Anti-corrosion method for oxygen lance nozzle and oxygen lance nozzle

An oxygen lance nozzle and nozzle technology, which is used in the manufacture of converters, devices for coating liquid on surfaces, coatings, etc., can solve the problems of deterioration of oxygen jet performance, poor operability, and sticking to steel on the end face of nozzles. To achieve the effect of strong scouring and soaking ability, significant economic significance, and avoidance of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An anti-corrosion method for an oxygen lance nozzle, which adopts the following steps: 1) first process the cast oxygen lance nozzle into a required size; 2) utilize a press to extrude the nozzle end face of the processed oxygen lance nozzle, Make the arrangement of grains on the end face of the nozzle more compact; 3) Clean and polish the end face of the extruded oxygen lance nozzle to make it reach the original metal luster; 4) Preheat the cleaned oxygen lance nozzle to achieve At a certain temperature, spray alloy heat insulation material on the end surface of the nozzle to form a heat insulation layer. The alloy heat insulation material used in this embodiment is aluminum silicate ceramic fiber spray paint. It uses the high-efficiency heat insulation characteristics of refractory fibers, and through special fiber spraying equipment, uses high-pressure air to uniformly mix the fibers and high-temperature binders, and then attaches them to the end face of the nozzle t...

Embodiment 2

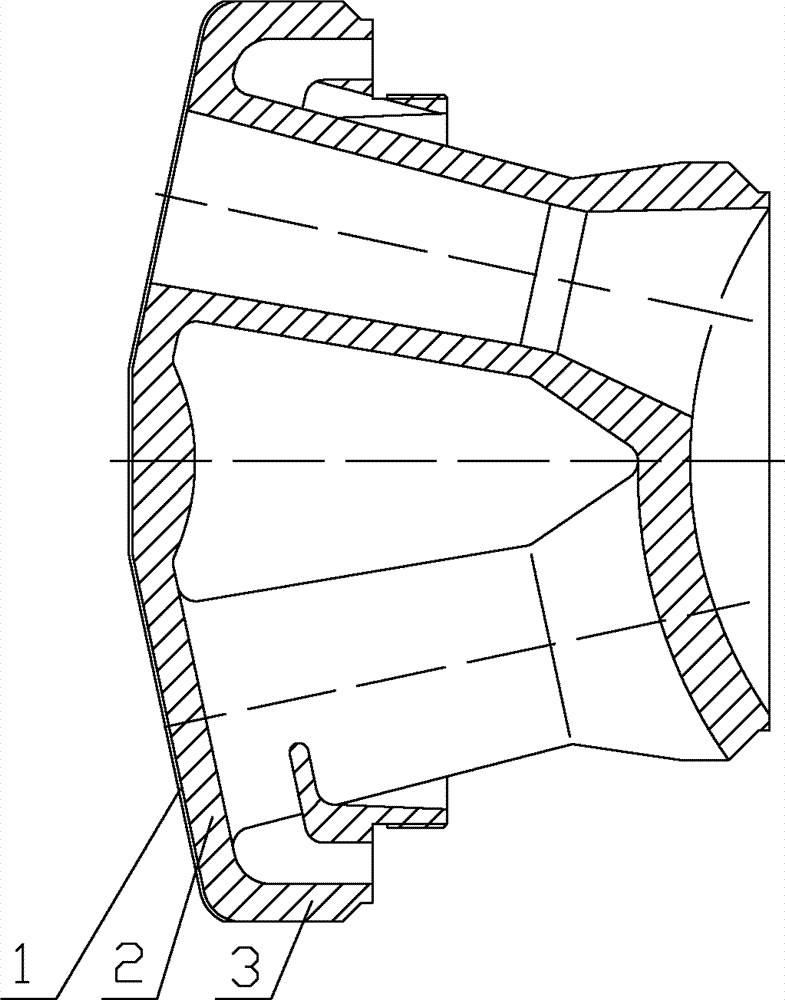

[0022] As shown in the drawings, it is an oxygen lance nozzle, including a nozzle body 3, the nozzle body end surface 2 of the nozzle body 3 is compacted, and the surface of the nozzle body end surface 2 is sprayed with an alloy heat insulating material to form Insulation layer1. The heat insulation layer 1 in this embodiment is the heat insulation layer of aluminum silicate ceramic fiber spray paint. The thermal insulation layer of aluminum silicate ceramic fiber spray coating uses special fiber spraying equipment to uniformly mix refractory fiber and high temperature binder with high-pressure air and then attaches to the end face of the nozzle to form a fiber spray thermal insulation refractory layer. The heat insulation layer is resistant to high temperature and is not easy to fall off. It enhances the heat insulation, radiation insulation and erosion resistance of the end face of the nozzle, avoids the bonding of copper and steel at high temperature, makes the oxygen lance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com