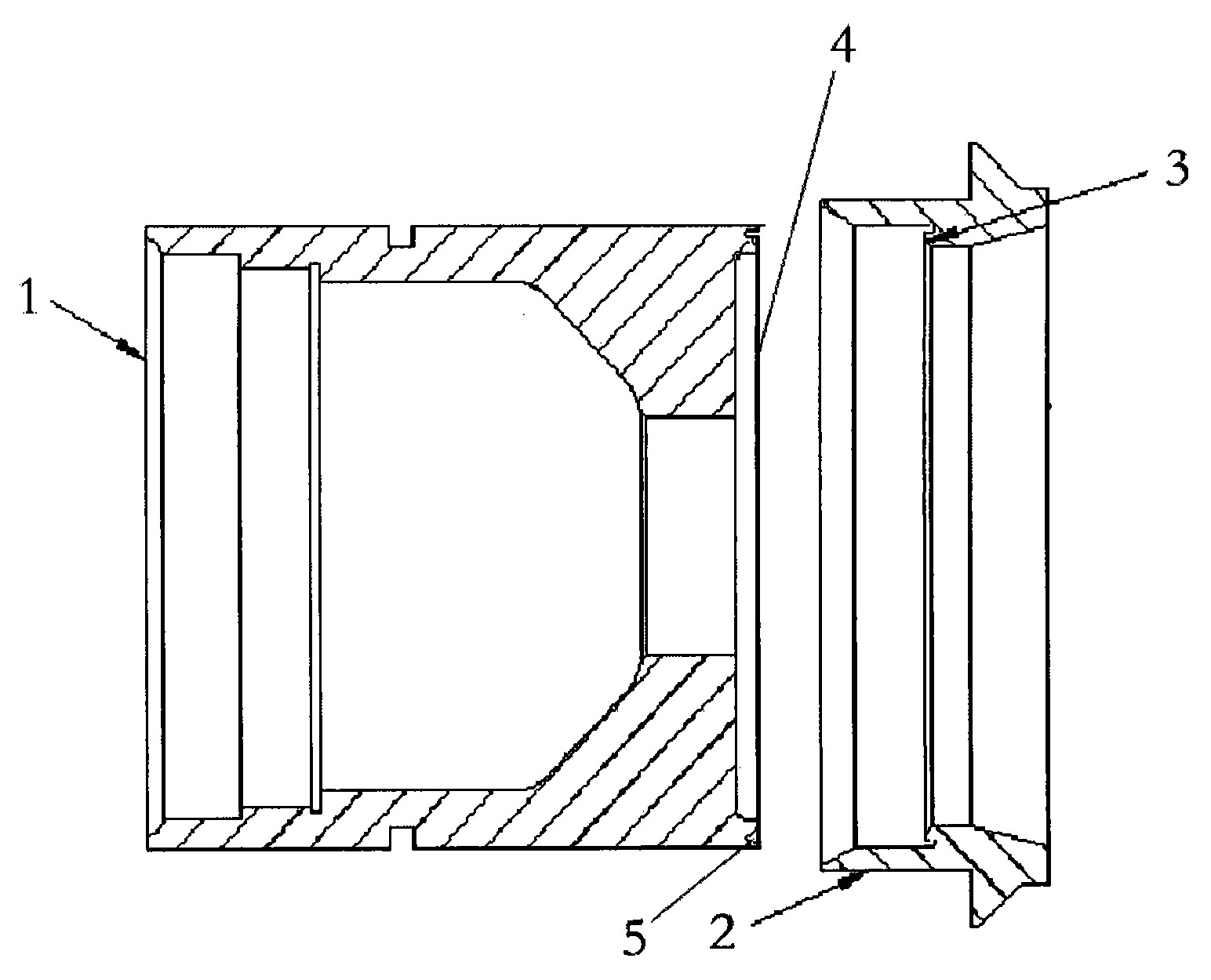

[0008] An embodiment of the present invention provides a sealing surface structure of an anti-scouring throttle valve, including: a valve clack 1, a valve cage 2, and a valve seat. On the inner wall of the valve cage 2; the upper surface of the valve flap 1 is the valve flap sealing surface 4, and a shroud 5 is arranged on the circumference of the valve flap sealing surface 4 to prevent fluid erosion. The distance between the disc 1 and the cage 2 or the depth of the disc 1 inserted into the cage 2 is used to control the flow area, and the valve is completely closed by the close contact between the sealing surface 4 of the disc and the sealing surface 5 of the valve seat. Made of wear-resistant alloy.

[0009] The above description is only the preferred embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com