System and method for incineration treatment of saliferous waste residue, saliferous waste water and stink waste gas

A technology of salt-containing wastewater and treatment system, applied in the incineration treatment system of salt-containing wastewater and odorous waste gas, and the field of salt-containing waste residue, can solve the problems of large equipment investment, high treatment cost, and inability to obtain pure salt, and reduce equipment investment. , the effect of reducing adhesion and deposition, reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical content and features of the present invention will be described in detail below by referring to the illustrated embodiments in conjunction with the accompanying drawings. For the convenience of description, the "up" and "down" described below are consistent with the directions of up and down in the drawings, but this should not be a limitation of the technical solution of the present invention.

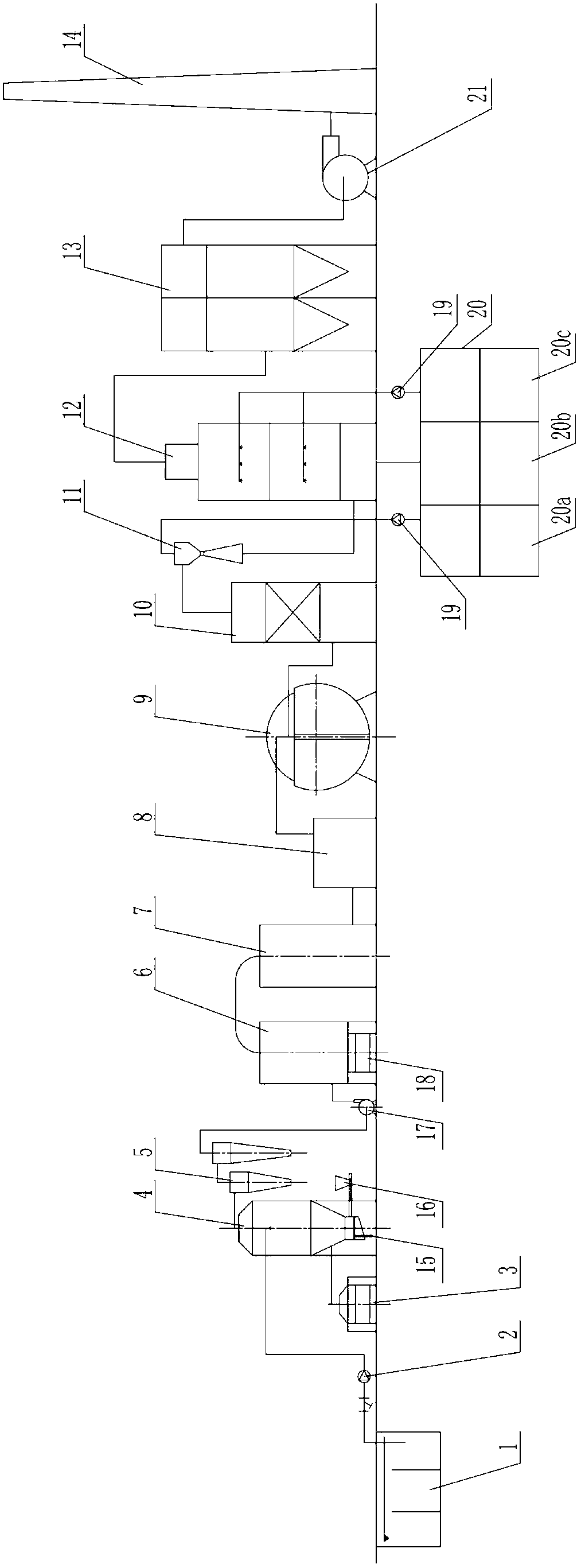

[0037] combine figure 1 The incineration treatment system for salty waste residue, salty waste water and malodorous waste gas of the present invention includes a pretreatment chamber 4 arranged in sequence according to the flow direction of waste liquid and waste gas, an incineration device, a waste heat recovery device and a tail gas purification device. The pretreatment chamber 4 adopts a fluidized bed structure, and the side wall of the lower part of the pretreatment chamber 4 is respectively provided with a waste residue inlet 16 and a coal burning device 3. Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com