Household garbage pyrolysis combustion furnace and operation process thereof

A technology for domestic waste and incinerators, which can be used in combustion methods, combustion types, incinerators, etc., and can solve problems such as indistinguishable and ineffective control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

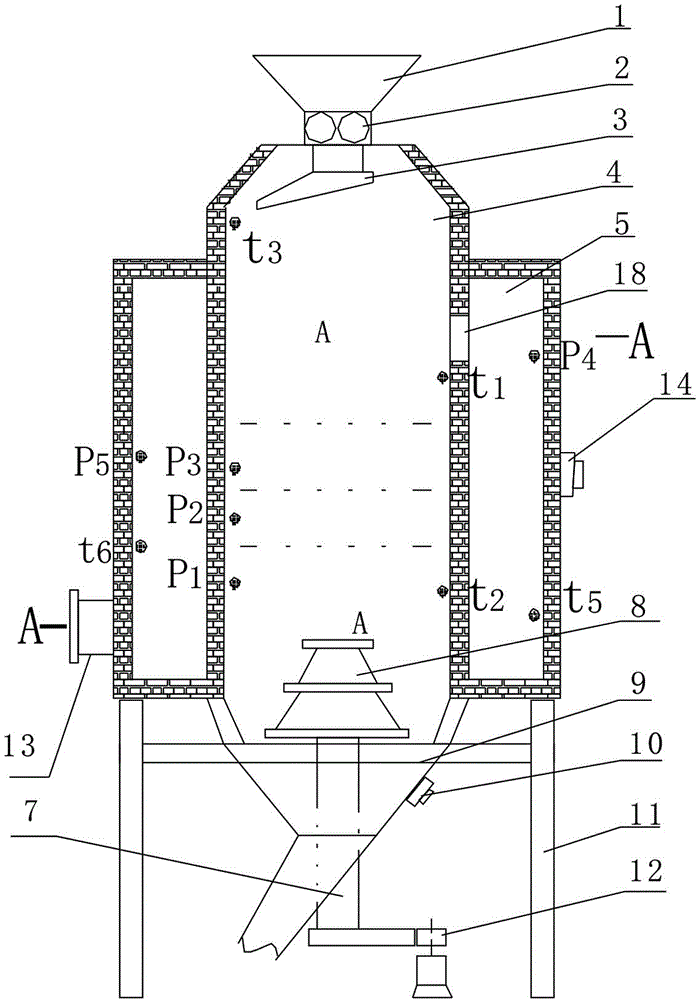

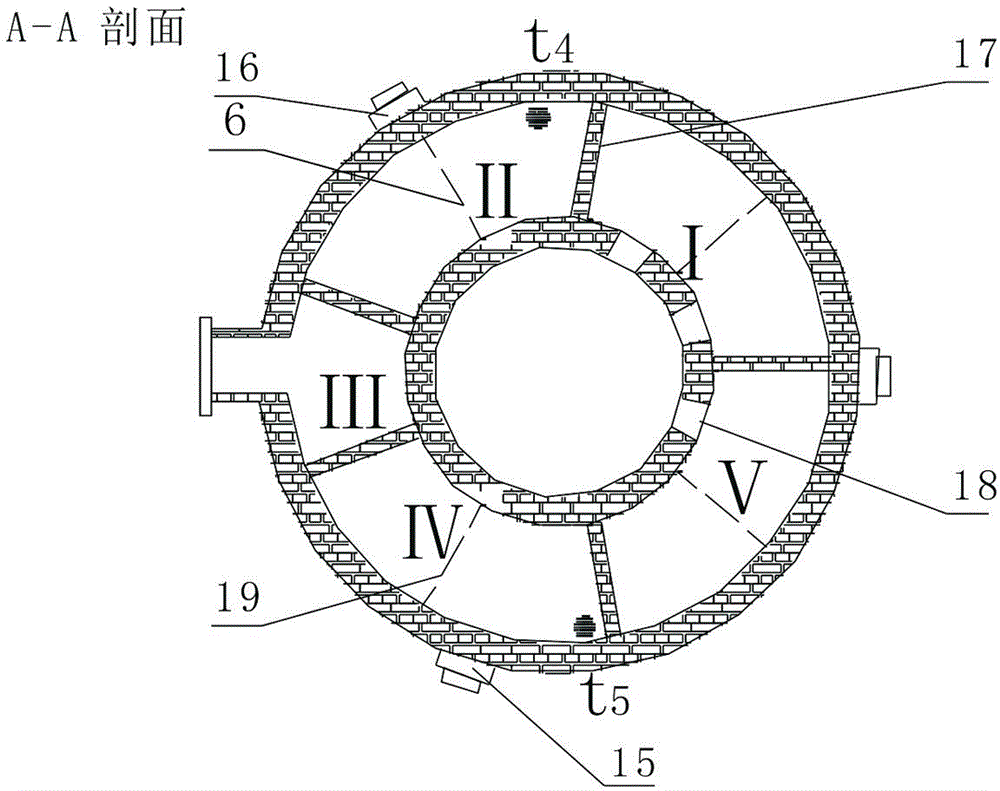

[0022]A domestic waste pyrolysis combustion furnace, the device is a vertical sleeve furnace, the furnace body is composed of a cylindrical pyrolysis gasification furnace 4 and a secondary combustion chamber 5 surrounding it, and the secondary combustion chamber 5 is provided with 5 A partition wall 17 separates the secondary combustion chamber 5 into 5 secondary combustion furnaces I, II, III, IV, V, the secondary combustion furnace III corresponds to the exhaust port 13, and the secondary combustion furnaces I, II, IV , V furnaces are provided with a flower wall 19, and each flower wall 19 is provided with several flue gas running through holes 6 with different diameters, and 3 secondary air supply systems 14, 15 are arranged outside the secondary combustion chamber 5, 16. The upper wall of the pyrolysis gasification furnace 4, that is, the inner walls of the secondary combustion furnaces I, II, IV, and V are each provided with a pyrolysis exhaust port 18.

