A simulation test device and method for multi-angle inclined drilling and grouting process of coal seam floor under the action of pressure and dynamic water

A coal seam floor and inclined drilling technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems of difficult control of high-pressure water flow expansion, large number of long boreholes, and difficult sealing, etc., to achieve The effects of solving visualization problems, solving water erosion, and solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

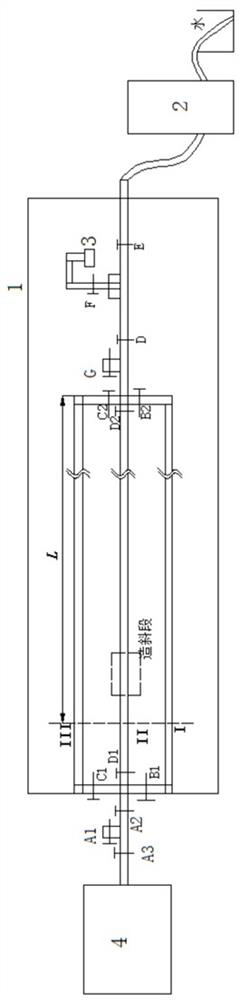

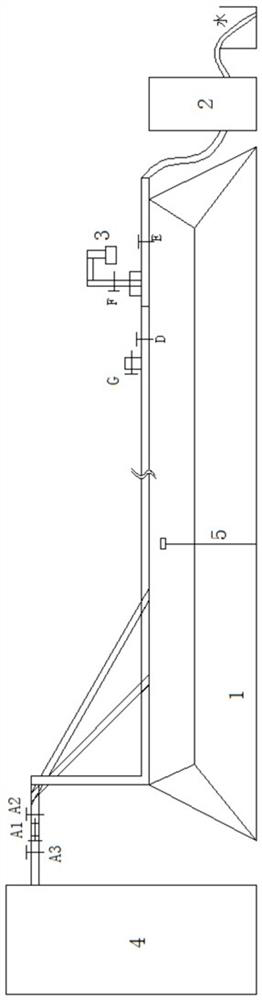

[0035] Specific implementation mode 1: This implementation mode provides a simulation test device for the multi-angle inclined drilling and grouting process of the coal seam floor under the action of pressure and dynamic water, such as figure 1 with figure 2 As shown, the shown device includes a test bench 1, a water source application device for a confined aquifer, a multi-angle drilling and crack simulation device with different apertures, and a grouting device, wherein:

[0036] The test bench 1 is a metal frame, which can support multi-angle drilling and crack simulation devices with different apertures as a bottom load-bearing body.

[0037] The multi-angle drilling and crack simulation device with different apertures can change the pipe diameter according to the experimental needs to simulate the needs of grouting in cracks of different sizes. According to the drilling angle and crack size, it is divided into multiple groups, which are multiple groups of tubular compone...

specific Embodiment approach 2

[0046] Embodiment 2: In this embodiment, the method of using the device described in Embodiment 1 is introduced by taking the technological process of simultaneous grouting in three different angles of grouting holes as an example.

[0047] The first use requires the assembly of a test bench, a water source application device for a confined aquifer, a multi-angle drilling and fracture simulation device with different apertures, and a grouting device. The drilling angle is determined as required, and the device can simulate three different angles of grouting drilling at one time, such as 90°, 30° and 45°. Connect the experimental device and prepare for the experiment. During the connection process, pay attention to the tightness and avoid air leakage.

[0048] Aquifer simulation: Open the grouting hole selection switches B1, C1, D1, B2, C2, D2, closed crack control valve D, and open open crack control valve E, and close the non-disassembly flushing valve G. Set the water pres...

specific Embodiment approach 3

[0055] Specific implementation mode three: this implementation mode is a further description of specific implementation mode two, and the specific experimental process is as follows:

[0056] 1) Set the threshold of the water pressure regulating valve F, such as 0.6MPa. Close the no-disassembly flushing valve G. Open the open-source crack control valve E, close the crack control valve D, and close the disassembly-free flushing valve G. Open the grouting hole selection switches B1, C1, D1, B2, C2, D2; open the grout flushing valve A1 and the grouting channel valve A2. Start the constant pressure water pump 2 for water injection. When the grout flushing valve A1 has water flowing out, close the grouting channel valve A2. Continue to inject water, and the water pressure increases until the water pressure regulating valve F overflows, and the open-source crack control valve E is closed. When simulating a closed crack, the closed crack control valve D is directly closed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com