V-type ammonia spraying and mixing system for SCR (Selective Catalytic Reduction) smoke denitrification device

A mixing system and flue gas technology, applied in the field of flue gas purification, can solve the problems of weakening the synergy of mixing elements and weakening the mixing effect, and achieve the effects of high energy utilization efficiency, improved uniform distribution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

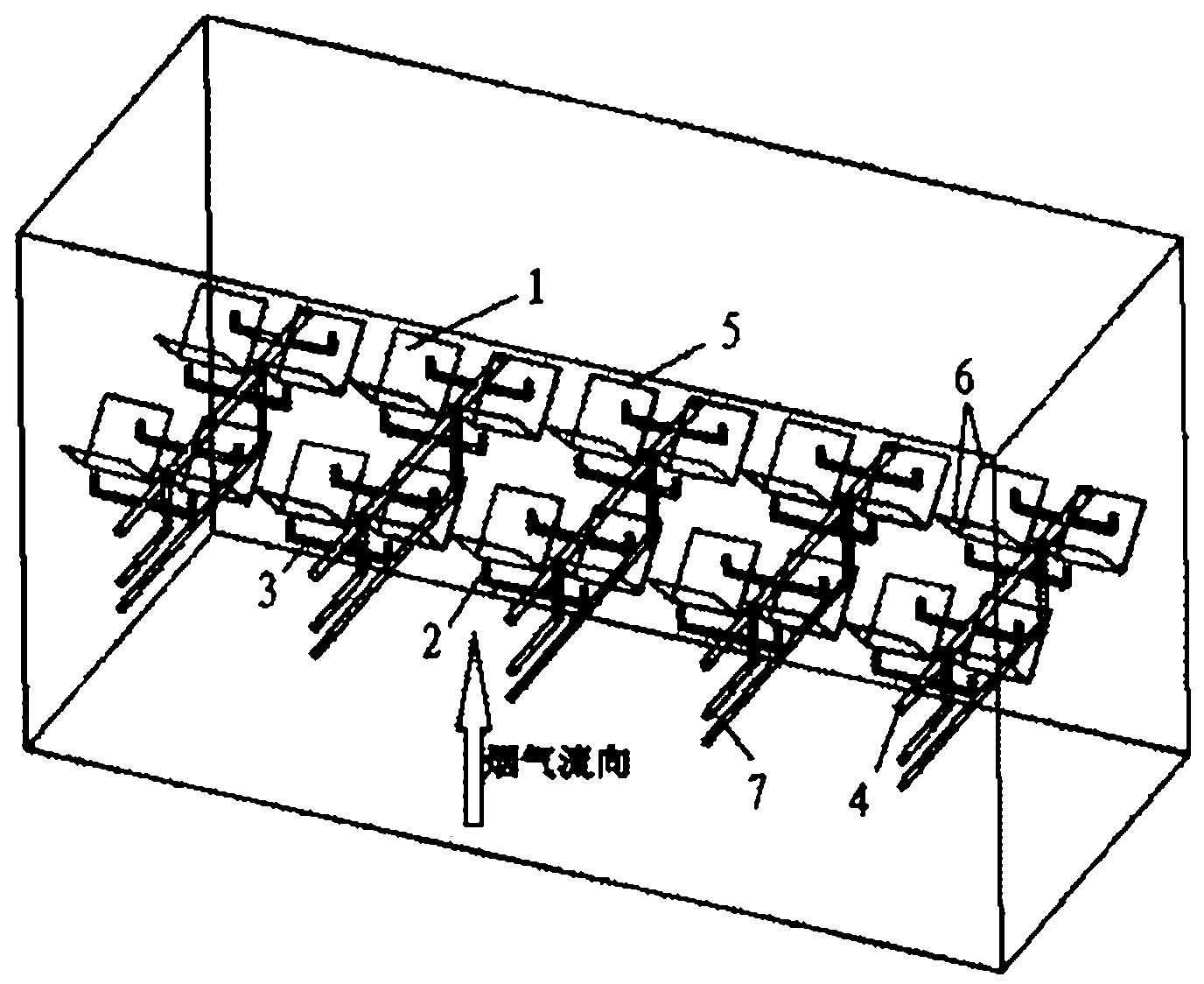

[0032] Such as figure 1 , 2 As shown in , 3, the V-type ammonia injection mixing system used in the SCR flue gas denitration device of a thermal power plant includes a static mixer 1, an ammonia injection branch pipe 3 with a nozzle 2 at the end, and an ammonia injection branch pipe 3 connected Ammonia injection master pipe 4. The coverage rate of the static mixer 1 in the flue is 33%. The static mixer 1 is composed of 20 mixing units 5 arranged side by side in two rows. The mixing unit 5 is composed of two rectangular blades 6 arranged in a V shape, and the blades 6 At 45° to the flue gas flow direction, the mixing unit 5 is fixed on the side wall of the flue through a stainless steel rod. In the same row, two adjacent mixing units 5 share an ammonia injection main pipe 4, and the ammonia injection main pipe 4 is connected to the supply The ammonia delivery pipes 7 for the reducing agent ammonia are connected. According to the size of the flue, a total of 10 ammonia deliver...

