Efficient wet-type variable flow fog-spraying sprinkling dust-removing purification device

A purification device and wet technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve problems such as difficulty in meeting the special emission limit requirements of air pollutants, achieve enhanced uniform rotary cutting contact, reduce The effect of total power consumption and high dust removal and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

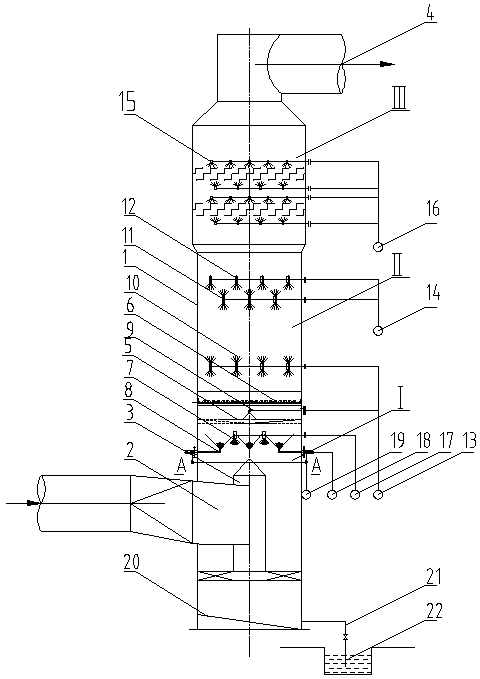

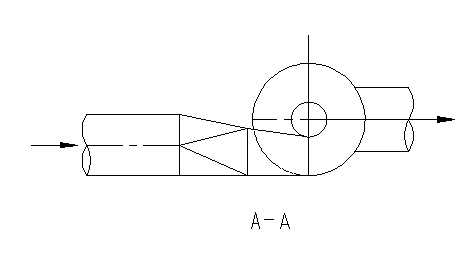

[0046] The wet-type variable-flow spray spray high-efficiency dust removal and purification device includes a washing tower 1, the lower end of the washing tower 1 is provided with a flue gas inlet 2 tangential to it, and the middle of the lower end of the washing tower 1 is provided with a central flow stabilization column 3 and the washing tower 1. In the annular channel, the central flow stabilization column 3 is provided with fog condensation and trapping area I, spray washing area II and dehydration and demisting area III in sequence from bottom to top, and fog condensation trapping area I and spray washing area 11 are set There is a variable flow jet intercepting layer, and the upper end of the washing tower 1 is provided with a flue gas outlet 4 . The variable flow jet intercepting layer is composed of a group of outward-facing swirl plates 5 and a group of single-layer or multi-layer rod grid layers 6 in series or composed of a group of single-layer or multi-layer rod g...

Embodiment 2

[0055] The slag treatment comprehensive transformation project of a large iron and steel company adopts the drum method slag treatment process, and the dust-laden steam stream from the slag treatment device has a high moisture content: 13%-15%, and the dust carried is ultra-fine steel slag. Powder, with hydraulic and sticky (knot) properties. From the perspective of dust particle size distribution: volume percentage / %: particle size > 10um accounted for 56%, particle size 2-10um accounted for 32%, and the rest <2um accounted for 12%. The dust is easy to harden on the cloth bag and the plastic burning board, and it is difficult to remove the dust. Therefore, the wet spray dust removal equipment is selected and installed before the induced draft fan. The purified gas is discharged to the atmosphere through the fan and the exhaust pipe.

[0056] The relevant operating parameters of this embodiment are as follows:

[0057] Flue gas volume 15×10 4 m 3 / h

[0058] Inlet flue gas t...

Embodiment 3

[0080] A large iron and steel company adopts the hot-splashing steel slag treatment process. The basic process principle is: when the slag is higher than the hardenable temperature, spray limited water on the slag, so that the temperature stress generated by the slag is greater than the ultimate stress of the slag itself, resulting in fragmentation. The hydration of free calcium oxide further cracks the slag particles. During the treatment process, the dust content is high, the moisture content is high: 12%-16%, and the steam volume is large. A group of two hot slag removal boxes from the slag treatment device, the dust carried by the dust-laden steam flow and flue gas is the ultra-fine powder of steel slag, which has hydraulic hardness and stickiness.

[0081] From the perspective of dust particle size distribution: volume percentage / %: particle size > 10um accounted for 46%, particle size ≤ 10um accounted for 54%. The dust is easy to harden on the cloth bag and the plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com