Counter-flow axial energy dissipation valve

A counter-flow, axial technology, applied in the direction of the valve's energy-absorbing device, valve lift, valve details, etc., can solve problems such as paddy field erosion, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

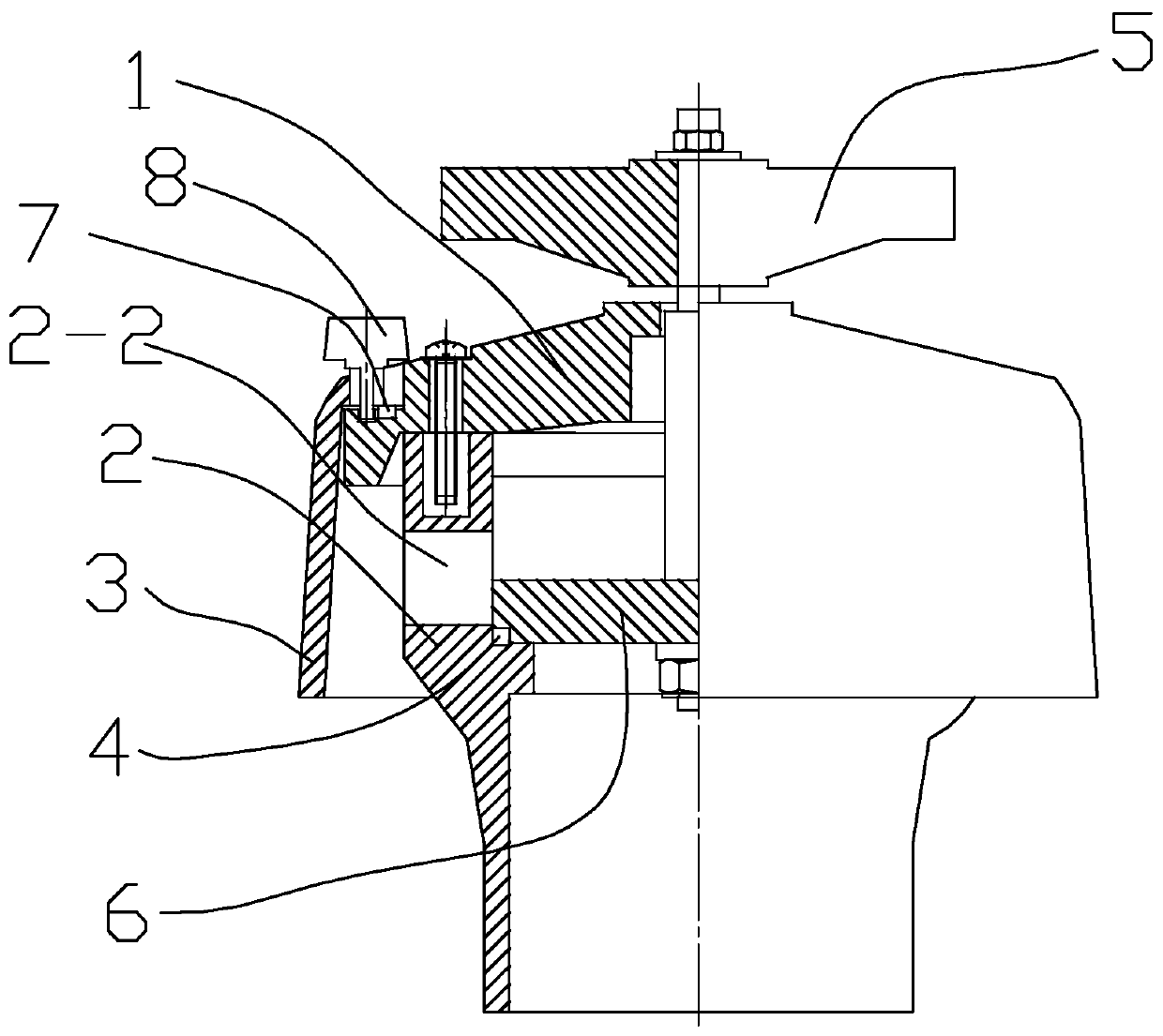

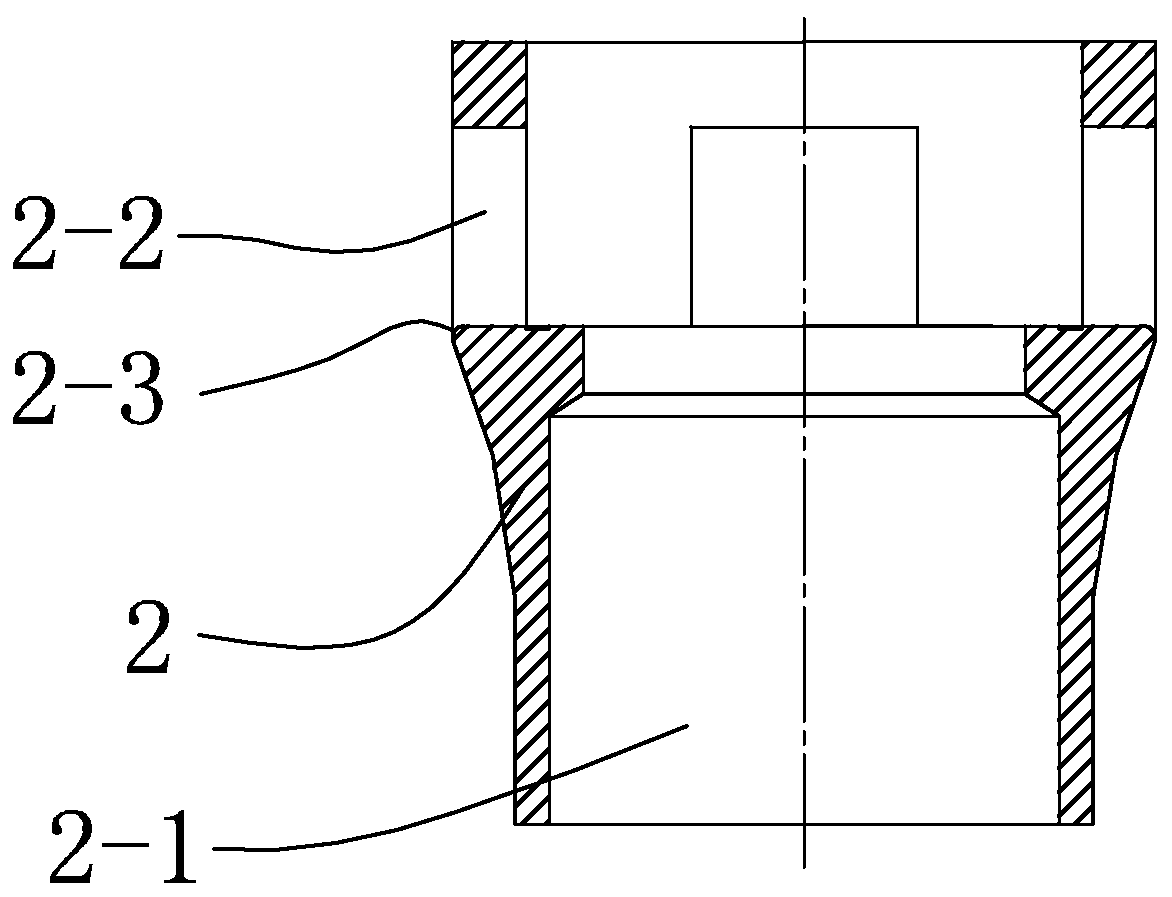

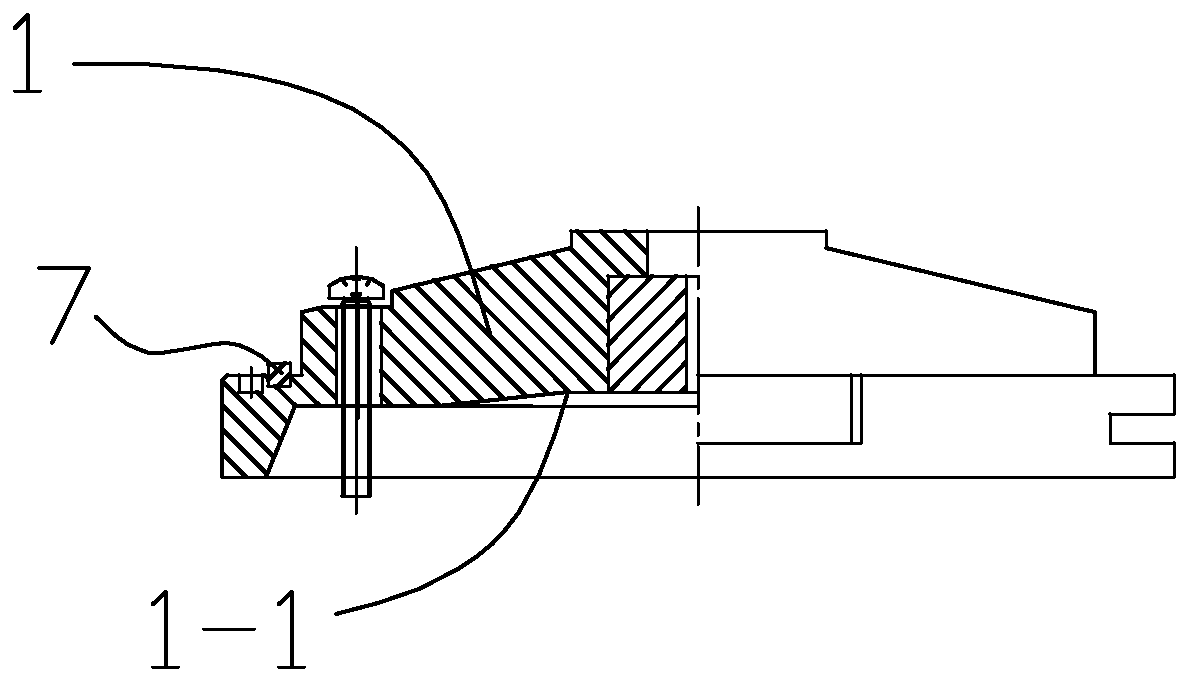

[0017] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, this embodiment includes a valve cover 1, a valve body 2, a guide sleeve 3, a first sealing ring 4, a hand wheel 5, a valve plate 6, a second sealing ring 7 and fasteners 8;

[0018] The valve body 2 is provided with a water inlet 2-1 and a water outlet 2-2, the direction of the water inlet 2-1 on the valve body 2 is perpendicular to the direction of the water outlet 2-2, and the valve plate 6 is arranged in the valve body 2 The water inlet 2-1, and the first sealing ring 4 is provided between the valve plate 6 and the valve body 2, the valve cover 1 and the valve body 2 are fixed together, the handwheel 5 is connected with the valve cover through a screw rod, and the screw rod and the valve body The valve plate 6 is fixed so that the valve plate 6 can move along the direction of the water inlet 2-1 of the valve body 2, and the guide sleeve 3 and the valve cover 1 are sealed by t...

specific Embodiment approach 2

[0020] Embodiment 2: The flow area of the water outlet 2-2 of the valve body 2 in this embodiment is larger than the flow area of the water inlet 2-1.

[0021] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The flow area of the water outlet 2-2 of the valve body 2 in this embodiment is 23% larger than the flow area of the water inlet 2-1.

[0023] Such setting increases the ability of water discharge, and ensures that the water has a certain kinetic energy to be ejected from the present invention, and also ensures that the paddy field will not be washed away due to excessive kinetic energy of the water.

[0024] Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com