[0023] The outsi...

Embodiment 2

[0028] A domestic waste pyrolysis combustion furnace and its operating process, comprising the following steps:

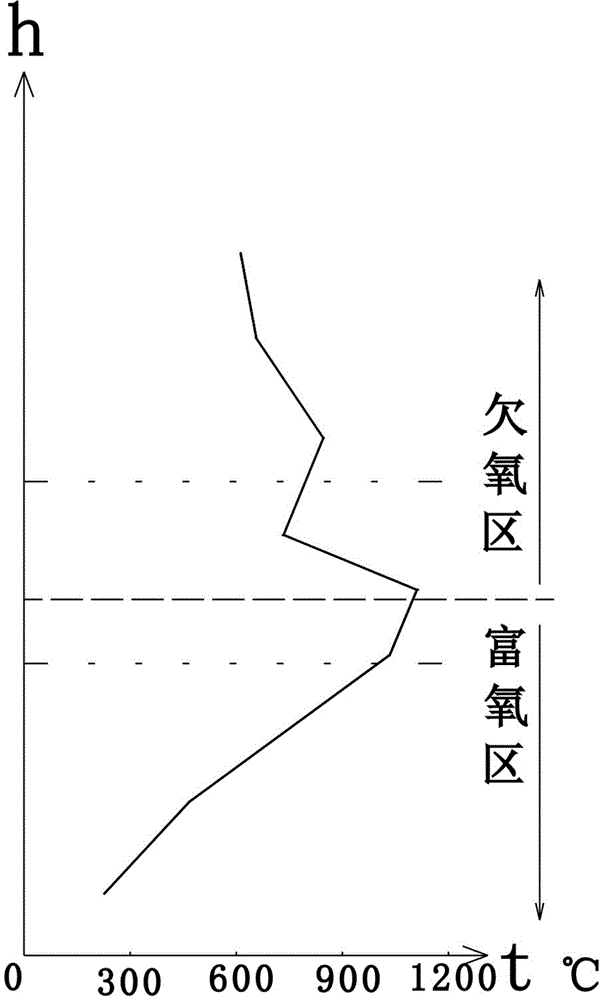

[0029] 1) After the material enters the silo, it enters the pyrolysis gasification furnace evenly through the rotating distributor at a speed of 9-12 tons / h, opens the primary air supply system, and passes through the primary air to control the temperature in the pyrolysis gasification furnace The temperature is 500-700°C. The material is dried sequentially from the top to the bottom of the pyrolysis gasification furnace, pyrolysis gasification, surface combustion, carbon combustion, and finally until it is burnt into slag and cold slag, it is discharged from the body through the ash hopper. Simultaneously produce combustible gas, the pressure sensor P 2 The control is -30~-50Pa, the pressure sensor P 1 1-20Pa, pressure sensor P 1 5-10Pa;

[0030] 2) The air flow of the combustible gas rises to the pyrolysis smoke exhaust port on the upper part of the pyrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com