Waste gas processing and heat efficient recycling device

A waste gas treatment and recovery device technology, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of small gas convective heat transfer coefficient, difficult heat recovery, low energy enthalpy, etc., to achieve Low operating cost, broad market prospect, simple and reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

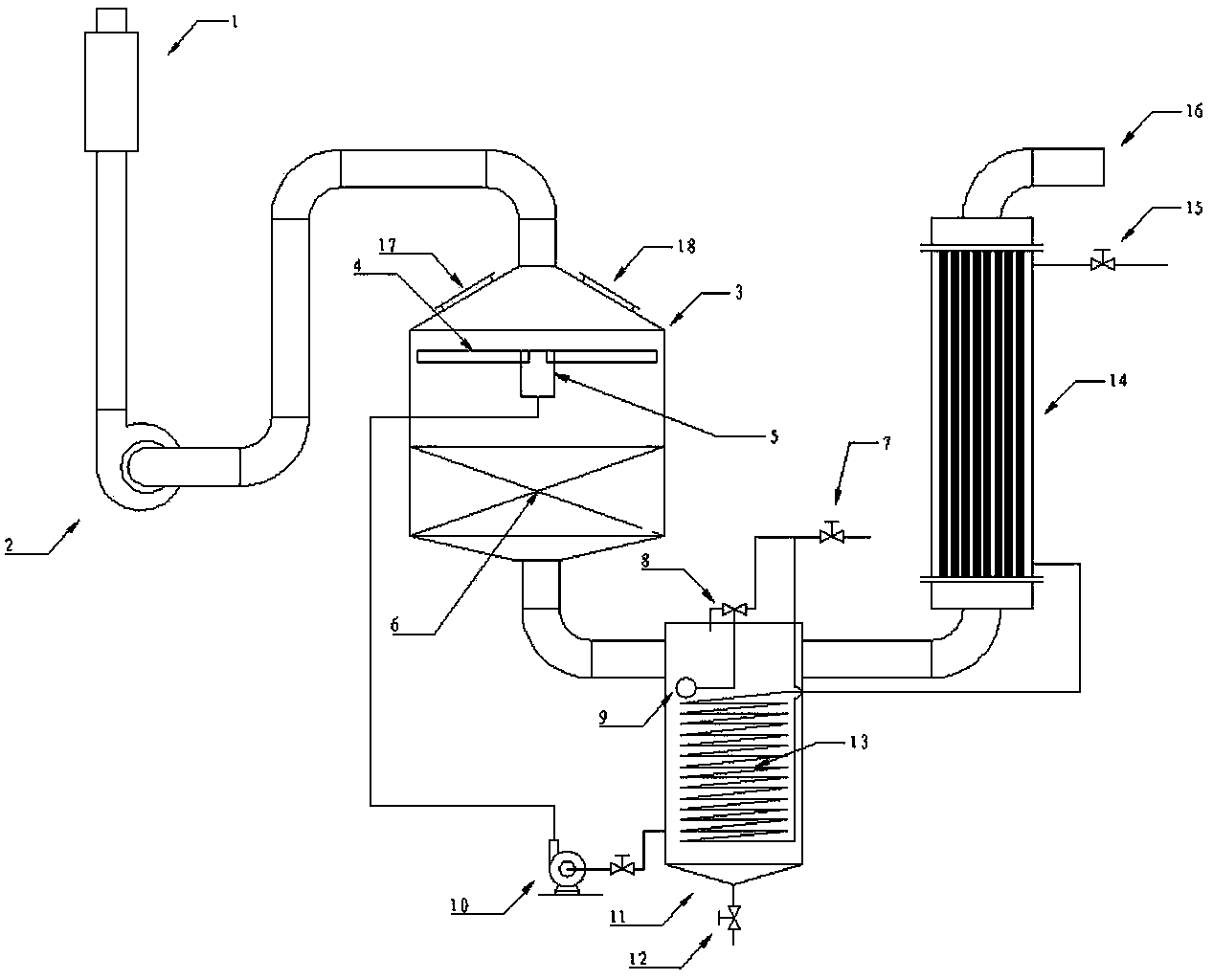

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0023] Such as figure 1 The exhaust gas treatment and high-efficiency heat recovery device shown includes a tube heat exchanger 14, the upper tube side of the tube heat exchanger 14 is connected to the exhaust gas inlet pipe 16, the lower tube side is connected to the inlet of the water tank 11, and the outlet of the water tank 11 is connected to the spray tower 3 The bottom inlet, the top outlet of the spray tower 3 is connected to the waste gas outlet pipe 1; the spray tower 3 is a closed structure with a packing layer 6 inside, and the water distribution pipe 4 and the drum 5 are arranged above the packing layer 6, and the water distribution pipe 4 is provided with holes , the water distribution pipe 4 drives the drum 5 and the water distribution pipe 4 to spin through the hole spraying water; the water tank 11 communicates with the water distribution pipe 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com