Embodiment 2

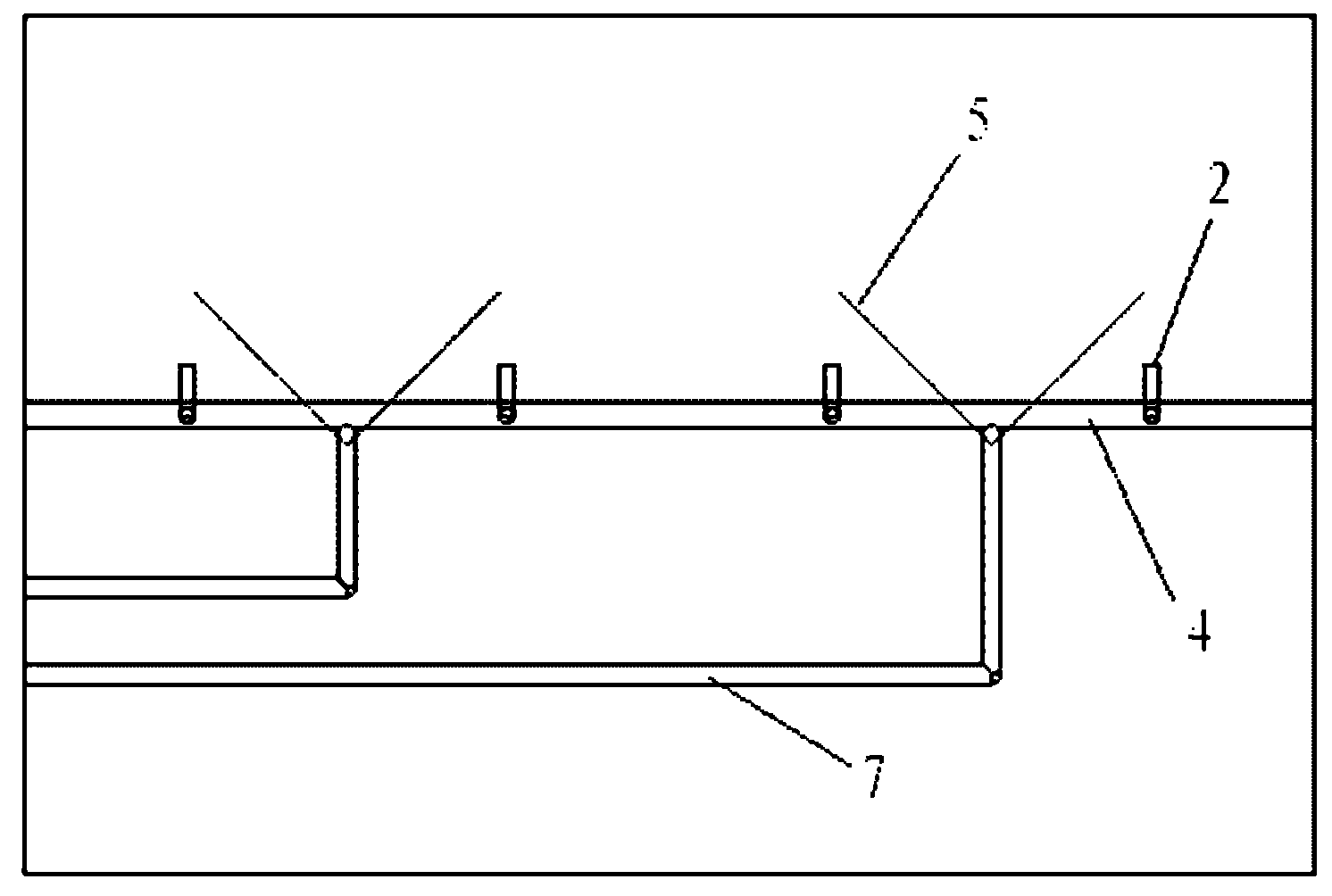

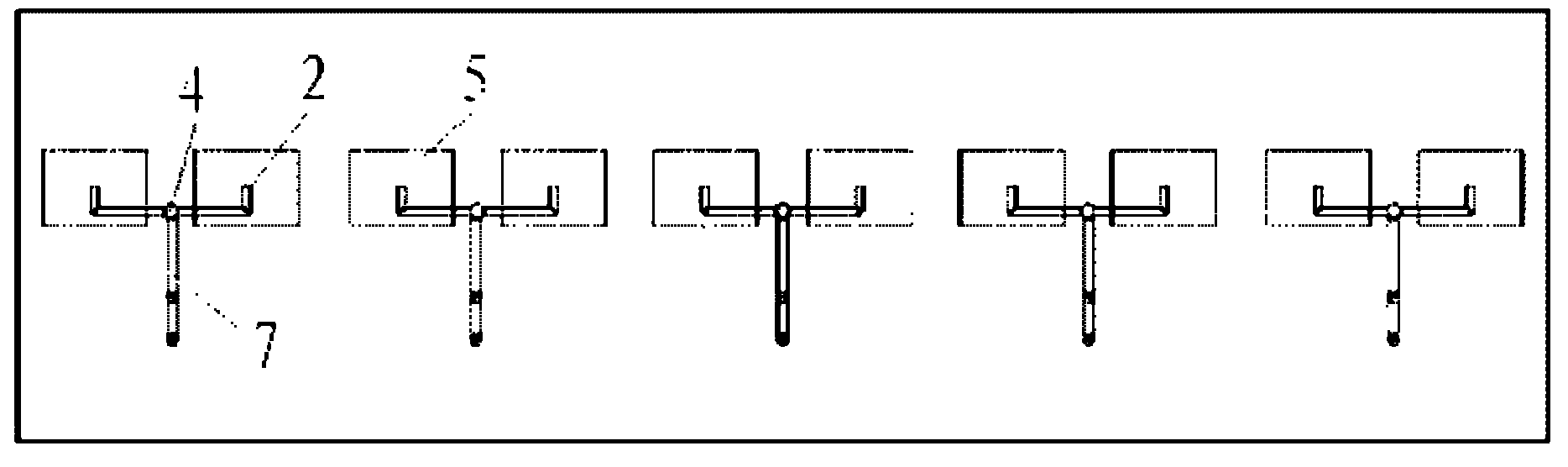

[0035] Such as Figure 4 , 5As shown in , 6, the V-type ammonia injection mixing system used in the SCR flue gas denitration device of a thermal power plant includes a static mixer 1, an ammonia injection branch pipe 3 with a nozzle 2 at the end, and an ammonia injection branch pipe 3 connected Ammonia injection main pipe 4; the coverage rate of static mixer 1 in the flue is 42%. Static mixer 1 is composed of 8 mixing units 5 arranged in a single row, and mixing unit 5 is composed of two V-shaped rectangular blades 6 Composed, and the vane 6 is 55° to the flue gas flow direction, the mixing unit 5 is fixed on the side wall of the flue through a stainless steel rod, two adjacent mixing units 5 form a group, and each group of mixing units 5 shares an ammonia spraying mother The pipe 4 and the ammonia injection main pipe 4 are in communication with the ammonia delivery pipe 7 that supplies the reducing agent ammonia. According to the size of the flue, four ammonia delivery pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com