Novel regulating valve for coal slurry control

A regulating valve, a new type of technology, applied in the direction of valve details, valve device, valve shell structure, etc., can solve the problems that cannot be overcome, cannot overcome the erosion of coal powder on the valve core, cannot meet the harsh working conditions of coal chemical industry, and achieve the solution of domestic The needs of modernization and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

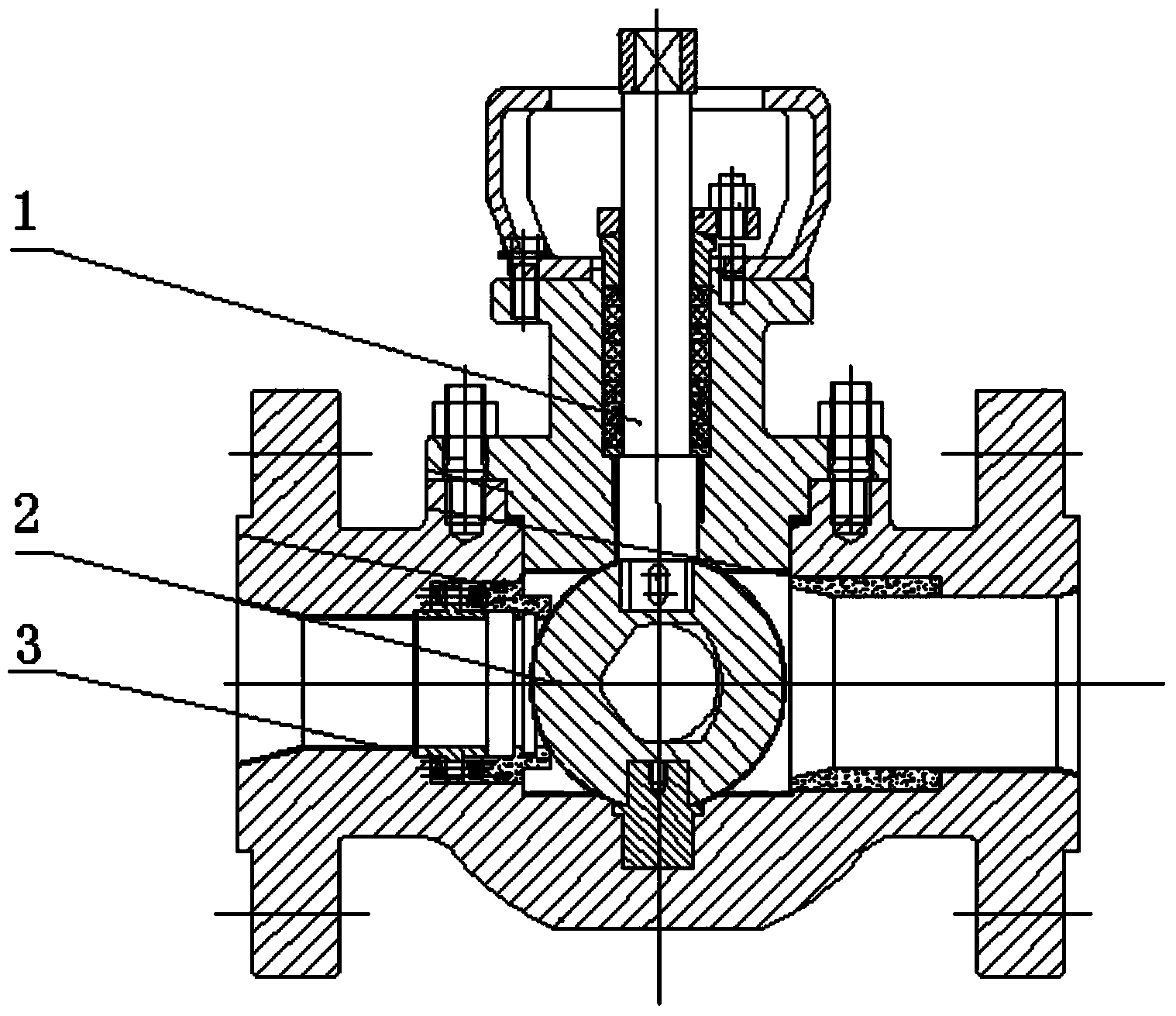

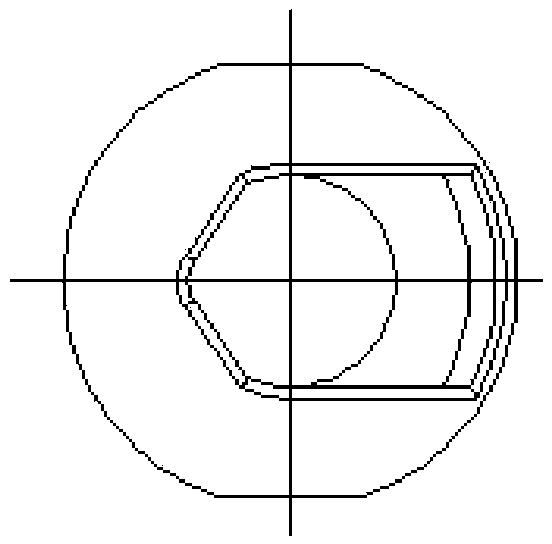

[0014] Such as figure 1 , 2 , 3, 4, and 5, the present invention is a novel control valve for coal slurry control, comprising a main shaft 1, a valve body 3, a valve seat and a valve core 2, the upper end of the valve core 2 is connected to the main shaft 1 and its The lower end is connected with the auxiliary shaft, and the auxiliary shaft is installed on the valve body 3, a V-shaped window is opened on the valve core 2, and the top of the V-shaped window is a spherical surface.

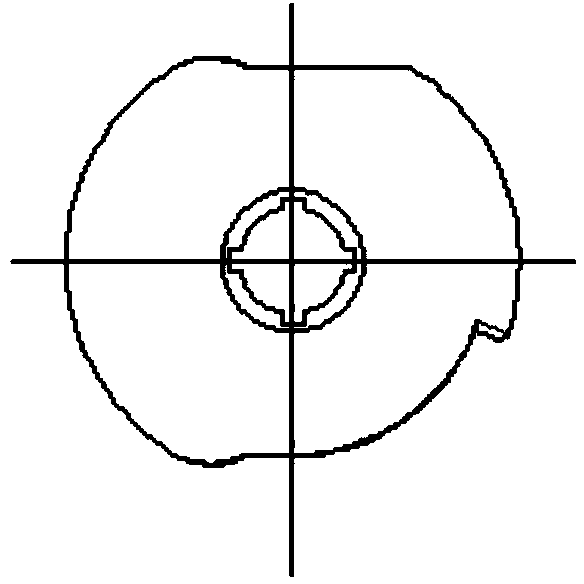

[0015] Wherein the inner surface of the outlet of the valve body 3 next to the valve core 2 is provided with a wear-resistant alloy bushing, the wear-resistant alloy bush is YG11 alloy, and the thickness of the alloy is in the range of 5-10mm. The wear-resistant alloy bushing is in the shape of a circular tube, and an inclined surface is provided on the inner wall of the wear-resistant alloy bush near the valve core 2 . In addition, the spool 2 is made of HG11 alloy.

[0016] The working principl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com