Device for removing fine particles by combining sound wave agglomeration and conventional dedusting

A fine particle, conventional technology, applied in the field of fine particle removal device, can solve the problem of low removal efficiency of fine particle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

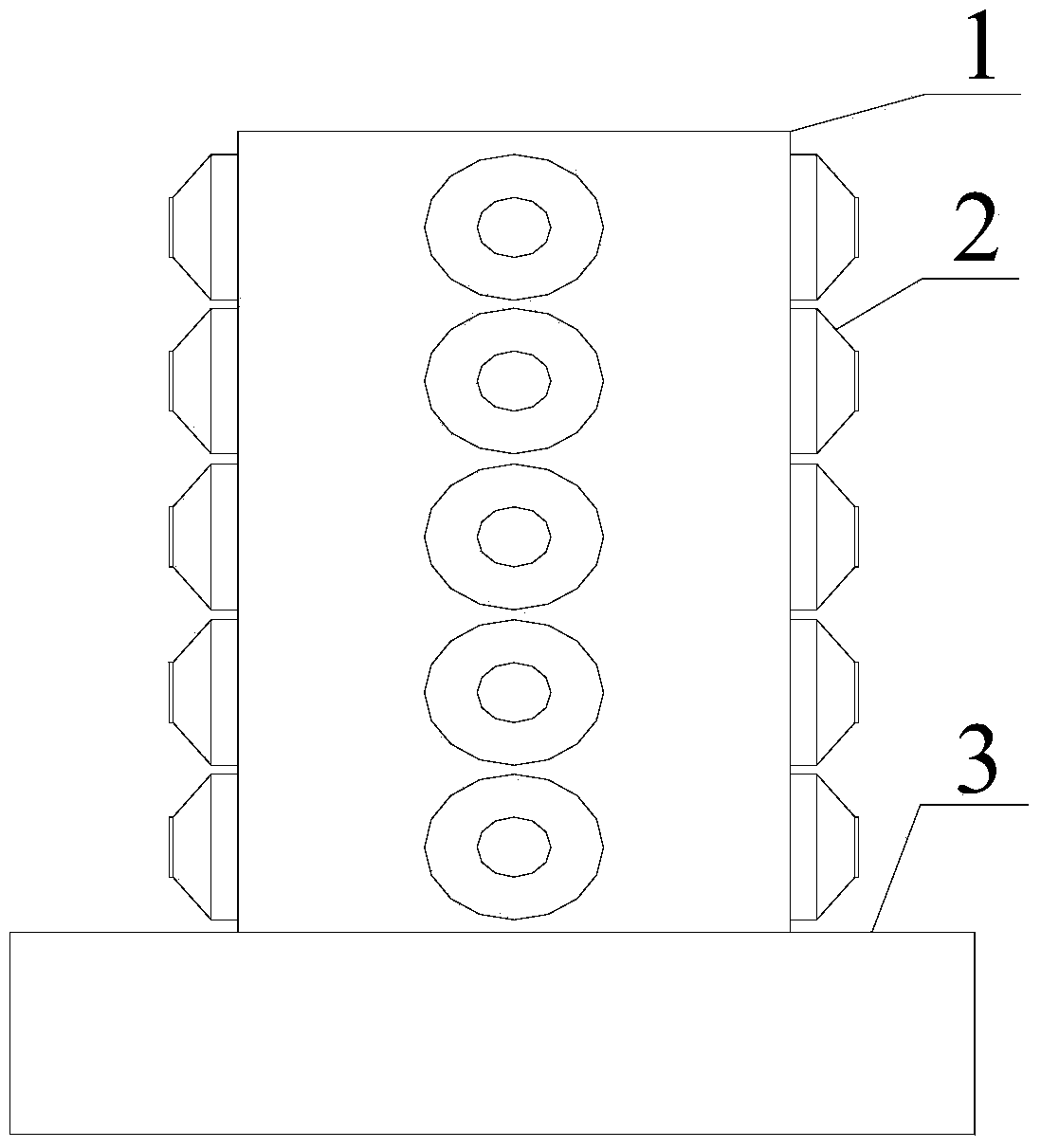

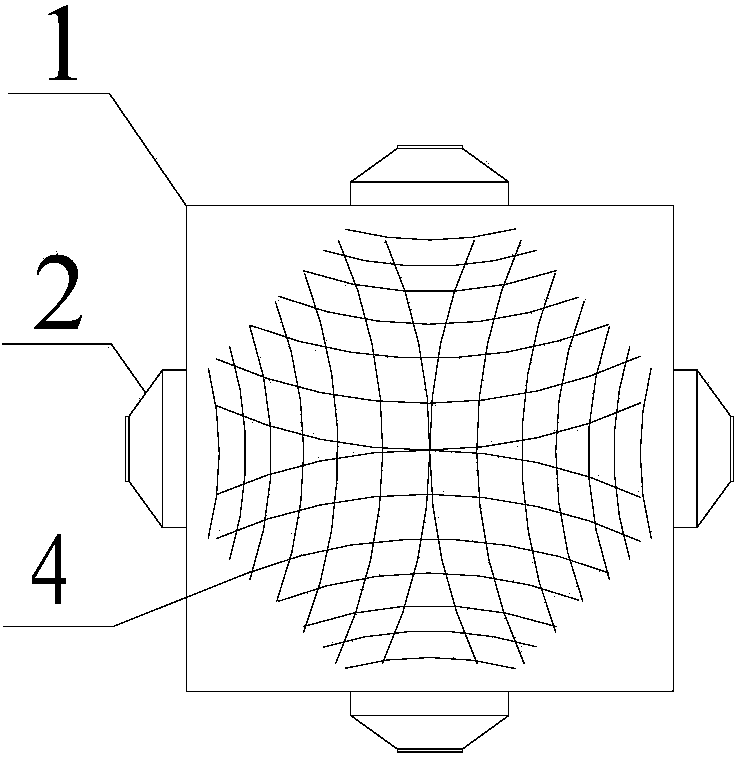

[0022] like figure 1 Shown is a sonic coagulation-conventional dedusting composite device for removing fine particles, including a cuboid flue gas pipe 1 , a sound source 2 and a conventional dust collector 3 .

[0023] The flue gas pipe 1 is placed vertically, and the flue gas flows from top to bottom in the flue gas pipe 1. The cross section of the flue gas pipe 1 is a square, and the side length of the square satisfies that the sound wave of the sound source 2 is formed in the cross section. Standing wave sound field:

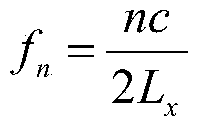

[0024] f n = nc 2 L x

[0025] Among them, f n is the frequency used by the sound source 2, n=1,2,3,... is the resonance order, c is the local speed of sound, L x is the side length of the square...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com