Range hood with smoke deflector

A technology of range hoods and smoke deflectors, which is applied in the direction of removing oil fume, removing smoke dust, and increasing household heat, etc. It can solve problems such as difficult design, unfavorable flow of high-temperature oil fume, and affect the mood of users, so as to achieve the effect of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

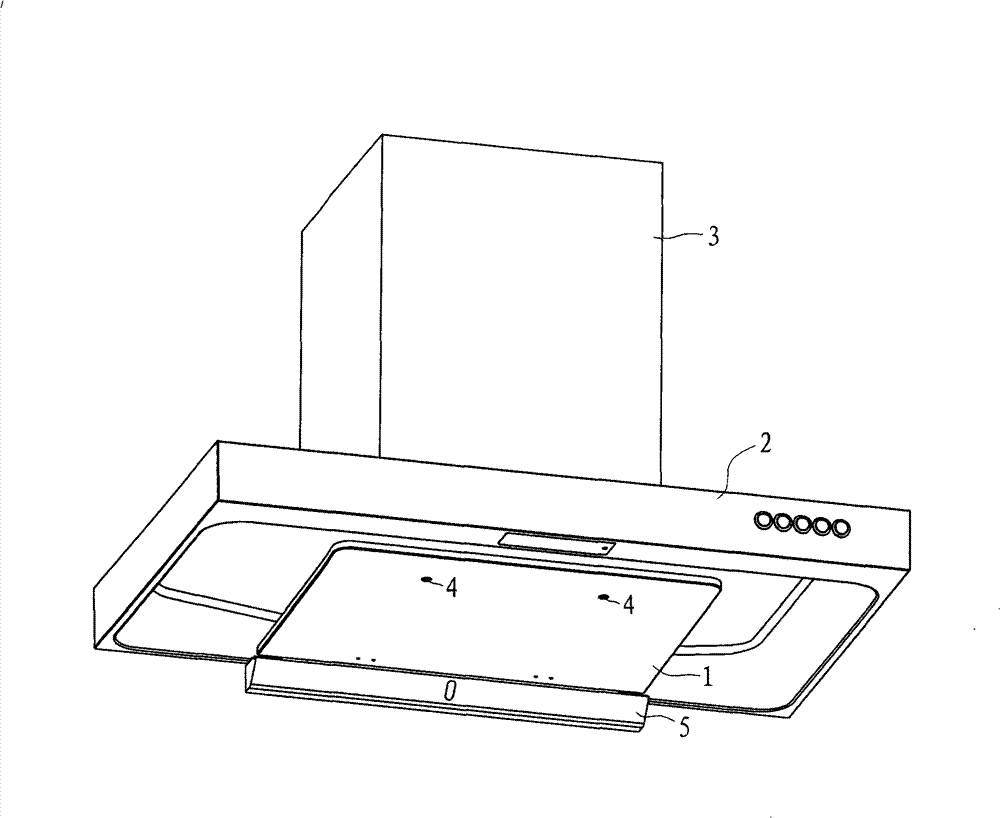

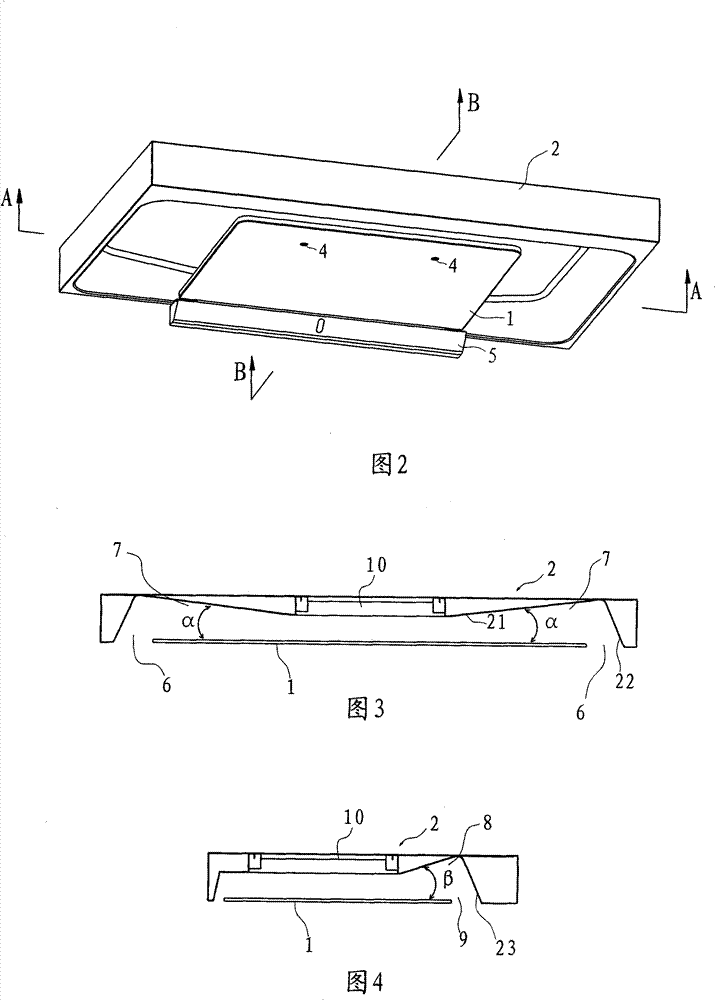

[0018] Example: Reference figure 1 and figure 2 , this embodiment includes a smoke guide plate 1, a smoke collection hood 2 and a body 3. The smoke guide plate 1 is horizontal and has an oil collection groove 5 on the inner side. The smoke guide plate 1 is arranged on the air inlet of the smoke collection hood 2 through two bolts 4. On the end face, the smoke collecting hood 2 has a central air inlet 10 (such as image 3 and Figure 4 Shown), the body 33 has a fan and has an air outlet.

[0019] Such as image 3 and Figure 4 As shown, the front end and the two sides of the end surface of the air inlet of the smoke collecting hood 2 protrude to form the front peripheral part 23 and the side peripheral part 22 respectively, and the middle part is concave to form the air inlet part 21 . The air inlet portion 21 smoothly transitions from the edge to the middle and gradually protrudes downwards until reaching the air inlet 10 of the smoke collecting hood.

[0020] The front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com